PDF - International Journal of Research in Chemistry and

advertisement

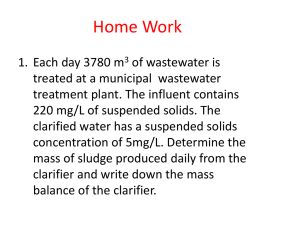

Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) International Journal of Research in Chemistry and Environment Vol. 4 Issue 2 April 2014(136-142) ISSN 2248-9649 Research Paper Assessment of Physico-chemical Pollutants in Pharmaceutical Industrial Wastewater of Pharma city, Selaqui, Dehradun *Rana Rajender S.1, Prashant Singh1, Rakesh Singh2, Gupta Sanjay3 1 Department of Chemistry, DAV (PG) College, Dehradun, INDIA Department of Chemistry, DBS (PG) College, Dehradun, INDIA 3 Department of Biotechnology & Biochemistry, SBSPGI, Balawala, Dehradun, INDIA 2 (Received 08th March 2014, Accepted 24th March 2014) Available online at: www.ijrce.org Abstract: Water pollution is a great challenge of today’s civilization. In Dehradun district of Uttarakhand state during past 10 years, there is an extreme growth registered in pharmaceutical industry. This rapid industrialization contributes to water pollution in and around Dehradun district. Although, these pharmaceutical industries work under the strict guideline of Central Pollution Control Board (CPCB), Govt. of India, but the situation is far from satisfaction. Time to time monitoring of pharmaceutical wastewater is necessary to check the level of pollutants, which helps in upgradation and designing of proper treatment strategy. In this study, we selected five different sites, located in Pharma City, Selaqui, Dehradun, Uttrakhand, India, for wastewater assessment. pH, total suspended solids (TSS), total dissolved solids (TDS), electrical conductivity (EC), chloride, phenols, chemical oxygen demand (COD), biochemical oxygen demand (BOD), boron, sulphate, nitrate, fluoride and sodium absorption ratio (SAR) were selected for wastewater assessment. Twelve months sampling (January 2012 to December 2012) was carried out and analysis was done every month for physico-chemical study. All parameters were compared with the general standards for discharge of industrial effluents into inland surface water, provided by CPCB and Bureau of Indian standards (BIS). The range of concentrations of all parameters for five different sampling sites were found in the following range 4.66-6.95 for pH, 87408 mg/L for TSS, 764-4456 mg/L for TDS, 1168-6778 (µS/cm)for EC, 45-732 mg/L for chloride, 0-4.62 mg/L for phenolic compounds, 823-3302 mg/L for COD, 102-390 mg/L for BOD, 0-1.45 mg/L for boron, 37-837 mg/L for sulphate, 0.12-16.8 mg/L for nitrate, 0-0.89 mg/L for fluoride and 3.78-21.23 for SAR. Further this study was subjected to statistical analysis by using Box and Whisker Vertical Plots, Pearson’s Correlation and Annova. It was concluded that in all sampling sites, average value for phenolic compounds, COD and BOD parameters were found above the standards limits and for pH, chloride, boron, sulphate, nitrate and fluoride it was found below the standard limits provided by CPCB and BIS. This study further helps us to design an appropriate treatment plan for pharmaceutical industries wastewater containing other pollutants. Keywords: Assessment, Pharmaceutical industries, Selaqui, Wastewater. Introduction enhanced the level of surface water pollution up to 20 times the safe level in 22 critical polluted areas of the country. It is found that almost all rivers are polluted in most of the stretches by some industries[4,5]. Level of wastewater pollution varies from industry to industry depending upon the type of processes and the size of the industries[6]. The worldwide growth and expeditious industrialization have led to the