unitized overhead switchgear ! warning caution

advertisement

INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

for A.B. CHANCE COMPANY

UNITIZED OVERHEAD SWITCHGEAR

SERIAL NO.:

TYPE "D7" AND "S" SWITCHES

HORIZONTAL

VERTICAL

PHASE/PHASE

DELTA

!!

WARNING

The following instructions must be read and understood before using this equipment. Failure to read and follow this

information may result in serious injury or death.

!!

CAUTION

These Installation, Operation, and Maintenance Instructions contain Important Safety Information. Only qualified

and properly trained personnel should apply, operate and maintain this Switch. Read and follow complete

Installation, Operation, Adjustment, and Maintenance instructions throughly before placing in operation.

This Switch is a unitized, three-phase, side break air disconnect switch. The Duogap® interrupter, when supplied,

makes the Switch a loadbreak switch. Follow these instructions and the enclosed control drawing to install, operate

and maintain this Switch. The only area adjustable by the installation crew is the handle and lock segment.

Before beginning the installation procedure visually, inspect the switch for damage or missing parts. Compare your

switch with the enclosed control drawing. If damage from rough handling is evident, immediately file a claim with

the transportation company. Promptly contact the nearest Chance Sales Office for information regarding replacement parts.

TABLE OF CONTENTS

SECTION A ................................ SWITCH MOUNTING

SECTION B1 .............................. CONTROLS INSTALLATION (Swing Handle)

or

SECTION B2 .............................. CONTROLS INSTALLATION (Pump Handle)

SECTION C or D or E ................ FINAL SWITCH INSPECTION

SECTION F ................................. MAINTENANCE INSTRUCTIONS

{

(1) COPY OF CONTROL DRAWING

This drawing is supplied with every new switch along

with these instructions. It shows the orientation of the

switch and operating controls as they would be mounted

to the pole. Then use these instructions for details.

NOTE: These instructions are coded with the serial number of this switch.

It is recommended they be filed for future reference in case of repair or maintenance.

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be

met with concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular

problems are encountered which are not sufficiently covered in this guide, contact A.B. Chance Company.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design and specifications without notice.

®

®

POWER SYSTEMS, INC.

© Copyright 1993 Hubbell / Chance, 210 N. Allen, Centralia, MO 65240

Printed in USA

P816-0606

SECTION A. CHANCE UNITIZED SWITCHGEAR MOUNTING

Refer to the illustrations included with these instructions, and the control drawing furnished with the switch.

NOTICE

The user will supply all thru-bolts and lag screws.

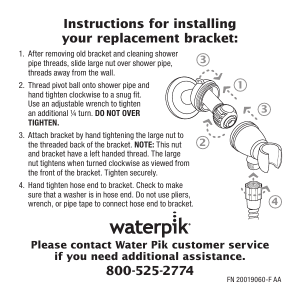

Step 1.

switch off of crate base. See illustrations below for

appropriate style of switch. Attach a guide rope for

control.

Remove crate top, sides, and ends.

NOTE: Do not remove the ties that hold the switch

phases closed until later.

Step 2.

Attach a sling to the lift brackets that are clamped to

the crossarm or frame. A clevis is preferred to attach to

the bracket. Remove crate mounting straps and lift

!

WARNING

Do not lift by rigging to the "live parts." Contacts and

blades could bend, causing the blade to miss the

contact. A resulting arc could damage equipment and

injure operator.

Sling

Lift Bracket

(Note: Loop sling

around phase base if

bracket is not supplied.)

Sling

Lift Bracket

Lift Bracket

Guide Rope

Horizontal Configuration

Guide Rope

Phase/Phase Configuration

Lift Bracket if

Furnished or Pull

Off Eye on Base

Sling

Lift Bracket if

Furnished or Pull

Off Eye on Base

Sling

Lift Bracket

Guide Rope

Guide Rope

Vertical Configuration

Delta ("S" Switch only) Configuration

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be met

with concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular problems

are encountered which are not sufficiently covered in this guide, contact A. B. Chance Company.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design and specifications without notice.

© Copyright 1997 Hubbell / Chance, 210 N. Allen, Centralia, MO 65240

Printed in USA

®

®

Page 1 of 2

POWER SYSTEMS, INC.

