Product Data Sheet

August 2012

00813-0100-4728, Rev RD

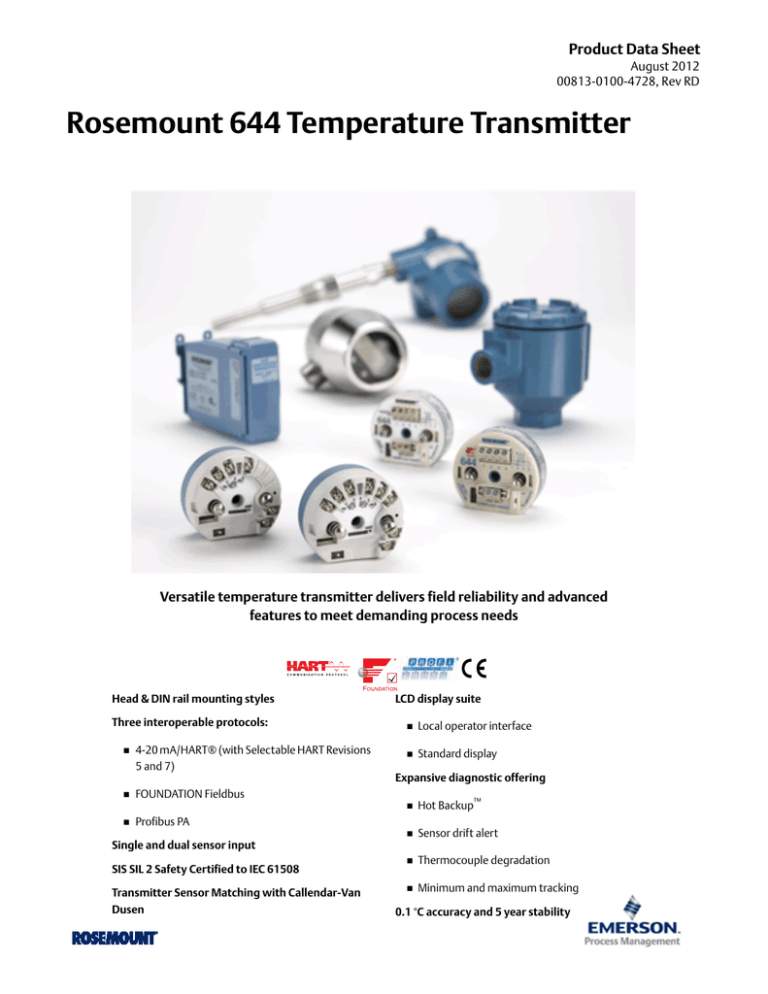

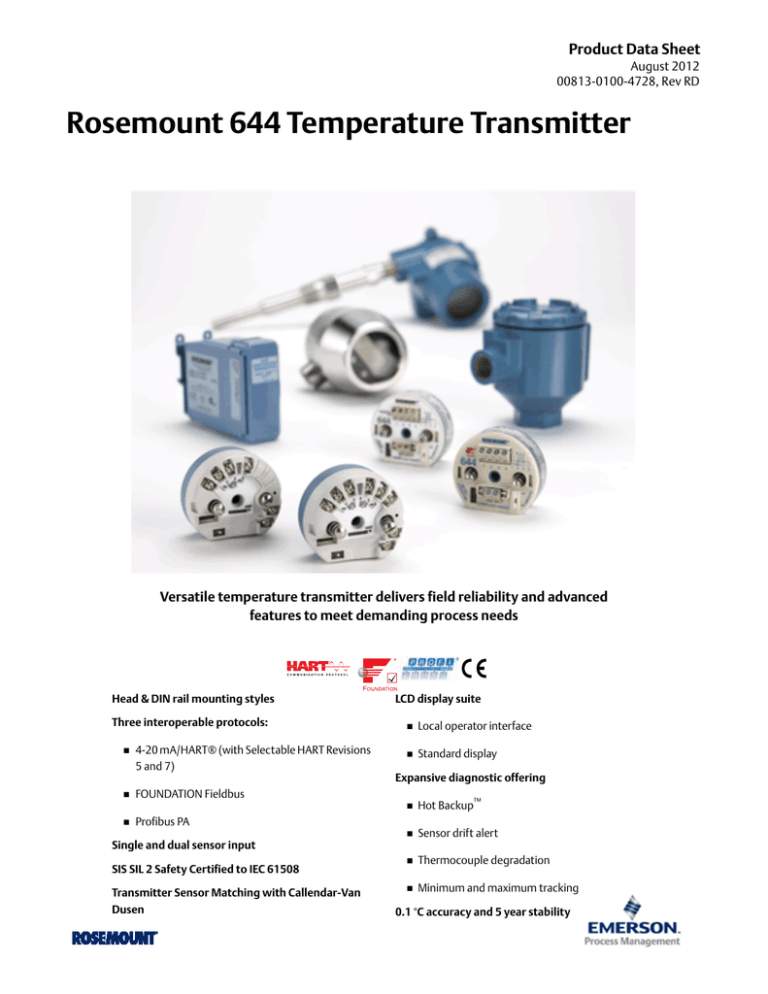

Rosemount 644 Temperature Transmitter

Versatile temperature transmitter delivers field reliability and advanced

features to meet demanding process needs

Head & DIN rail mounting styles

Three interoperable protocols:

4-20 mA/HART® (with Selectable HART Revisions

5 and 7)

LCD display suite

Local operator interface

Standard display

Expansive diagnostic offering

FOUNDATION Fieldbus

Hot Backup™

Sensor drift alert

Thermocouple degradation

Minimum and maximum tracking

Profibus PA

Single and dual sensor input

SIS SIL 2 Safety Certified to IEC 61508

Transmitter Sensor Matching with Callendar-Van

Dusen

0.1 °C accuracy and 5 year stability

Rosemount 644

August 2012

Simplify with Rosemount 644 Temperature Transmitter

Fit your needs with a customizable transmitter design all within one model family.

