Spec Sheet - The Reynolds Company

advertisement

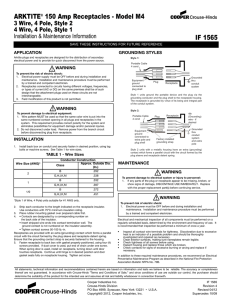

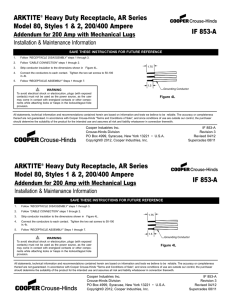

Engineering Safety & Productivity PowerMate™ Drilling Pin and Sleeve Connectors Greatest Personnel Safety Improved Rig-up & Rig-down Operation Maximized Reliability PowerMate ™ Plugs, Receptacles and Connectors POWERMATE DRILLING RIG POWER CONNECTIONS The PowerMate offering is designed to support modularity of drilling rig systems by providing safe and reliable power connections for riggingup and rigging-down equipment quickly and efficiently. This offering is the ideal rig power connection solution providing: • Longer product life • Reduced maintenance • Enhanced safety • Easy installation The PowerMate product offering is also compatible with all UL 1686 listed plugs and receptacles, including: • Cooper Crouse-Hinds Arktite™ • Appleton Powertite® • Killark VersaMate® TABLE OF CONTENTS Applications����������������������������������������������������� 2 Specifiable Features���������������������������������������� 3 Certifications��������������������������������������������������� 3 Standard Materials������������������������������������������ 3 Standard Finishes�������������������������������������������� 3 Options������������������������������������������������������������ 3 PowerMate™ Features and Benefits�������������4-5 PowerMate™ Offering: 30A������������������������������������������������������������������ 6 60A������������������������������������������������������������������ 7 100A���������������������������������������������������������������� 8 150A���������������������������������������������������������������� 9 200A and 400A Offering���������������������������������� 9 APPLICATIONS Grounding������������������������������������������������������ 10 PowerMate Plugs, Receptacles, and Connectors are used: • On SCR/VFD houses to provide power to rig equipment such as shakers, agitators, lighting circuits, mud pumps, motors, etc. • To quickly and efficiently connect power during rig-ups and disconnect power during rig-downs. Electrical Rating Ranges������������������������������� 10 Product Dimensions�������������������������������������� 11 Replacement Parts���������������������������������������� 12 Wire Sizes������������������������������������������������������ 12 PowerMate™ Part Numbers��������������������������� 13 Plug and Receptacle Solutions for Land-Based Drilling����������������������������14-15 2 SPECIFIABLE FEATURES Lockout Plug Safety Insulator Diamond Clamp Split Pin Contacts STANDARD MATERIALS • Receptacle housing, plug and cord connector bodies - high impact strength copper-free aluminum (less than 0.4% copper) • Back boxes - cast aluminum • Insulation - fiberglass reinforced polyester • Contacts - naval brass Type P Cable STANDARD FINISHES CERTIFICATIONS • UL Standards: UL 1682, UL 1686, NEMA 250 • CSA Standard: C22.2 No. 182.1 • Listed for use with Type P cable, flexible cord and cables rated for extra hard usage • NEMA 4X • Copper-free aluminum - epoxy powder coat • Fiberglass reinforced polyester - natural (red) • Naval brass - natural OPTIONS • -RS...Reverse Service. Receptacle assembled with plug interior and plug assembled with receptacle interior. For applications where plug is energized to feed normally de-energized receptacle. NOTE: 30, 60, and 100A interiors can be interchanged in the