Bulletin 14-9305

P816-0647 Rev. A

SECTION A. CHANCE UNITIZED SWITCHGEAR MOUNTING

NOTE:

Following steps refer to standard thru bolt pole mounting. For special mountings such as pole

bands, square poles, etc., please refer to the special control drawing supplied with your switch.

Step 3.

Step 4-A.

Drill two 11⁄16" dia. holes on centerline of pole for mounting of gang switch. Locate and drill according to dimensions shown on the control drawing.

FOR DELTA AND VERTICAL PHASE/PHASE INSTALLATIONS

Place thru bolts thru pole. Align mounting brackets

with thru bolts. Lower switch into slots and tighten

securely. Use 1⁄2" x 5" lag screws in side straps as

required.

NOTE: Check switch again for damaged or broken

parts.

Step 4.(HORIZONTAL) or (VERTICAL)

Style Switches

Using the top 11⁄16" dia. hole that was drilled in Step 3,

assemble a thru-bolt with washer behind the head

through the pole. Assemble a large curved pole washer

on the bolt and then screw a nut on. Draw bolt head and

washer up to approximately 1" from the pole. Lift

switch to desired level, then let switch down enough to

allow key hole slot in top of bracket to slide behind bolt

head and washer (as illustrated below). Tighten bolt

enough to pull bracket up to pole. Align bracket slot

with bottom thru hole, place washer under bolt head

and insert thru bracket and pole. Assemble curved

washer and nut/nuts and tighten all hardware securely. Check for position and level. Assemble the pole

bands as shown on the control drawing and tighten

securely.

NOTE: Crossarm braces should be installed at this

time as required. Drill thru hole on centerline of pole

for crossarm brace bracket as required, (see control

drawing for dimension).

Step 5.

Remove all lift brackets at this time.

!!

WARNING

Failure to remove the lifting angles and brackets will

greatly reduce the basic insulation level, resulting in

switch flashover.

Switch mounting should be complete at this time,

NOTE: Deadending and terminal connections may be

made at this time. NOTE: It is recommended that all

terminal connections be cleaned (wire brushed) and

Chance contact sealing paste, “ZLN”, be applied between conductor and terminal and between terminal

and terminal pad on switch.

Proceed to section "B" for control mounting.

Washer

Curved washer

Mounting

Bracket

Mounting

Bracket

Nut

Thru-Bolts

Thru-Bolt

J-Hook Bolt

Crossarm

Pole Band

Crossarm

Centerline of pole

END/SIDE VIEW

FRONT VIEW

Page 2 of 2

Bulletin 14-9305

P816-0647 Rev. A

SECTION B1 - CONTROLS MOUNTING (Swing Handle)

Step 2.

NOTE:

Swing bottom/free end of section to centerline of

pole, mark and drill 11/16" dia. thru hole 6 inches

below end of section. NOTE: Some controls may

require guides at closer intervals. Be sure to follow

guidelines as shown on control drawing.

For safe and proper operation of the switch it is

required the controls be free of interference from

other lines and underbuild.

Step 1.

See illustrations below or refer to control drawing

for proper mounting of guides that were supplied

with your switch.

Connect vertical steel or insulated section to the

controlling bracket or phase as shown below or on

control drawing with hardware provided. (NOTE:

Follow your utility's requirements if different

from that shown on drawing).

DETAIL "A"

Adjustable Guide

Assembly

(Optional)

Step 1

Use

PP001-1912

clevis pin &

P055902

cotter pin

here for

univ.

installation.

Universal

Vertical

Section

(Steel or Epoxiglas)

Centerline

of

pole

Centerline

of pole

3 in/76 mm

Approx (typical)

6 in/152 mm

Approx (typical)

This dimension

should be

approximately 3"

below the

universal joint or

coupling.

ThruBolt

3" Approx.

Approx.

6"

Step 2

Curved

washer

Nut

Thru-Bolt

Use

PP001-1907

spline bolt &

PP001-1570 lock

nut here for univ.

to vertical control

pipe connection.

Step 2

Lag Screws

See Detail "A"

DETAIL "A"

Typical mounting for Torsional Type Guide Plates

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be met

concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular problems

are encountered which are not sufficiently covered in this guide, contact A. B. Chance Company.

