Freescale Semiconductor

Engineering Bulletin

EB213

Rev. 0, 5/2003

Surge - Ringing Wave Clamp for GaAs

CATV Module Protection

by: Jeff Gengler

Freescale Semiconductor

INTRODUCTION

CLAMP DEVICE SELECTION CRITERIA

CATV amplifiers are required to withstand surges induced

by nearby lightning strikes. Manufactures use crowbar

devices such as gas discharge tubes and semiconductor

devices that are intended to limit surge voltages and conduct

surge currents. These devices have a very fast turn - on once

their threshold voltage is reached, causing a very fast change

in voltages (dv/dt). This in turn induces several cycles of high

voltage ringing within the pass band of the diplex filter,

allowing the surge- ringing wave to propagate to the output of

the hybrid module. Commonly deployed crowbar devices

such as gas discharge tubes generate a few cycles as high as

200 V peaks at 50 to 150 MHz when they fire during a 6 kV

surge event. Because GaAs CATV modules are susceptible

to ring wave stresses, a surge- ringing wave clamp is needed

for additional protection.

The surge - ringing wave clamp is constructed using two

silicon bipolar transistors. The bipolar transistor device

chosen is critical for successful surge ring wave clamping.

Commercially available RF bipolar transistors are suitable

devices because the surge - ringing waves are within the

CATV pass band. The criteria for a clamp device is as follows:

1. The transistor should have a transition frequency with a

minimum of 5 GHz to ensure sufficient reaction speed to

incoming surge - ringing waves.

2. The collector - to - emitter breakdown voltage (V(BR)CEO)

of each individual transistor should have a high enough

breakdown voltage to avoid impacting distortion

performance. If this parameter is too low, the high output

voltage peaks will be clipped, causing degradation in

distortion performance. The V(BR)CEO should be selected

SURGE- RINGING WAVE CLAMP

above the peak output but not too far above the peak

voltage output. The most effective clamp has the lowest

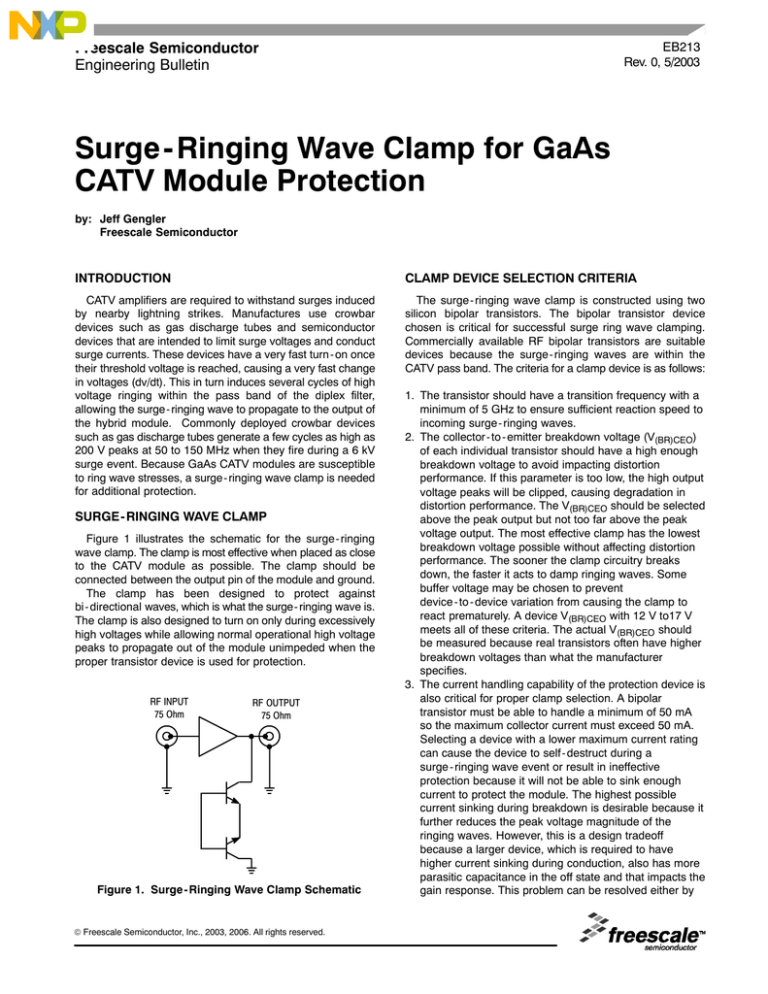

Figure 1 illustrates the schematic for the surge - ringing

breakdown voltage possible without affecting distortion

wave clamp. The clamp is most effective when placed as close

performance. The sooner the clamp circuitry breaks

to the CATV module as possible. The clamp should be

down, the faster it acts to damp ringing waves. Some

connected between the output pin of the module and ground.

buffer voltage may be chosen to prevent

The clamp has been designed to protect against

device - to - device variation from causing the clamp to

bi - directional waves, which is what the surge- ringing wave is.

react prematurely. A device V(BR)CEO with 12 V to17 V

The clamp is also designed to turn on only during excessively

meets all of these criteria. The actual V(BR)CEO should

high voltages while allowing normal operational high voltage

be measured because real transistors often have higher

peaks to propagate out of the module unimpeded when the

breakdown voltages than what the manufacturer

proper transistor device is used for protection.

specifies.