recognition and increasing understanding of the interrelationship between pollution, public health and environment. Presently, 3.4 million people die each year in the world from water borne diseases owing to rapid industrialization[1,2]. The surface water is the main source of industries for wastewater disposal[3]. Untreated or allegedly treated industrial effluents have In India, during the past few decades pharmaceutical industries have registered a quantum [136] Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) jump. Pharmaceutical industry production includes raw material, antibiotics, variety of medicines and cosmetic products, which in turn generates the effluent containing constituents harmful to human and aquatic life[7,8]. Although, maintenance and housekeeping activities are similar from one plant to another, but pharmaceutical industries do not generate uniform waste streams, due to the variety of medicines produced during any given manufacturing process[8,912] . Though the volume of untreated or incompletely treated pharmaceutical industrial wastewater (PIWW) is small but it contains high level of pollutants because of the presence of non-biodegradable organic matter, heavy metals (such as Lead, Mercury, Cadmium, Nickel, Chromium) and other pollutants[13-15]. Predicted impacts of the wastewater on the flora and fauna vary widely due to the wide variations in the characteristics of the wastewater. When these pollutants are discharged on the ground or in the water bodies, they accumulate in the system through the food chain and affect the human health and other living organisms[16]. monitoring further helps in wastewater treatment plan. Previous study on PIWW reveals the presence of organic and inorganic pollutants[4,9,13,17-18]. The proportionate increased level of water pollution in and around Dehradun[19], generates a need for assessment of physico-chemical contaminants in PIWW of Pharmacity, Selaqui, Dehradun, Uttarakhand, India. Material and Methods Sampling area and sample preparation: Water pollution level of nearby area of Selaqui region of Dehradun district is increasing[19] due to improper treatment of wastewater discharged from industrial area of Selaqui, Dehradun, Uttrakhand, India. Therefore, the Pharmaceutical Industrial Area (Pharma City), Selaqui was chosen for the study, which is located 25 km from Dehradun, the capital of Uttrakhand State. Samples were collected from five different sampling sites, designated as S1 to S5. Wastewater samples were collected from the discharge point near RFCL Bridge designated as S1, near Round Chowk as S2, near TVS Electronics as S3, near IGL as S4 and S5 was located at near Netco Pharma. Wastewater samples were collected in 1 litre Tarson sampling bottles previously cleaned by washing with non-ionic detergent, rinsed with tap water and later soaked in 10% HNO3 for 24 hours and finally rinsed with deionised water prior to use. Assessment of PIWW is necessary to evaluate the pollutants level and also for its reuse in different other process. Agriculture is the major user of water that can accept lower quality water than domestic and industrial users. It is, therefore, unavoidable that there will be a growing tendency to look toward irrigated agriculture for solutions to the overall effluent disposal problem. Although all pharmaceutical industries work under the strict guideline of CPCB but untreated or improperly treated wastewater generation requires a time to time monitoring of wastewater. CPCB and BIS provide general standards for discharge of industrial effluents into inland surface water. During