field using a screwdriver. CDR - S22 (reverse service) PowerMate Receptacle Transformer Switch CCP PowerMate Plug Generator CCP - RS (reverse service) PowerMate Plug CDR - RS PowerMate Receptacle • -P4...Special Polarity. Receptacle interior rotated 22 1⁄2 degrees to right and plug changed to match. For use where two or more receptacles of the same ampere rating, style, and number of poles are to be installed in the same area for use on different voltages and/or frequencies. Prevents insertion of a plug in a receptacle with different electrical rating. 3 PowerMate ™ Features and Benefits Specifiable Features 1 Lockout Plug (Patent Pending) • Guarantees isolated power supply with OSHA compliant lockout/tagout. • Ensures plug cannot be inserted into receptacle when maintenance is being performed downstream of power supply. 2 Fixed Safety Insulator (Patent Pending) • Prevents electrical shock and shorts with plastic barrier between insulator body and metal housing. • Fixed-in-place design ensures insulator will not be lost or discarded during cable termination process. 3 8-Point Diamond Cable Clamps (Patent Pending) • 8 points of contact around diameter of cable for increased grip and even distribution of pressure. • Cable jacket does not get pinched, eliminating potential for damage to internal conductors. 4 Split Pin Contact Design • Provides nearly 360° of contact at every insertion, ensuring protection against heat rise and eliminating arcing on critical surfaces. • Self-wiping at every insertion to remove foreign particles that create electrical resistance and product failure. 5 Extended Cable Range • Industry’s largest cable diameter range. • Specifically designed, third party tested and certified for use with Type P cable. • Sealing system utilizes industry standard bushings. 6 Enhanced Nomenclature and Nameplate • Easily understandable nomenclature increases ease of part configuration identification. • Mechanically attached nameplate ensures that critical information is permanently fixed to product. 7 Spring and Threaded Cover • Each receptacle comes with both spring cap and threaded cap to provide a variety of cover options. 8 Combination Drive Stainless Steel Hardware • Increases ease of installation by allowing for more than one option for installation tools. • Stainless steel external hardware eliminates corrosion on critical components and extends product life. 9 Handle Body • Thick epoxy powder coating is standard finish on PowerMate products. • Coating reduces corrosion and increases life of product. • Industry standard profile increases ease of plugging and unplugging. 10 Combination Slot and Hex Mechanical Lugs* • Increases ease of installation by allowing for more than one option for installation tools. • Hex head allows for easy achievement of specified torque value. 11 Insulator Assemblies • Unimpeded, easy-access phase and ground terminals make wire termination quick and easy. • Molded-in-place markings for phase/ground and conductor strip lengths reduce installation errors.* Lockout Plug Safety Insulator Diamond Clamp Split Pin Contacts Type P Cable Compatible with all UL 1686 listed plugs and receptacles. Type P Cable Lockout Compliant *60, 100, and 150A offering. 