3. The current handling capability of the protection device is

also critical for proper clamp selection. A bipolar

RF INPUT

RF OUTPUT

transistor must be able to handle a minimum of 50 mA

75 Ohm

75 Ohm

so the maximum collector current must exceed 50 mA.

Selecting a device with a lower maximum current rating

can cause the device to self - destruct during a

surge - ringing wave event or result in ineffective

protection because it will not be able to sink enough

current to protect the module. The highest possible

current sinking during breakdown is desirable because it

further reduces the peak voltage magnitude of the

ringing waves. However, this is a design tradeoff

because a larger device, which is required to have

higher current sinking during conduction, also has more

parasitic capacitance in the off state and that impacts the

Figure 1. Surge - Ringing Wave Clamp Schematic

gain response. This problem can be resolved either by

designing around it or selecting a device that

compromises the amount of current it can sink (as long

© Freescale Semiconductor, Inc., 2003, 2006. All rights reserved.

EB213

RF Engineering Bulletin

Freescale Semiconductor

1

as the minimum requirement is met) and the amount of

capacitance the clamp introduces. Devices close to the

minimum often have negligible parasitic capacitance,

and no special response considerations are necessary.

CONCLUSION

To ensure field reliability of GaAs CATV modules, additional

protection circuitry must be implemented. Incorporation of the

ringing wave clamp shown in Figure 1 results in a major

reduction in the voltage magnitude of offending waves during

surge events to a level that will not harm GaAs CATV modules.

Proper bipolar transistor device selection when used in the

surge - ringing wave clamp configuration is an effective means

of protection without impacting distortion performance. A

reduction of more than 80% in the peak voltages of the ringing

waves has been demonstrated in some applications when the

clamp is applied versus those in an unprotected module.

The transistor devices used to realize the clamp protection

circuitry is important. There are many different commercially

available bipolar transistors that meet the criteria to be

implemented in the surge - ringing wave clamp configuration

that the designer can choose from to incorporate packaged

transistors into a design. Bipolar transistors are very

inexpensive so the extra cost of the additional components is

easily offset by the increased field reliability that they provide

against lightning - induced surges.

EB213

2

RF Engineering Bulletin

Freescale Semiconductor

How to Reach Us:

Home Page:

www.freescale.com

E - mail:

support@freescale.com

USA/Europe or Locations Not Listed:

Freescale Semiconductor

Technical Information Center, CH370

1300 N. Alma School Road

Chandler, Arizona 85224

+1 - 800 - 521 - 6274 or +1 - 480 - 768 - 2130

support@freescale.com

Europe, Middle East, and Africa:

Freescale Halbleiter Deutschland GmbH

Technical Information Center

Schatzbogen 7

81829 Muenchen, Germany

+44 1296 380 456 (English)

+46 8 52200080 (English)

+49 89 92103 559 (German)

+33 1 69 35 48 48 (French)

support@freescale.com

Japan:

Freescale Semiconductor Japan Ltd.

Headquarters

ARCO Tower 15F

1 - 8 - 1, Shimo - Meguro, Meguro - ku,

Tokyo 153 - 0064

Japan

0120 191014 or +81 3 5437 9125

support.japan@freescale.com

Asia/Pacific:

Freescale Semiconductor Hong Kong Ltd.

Technical Information Center

2 Dai King Street

Tai Po Industrial Estate

Tai Po, N.T., Hong Kong

+800 2666 8080

support.asia@freescale.com

For Literature Requests Only:

Freescale Semiconductor Literature Distribution Center

P.O. Box 5405

Denver, Colorado 80217

1 - 800 - 441 - 2447 or 303 - 675 - 2140

Fax: 303 - 675 - 2150

LDCForFreescaleSemiconductor@hibbertgroup.com

Information in this document is provided solely to enable system and software

implementers to use Freescale Semiconductor products. There are no express or

implied copyright licenses granted hereunder to design or fabricate any integrated

circuits or integrated circuits based on the information in this document.

Freescale Semiconductor reserves the right to make changes without further notice to

any products herein. Freescale Semiconductor makes no warranty, representation or

guarantee regarding the suitability of its products for any particular purpose, nor does

Freescale Semiconductor assume any liability arising out of the application or use of

any product or circuit, and specifically disclaims any and all liability, including without

limitation consequential or incidental damages. “Typical” parameters that may be

provided in Freescale Semiconductor data sheets and/or specifications can and do

vary in different applications and actual performance may vary over time. All operating

parameters, including “Typicals”, must be validated for each customer application by

customer’s technical experts. Freescale Semiconductor does not convey any license

under its patent rights nor the rights of others. Freescale Semiconductor products are

not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life,

or for any other application in which the failure of the Freescale Semiconductor product

could create a situation where personal injury or death may occur. Should Buyer

purchase or use Freescale Semiconductor products for any such unintended or

unauthorized application, Buyer shall indemnify and hold Freescale Semiconductor

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all

claims, costs, damages, and expenses, and reasonable attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such

unintended or unauthorized use, even if such claim alleges that Freescale

Semiconductor was negligent regarding the design or manufacture of the part.

Freescalet and the Freescale logo are trademarks of Freescale Semiconductor, Inc.

All other product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2003, 2006. All rights reserved.

EB213

RF

Engineering Bulletin

EB213

Rev. 0, 5/2003

Freescale

Semiconductor

3