sampling, sample bottles were rinsed with sample water three times and then wastewater was filled from each of the five designated sampling points (S1 to S5). The samples were labelled and transported to the State Level Water Quality Analysis Laboratory, Uttarakhand Jal Sansthan, Dehradun and stored at 60C in refrigerator. Table 1 Water Quality Standards for water use in irrigation and industrial cooling (Source IS 2296:1992) Characteristics (all parameters in mg/l, max except pH, EC, SAR) pH TDS Chlorides Sulphates EC, (µS/cm) max Sodium absorption ratio (SAR), max Boron All parameters were analysed as per standard method[20]. Assessment of pH, TDS and EC were done on site itself. For pH assessment, Chlorine/pH Meter (Pocket ColorimeterTMII; Make: HACH, USA) and for TDS & EC analysis, TDS/Conductivity meter (HACHsension5) were used. Sulphate, nitrate and fluoride were analysed by spectrophotometer (Model: DR 5000; Make: HACH, USA). For Irrigation and Industrial Cooling (Class E) 6.0-8.5 For SAR estimation, assessment of sodium, calcium and magnesium were done by atomic absorption spectrophotometer (Model: AA 240A; Make: Varian, Australia). SAR was calculated by following formula: 2,100 600 1,000 2,250 26 SAR = Na / [ (Ca+Mg) / 2]0.5 Statistical analysis: The data obtained were subjected to statistical analysis using “Graph Pad Prism 5” software. By using this software box and whisker plots, analysis of variance (ANOVA) and Pearson’s correlation were observed. With the help of box and 2 Previous data on water pollution caused by pharmaceutical industries points out the need of regular monitoring of pollution level and this [137] Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) whisker plots, estimation of the range (minimum to maximum), median, mean, interquartile range were done. Box plots can be drawn either horizontally or vertically[21,22]. Results and Discussion Box and whisker plots are shown in Figure 1 to 13, shows the minimum to maximum limits and mean value (+) of parameters for each sampling sites. Figure 4: Box and Whisker Plot of EC analysed at 5 sites of Pharmacity, Dehradun Figure 1: Box and Whisker Plot of pH analysed at 5 sites of Pharmacity, Dehradun Figure 5: Box and Whisker Plot of Chloride analysed at 5 sites of Pharmacity, Dehradun Figure 2: Box and Whisker Plot of TSS analysed at 5 sites of Pharmacity, Dehradun Figure 6: Box and Whisker Plot of Phenols analysed at 5 sites of Pharmacity, Dehradun Figure 7: Box and Whisker Plot of COD analysed at 5 sites of Pharmacity, Dehradun Figure 3: Box and Whisker Plot of TDS analysed at 5 sites of Pharmacity, Dehradun [138] Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) Figure 8: Box and Whisker Plot of BOD analysed at 5 sites of Pharmacity, Dehradun Figure 11: Box and Whisker Plot of Nitrate analysed at 5 sites of Pharmacity, Dehradun Figure 9: Box and Whisker Plot of Boron analysed at 5 sites of Pharmacity, Dehradun Figure 12: Box and Whisker Plot of Fluoride analysed at 5 sites of Pharmacity, Dehradun Figure 10: Box and Whisker Plot of Sulphate analysed at 5 sites of Pharmacity, Dehradun Figure 13: Box and Whisker Plot of SAR analysed at 5 sites of Pharmacity, Dehradun From these plots it was observed that the maximum value of pH found in S2 sampling sites (6.95) and minimum in S2 (4.66), maximum concentration of phenols found in S5 (4.62 mg/l) and minimum in S3 (0 mg/L), maximum concentration of COD found in S5 (3302 mg/l) and minimum in S3 (823 mg/L), maximum concentration of BOD found in S5 (390 mg/l) and minimum in S1 (102 mg/L), maximum concentration of boron found in S5 (1.45 