city of battle creek, michigan

advertisement

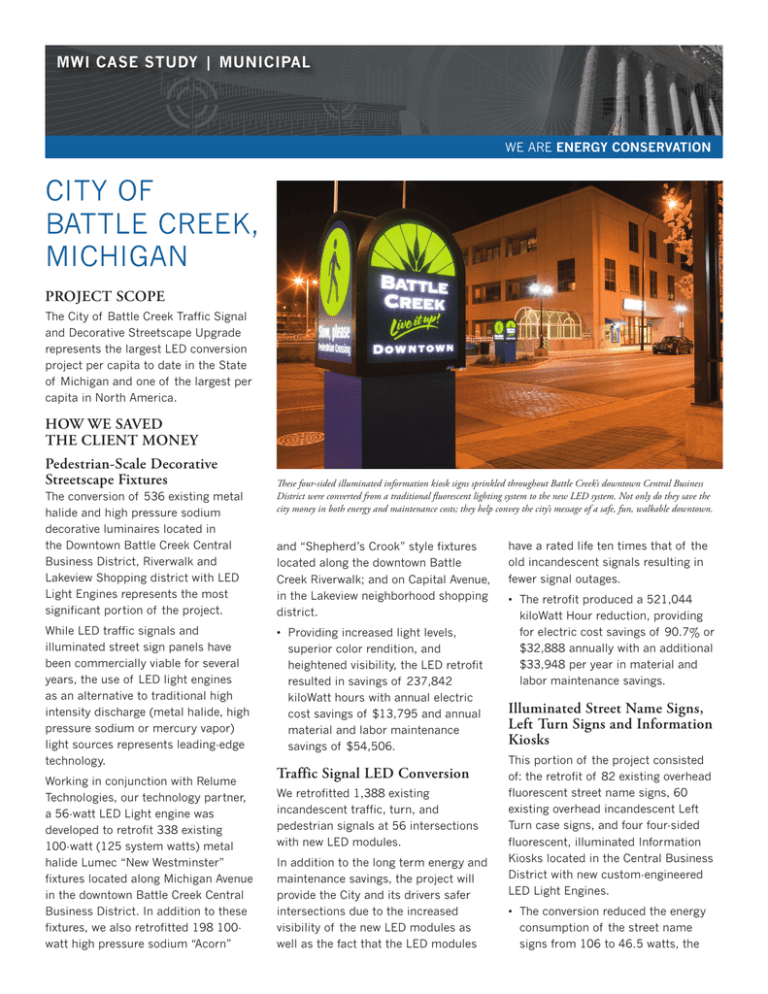

MWI CASE STUDY | MUNICIPAL WE ARE ENERGY CONSERVATION CITY OF BATTLE CREEK, MICHIGAN PROJECT SCOPE The City of Battle Creek Traffic Signal and Decorative Streetscape Upgrade represents the largest LED conversion project per capita to date in the State of Michigan and one of the largest per capita in North America. HOW WE SAVED THE CLIENT MONEY Pedestrian-Scale Decorative Streetscape Fixtures The conversion of 536 existing metal halide and high pressure sodium decorative luminaires located in the Downtown Battle Creek Central Business District, Riverwalk and Lakeview Shopping district with LED Light Engines represents the most significant portion of the project. While LED traffic signals and illuminated street sign panels have been commercially viable for several years, the use of LED light engines as an alternative to traditional high intensity discharge (metal halide, high pressure sodium or mercury vapor) light sources represents leading-edge technology. Working in conjunction with Relume Technologies, our technology partner, a 56-watt LED Light engine was developed to retrofit 338 existing 100-watt (125 system watts) metal halide Lumec “New Westminster” fixtures located along Michigan Avenue in the downtown Battle Creek Central Business District. In addition to these fixtures, we also retrofitted 198 100watt high pressure sodium “Acorn” These four-sided illuminated information kiosk signs sprinkled throughout Battle Creek’s downtown Central Business District were converted from a traditional fluorescent lighting system to the new LED system. Not only do they save the city money in both energy and maintenance costs; they help convey the city’s message of a safe, fun, walkable downtown. and “Shepherd’s Crook” style fixtures located along the downtown Battle Creek Riverwalk; and on Capital Avenue, in the Lakeview neighborhood shopping district. • Providing increased light levels, superior color rendition, and heightened visibility, the LED retrofit resulted in savings of 237,842 kiloWatt hours with annual electric cost savings of $13,795 and annual material and labor maintenance savings of $54,506. Traffic Signal LED Conversion We retrofitted 1,388 existing incandescent traffic, turn, and pedestrian signals at 56 intersections with new LED modules. In addition to the long term energy and maintenance savings, the project will provide the City and its drivers safer intersections due to the increased visibility of the new LED modules as well as the fact that the LED modules have a rated life ten times that of the old incandescent signals resulting in fewer signal outages. • The retrofit produced a 521,044 kiloWatt Hour reduction, providing for electric cost savings of 90.7% or $32,888 annually with an additional $33,948 per year in material and labor maintenance savings. Illuminated Street Name Signs, Left Turn Signs and Information Kiosks This portion of the project consisted of: the retrofit of 82 existing overhead fluorescent street name signs, 60 existing overhead incandescent Left Turn case signs, and four four-sided fluorescent, illuminated Information Kiosks located in the Central Business District with new custom-engineered LED Light Engines. • The