4 5 60 AMP 30 AMP Receptacles, Plugs and Connectors Receptacles, Plugs and Connectors NEMA 4X Watertight 600 VAC / 250 VDC 50 - 400 Hz NEMA 4X Watertight 600 VAC / 250 VDC 50 - 400 Hz DESCRIPTION AND CONFIGURATION: 2 Wire 2 Pole Style 1 CDR3022 CABLE RANGE CAT. NO. .340-1.375” CCP3022BC .340-1.375” CRC3022BC GR GR 3 Wire 4 Pole Style 2 GR CDR3034 .340-1.375” CRC3033BC CCP3034BC .340-1.375” CRC3034BC GR CDR3044 .340-1.375” CCP3044BC .340-1.375” CRC3044BC GR CABLE RANGE CAT. NO. CABLE RANGE CAT. NO. CDR6022 .440-1.375” CCP6022BC 0.440-1.375” CRC6022BC CDR6023 .440-1.375” CCP6023BC 0.440-1.375” CRC6023BC CDR6033 .440-1.375” CCP6033BC 0.440-1.375” CRC6033BC CDR6034 .440-1.375” CDR6044 .440-1.375” CCP6044BC 0.440-1.375” CRC6044BC CCP6034BC 0.440-1.375” CRC6034BC GR Back Boxes (for Receptacles) HUB SIZE CEE CERH CERC ⁄2” CEE13 CERH13 CERC13 3 ⁄4” CEE23 CERH23 1” CEE33 CERH33 6 4 Wire 4 Pole Style 1 CORD CONNECTOR PLUG GR 3 Wire 3 Pole Style 1 .340-1.375” CCP3033BC .340-1.375” RECEPTACLE GR GR GR .340-1.375” CCP3023BC .340-1.375” CRC3023BC Back Boxes (for Receptacles) 1 2 Wire 2 Pole Style 1 GR CDR3033 3 Wire 4 Pole Style 2 CAT. NO. DESCRIPTION AND CONFIGURATION: 2 Wire 3 Pole Style 2 CDR3023 3 Wire 3 Pole Style 1 CORD CONNECTOR PLUG CABLE RANGE GR GR GR GR 2 Wire 3 Pole Style 2 4 Wire 4 Pole Style 1 RECEPTACLE • The back boxes at left are standard with Corro-Free™ epoxy powder coat finish for increased corrosion resistance. • For optional reversed interior, use suffix -RS (see page 3). • For optional rotated interior, use suffix -P4 (see page 3). • For dimensions, see page 11. • Maximum conductor size (wire well) 0.281” (see page 12). HUB SIZE CEE CERH CJA CERC ⁄2” CEE36 CERH36 CJA310 CERC36 CERC23 1-1⁄4” CEE46 CERH46 CJA410 CERC46 CERC33 1-1⁄2” CEE56 CERH56 CJA510 CERC56 2” ---- ---- CJA610 ---- 1 • The back boxes at left are standard with Corro-Free™ epoxy powder coat finish for increased corrosion resistance. • For optional reversed interior, use suffix -RS (see page 3). • For optional rotated interior, use suffix -P4 (see page 3). • For dimensions, see page 11. • Maximum conductor size (wire well) 0.312” (see page 12). 7 150 AMP 100 AMP Receptacles, Plugs and Connectors Receptacles, Plugs and Connectors NEMA 4X Watertight 600 VAC / 250 VDC 50 - 400 Hz NEMA 4X Watertight 600 VAC / 250 VDC 50 - 400 Hz DESCRIPTION AND CONFIGURATION: 2 Wire 2 Pole Style 1 GR GR GR GR 2 Wire 3 Pole Style 2 CDR1022 CORD CONNECTOR PLUG CABLE RANGE CDR1023 CAT. NO. CABLE RANGE CAT. NO. .875-1.906” CCP1022CD .875-1.906” CRC1022CD .875-1.906” CCP1023CD .875-1.906” CRC1023CD GR 3 Wire 3 Pole Style 1 CDR1033 .875-1.906” CCP1033CD .875-1.906” CRC1033CD DESCRIPTION AND CONFIGURATION: 3 Wire 4 Pole Style 2 4 Wire 4 Pole Style 1 GR CDR15044 GR CAT. NO. CABLE RANGE CAT. NO. .875-1.906” CCP15034CD .875-1.906” CRC15034CD 1.250-2.190” CCP15034DE 1.250-2.190” CRC15034DE .875-1.906” CCP15044CD .875-1.906” CRC15044CD 1.250-2.190” CCP15044DE 1.250-2.190” CRC15044DE 200 AMP and 400 AMP Arktite ™ CDR1034 .875-1.906” CCP1034CD .875-1.906” CRC1034CD GR Receptacles, Plugs and Connectors 200A and 400A options available as part of our Cooper Crouse-Hinds Arktite™ Series CDR1044 .875-1.906” CCP1044CD .875-1.906” CRC1044CD GR HUB SIZE CJA ⁄2” CJA310 1-1⁄4” CJA410 1-1⁄2” CJA510 2” CJA610 8 CABLE RANGE CDR15034 CORD CONNECTOR PLUG Back Boxes (for Receptacles) - see page 8. AMPERAGE AND CONFIGURATION: Back Boxes (for Receptacles) 1 RECEPTACLE GR 3 Wire 4 Pole Style 2 4 Wire 4 Pole Style 1 RECEPTACLE CJA ADAPTER ONLY CJA100 • The back boxes at left are standard with Corro-Free™ epoxy powder coat finish for increased corrosion resistance. • For optional reversed interior, use suffix -RS (see page 3). • For optional rotated interior, use suffix -P4 (see page 3). • For dimensions, see page 11. • Maximum conductor size (wire well) 0.390” (see page 12). 