mg/l) and minimum in S2 and S3 (0 mg/L), maximum concentration of sulphate found in S5 (837 mg/l) and minimum in S4 (37 mg/L), maximum concentration of nitrate found in S3 (16.8 mg/l) and minimum in S4 (0.12 mg/L), maximum concentration of fluoride found in S3 (0.89 mg/l) and minimum in S1 and S4 (0 mg/L), maximum concentration of chloride found in S2 (732 mg/l) and minimum in S1 (45 mg/L), maximum concentration of TSS found in S4 (408 mg/l) and minimum in S1 (87 mg/L), maximum concentration of TDS found in S5 (4456 mg/l) and minimum in S1 (764 mg/L), maximum value of EC found in S5 (6778 µS/cm) and minimum in S1 (1165 µS/cm), maximum value of SAR found in S5 (21.23 and minimum in S3 3.78). [139] Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) From Table 2, it was observed that average values of pH, chloride, boron, sulphate, nitrate and fluoride, in all sampling sites were found under the tolerance limit provided by Indian standard (standard A and B). In all sampling sites, the average values of TSS, COD, BOD and phenols were found above the standard tolerance limit. between the following parameters: EC-TDS (0.999), SAR-TDS (0.776), SAR-EC (0.775), SAR-Sulphate (0.719), Sulphate-Chloride (0.676), Sulphate-TDS (0.655), Sulphate-EC (0.651), Chloride-TDS (0.645), Chloride-EC (0.638), SAR-BOD (0.578), SARChloride (0.565), COD-TDS (0.537), SAR-COD (0.518), Phenols-TDS (0.516), Phenols-EC (0.514) and COD-EC (0.514). And high negative correlation exhibit between the following parameters: NitrateTDS (-0.331), Nitrate-EC (-0.327), Nitrate-Chloride (-0.291), Nitrate-Sulphate (-0.291), SAR-Nitrate (0.261), Fluoride- Phenols (-0.254) and Fluoride-pH (-0.240). The result of ANOVA (one way) for all parameters has shown in Table 4. From the above table it was concluded that there is a significant difference observed for all parameters except pH. Pearson’s correlation coefficient matrix: Earlier researcher reported the correlation between water quality parameters, which showed strong positive and strong negative correlation[23,24]. In this study Pearson’s correlation coefficient matrix was prepared between the analysed parameters and shown in Table 3. From this table, it is observe that high positive correlations among all the parameters exhibit Table 2 Comparison of average value of parameters with tolerance limits for discharge of industrial effluents into inland surface, provided by CPCB and BIS (IS: 2490, Part-I-1981) S. No. Parameters Sampling Sites Standard A (CPCB) S1 S2 S3 S4 S5 5.89 151 1588 2452 5.75 159 2304 3505 5.71 186 1830 2798 5.79 215 1836 2804 5.76 184 2735 4183 5.5-9.0 100 - Standard B (IS:2490, part-1-1981) 5.5-9.0 100 - 1 2 3 4 pH TSS (mg/L) TDS (mg/L) EC (µS/cm) 5 6 7 8 9 Chloride (mg/L) Phenols (mg/L) COD (mg/L) BOD (mg/L) Boron (mg/L) 142 1.685 1564 182.3 0.2798 375 2.013 1879 227.9 0.2384 229 1.279 1692 194.08 0.2279 231 2.042 1594 204.4 0.1912 420 2.342 2159 255.1 0.5612 1 250 30 - 1000 1 250 30 2 10 Sulphate (mg/L) 166 362 216 138 374 - 1000 11 Nitrate (mg/L) 8.25 4.295 8.19 1.7 2.48 10 - 12 Fluoride (mg/L) 0.222 0.625 0.559 0.202 0.418 2 2 13 SAR 5.42 8.02 5.85 6.0 9.17 - - pH TDS EC Chloride Phenols COD BOD Boron Sulphate Nitrate Fluoride SAR pH 1.000 -0.111 -0.115 -0.037 0.131 0.058 0.070 0.250 -0.041 0.005 -0.240 -0.046 TDS EC 1.000 0.999 0.645 0.516 0.537 0.573 0.197 0.655 -0.331 0.127 0.776 1.000 0.638 0.514 0.537 0.566 0.194 0.651 -0.327 0.122 0.775 Table 3 Correlation between all parameters Chloride Phenols COD BOD Boron Sulphate Nitrate Fluoride SAR 1.000 0.431 0.410 0.368 0.248 0.676 -0.291 0.247 0.565 1.000 0.401 0.416 0.332 0.421 -0.173 -0.254 0.435 1.000 0.670 0.216 0.461 -0.027 0.011 0.518 [140] 1.000 0.160 0.456 -0.169 -0.0385 0.578 1.000 0.141 -0.133 -0.120 0.141 1.000 -0.291 0.109 0.719 1.000 0.022 1.000 -0.261 -0.007 1.000 Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) Table 4 Result of analysis of variance for all parameters pH P value TDS EC Chloride Phenols COD BOD Boron Sulphate Nitrate Fluoride SAR < < 0.0004 0.0004 0.026 0.027 0.0121 0.003 0.0001 0.0001 ns *** *** *** *** * * * ** 0.978 P value summary Are means significant different? (P< 0.05) Number of groups No Yes Yes Yes Yes 5 5 5 5 5 Yes Yes 5 5 < < 0.0001 0.001 0.0001 *** *** *** Yes Yes Yes Yes Yes 5 5 5 5 5 5.39 F 0.110 7.568 7.499 6.132 6.132 2.990 2.967 3.544 4.50 8.912 9.867 R squared 0.008 0.355 0.352 0.308 0.308 0.178 0.177 0.204 0.246 0.393 0.417 0.281 Conclusion Sansthan (UJS,) Dehradun is also duly acknowledged for technical support. This study enable us to conclude that average value of pH, chloride, boron, sulphate, nitrate and fluoride were found within the tolerance limits for discharge of wastewater into inland surface, recommended by CPCB and BIS. The average concentration of TSS, phenols, COD and BOD were found above the tolerance limit provided by CPCB and BIS for discharge of wastewater into inland surface or water streams. Wastewater treatment is necessary for reuse of water for agriculture purpose because agriculture is a major site which can accept lower grade of water. From the Table 1, provided by BIS, indicated that some selected parameter such as sulphate, chloride, SAR and boron were found within the permissible limit and there is a no need for treatment of these parameters in PIWW. References 1. Rajaram T. and Das A., Water pollution by industrial effluents in India: discharge scenarios and case for participatory ecosystem specific local regulation, Futures, 40(1), 56-69 (2008) 2. Khan S., Khan A.M. and Khan M.N., Investigation of pollutants in wastewater of Hayatabad Industrial Estate Peshawar, Pakistan, J. Appl. Sci., 2(4), 457-461 (2002) 3. Kar D., Sur P., Mandal S.K., Saha T. and Kole R.K., Assessment of heavy metal pollution in surface water, Int. J. Environ. Sci. Tech., 5(1), 119–124 (2008) 4. Lokhande R.S., Singare P.U. and Pimple D.S., Study on physico-chemical parameters of wastewater effluents from Taloja Industrial Estate of Mumbai, India, Int. J. Ecosystem, 1(1), 1-9 (2011) Table 1 showed the results of phenols, COD and BOD in wastewater, which reveals that there is a need for treatment of PIWW with reference to the pH, TSS, TDS, EC, phenols, COD and BOD. Previous study on heavy metals (Al, AS, Cd, Cr+6, Cu, Fe, Pb, Mn and Zn) concentration in PIWW, done by authors also reveals that there is no need to treat this wastewater with reference to above heavy metals. Therefore, it is significant to assess the wastewater of pharmaceutical industries of Selaqui region of Dehradun district on regular basis to enable its treatment regarding pH, TSS, TDS, phenols, COD and BOD by fixed bed bioreactor (FBR) system using the microbial consortia, designed for lowering the organic and inorganic pollutants parameters and designate the water discharge after treatment as deemed fit for agricultural trials. 