®

®

POWER SYSTEMS, INC.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the

right to change design and specifications without notice.

©1997

Hubbell/Chance, 210 N. Allen St., Centralia, MO 65240 USA

Printed in USA

P816-0648 Rev. A 7/97

SECTION B1 - CONTROLS MOUNTING (Swing Handle)

Step 3.

Top

Universal Section

Slide first section of vertical pipe up thru first guide

bracket and bolt/clamp to top section with hardware

provided. See control drawing.

Step 3

Step 4.

3" Approx.

Follow above procedures for additional sections as

required or as shown on control drawing until you are

ready to cut and install the section for handle and

lock segment assembly.

Pipe Guide

NOTE:

Control Pipe

This dim./height may vary with each utility.

Pipe Coupling

See Detail "B" or "C"

NOTE:

Tapered or small end of

insulator must be on top

side as shown.

Typical mounting location for vertical

insulator (porcelain or polymer).

Top

Bottom

(Base)

Fiberglass Vertical Insulation

Section shown here (Optional).

VERTICAL

INSULATOR

(optional)

3" Approx.

Handle

Ass'y

See

Page 3

Lock

Segment

Ass'y

Step 5

Grd. Strap (Step 7)

Swing Away

Locking Hasp

Approx. 1 ft.

Step 6

Handle

Height

Determined

by Customer

(See Note

under Step 4)

Use

PP001-1907

Spline Bolt &

PP001-1570

locknut here to

connect vertical

control pipe and

coupling

Centerline

of

pole

Control pipe

Control

Pipe

Pipe

Coupling

3"

Approx.

3"

Approx.

Pipe

Guide

Control

pipe

TYPICAL TORSIONAL CONTROL

(SEE CONTROL DWG. FOR SPACING)

P816-0648 Rev. A

Piercing

Coupling

(Optional)

TYPICAL STANDARD TORSIONAL

CONTROL PIPE COUPLING

DETAIL "B"

Pipe

Guide

Control Pipe

TYPICAL PIERCING

COUPLING

APPLICATION

WHEN SUPPLIED

(optional)

DETAIL "C"

Page 2 of 4

SECTION B1 - CONTROLS MOUNTING (Swing Handle)

!!

WARNING

Failure to properly adjust handle may lead to switch failure.

Step 5.

Step 9.

Drill (2) 11/16" holes thru centerline of pole to mount

lock segment bracket, see control drawing for dimensions.

Loosen handle assembly clamp and slide down to

1⁄2" above lock segment, and place handle in closed

side of lock segment. Tighten slightly at this time.

See page 4 for final adjustment.

NOTE:

Height of these holes may vary due to utilities

requirements.

Step 6.

(Torsional Control Only) Measure from bottom of

last installed pipe to 1 ft. (12 inches) past the (2)

holes drilled in step 5. Cut pipe to this dimension

and treat fresh cut end with Galvicon, or zinc rich

paint. Assemble this piece of pipe to the coupling

above. Use hardware supplied with switch.

Step 10.

Fasten loose end of ground strap assembly to lock

segment plate to (1) hole in plate. Install suitable

earth ground wire in P.G. (Parallel Groove) clamp

and tighten bolt securely.

NOTICE: THE GROUNDING RECOMMENDATIONS MADE

MAY DIFFER FROM THE STANDARD OPERATING AND

SAFETY PROCEDURES OF CERTAIN ELECTRIC UTILITY

COMPANIES. WHERE DIFFERENCES EXIST, THE OPERATING PROCEDURES OF THE ELECTRIC UTILITY APPLY.

Step 7.

Slide ground strap up this section approx. 2 ft. (24

inches). Slide swing handle assembly up this section

of pipe approx. 18 inches and clamp enough to keep

from sliding off.

Step 8.

Slide lock segment up pipe below handle

assembly and fasten to pole with (2) 5/8"

thru-bolts. Use holes that were drilled in

Step 5. Use curved washer on opposite side

from lock segment. Fasten securely.

Lag

Screws

6"

(Fixed Dim.)