Head mount and DIN Rail mounting styles

Three interoperable protocols:

4-20 mA/HART®

(with Selectable HART Revisions 5 and 7)

FOUNDATION Fieldbus

Profibus PA

Single or dual sensor inputs from RTD, Thermocouple, mV

and Ohm

LCD Display suite:

Local Operator Interface

Standard display

SIL 2 SIS Safety Certified to IEC 61508

Enhanced performance of 0.1°C accuracy and 5 year stability

A variety of enclosures

Transmitter Sensor Matching with Callendar-Van Dusen

COMING SOON

Integral Transient Protection

and

Large, 3-Conduit Junction Box

(Consult factory for availability)

Contents

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . page 4

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . page 27

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Specifications and Reference Data for 644 HART (Device

revision 7 or previous) . . . . . . . . . . . . . . . . . . . . . . . page 35

Product Certifications . . . . . . . . . . . . . . . . . . . . . . . page 21

2

www.rosemount.com

Rosemount 644

August 2012

Easy to use Human-Centered Designs to make your job simple

Diagnostic information and process

health at your finger tips with intuitive

Device Dashboards

Communication clips easily accessible

when a LCD display is attached

Easy wiring practices with captive sensor

screw terminals and optimized wiring

diagrams

Optimize plant efficiency and increase visibility into the process with an expansive diagnostic offering

Keep your process up and running with Hot Backup where if your primary sensor fails, a second sensor seamlessly takes over and

prevents the measurement failure

Tighten control with Sensor Drift Alert that detects drifting sensor and proactively notifies the user

Enable predictive maintenance practices with Thermocouple Degradation Diagnostic that monitors the health of a

thermocouple loop

Improve quality with Minimum and Maximum Temperature Tracking that records temperature extremes of the process sensors

and the ambient environment

Explore the benefits of a Complete Point Solution from Rosemount Temperature Measurement

www.rosemount.com

Reduce installation and procurement complexity by receiving

an installation-ready transmitter and sensor assembly from

Emerson

Emerson offers a selection of RTDs, thermocouples, and

thermowells that bring superior durability and Rosemount

reliability to temperature sensing, complementing the

Rosemount Transmitter portfolio

3

Rosemount 644

August 2012

Ordering information

The Rosemount 644 is a versatile temperature transmitter that

delivers field reliability and advanced accuracy and stability to

meet demanding process needs.

Transmitter features include:

HART/4-20 mA with Selectable Revision 5 and 7 selectable

(Option Code A), FOUNDATION fieldbus (Option Code F) or

PROFIBUS PA (Option Code W)

DIN A Head mount or Rail Mount transmitter styles

Dual Sensor Input (Option Code S)

SIS SIL 2 Safety Certification (Option Code QT)

Local Operator Interface (Option Code M4)

LCD Display (Option Code M5)

Advanced Diagnostics (Option Codes DC and DA1)

Enhanced Transmitter Accuracy and Stability

(Option Code P8)

Transmitter-Sensor Matching (Option Code C2)

Table 1. Rosemount 644 Smart Temperature Transmitter Ordering Information

★ The Standard offering represents the most common models and options. These options should be selected for best delivery.

__The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

● = Available

– = Not Available

Model

Product Description

644

Temperature Transmitter

Transmitter Type

Standard

H

DIN A Head Mount - Single Sensor Input

R

Rail Mount - Single Sensor Input

S

DIN A Head Mount - Dual Sensor Input (HART only)

Standard

★

★

★

Output

Standard

A

4–20 mA with digital signal based on HART protocol

FOUNDATION fieldbus digital signal (includes 2 AI function blocks and Backup

F

Link Active Scheduler)

W

Profibus PA digital signal

Head

Rail

●

●

●

–

●

–

Standard

★

★

★

Product Certifications

Hazardous Locations Certificates (consult factory for availability)

Standard

NA

No approval

E5

FM Explosion-proof; Dust Ignition-proof

4

A

F

W

A

Standard

●

●

●

●

★

●

●

●

–

★

www.rosemount.com

Rosemount 644

August 2012

Table 1. Rosemount 644 Smart Temperature Transmitter Ordering Information

★ The Standard offering represents the most common models and options. These options should be selected for best delivery.

__The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

● = Available

– = Not Available

A

A F W

I5

K5

NK

KC

KB

KD

I6

K6(1)

I3

E3

N3

E1

N1

NC(2)

K1

ND

KA

I1

E7

I7

N7

NG(2)