200A 2 Wire 3 Pole - Style 2 3 Wire 3 Pole - Style 1 3 Wire 4 Pole - Style 2 4 Wire 4 Pole - Style 1 400A 2 Wire 3 Pole - Style 2 3 Wire 3 Pole - Style 1 3 Wire 4 Pole - Style 2 4 Wire 4 Pole - Style 1 RECEPTACLE PLUG CORD CONNECTOR For detailed part numbers and technical information, please refer to section 1P of the Cooper Crouse-Hinds catalog. 9 PowerMate ™ Plugs, Receptacles and Connectors Grounding Product Dimensions Style 1 Receptacle, Plug, Cord Connector CDR Receptacle Style 1 units complete the grounding circuit through the metallic plug shell, receptacle housing, or connector shell. Style 2 CCP Plug† CRC Cord Connector† a b a b a b 30A 2-7⁄8” 3-3⁄8” 6-1⁄2” 2-5⁄16” 6-3⁄5” 2-9⁄16” 60A 3p 4-1⁄4” 4-1⁄2” 8-1⁄6” 3-5⁄8” 8-3⁄10” 2-5⁄16” 60A 4p 1 4- ⁄4” 4- ⁄2” 1 8- ⁄6” 3- ⁄4” 3 8- ⁄10” 2- ⁄16” 100A 3p 5-1⁄4” 4-1⁄4” 10-4⁄5” 3-3⁄4” 11-1⁄2” 3-3⁄16” 100A 4p 5-1⁄4” 4-1⁄4” 10-4⁄5” 4-1⁄8” 11-1⁄2” 3-7⁄16” 150A (CD) 1 5- ⁄4” 1 4- ⁄4” 10- ⁄5” 1 4- ⁄8” 11- ⁄2” 3-7⁄16” 150A (DE) 5-1⁄4” 4-1⁄4” 10-4⁄5” 4-1⁄8” 11-1⁄2” 3-7⁄16” a 1 b 4 a 3 b 1 a 5 b †Dimensions are approximate and vary with cable size. CEE Back Boxes Style 2 metallic units with metal housing have a separate designated ground contact that is bonded to the metallic housing. The metallic housing of the plug, receptacle, or connector forms a parallel ground circuit through the receptacle or connector detent spring. Electrical Rating Ranges • Voltage - 600 VAC, 50 to 400 Hz; 250 VDC* • Amperes - 30, 60, 100, 150 10 Rating Size CEE13 30A 1 a CEE23 30A CEE33 ⁄2 1- ⁄32” 11 3 ⁄4 1-27⁄32” 13 30A 1 1-31⁄32” 15 CEE36 60A 1 2- ⁄16” 15 CEE46 60A 1-1⁄4” 2-5⁄8” 1-3⁄16” CEE56 60A 1-1⁄2” 2-11⁄16” 1-5⁄16” 9 60A 30A b 27 ⁄16” ⁄16” ⁄16” ⁄16” CJA Maximum Horsepower for Plug and Receptacle Combinations by Input Voltage** The following values are typical horsepower ratings based on NEC Article 430 tables. HP Ratings are based on the largest conductor size for each plug and receptacle combination per the Wire Size table below. Ampere Rating Plug and Receptacle Cat. No. Motor Horsepower ** 240 Volts 480 Volts 600 Volts 30 15 30 40 60 20 40 50 100 30 60 75 150 40 75 100 200 60 125 150 * This guide is for reference only. Consult your local electrical codes before installation. ** Cooper Crouse-Hinds recommends circuit breaking use be limited to emergency conditions only and that a horsepower rated switch or Cooper Crouse-Hinds Interlocked Receptacle be used for making and breaking under load. With 60, 100 and 150A Angle Adapters Cat. No. Hub Size a b c d e f CJA310 1” 7 5- ⁄8” 8” 7 7- ⁄16” 7 4- ⁄8” 7” 15° CJA410 1 1- ⁄4” 7 5- ⁄8” 8” 7 7- ⁄16” 7 4- ⁄8” 7” 15° CJA510 1-1⁄2” 5-7⁄8” 8” 7-7⁄16” 4-7⁄8” 7” 15° CJA610 2” 5- ⁄8” 8” 8” 4- ⁄8” 7” 15° 7 7 • Back boxes are standard with Corro-Free™ epoxy powder coat finish for increased corrosion resistance. • Thru-feed back boxes are furnished with one close-up plug in bottom recessed hub. • CJA back boxes are recommended when additional wiring space is required. • The angle adapter on CJA back boxes can be installed at 90° rotations, making it possible to enter hub from several directions. 