NON-ADJUSTABLE

LOCK SEGMENT BRACKET

(STANDARD)

Page 3 of 4

Ground Strap

Step 10

11/16 Holes

5/8 thru bolts

Steps 5 and 8

(See Note)

TYPICAL LOCK SEGMENT MOUNTING

Adjustable

Dim.)

ADJUSTABLE

LOCK SEGMENT BRACKET

(OPTIONAL)

P816-0648 Rev. A

SECTION B1 - CONTROLS MOUNTING (Swing Handle)

WARNING

!!

Resistance in the form of wrap up in swing handle controls must be maintained in the closed position in order to

assure proper closing of the switch and to prevent creepage or accidental opening. See detail "A" for proper final

adjustment. Failure to do so could result in switch damage.

Step 12.

Step 11.

Remove all wire ties that are holding blades closed, if

you have not done so already.

Tighten handle clevis bolt. (Do not pierce yet).

Open and close switch several times. Inspect entire

installation.

Step 13.

!!

Final adjustment for swing handle controls. (See

detail "A" below).

WARNING

Failure to do so will result in damaging the switch.

Step 14.

Tighten all hardware to 25-28 ft.-lb. torque. Pierce

set screws where applicable.

Piercing Set Screw

Handle Clamp Bolt

Lock Segment Assy.

Handle Slot

in Lock Segment

Handle slots

(Typical both open

and closed sides)

Locking Hasp

Locking Hasp

Carriage Bolts

Second Step

Loosen carriage

bolts in lock

segment assy. and

move handle slot

approx. 10°-15°

past centerline of

handle.

NOTE: This will

provide torsional

wrap-up in closed

position.

First Step

With all switch

phases fully closed

against stops, set

operating handle

approx. 60°-65°.

Tighten handle

clamp bolt securely.

Do not set piercing

set screws yet.

Handle shown in

locking position for

counterclockwise

opening switch. For

clockwise, reverse

handle position.

Third Step

Open switch

completely until

rotating insulator

levers are against

stops. Total

rotation from close

to open should be

approx. 120°-130°.

Approx. 1/2"

clearance above

locking plate

Grounding Bar

Fourth Step

Move handle slot in

lock segment to

approx. 10°-15°

past centerline of

handle.

NOTE: This will

provide torsional

wrap-up in open

position.

Fifth Step

Recheck all positions as mentioned

above and tighten

all hardware. If all

settings are

complete as

recommended,

pierce set screws in

handle casting.

DETAIL "A" (TORSIONAL CONTROLS)

P816-0648 Rev. A

Page 4 of 4

SECTION B2 - CONTROLS MOUNTING (Pump Handle)

NOTE: For safe and proper operation of the switch it is

required the controls be free of interference from other lines

and underbuild.

Step 1.

Connect vertical steel/insulated section to the

controlling bracket or phase as shown on control

drawing with hardware provided. (NOTE: Follow

your utility's requirements if different from that

shown on drawing). See Detail "A-1".

Step 2. (Guide Placement)

For 11⁄4" control pipe with steady lever.

A. Attach steady lever to loose end of top section,

swing to centerline of pole, set at 45° and mark pole

where bracket holes are located. See detail B.

B. Swing aside and drill (2) 11⁄16" dia. holes for thru

bolts. See detail B.

CL

SWITCH BASE OF CONTROLLING PHASE

HORIZONTAL

INTERPHASE

ON VERTICAL

MOUNTED

SWITCH

VERTICAL

INTERPHASE

ON PHASE

OVER PHASE

STYLE

SWITCH

FIBERGLASS

"A-1"

Using slots

in lever,

provide

clearance

for vertical

operating

shaft if

angle of

control

requires it.

PIN &

COTTER PIN

TOP

VERTICAL

CONTROL

SECTION

FIBERGLASS

OR STEEL

6"

PIN &

COTTER PIN

FIBERGLASS

OR STEEL

TOP

VERTICAL

CONTROL

SECTION

11⁄4" I.P.S. PIPE CONTROL

DETAIL "A-1"

TYP. TOP CONTROL SECTION

CONNECTIONS FOR 1-1/4" I.P.S. PIPE

6"

PAGE 3

STEADY

LEVER

GUIDE

6"

6"

6"

DETAIL "B"

TYP. STEADY LEVER GUIDE BRACKET WHEN

SUPPLIED

TYP. RECIPROCATING CONTROL WITH

1-1/4" I.P.S. PIPE

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be met

concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular problems are

encountered which are not sufficiently covered in this guide, contact A. B. Chance Company.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design and specifications without notice.