K7

I2

E4

E2

FM Intrinsically Safe; Non-incendive

FM Explosion-proof; Intrinsically Safe; Non-incendive; Dust Ignition-proof

IECEx Dust

FM and CSA Intrinsically Safe and Non-incendive

FM and CSA: Explosion-proof; Intrinsically Safe; Non-incendive; Dust

Ignition-proof

FM, CSA and ATEX Explosion-proof, Intrinsically Safe

CSA Intrinsically Safe

CSA Explosion-proof; Intrinsically Safe; Non-incendive; Dust Ignition-proof

China Intrinsic Safety

China Flameproof

Chine Type n

ATEX Flameproof

ATEX Type n

ATEX Type n Component

ATEX Flameproof; Intrinsic Safety; Type n; Dust

ATEX Dust Ignition–Proof

CSA and ATEX: Explosion-proof; Intrinsically Safe; Non-incendive

ATEX Intrinsic Safety

IECEx Flameproof

IECEx Intrinsic Safety

IECEx Type n

IECEx Type n Component

IECEx Flameproof; Intrinsic Safety; Type n; Dust

INMETRO Intrinsic Safety

TIIS Flameproof

INMETRO Flameproof

●

●

●

●

★

●

●

●

–

★

●

–

–

–

★

–

–

–

●

★

●

–

–

–

●

●

●

●

●

●

●

★

●

●

●

–

★

●

–

–

–

★

●

●

●

–

★

●

–

–

–

★

●

●

●

–

★

●

●

●

–

★

●

●

●

●

★

●

●

●

●

●

●

–

★

●

–

–

–

★

●

●

●

●

★

●

●

●

–

★

●

●

●

●

★

●

●

●

–

★

●

●

●

●

★

●

–

–

–

★

●

–

–

–

★

●

●

–

–

★

●

●

●

–

★

W

A

★

★

★

Options

A

F

PlantWeb Control Functionality

Standard

A01

FOUNDATION fieldbus Advanced Control Function Block Suite

Standard

–

●

–

–

●

–

–

–

●

–

–

–

●

●

●

–

●

●

●

–

★

PlantWeb Standard Diagnostic Functionality

Standard

DC

Diagnostics: Hot Backup and Sensor Drift Alert

Standard

★

PlantWeb Advanced Diagnostic Functionality

Standard

DA1

Standard

HART Sensor and Process Diagnostic Suite: Thermocouple Diagnostic and

Min/Max Tracking

★

Enclosure Options

Standard

J5(3)(4)

J6(3)

Standard

Universal Head (junction box), aluminum alloy with 50.8 mm (2-in.) SST pipe

bracket (M20 entries)

Universal Head (junction box), aluminum alloy with 50.8 mm (2-in.) SST pipe

bracket (1/2–14 NPT entries)

www.rosemount.com

★

★

5

Rosemount 644

August 2012

Table 1. Rosemount 644 Smart Temperature Transmitter Ordering Information

★ The Standard offering represents the most common models and options. These options should be selected for best delivery.

__The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

● = Available

– = Not Available

A

A F W

R1

Rosemount Connection Head, Aluminum alloy (M20 x 1.5 conduit and entries)

R2

Rosemount Connection Head, Aluminum alloy (1/2–14 NPT entries)

Expanded

R3

Rosemount Connection Head, cast SST (M20 x 1.5 conduit and entries)

R4

Rosemount Connection Head, cast SST (1/2–14 NPT entries)

Universal Head (junction box), cast SST with 50.8 mm (2-in.) SST pipe bracket

J7(3)(4)

(M20 entries)

Universal Head (junction box), cast SST with 50.8 mm (2-in.) SST pipe bracket

J8(3)

(1/2–14 NPT entries)

S1

Connection Head, Polished Stainless Steel (1/2–14 NPT entries)

S2

Connection Head, Polished Stainless Steel (1/2–14 NPSM entries)

S3

Connection Head, Polished Stainless Steel (M20 x 1.5 conduit and entries)

Connection Head, Polished Stainless Steel (M20 x 1.5 conduit entries, M24 x

S4

1.5 head entry)

●

●

●

–

★

●

●

●

–

★

●

●

●

–

●

●

●

–

●

●

●

–

●

●

●

–

●

●

●

–

●

●

●

–

●

●

●

–

●

●

●

–

●

–

–

–

★

●

●

●

–

★

●

●

●

●

●

–

–

–

●

–

–

●

★

●

–

–

●

★

●

–

–

●

★

●

●

●

●

★

●

●

●

●

★

●

●

●

●

●

●

●

●

●

●

●

●

★

●

●

●

–

★

Display and Interface Options

Standard

M4

LCD Display with Local Operator Interface

M5

LCD Display

Standard

Software Configuration

Standard

C1

Standard

Custom Configuration of Date, Descriptor and Message (Requires CDS with

order)

★

Enhanced Performance

Standard

P8

Enhanced Transmitter Accuracy and Stability

Standard

★

Alarm Level Configuration

Standard

A1

NAMUR alarm and saturation levels, high alarm

CN

NAMUR alarm and saturation levels, low alarm

C8

Low Alarm (Standard Rosemount Alarm and Saturation Values)

Standard

Line Filter

Standard

F5

50 Hz Line Voltage Filter

F6

60 Hz Line Voltage Filter

Standard

Sensor Trim

Standard

C2

Standard

Transmitter-Sensor Matching - Trim to Specific Rosemount RTD Calibration

Schedule (CVD constants)

★

5-Point Calibration Option

Standard

C4

5-point calibration. Use option code Q4 to generate a calibration certificate

Standard

★

Calibration Certificate

Standard

Q4

Calibration certificate. 3-Point calibration with certificate

QP

Calibration Certification & Tamper Evident Seal

6

Standard

www.rosemount.com

Rosemount 644

August 2012

Table 1. Rosemount 644 Smart Temperature Transmitter Ordering Information

★ The Standard offering represents the most common models and options. These options should be selected for best delivery.

__The Expanded offering is manufactured after receipt of order and is subject to additional delivery lead time.

● = Available

– = Not Available

A

F

W

A

Quality Certification for Safety

Standard

QT

Safety Certified to IEC 61508 with certificate of FMEDA data

Standard

●

–

–

–

●

●

●

–

●

●

●

–

★

●

●

●

–

★

●

●

●

–

●

●

●

–

★

●

●

●

–

★

●

●

●

–

●

–

–

–

●

●

●

–

★

External Ground

Standard

G1

Standard

External ground lug assembly (see “External Ground Screw Assembly” on

page 8)

★

Cable Gland Option

Standard

G2(5)

Cable gland (7.5 mm - 11.99 mm)

G7

Cable gland, M20x1.5, Ex e, Blue Polyamide (5 mm - 9 mm)

Standard

Cover Chain Option

Standard

G3

Cover chain

Standard

★

Conduit Electrical Connector

Standard

GE(6)

M12, 4-pin, Male Connector (eurofast®)

(6)

GM

A size Mini, 4-pin, Male Connector (minifast®)

Standard

External Label

Standard

EL

External label for ATEX Intrinsic Safety

Standard

★

HART Revision Configuration

Standard

HR7(7) Configured for HART Revision 7

Standard

★

Assemble To Options

Standard

XA

Sensor Specified Separately and Assembled to Transmitter

Standard

★

Typical Rail Mount Model Number: 644 R A I5

Typical Head Mount Model Number: 644 S A I5 DC DA1 J5 M5

(1) Requires housing option R2, R4, J6, or J8.