11 PowerMate ™ Plugs, Receptacles and Connectors Replacement Parts PowerMate™ Part Numbers Standard Replacement Parts CCP Replacement Interiors 30, 60, 100, 150A Complete insulator and contact assembly 2W2P 2W3P 3W3P 3W4P 4W4P 30A 60A 100A 150A CRI Receptacle & Connector Interior CDR-CRC CRI-3022 CRI-6022 CRI-1022 --- CCP CPI-3022 CPI-6022 CPI-1022 --- CDR-CRC CRI-3023 CRI-6023 CRI-1023 --- CCP CPI-3023 CPI-6023 CPI-1023 --- CDR-CRC CRI-3033 CRI-6033 CRI-1033 --- CCP CPI-3033 CPI-6033 CPI-1033 --- CDR-CRC CRI-3034 CRI-6034 CRI-1034 CRI-15034 CCP CPI-3034 CPI-6034 CPI-1034 CPI-10534 CDR-CRC CRI-3044 CRI-6044 CRI-1044 CRI-15044 CCP CPI-3044 CPI-6044 CPI-1044 CPI-15044 CPI Plug Interior Miscellaneous Replacement Parts Amperage Configuration Center Center CDR Spring Cover CDR Threaded Cover CCP Fastening Ring Bushings Kits Center 30A 2-pole, 3-pole 4-pole PTSC30 PTTC30 CLMPR30 PTGB30 60A 2-pole, 3-pole 4-pole PTSC60A PTSC60B PTTC60A PTTC60B CLMPR23P60 CLMPR4P60 PTGB60 100A 2-pole, 3-pole 4-pole PTSC100A PTSC100B PTTC100A PTTC100B CLMPR23P100 CLMPR4P100 PTGBCD CLMPR4P150 PTGBCD (CD Size) PTGBCD (DE Size) 150A 4-pole PTSC150B PTTC150B Spring Cover Threaded Cover Diameter of Wire Recess in Plug & Receptacle Contacts Amperage Rating Contact Type Diameter of Recess Wire Size †† Extra Flex 30 (2, 3, & 4-pole) Pressure .281” #10-#8 60 (2, 3, 4-pole) Pressure .312” #8-#4 100 (2, 3, & 4-pole) Pressure .390” #4-#2 150 (4-pole) Pressure .390” #2-1/O 3 4 BC RS PRODUCT TYPE CCP - Plug CDR - Receptacle CRC - Connector CDRE - Receptacle with CEE Back Box CDJA - Receptacle with CJA Back Box AMPERAGE 30 - 30 Amp 60 - 60 Amp 10 - 100 Amp 150 - 150 Amp (200 & 400 Amp options avail. as part of Arktite Series)* WIRE 2 - 2-Wire 3 - 3-Wire 4 - 4-Wire Wire Sizes The table below lists the diameter of the wire recess in PowerMate plug and receptacle contacts so that maximum size of bare conductor can be determined. Range of wire sizes shown in table are intended only as a guide. Depending on type of wire used (building wire, flexible or extra flexible cable) and its construction (number and size of strands), bare copper diameters vary widely. 30 Bushing Kit POLE 2 - 2-Pole 3 - 3-Pole 4 - 4-Pole CABLE RANGE ** (plug and connector only) BC - 0.390” to 1.375” CD - 0.875” to 1.906” DE - 1.250” to 2.190” E - 1.875” to 2.500” F - 2.500” to 3.000” G - 3.000” to 3.500” OPTIONS RS - Reverse Service P4 - Special Polarity HUB SIZE*** (receptacle with back box only) 50 - 1⁄2” 75 - 3⁄4” 100 - 1” 125 - 1-1⁄4” 150 - 1-1⁄2” 200 - 2” 250 - 2-1⁄2” 300 - 3” 350 - 3-1⁄2” 400 - 4” 500 - 5” * Refer to section 1P of the Cooper Crouse-Hinds catalog. ** Cable Range only applies to specific plug part numbers. *** Hub size only applies to specific receptacle part numbers. ††Do not use wire size smaller than minimum size recommended. 12 13 It’s about knowing your challenges inside out Plug and Receptacle Solutions for Land-Based Drilling Drilling Rig Locations 1 Derrick/Mast 2 VFD/Generator(s) 3 Product Photo Environmental Conditions Fuel Tank 1 4 5 Doghouse/ Operator’s House 6 Power/Pump Station 7 Shale Shaker 8 9 10 Industrial Motor Control/VFD/ SCR House(s) Areas prone to dust, dirt, grime, vibration, hard use and abuse. Wet Locations Protection from wind-blown dust and rain, splashing and hose-directed water and external formation of ice. Mud Tanks/Pumps Vibration Locations that need products designed to withstand continuous movement and may require maintenance and repair. Drawworks & Top Drive Drilling Floor Corrosive Areas Protection for areas with corrosive chemicals, atmospheres and water. 