®

®

POWER SYSTEMS, INC.

©1999

Hubbell/Chance, 210 N. Allen St., Centralia, MO 65240 USA

Printed in USA

Page 1 of 5

P816-0653 Rev. A

SECTION B2 - CONTROLS MOUNTING (Pump Handle)

Step 3. (Guide Placement)

For 3⁄4" control pipe or 1" Fiberglass rod.

C. Measure, mark, and drill 11⁄16" dia. hole on

centerline of pole. See Detail "C".

A. Refer to control dwg. for dim. where top guide will

be placed.

D. Slide guide nut up from bottom of top section to

previously drilled hole, assemble thru bolt and

hardware but leave loose until later.

B. Fasten top control section to controlling bracket,

lever on back of controlling phase or directly to

end of interphase as shown in detail A2. See

control drawing.

BASE BRACKET

CL

TYP. RECIPROCATING CONTROL WITH

3/4" I.P.S. PIPE / 1" O.D. FIBERGLASS

TOP VERTICAL

SECTION

PIN &

COTTER

PIN

VERTICAL

INTERPHASE

ON PHASE

OVER PHASE

STYLE

SWITCH

HORIZONTAL

INTERPHASE

ON VERTICAL

MOUNTED

SWITCH

PIN &

COTTER

PIN

FIBERGLASS

EPOXY

OR STEEL

COUPLING

SEE DETAIL E

PAGE 3

TOP

VERTICAL

CONTROL

SECTION

FIBERGLASS OR STEEL

TOP

VERTICAL

CONTROL

SECTION

CONTROL PIPE

STEEL OR

EPOXIGLAS

DETAIL "A2"

TYP. 3⁄4" I.P.S. PIPE/1" O.D. FIBERGLASS

CONTROL CONNECTIONS

AS REQ'D

DETAIL "C"

TYP. EYE NUT TYPE GUIDES WHEN SUPPLIED

PIPE GUIDE

SEE DETAIL C

STEP 3

CENTERLINE

OF CONTROL

PIPE / ROD

AS REQ'D

GROUND

STRAP

CURVED

WASHER

CURVED

WASHER

RECIPROCATING

PUMP HANDLE

(SEE PAGE 5 FOR

FINAL ADJ.)

SEE STEP 6

PAGE 4

NUT

NUTS

AS REQ'D

SEE NOTE

PAGE 3

P816-0653 Rev. A

Page 2 of 5

EYE

NUT

SECTION B2 - CONTROLS MOUNTING (Pump Handle)

Step 4.

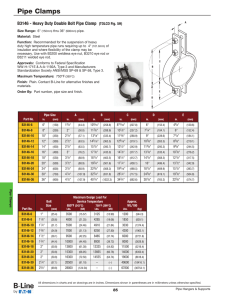

PIPE CLAMP

END FITTING

Follow above procedures for additional guides required or as shown on control drawing until desired

height is reached for handle mounting bracket.

11⁄4" I.P.S.

CONTROL

PIPE

NOTE:

This dim./height may vary with each utility.

PIN &

COTTER

PIN

NOTE:

APPROX. 45°

When eye nut guides are supplied, leave D.A. or thru

bolts loose until handle assembly is installed. Then

align all guides so as to form a straight line.

STEADY

LEVER

GUIDE

Step 5.

Connect each additional section of pipe/rod with

couplings that have been supplied with the switch

controls. See illustrations for typical coupling connections. Detail D or E.

CONTROL PIPE/ROD

PIPE CLAMP

END FITTING

DETAIL "D"

TYP. RECIPROCATING CONTROL COUPLING

FOR 1-1/4" I.P.S. PIPE

3⁄ " I.P.S. PIPE

4

1 DIA. EPOXY

ROD

14"

MIN.

8 BOLT

CLAMP

COUPLING

EYE NUT

GUIDE BKT.