(2) Approval not valid if ordered with a housing.

(3) Suitable for remote mount configuration.

(4) When ordered with XA, 1/2-in. NPT enclosure will come equipped with an M20 adapter with the sensor installed as process ready.

(5) Requires housing options J6, J8, R2, or R4.

(6) Available with Intrinsically Safe approvals only. For FM Intrinsically Safe or non-incendive approval (option code I5), install in accordance with Rosemount drawing

03151-1009.

(7) Configures the HART output to HART Revision 7. The device can be field configured to HART Revision 5 if needed.

Note

For additional options (e.g. “K” codes), please contact your local Emerson Process Management representative.

www.rosemount.com

7

Rosemount 644

August 2012

Tagging

Considerations

Hardware

External Ground Screw Assembly

13 characters total

Tags are adhesive labels

Tag is permanently attached to transmitter

The external ground screw assembly can be ordered by

specifying code G1 when an enclosure is specified. However,

some approvals include the ground screw assembly in the

transmitter shipment, hence it is not necessary to order code

G1. The table below identifies which approval options include

the external ground screw assembly and which do not.

Software

The transmitter can store up to 13 characters for FOUNDATION

fieldbus and Profibus PA or 8 for HART protocol. If no

characters are specified, the first 8 characters of the hardware

tag are the default. An optional 32 character Long Software

Tag is available when option code HR7 is ordered.

Approval Type

E5, I1, I2, I5, I6, I7, K5, K6,

NA, I4, KB

E1, E2, E3, E4, E7, K7, N1,

N7, ND, K1, K2, KA, NK

External Ground Screw

Assembly Included?

No–Order option code G1

Yes

Table 2. Transmitter Accessories

Part Description

Part Number

Aluminum Alloy Universal Head, Std Cover - M20

Aluminum Alloy Universal Head, Meter Cover - M20

Aluminum Alloy Universal Head, Std Cover - 1/2 - 14 NPT

Aluminum Alloy Universal Head, Meter Cover - 1/2 - 14 NPT

SST Universal Head, Std Cover - M20

SST Universal Head, Meter Cover - M20

SST Universal Head, Std Cover - 1/2 - 14 NPT

SST Universal Head, Meter Cover -1/2 - 14 NPT

Aluminum Alloy Conn Head, Std Cover - M20 X 1/2 ANPT

Aluminum Alloy Conn Head, Std Cover - 1/2 - 14 NPT x 1/2 2 ANPT

Aluminum Alloy Conn Head, Meter Cover - M20 X 1/2 ANPT

Aluminum Alloy Conn Head, Meter Cover - 1/2 - 14 NPT X 1/2 ANPT

SST Conn Head, Std Cover - M20 X 1/2 ANPT

SST Conn Head, Std Cover - 1/2 - 14 NPT x 1/2 ANPT

SST Conn Head, Meter Cover - M20 X 1/2 ANPT

SST Conn Head, Meter Cover -1/2 - 14 NPT X 1/2 ANPT

Polished SST Connection Head, Standard Cover - 1/2 -14 NPT entries

Polished SST Connection Head, Meter Cover - 1/2 -14 NPT entries

Polished SST Connection Head, Standard Cover - 1/2 -14 NPSM entries

Polished SST Connection Head, Meter Cover - 1/2 -14 NPSM entries

Polished SST Connection Head, Standard Cover - M20 x 1.5 entries

Polished SST Connection Head, Meter Cover -M20 x 1.5 entries

Polished SST Connection Head, Standard Cover - M20 x 1.5 / M24 x 1.5 entries

Polished SST Connection Head, Meter Cover - M20 x 1.5 / M24 x 1.5 entries

Ground Screw Assembly Kit

Mounting Screws and Springs

Hardware for Mounting a Rosemount 644H to a DIN rail

Hardware for Retrofitting a Rosemount 644H in an existing Threaded Sensor Connection Head (former

option code L1)

U-Bolt kit for Universal Housing

Universal Clip for Rail or Wall Mount

24 Inches of symmetric (Top Hat) Rail

24 Inches of asymmetric (G) Rail

00644-4420-0002

00644-4420-0102

00644-4420-0001

00644-4420-0101

00644-4433-0002

00644-4433-0102

00644-4433-0001

00644-4433-0101

00644-4410-0021

00644-4410-0011

00644-4410-0121

00644-4410-0111

00644-4411-0021

00644-4411-0011

00644-4411-0121

00644-4411-0111

00079-0312-0011

00079-0312-0111

00079-0312-0022

00079-0312-0122

00079-0312-0033

00079-0312-0133

00079-0312-0034

00079-0312-0134

00644-4431-0001

00644-4424-0001

00644-5301-0010

8

00644-5321-0010

00644-4423-0001

03044-4103-0001

03044-4200-0001

03044-4201-0001

www.rosemount.com

Rosemount 644

August 2012

Table 2. Transmitter Accessories

Part Description

Part Number

Ground Clamp for symmetric or asymmetric Rail

Snap Ring Kit

Cover Clamp Assembly

O-ring Kit (Qty 12)

03044-4202-0001

00644-4432-0001

00644-4434-0001

03031-0232-0001

Table 3. Display Accessories

644 HART LCD Display (M5)

644 HART Local Operator Interface (M4)

644 FOUNDATION Fieldbus LCD Display (M5)

644 Profibus PA LCD Display (M5)

Display only

Display and Aluminum

Housing Cover(1)

Display and SST Housing

Cover(1)

00644-7630-0001

00644-7630-1001

00644-4430-0002

00644-4430-0002

00644-7630-0011

00644-7630-1011

00644-4430-0001

00644-4430-0001

00644-7630-0021

00644-7630-1021

00644-4430-0011

00644-4430-0011

(1) Covers provided are compatible with the Universal Junction Box and Rosemount Connection Head enclosure styles.

www.rosemount.com

9

Rosemount 644

August 2012

Specifications

HART, FOUNDATION Fieldbus, and

Profibus PA

Functional Specifications

Inputs

User-selectable; sensor terminals rated to 42.4 Vdc. See

“Accuracy” on page 15 for sensor options.