5. Modak D.P., Singh K.P., Ahmed S. and Ray P.K., Trace metal ion in Ganga water system, Chemosphere, 21(1-2), 275-287(1990) 6. Garcia A., Rivas H.M., Figueroa J.L. and Monroe A.L., Case history: Pharmaceutical wastewater treatment plant upgrade, Smith Kline Beecham pharmaceuticals company, Desalination, 102(1-3), 255-263 (1995) 7. Dixit D., Parmar N., Treatment of pharmaceutical waste water by electro-coagulation and natural coagulation process: review, VSRD Int. J. Technol. NonTechnol. Res., 4(5), 79-88 (2013) 8. Chang C.Y., Chang J.S., Vigneswaran S. and Kandasamy J., Pharmaceutical wastewater treatment by membrane bioreactor process – a case study in southern Taiwan, Desalination, 000, 1-9 (2008) Acknowledgement Authors are thankful to the Water Technology Initiative (WTI) Programme, Department of Science and Technology, Govt. of India, New Delhi for financial assistance provided for this work. The State Level Quality Analysis Laboratory of Uttarakhand Jal 9. Kavitha R.V., Murthy V.K., Makam R. and Asith K.A., Physico-chemical analysis of effluents from pharmaceutical industry and its efficiency study, Int. J. Eng. Res. Appl., 2(2), 103-110 (2012). [141] Rana et al. Int. J. Res. Chem. Environ. Vol.4 Issue 2 April 2014(136-142) 10. Wei X., Li B., Zhao S., Wang L., Zhang H., Li C. and Wang S., Mixed pharmaceutical wastewater treatment by integrated membrane-aerated biofilm reactor (MABR) system – a pilot-scale study, Bioresour. Technol., 122, 189195 (2012) 17. Idris M.A., Kolo B.G., Garba S.T. and Ismail M.A., Physico-chemical analysis of pharmaceutical effluent and surface water of river Gorax in Minna, Niger State, Nigeria, Bull. Env. Pharmacol. Life Sci., 2(3), 45-49 (2013). 18. Imran H., Wastewater monitoring of pharmaceutical industry: treatment and reuse options, Electron. J. Environ. Agric. Food Chem., 4 (4), 994-1004 (2005) 11. Madukasi E.I., Dai X., He C. and Zhou J., Potentials of phototrophic bacteria in treating pharmaceutical wastewater, Int. J. Environ. Sci. Technol., 7(1), 165-174 (2010) 19. Singh S.N., Srivastav G. and Bhatt A., Physicochemical determination of pollutants in wastewater in Dehradun, Current World Environ., 7(1), 133-138 (2012) 12. Rao A.G., Naidu G.V., Prasad K.K., Rao N.C., Mohan S.V., Jetty A. and Sharma P.N., Anaerobic treatment of wastewater with high suspended solids from a bulk drug industry using fixed film reactor (AFFR), Bioresour. Technol., 93, 241-247 (2004) 20. Eaton A.D., Clesceri L.S., Rice E.W. and Greenberg A.E., Standard methods for the examination of water and waste water, Washington, DC: American Public Health Association, (2005) 13. Ramola B. and Singh A., Heavy metal concentrations in pharmaceutical effluents of industrial area of Dehradun (Uttarakhand), India, Int. J. Environ. Sci. Res., 2(2), 140-145 (2013) 21. McGill R., Tukey J.W. and Larsen W.A., Variations of Boxplots, The American Statistician, 32(1), 12–16 (1978) 14. Vuppala N.V.S., Suneetha C. And Saritha V., Study on treatment process of effluent in Bulk drug industry, Int. J. Res. Pharm. Biomed. Sci., 3(3), 1095-1102 (2012) 22. Frigge M., Hoaglin D.C. and Iglewicz B., Some implementations of the boxplot, The American Statistician, 43 (1), 50–54 (1989) 15. Chelliapan S., Yuzir A., Md Din M.F. and Sallis P.J. Anaerobic pre-treatment of pharmaceutical wastewater using packed bed reactor, Int. J. Chem. Eng. Appl., 2(1), 32-37 (2011) 23. Damodhar U. and Reddy M.V., Impact of pharmaceutical industry treated effluents on the water quality of river Uppanar, South east coast of India: A case study, Appl. Water. Sci., 3(2), 501–514 (2013) 16. Nadal M., Schuhmacher M. and Domingo J.L., Metal pollution of soils and vegetation in an area with petrochemical industries, Sci. Total Environ., 321(1-3), 5969 (2004) 24. Ahamed A.J., Ananthakrishnan S., Loganathan K. and Manikandan K., Assessment of groundwater quality for irrigation use in Alathur Block, Perambalur District, Tamilnadu, South India, Appl. Water Sci., 3(4), 763-771 (2013). [142]