DETAIL "E"

TYP. RECIPROCATING CONTROL FOR

3/4" PIPE/ROD COUPLING

Page 3 of 5

P816-0653 Rev. A

SECTION B2 - CONTROLS MOUNTING (Pump Handle)

Step 6.

Step 10.

Drill (2) 11/16" holes thru centerline of pole to mount

handle assembly, see control drawing for dimensions. Assemble handle and bracket assembly to pole

using (2) 5/8" thru-bolts. Use curved washer on

opposite side from bracket. Assemble ground strap

bar and lug to top thru-bolt and bracket as shown in

Figure A. Tighten securely.

Swing handle and clevis up to full closed position

(switch fully closed) and cut pipe as shown in figure

A. Assemble "U" bolts/clamp to hold pipe/rod in

position. Do not tighten yet.

Step 7.

Slide bottom section of pipe or rod up thru guide

above and clamp together using hardware provided.

Step 8.

Slide ground strap up pipe/rod and clamp lightly.

Step 9.

Assemble handle clevis to handle assembly. Adjust

with double nutting so that clevis will pivot. See

control drawing for clevis number.

Step 11.

Fasten loose end of ground strap assembly to tab on

handle bracket and tighten securely. Install suitable

earth ground wire in P.G. (Parallel Groove). Clamp

and tighten bolt securely.

NOTICE: THE GROUNDING RECOMMENDATIONS MADE

MAY DIFFER FROM THE STANDARD OPERATING AND

SAFETY PROCEDURES OF CERTAIN ELECTRIC UTILITY

COMPANIES. WHERE DIFFERENCES EXIST, THE OPERATING PROCEDURES OF THE ELECTRIC UTILITY APPLY.

Step 12. (Eye Nut Guides Only)

Adjust and tighten all guides to insure a straight

alignment of entire length of controls.

Proceed to page 5.

6"

6"

TYP. HANDLE MOUNTING FOR 3/4" I.P.S. PIPE OR

1" DIA. EPOXY ROD RECIPROCATING CONTROLS

TYP. HANDLE MOUNTING FOR 1-1/4" I.P.S.

RECIPROCATING CONTROLS

FIGURE A

P816-0653 Rev. A

Page 4 of 5

SECTION B2 - HANDLE ADJUSTMENT (Pump Handle Controls)

!!

WARNING

Resistance in the form of compression in reciprocating controls must be maintained in the closed position in order to

assure proper closing of the switch and to prevent creepage or accidental opening. See detail "A" for proper final

adjustment. Failure to do so could result in switch damage..

Step 1.

Step 3.

Remove all wire ties that are holding blades closed.

Final adjustment for reciprocating controls. (See

detail "A" below).

!!

WARNING

Failure to do so will result in damaging the switch.

Step 2.

Tighten handle clevis bolts or "U" bolts. (Do not

pierce yet). Open and close switch several times.

Inspect entire installation.

See Step 3

With switch in fully closed position with blades

against stops, loosen handle clamp hardware, pull

handle back approximately 15°-20° and retighten

clamp hardware. Push handle closed, a definite overtoggle effect should occur. NOTE: If switch should

happen to not fully open with this setting, loosen

hardware and set handle approximately 15°. repeat

this procedure until switch has an over-toggle

compression in closed position and will still fully

open.

Step 4.

Tighten all hardware to 25-28 ft. lbs. torque. Pierce

set screws where applicable.

DETAIL "A"

RECIPROCATING

PUMP HANDLE-CONTROLS

Handle adjustment and

grounding recommendation.

15° -20° Approx. can be obtained by

aligning back side of handle with back

side of padlocking hole as shown.

Tighten all clamps or "U" bolts.

SIDE VIEW

FRONT VIEW

Page 5 of 5

P816-0653 Rev. A

SECTION D. FINAL SWITCH FIELD INSPECTION:

TYPE "D" COUNTERCLOCKWISE SWITCH SHOWN WITH

ARCING HORNS AND DUOGAP® INTERRUPTERS

(Clockwise - Same Except Opposite Hand)

NOTICE

®

If the switch does not include Duogaps , ignore reference to pickup bolt and operating lever. All other action will be the same.