Output

Single 2-wire device with either 4–20 mA/HART, linear with

temperature or input; or completely digital outputs with

FOUNDATION fieldbus communication (ITK 5.01 compliant), or

PROFIBUS PA (compliant with profile 3.02).

Accuracy (default configuration) PT 100

HART Standard: ±0.15 °C

HART Enhanced : ±0.1 °C

FOUNDATION fieldbus: ±0.15 °C

Profibus PA: ±0.15 °C

Physical Specifications

Electrical Connections

Model

Power and Sensor Terminals

644 Head (HART)

644 Head (FF/Profibus)

Isolation

Input/output isolation tested to 600 Vrms.

Local Display Options

LCD Display

An optional 11 digit, 2 line integral LCD display operates with a

floating or fixed decimal point. It displays engineering units (°F,

°C, °R, K, Ohms and mV), mA, and percent of range. The display

can be configured to alternate between selected display

options. Display settings are pre-configured at the factory

according to the standard transmitter configuration. They can

be re-configured in the field using either HART, FOUNDATION

fieldbus, or Profibus PA communications.

LCD Display with Local Operator Interface

An optional 14 digit, 2 line integral LCD display operates with a

floating or fixed decimal point. The LOI includes all features and

functionality available in the regular display with an added

2-button configuration capability directly at the display

interface. The LOI also has optional Password Protection for

secure operations. The LOI is only available on the 644 HART

Head mount product.

For more information on the LOI configuration options or

further functionality that the LOI offers, see Appendix D: Local

Operator Interface (LOI) in the Rosemount 644 Temperature

Transmitter Product Manual (00809-0200-4728), available on

Rosemount.com.

644 Rail (HART)

Captivated screw terminals

permanently fixed to terminal block

Compression screw terminals

permanently fixed to the terminal

block

Compression screw permanently

fixed to front panel

Field Communicator Connections

Communication Terminals

644 Head

644 Rail

Clips permanently fixed to terminal block

Clips permanently fixed to front panel

Materials of Construction

Electronics Housing and Terminal Block

644 Head mount

644 Rail mount

Noryl® glass reinforced

Lexan® polycarbonate

Enclosure (Options J5, J6, R1, and R2)

Housing

Paint

Cover O-ring

Low-copper aluminum

Polyurethane

Buna-N

Materials of Construction

(Stainless Steel Housing for Biotechnology,

Pharmaceutical Industries, and Sanitary Applications)

Housing and Standard Meter Cover

316 SST

Cover O-Ring

Humidity Limits

Buna-N

0–95% relative humidity

Update Time

Mounting

0.5 sec. Per Sensor

The 644R attaches directly to a wall or a DIN rail. The 644H

installs in a connection head or universal head mounted directly

on a sensor assembly, apart from a sensor assembly using a

universal head, or to a DIN rail using an optional mounting clip.

10

www.rosemount.com

Rosemount 644

August 2012

Special Mounting Considerations

See “Mounting Kits for 644H” on page 28 for the special

hardware that is available to:

Mount a 644H to a DIN rail. (see Table 2 on page 8)

Retrofit a new 644H to replace an existing 644H transmitter

in an existing threaded sensor connection head. (see Table 2

on page 8)

644H

644H

644R

M5

M4

J5, J6

J5, J6

J7, J8

J7, J8

R1, R2

R1, R2

R3, R4

R3, R4

EMC (ElectroMagnetic Compatibility)

NAMUR NE 21 Standard

The 644H HART meets the requirements for NAMUR NE 21

Rating.

Susceptibility Parameter

Influence

HART

6 kV contact discharge

8 kV air discharge

80 – 1000 MHz at 10 V/m

AM

1 kV for I.O.

0.5 kV line–line

ESD

Weight

Code

644H

Performance Specifications

Options

HART, Head Mount Transmitter

FOUNDATION fieldbus,

Head Mount Transmitter

Profibus PA

Head Mount Transmitter

HART, Rail Mount Transmitter

LCD Display

LCD Display with Local Operator

Interface

Universal Head, Standard Cover

Universal Head, Meter Cover

SST Universal Head, Std. Cover

SST Universal Head, Meter Cover

Aluminum Connection Head,

Std. Cover

Aluminum Connection Head,

Meter Cover

Cast SST Connection Head, Std

Cover

Cast SST Connection Head,

Meter Cover

Weight

95 g (3.39 oz)

92 g (3.25 oz)

Radiated

Burst

Surge

174 g (6.14 oz)

35 g (1.34 oz)

Conducted

577 g (20.35 oz)

667 g (23.53 oz)

1620 g (57.14 oz)

1730 g (61.02 oz)

523 g (18.45 oz)

618 g (21.79 oz)

92 g (3.25 oz)

35g (1.34 oz)

None

< 1.0%

None

None

1 kV line–ground (I.O. tool)

10 kHz to 80 MHz at 10 V

< 1.0%

CE Electromagnetic Compatibility Compliance Testing

The 644 is compliant with Directive 2004/108/EC. Meets the

criteria under IEC 61326:2006, IEC 61326-2-3:2006

Power Supply Effect

Less than ±0.005% of span per volt

Stability

RTDs and thermocouples have a stability of ±0.15% of output

reading or 0.15 °C (whichever is greater) for 24 months

1615 g (56.97 oz)

When ordered with the P8 option code:

1747 g (61.62 oz)

RTDs: ±0.25% of reading or 0.25 °C, whichever is greater, for 5

years

Thermocouples: ±0.5% of reading or 0.5 °C, whichever is

greater, for 5 years

Weight (Stainless Steel Housing for Biotechnology,

Pharmaceutical Industries, and Sanitary Applications)

Option

Code

Standard Cover

Meter Cover

S1

S2

S3

S4

840 g (27 oz)

840 g (27 oz)

840 g (27 oz)

840 g (27 oz)

995 g (32 oz)

995 g (32 oz)

995 g (32 oz)

995 g (32 oz)

Enclosure Ratings (644H)

Self Calibration

The analog-to-digital measurement circuitry automatically

self-calibrates for each temperature update by comparing the

dynamic measurement to extremely stable and accurate

internal reference elements.

