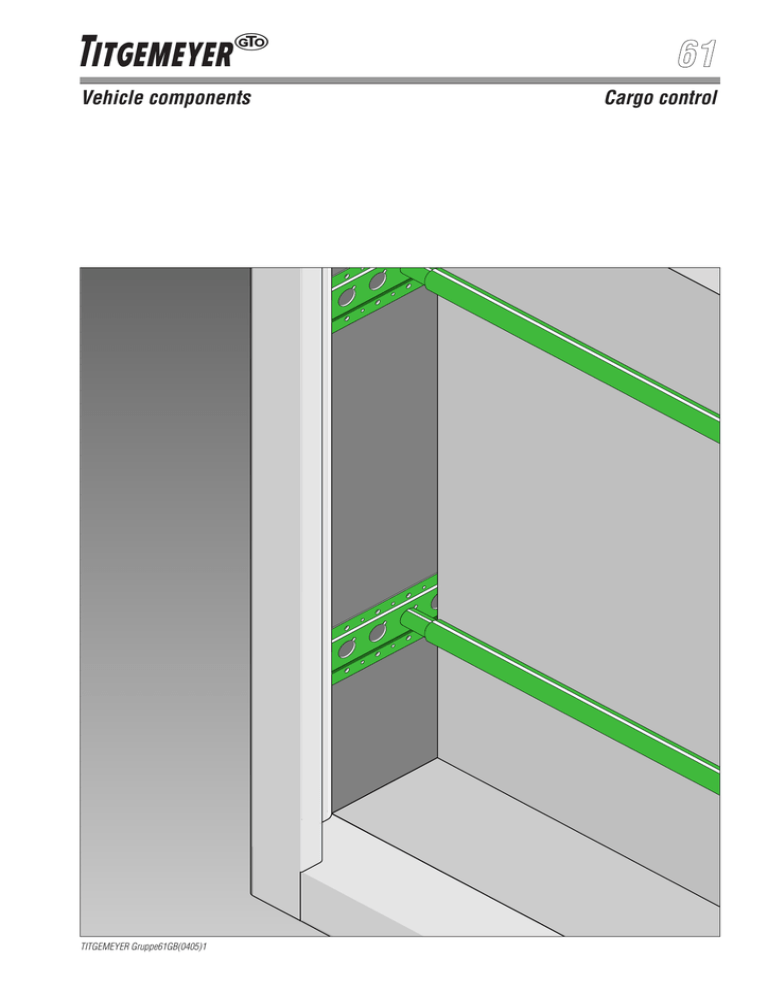

Vehicle components Cargo control

advertisement