BLADE TIP

CASTING

TERMINAL

PAD

DUOGAP®

INTERRUPTER

DUOGAP®

INTERRUPTER

OPERATING LEVER

STATIONARY

SPRING

CONTACTS

ARC BOLT

ARCING HORN

BLADE

Step 1.

Step 2.

The arc bolt should contact the arcing horn before

the blade leaves the spring contacts.

The arc bolt will slide along the arcing horn. The

blade tip casting (on the end of the blade) contacts and

moves the Duogap® lever toward the trip position.

Step 3.

Step 4.

The arc bolt separates from the arcing horn. The

Duogap® trips. (When energized it would interrupt

the current.)

The blade tip casting slides free of the operating

lever. The blade moves to the open position and the

operating lever resets.

⁄4"

1

Step 5.

Step 6.

When closing the switch, the arc bolt must contact

the arcing horn before the blade tip casting contacts

and wipes past the operating lever.

When the switch is fully closed, the Duogap® operating lever is free of the blade tip casting. There will be

a 1⁄4" gap between the arc bolt and the arcing horn.

If any phase of the switch does not operate as described above, contact the nearest A.B. Chance Sales Office.

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be met

concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular problems are

encountered which are not sufficiently covered in this guide, contact A.B. Chance Company.

®

®

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to

change design and specifications without notice.

© 1997 Hubbell/Chance, 210 N. Allen, Centralia, MO 65240 — Printed in USA

POWER SYSTEMS, INC.

Bulletin 14-9309

P816-0651 Rev. A

A.B. CHANCE OVERHEAD SWITCHGEAR

SECTION F.

MAINTENANCE INSTRUCTIONS

Following a periodic inspection and maintenance

program will prolong the life of the Switch. The

Switch is designed for long-term exposure to all

weather conditions. However, certain environments

may reduce its life without some type of periodic

maintenance. Minimum inspection and maintenance specifications have been established. Following them will help ensure long service life.

Step 3.

NOTE: It is recommended that all overhead

switchgear go through a maintenance check at least

once a year, more frequent if switch is in a contaminated area.

Inspect all controls, interphase, and moving parts for

damaged or worn-out parts. Replace any damaged or

worn-out parts.

!!

CAUTION

Check for eroded contacts, alignment, and corrosion

of the hot parts. Replace any damaged components.

Lubricate all contacts and arcing horns with Dow

Corning FS-1292 silicone grease or equal.

Step 4.

Lubricate all control components with A.B. Chance

silicone spray Cat. #C400-1749 or equal.

Step 5.

A.B. Chance Company recommends that all maintenance work be performed on de-energized

switches. When working on live lines, follow your

utility's standard safe operating procedures.

WARNING —

Fiberglass Crossarms

!

Contact with the switch bases, mounting hardware or crossarm could result in electrical shock.

Check and tighten all thru bolts and mounting

hardware.

Step 6.

Inspect all pins, rivets, and bolted connections.

Tighten all hardware and replace damaged or wornout parts.

Step 7.

Check insulators for cracks, breaks or burns. Replace any damaged insulators.

Step 8.

Can cause severe injury or death.

Ground the switch bases, and mounting hardware

prior to performing adjustments or main work.

Step 1.

When possible, open and close the switch several

times to clean the contact surfaces and loosen

moving parts.

Make sure interrupters or arc chutes are free and

operating properly.

Step 2.

Refer to section C, D or E and inspect the switch for

proper operating sequence.

NOTICE

Check operation of the switch making sure over

toggle effect or wrap up still occurs when

closed. If not, readjust.

See Section B1 or B2.

Refer to ANSI C37.35 for additional recommendations. C37.35 is "IEEE Guide for the Application,

Installation, Operation, And Maintenance Of HighVoltage Air Disconnection and Load Interrupter

Switches."

These instructions do not claim to cover all details or variations in equipment, nor to provide for all possible conditions to be met

with concerning installation, operation, or maintenance of this equipment. If further information is desired or if particular problems

are encountered which are not sufficiently covered in this guide, contact A.B. Chance Company.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserves the right to change design and specifications without notice.

®

®

POWER SYSTEMS, INC.

© 1997 Hubbell/Chance, 210 N. Allen, Centralia, MO 65240

Printed in USA

Bulletin 14-9310

P816-0652 Rev. A