All available enclosures are Type 4X, IP66, and IP68.

Vibration Effect

Sanitary Housing Surface

The 644 HART is tested to the following specifications with no

effect on performance per IEC 60770-1, 2010:

Surface finish is polished to 32 RMA. Laser etched product

marking on housing and standard covers.

Frequency

Vibration

10 to 60 Hz

60 to 1000 Hz

0.35 mm displacement

5 g (50 m/s2) peak acceleration

The 644 Fieldbus and Profibus are tested to the following specifications

with no effect on performance per IEC 60770-1: 1999

www.rosemount.com

Frequency

Vibration

10 to 60 Hz

60 to 2000 Hz

0.21 mm displacement

3 g peak acceleration

11

Rosemount 644

Sensor connections for HART head mount transmitter

August 2012

Sensor connections for HART rail mount, FOUNDATION

fieldbus head mount, and profibus head mount

transmitters

644 Sensor Connections Diagram

644 Sensor Connections Diagram

1234

2-wire

RTD and 12 34

3-wire RTD

and *

1234

4-wire RTD

and 1234

T/C

and mV

* Rosemount Inc. provides 4-wire sensors for all single element RTDs.

You can use these RTDs in 3-wire configurations by leaving the

unneeded leads disconnected and insulated with electrical tape.

12

www.rosemount.com

Rosemount 644

August 2012

FOUNDATION Fieldbus Specifications

Function Blocks

Resource Block

The resource block contains physical transmitter information

including available memory, manufacture identification,

device type, software tag, and unique identification.

The transducer block contains the actual temperature

measurement data, including sensor 1 and terminal

temperature. It includes information about sensor type and

configuration, engineering units, linearization, reranging,

damping, temperature correction, and diagnostics.

LCD Block

Powered over FOUNDATION fieldbus with standard fieldbus power

supplies. The transmitter operates between 9.0 and 32.0 Vdc,

12 mA maximum.

Alarms

The AI function block allows the user to configure the alarms to

HI-HI, HI, LO, or LO-LO with hysteresis settings.

Backup Link Active Scheduler (LAS)

Transducer Block

Power Supply

The LCD block is used to configure the local display, if an LCD

Display is being used.

Analog Input (AI)

The transmitter is classified as a device link master, which means

it can function as a Link Active Scheduler (LAS) if the current link

master device fails or is removed from the segment.

The host or other configuration tool is used to download the

schedule for the application to the link master device. In the

absence of a primary link master, the transmitter will claim the

LAS and provide permanent control for the H1 segment.

FOUNDATION fieldbus Parameters

Schedule Entries

Links

Virtual Communications Relationships (VCR)

Processes the measurement and makes it available on the

fieldbus segment

Profibus PA Specifications

Allows filtering, alarming, and engineering unit changes.

Physical Block

PID Block

Function Blocks

The transmitter provides control functionality with one PID

function block in the transmitter. The PID block can be used to

perform single loop, cascade, or feedforward control in the

field.

Block

Execution Time

(milliseconds)

Resource

Transducer

LCD Block

Analog Input 1

Analog Input 2

PID 1

–

–

–

45

45

60

Turn-on Time

25

16

12

The Physical Block contains physical transmitter information

including manufacturer identification, device type, software

tag, and unique identification.

Transducer Block

The Transducer Block contains the actual temperature

measurement data, including sensor 1 and terminal

temperature. It includes information about sensor type and

configuration, engineering units, linearization, re-ranging,

damping, temperature correction, and diagnostics.

Analog Input Block (AI)

The Analog Input Block processes the measurement and

makes it available on the Profibus segment. Allows filtering,

alarming, and engineering unit changes.

Turn on time:

Performance within specifications in less than 20 seconds after

power is applied, when damping value is set to 0 seconds.

Performance within specifications in less than 20 seconds after

power is applied, when damping value is set to 0 seconds.

Status

Power Supply:

If self-diagnostics detect a sensor burnout or a transmitter

failure, the status of the measurement will be updated

accordingly. Status may also send the AI output to a safe value.

Powered over Profibus with standard fieldbus power supplies.

The transmitter operates between 9.0 and 32.0 Vdc,12 mA

maximum.

Alarms

The AI function block allows the user to configure the alarms to

HI-HI, HI, LO, or LO-LO with hysteresis settings.

www.rosemount.com

13

Rosemount 644

August 2012

4–20 mA / HART Specifications

Power Supply

External power supply required. Transmitters operate on 12.0 to

42.4 Vdc transmitter terminal voltage (with 250 ohm load, 18.1

Vdc power supply voltage is required). Transmitter power

terminals rated to 42.4 Vdc.

Load Limitations

Load (Ohms)

Maximum Load = 40.8 X (Supply Voltage - 12.0)(1)

4–20 mA dc

1240

1100

1000

Hardware and Software Failure Mode

The 644 features software driven alarm diagnostics and an

independent circuit which is designed to provide backup alarm

output if the microprocessor software fails. The alarm direction

(HI/LO) is user-selectable using the failure mode switch. If failure

occurs, the position of the switch determines the direction in

which the output is driven (HI or LO). The switch feeds into the

digital-to-analog (D/A) converter, which drives the proper alarm

output even if the microprocessor fails. The values at which the

transmitter software drives its output in failure mode depends

on whether it is configured to standard, custom, or

NAMUR-compliant (NAMUR recommendation NE 43, June

1997) operation. Table 4 shows the configuration alarm ranges.