3 Space Constraints 2 5 4 Areas with low ceilings, tight spaces and limited footprint potential. Class I, Div 1/Zone 1 10 6 9 7 8 Explosion protection for areas with flammable gases or vapors normally in the atmosphere. Class I, Div 2/Zone 2 Explosion protection for areas where flammable gases or vapors are not normally present. Class II, Zone 21 & 22 Protection for areas where ignitable dusts may be present. Please refer to your own company documentation for exact specifications and environmental conditions. 14 Product Solutions Env. Conditions Rig Location PowerMate Series • Supplies power to portable devices such as motor generator sets, compressors, heating/cooling, welders and lighting from 30 to 150A • NEMA 4X copper-free aluminum construction with epoxy powder coat finish is ideal for harsh environments • Arc-snuffing design enables large power loads to be disconnected under load without an arc flash (up to 100 amps) • 360° split pin contact reduces heat rise and eliminates arcing • Lockout/tagout hole in plug to ensure it cannot be inserted into receptacle when maintenance is being performed downstream Industrial Wet Locations Vibration Corrosive Areas Space Constraints ENR & ENP Series • Explosionproof outlet for convenience and lighting connections, 20A MAX • Factory-sealed chamber encloses potential arcing components between two explosionproof threaded joints • Frustration-free ENP with captive set screws assures ease of installation and reduces likelihood of losing critical components in the field • ENRM4 Series with gasketed screw cap cover offers features that protect interior from harsh environments, provide time saving saddle clamp terminals, and improved safety with lockout/tagout hole Industrial Vibration Space Constraints Class I, Div 1/Zone 1 Class I, Div 2/Zone 2 FSQC & EBBR Series • Interlocked units with dead front receptacles ensure connection cannot be made or broken under load, increasing safety and protection • PowerMate plugs can be used with both FSQC (30-60A) & EBBR (30-100A) Series to provide ultimate flexibility of portable equipment used throughout the rig • FSQC units are interlocked with switches and the EBBR Series is interlocked with circuit breakers for added protection Industrial Wet Locations Vibration Corrosive Areas Space Constraints Class I, Div 1/Zone 1 Class I, Div 2/Zone 2 4, 7, 8, 10 CES & CPH Series • Equipped with a delayed action rotating sleeve which prevents complete withdrawal of CPH plug in one continuous movement • The delayed action feature permits the plug to be used as an emergency push-pull switch • Receptacles are factory sealed to simplify installation and eliminate the need for external seals • Available in 30 and 60A • CPH also mates with FSQC, EPC, and EBBR receptacles of matching configuration Industrial Wet Locations Vibration Corrosive Areas Space Constraints Class I, Div 1/Zone 1 Class I, Div 2/Zone 2 7, 8 eXLink® Connectors • Signal and power connections can be switched under load • Reduces installation time, providing maintenance and labor savings • Can be factory installed and pre-wired with Cooper Crouse-Hinds industry leading light fixtures • Rated up to max. 16A and up to 400V Industrial Wet Locations Vibration