Compressed Gas Catalog

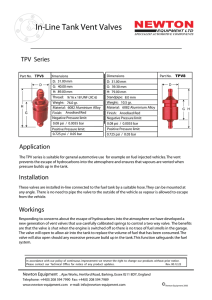

advertisement