Table 4. Available Alarm Range(1)

750

HART and Analog

Operating Range

500

250

0

10

18.1

12.0 Min

30

42.4

Analog Only

Operating Range

Supply Voltage (Vdc)

Linear

Output:

Fail High:

Fail Low:

Standard

NAMUR- NE 43

Compliant

3.9 I(2) 20.5

3.8 I 20.5

21.75 I 23

3.5 I 3.75

21.5 I 23

3.5 I 3.6

(1) Measured in mA.

(1) Without transient protection (optional).

(2) I = Process Variable (current output).

NOTE

HART Communication requires a loop resistance between 250 and 1100

ohms. Do not communicate with the transmitter when power is below

12 Vdc at the transmitter terminals.

Temperature Limits

With LCD(1)

Without LCD

Custom factory configuration of alarm and saturation level is

available with option code C1 for valid values. These values can

also be configured in the field using a Field Communicator.

Turn-on Time

Operating Limit

Storage Limit

–40 to 185 °F

–40 to 85 °C

–40 to 185 °F

–40 to 85 °C

–50 to 185 °F

–45 to 85 °C

–60 to 248 °F

–50 to 120 °C

(1) LCD may not be readable and display updates will be slower at

temperatures below -4 F (-20 C).

14

Custom Alarm and Saturation Level

Performance within specifications in less than 5.0 seconds after

power is applied, when damping value is set to 0 seconds.

External Transient Protection

The Rosemount 470 Transient Protector prevents damage from

transients induced by lightning, welding, or heavy electrical

equipment. For more information, refer to the Rosemount 470

Transient Protector Product Data Sheet (document number

00813-0100-4191).

www.rosemount.com

Rosemount 644

August 2012

Accuracy

Table 5. Rosemount 644 Transmitter Accuracy.

Sensor

Options

Sensor

Reference

2-, 3-, 4-wire RTDs

Input

Ranges

°C

Recommended Digital

Min. Span(1)

Accuracy(2)

°F

–328 to

1562

–328 to

1562

–328 to

1562

°C

°F

°C

°F

10

18

± 0.15

± 0.27

10

18

± 0.15

10

18

± 0.19

10

18

± 0.19

10

18

± 0.15

10

18

± 0.27

±0.03% of

span

±0.03% of

± 0.27

span

±0.03% of

± 0.34

span

±0.03% of

± 0.34

span

±0.03% of

± 0.27

span

±0.03% of

± 0.49

span

±0.03% of

± 0.27

span

±0.03% of

± 2.52

span

±0.03% of

± 0.54

span

±0.03% of

± 0.27

span

±0.03% of

± 2.41

span

±0.03% of

± 2.41

span

±0.03% of

± 1.20

span

±0.03% of

± 1.20

span

Pt 100 ( = 0.00385)

IEC 751

–200 to 850

Pt 200 ( = 0.00385)

IEC 751

–200 to 850

Pt 500 ( = 0.00385)

IEC 751

–200 to 850

Pt 1000 ( = 0.00385) IEC 751

–200 to 300

Pt 100 ( = 0.003916) JIS 1604

–200 to 645

Pt 200 ( = 0.003916) JIS 1604

–200 to 645

Ni 120

Edison Curve No. 7

–70 to 300

–94 to 572

10

18

± 0.15

Cu 10

Edison Copper Winding No. 15

–50 to 250

–58 to 482

10

18

±1.40

Pt 50 ( = 0.00391)

GOST 6651-94

–200 to 550

10

18

± 0.30

Pt 100 ( = 0.00391)

GOST 6651-94

–200 to 550

10

18

± 0.15

Cu 50 ( = 0.00426)

GOST 6651-94

–50 to 200

–58 to 392

10

18

±1.34

Cu 50 ( = 0.00428)

GOST 6651-94

–185 to 200

–301 to 392

10

18

±1.34

Cu 100 ( = 0.00426)

GOST 6651-94

–50 to 200

–58 to 392

10

18

±0.67

Cu 100 ( = 0.00428)

GOST 6651-94

–185 to 200

–301 to 392

10

18

±0.67

Type B(5)

NIST Monograph 175, IEC 584

100 to 1820

212 to 3308

25

45

± 0.77

± 1.39

Type E

NIST Monograph 175, IEC 584

–200 to

1000

25

45

± 0.20

± 0.36

Type J

NIST Monograph 175, IEC 584

–180 to 760

25

45

± 0.35

± 0.63

Type K(6)

NIST Monograph 175, IEC 584

25

45

± 0.50

± 0.90

Type N

NIST Monograph 175, IEC 584

–180 to

1372

–200 to

1300

–328 to

1832

–292 to

1400

–292 to

2501

–328 to

2372

25

45

± 0.50

± 0.90

Type R

NIST Monograph 175, IEC 584

0 to 1768

32 to 3214

25

45

± 0.75

± 1.35

Type S

NIST Monograph 175, IEC 584

0 to 1768

32 to 3214

25

45

± 0.70

± 1.26

Type T

NIST Monograph 175, IEC 584

–200 to 400

–328 to 752

25

45

± 0.35

± 0.63

DIN Type L

DIN 43710

–200 to 900

25

45

± 0.35

± 0.63

DIN Type U

DIN 43710

–200 to

–600

25

45

± 0.35

± 0.63

–328 to 572

–328 to

1193

–328 to

1193

–328 to

1022

–328 to

1022

D/A

Accuracy(3)

Thermocouples(4)

www.rosemount.com

–328 to

1652

–328 to

1112

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

±0.03% of

span

15

Rosemount 644

August 2012

Table 5. Rosemount 644 Transmitter Accuracy.