Corrosive Areas Space Constraints IEC 309 GHG 51 Series • Supplies power to portable devices with requirements of 16-125A • Reinforced polyester construction offers reliability from -20° to +55°C • Integrated AC3 rated disconnect switch Wet Locations Vibration Corrosive Areas Class I, Div 2/Zone 2 Roughneck™ Connectors • For use with single conductor 313-777 MCM cable, 1000 volts AC/DC, rated up to 1135A • Designed for heavy abuse - resistant to rain, mud and oil • Quickly connects and disconnects without any tools • Superior safety protection with totally shielded contacts • Color-coded insulators for easy identification to prevent reverse phasing in AC and cross polarization in DC • Mated assemblies are lockout/tagout compatible Industrial Wet Locations Vibration Corrosive Areas Space Constraints Pauluhn™ 80/86/96/wd (NRL) Connectors • Watertight ANSI NEMA type receptacle • Accepts standard ANSI NEMA type plugs • Mating plugs with integral threaded ring maintain a watertight seal • Available in seven different voltage configurations up to 20A • Captive threaded receptacle cap Industrial Wet Locations Vibration Corrosive Areas Space Constraints Pauluhn™ PPR Series Connectors • Watertight non-metallic construction including water shedding receptacle design • Corrosion and impact resistant closure • Captive threaded receptacle cap • 2P3W and 3P4W available in single or double gang types and with an in-line connector set up to 20A • Double gang receptacle provided with pre-stripped leads • Inter-mateable with other brands Industrial Wet Locations Corrosive Areas 2, 4, 5 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 1, 10 7, 8, 9 2, 4, 5, 6, 9, 10 1, 2, 4, 5, 7*, 8 2, 4, 5 * On enclosed rigs. 15 For more information: If further assistance is required, contact your local Cooper Crouse-Hinds Representative. Call customer service at 866-764-5454, or email crouse.customerctr@cooperindustries.com U.S. (Global Headquarters): Cooper Crouse-Hinds Wolf & Seventh North Streets Syracuse, NY 13221 (866) 764-5454 FAX: (315) 477-5179 FAX Orders Only: (866) 653-0640 crouse.customerctr@cooperindustries.com Canada: Cooper Crouse-Hinds Canada Toll Free: 800-265-0502 FAX: (800) 263-9504 FAX Orders Only: (866) 653-0645 Mexico/Latin America/Caribbean: Cooper Crouse-Hinds, S.A. de C.V. 52-555-804-4000 FAX: 52-555-804-4020 mxmercadotecnia@cooperindustries.com Europe (Germany): Cooper Crouse-Hinds GmbH 49 (0) 6271 806-500 49 (0) 6271 806-476 sales.CCH.de@cooperindustries.com Middle East (Dubai): Cooper Crouse-Hinds LLC 971 4 4272500 FAX: 971 4 4298521 Singapore: Cooper Crouse-Hinds Pte. Ltd. 65-6297-4849 FAX: 65-6297-4819 chsi-sales@cooperindustries.com China: Cooper Crouse-Hinds Pte. Ltd. 86-21-2899-3600 FAX: 86-21-2899-4055 cchsales@cooperindustries.com Australia: Cooper Electrical Australia 61-2 8787-2777 FAX: 61-2-9609-2342 CEASales@cooperindustries.com Colombia: +(57.1) 670 0315 FAX: +(57.1) 670 0376 ventascic@cooperindustries.com Brazil: +55 15 3238 3970 FAX: +55 15 3238 3976 vendasbrasil@cooperindustries.com Saudi Arabia: 966 3 812 2236 FAX: 966 3 812 1291 www.crouse-hinds.com Cooper Crouse-Hinds is a registered trademark of Cooper Industries, Ltd. ©2012 Cooper Industries, Ltd. Your Authorized Cooper Crouse-Hinds Distributor is: Cooper Industries, Ltd. 600 Travis, Ste. 5800 Houston, TX 77002-1001 P: 713-209-8400 www.cooperindustries.com 5022-0112 Printed in USA