conversion reduced the energy consumption of the street name signs from 106 to 46.5 watts, the Left Turn cases signs from 250 to 156 watts, and the Information Kiosks from 675 watts to 400 watts, for a total kiloWatt Hour reduction of 192,938 producing annual electric cost savings of $7,949 with annual material and labor maintenance savings of $6,122. • The illuminated street sign, and decorative streetscape LED light engines utilize Relume Technologies’ patented “silver circuitry” circuit board technology, which employs the Cree XRE 7,000-degree Kelvin color temperature LEDs, and an advance transformer power supply. With a projected live of 70,000 hours, the new light engines are projected to have a useful lifespan of at least 15 years, versus two years of the existing lighting systems. BY THE NUMBERS SUMMARY • Total Demand Savings of 217.725 kW • Total Use Savings of 951,824 kWh • Total Annual Electric Cost Savings of $54,632 or 81% • Total Annual Material and Labor Maintenance Savings of $94,576 “The decision to convert lighting to LED will help Battle Creek reduce its carbon footprint and overall costs,” said Michelle Reen, City of Battle Creek Assistant to the City Manager. “Midwest Illumination designed custom lighting solutions that helped Battle Creek meet its specific and unique needs.” About Our Partner any significant lumen depreciation occurs. After researching their competitors, Midwest Illumination selected Relume Technology as their LED technology partner due to their extensive research and development capability, their patented Silver Circuitry technology, as well as the fact that they are also an Oakland County, Michigan-based company. Relume’s competitors solder their LEDs to a metal circuit board or clip to cabling thereby retaining the significant heat generated by the diode. While LEDs have significant advantages over traditional light engines, heat is the enemy of LED light output. Heat significantly degrades lumen output and useful life. Luminous output declines 1% for every 1 degree C (1.8 F) increase in temperature. Heat is also the enemy of LED Lifespan. The lifespan of an LED is cut in half with every 17degree C (30 F) rise in temperature. Simply put, cooler LED’s are brighter and last longer. Powered by Relume’s technology inside, it is estimated the Battle Creek LED Light Engines will have a 15-year useful lifespan before Over 500 decorative streetside lamposts throughout Battle Creek’s Central Business District, Riverwalk, and shopping districts were retrofitted with the new LED lighting system. Relume’s patented Silver Circuitry design virtually eliminates the heat generated by the diode. No other LED light engine provider can make that statement. This Silver Circuitry is 95.5% pure silver, plated onto an aluminum heat-sinking substrate. LEDs are bonded to it using the same silver epoxy that LED manufacturers use to bond the LED diode to the LED leads. This design maximizes the extraction of heat from the diode through the leads, then through the circuit to the aluminum substrate, through the back of the housing and into the outside air. SPECIAL THANKS FOR THE BATTLE CREEK PROJECT ALSO GOES TO HONEYWELL 8405 Andersonville Road, Suite C | Clarkston, MI 48346 P: 866-620-3340 | F: 248-620-3342 | www.mwillumination.com