Sensor

Options

Sensor

Reference

Input

Ranges

Recommended Digital

Min. Span(1)

Accuracy(2)

Type W5Re/W26Re

ASTM E 988-96

0 to 2000

32 to 3632

25

45

± 0.70

± 1.26

GOST Type L

GOST R 8.585-2001

–200 to 800

–328 to

1472

25

45

± 1.00

± 1.26

D/A

Accuracy(3)

±0.03% of

span

±0.03% of

span

Other Input Types

Millivolt Input

–10 to 100 mV

±0.015 mV

2-, 3-, 4-wire Ohm Input

0 to 2000 ohms

±0.45 ohm

±0.03% of

span

±0.03% of

span

(1) No minimum or maximum span restrictions within the input ranges. Recommended minimum span will hold noise within accuracy specification with damping at zero

seconds.

(2) The published digital accuracy applies over the entire sensor input range. Digital output can be accessed by HART or FOUNDATION fieldbus Communications or Rosemount

control system.

(3) Total Analog accuracy is the sum of digital and D/A accuracies. This is not applicable for FOUNDATION fieldbus.

(4) Total digital accuracy for thermocouple measurement: sum of digital accuracy +0.5 °C. (cold junction accuracy).

(5) Digital accuracy for NIST Type B T/C is ±3.0 °C (±5.4 °F) from 100 to 300 °C (212 to 572 °F).

(6) Digital accuracy for NIST Type K T/C is ±0.70 °C (±1.26 °F) from –180 to –90 °C (–292 to –130 °F).

Accuracy Example (HART devices)

When using a Pt 100 ( = 0.00385) sensor input with a 0 to 100

°C span:

Accuracy Example (FOUNDATION fieldbus and Profibus

PA devices)

When using a Pt 100 ( = 0.00385) sensor input:

Digital accuracy = ±0.15 °C

Total accuracy = ±0.15 °C.

D/A accuracy = ±0.03% of 100 °C or ±0.03 °C

No D/A accuracy effects apply

Total accuracy = ±0.18 °C.

16

www.rosemount.com

Rosemount 644

August 2012

Ambient Temperature Effect

Table 6. Ambient Temperature Effect

Sensor Options

Sensor Reference

Temperature Effects per 1.0 °C

Input Range

(1.8 °F) Change in Ambient

(°C)

Temperature(1)

Range

D/A Effect(2)

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

Entire Sensor Input

Range

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.014 °C

T 1000 °C

0.032 °C – (0.0025% of (T –

300))

300 °C T < 1000 °C

0.054 °C – (0.011% of (T – 100))

100 °C T < 300 °C

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

2-, 3-, 4-wire RTDs

Pt 100 ( = 0.00385) IEC 751

-200 to 850

0.003 °C (0.0054 °F)

Pt 200 ( = 0.00385) IEC 751

-200 to 850

0.004 °C (0.0072 °F)

Pt 500 ( = 0.00385) IEC 751

-200 to 850

0.003 °C (0.0054 °F)

IEC 751

-200 to 300

0.003 °C (0.0054 °F)

JIS 1604

-200 to 645

0.003 °C (0.0054 °F)

JIS 1604

-200 to 645

0.004 °C (0.0072 °F)

-70 to 300

0.003 °C (0.0054 °F)

-50 to 250

0.03 °C (0.054 °F)

GOST 6651-94

-200 to 550

0.004 °C (0.0072 °F)

Pt 100 ( = 0.00391) GOST 6651-94

-200 to 550

0.003 °C (0.0054 °F)

Cu 50 ( = 0.00426)

GOST 6651-94

-50 to 200

0.008 °C (0.0144 °F)

Cu 50 ( = 0.00428)

GOST 6651-94

-185 to 200

0.008 °C (0.0144 °F)

GOST 6651-94

-50 to 200

0.004 °C (0.0072 °F)

GOST 6651-94

-185 to 200

0.004 °C (0.0072 °F)

Pt 1000 ( =

0.00385)

Pt 100 ( =

0.003916)

Pt 200 ( =

0.003916)

Ni 120

Cu 10

Pt 50 ( = 0.00391)

Cu 100 ( =

0.00426)

Cu 100 ( =

0.00428)

Edison Curve No.

7

Edison Copper

Winding No. 15

Thermocouples

Type B

NIST Monograph

175, IEC 584

100 to 1820

Type E

NIST Monograph

175, IEC 584

-200 to 1000 0.005 °C + (0.0043% of T)

Type J

NIST Monograph

175, IEC 584

-180 to 760

NIST Monograph

175, IEC 584

-180 to 1372

NIST Monograph

175, IEC 584

-200 to 1300 0.0068 °C + (0.00036% of T)

Type K

Type N

www.rosemount.com

All

0.0054 °C + (0.00029%of T)

T 0 °C

0.0054 °C + (0.0025% of

absolute value T)

T < 0 °C

0.0061 °C + (0.0054% of T)

T 0 °C

0.0061 °C + (0.0025% of

absolute value T)

T < 0 °C

All

17

Rosemount 644

August 2012

Table 6. Ambient Temperature Effect

Temperature Effects per 1.0 °C

Input Range

(1.8 °F) Change in Ambient

(°C)

Temperature(1)

Sensor Options

Sensor Reference

Type R

NIST Monograph

175, IEC 584

0 to 1768

NIST Monograph

175, IEC 584

0 to 1768

NIST Monograph

175, IEC 584

-200 to 400

DIN 43710

-200 to 900

Type S

Type T

DIN Type L

DIN Type U

Type W5Re/W26Re

GOST Type L

DIN 43710

ASTM E 988-96

GOST R

8.585-2001

-200 to 600

Range

D/A Effect(2)

0.016 °C

T 200 °C

0.023 °C – (0.0036% of T)

T < 200 °C

0.016 °C

T 200 °C

0.023 °C – (0.0036% of T)

T < 200 °C

0.0064 °C

T 0 °C

0.0064 °C +(0.0043% of

absolute value T)

T < 0 °C

0.0054 °C + (0.00029% of T)

T 0 °C

0.0054 °C + (0.0025% of

absolute value T)

T < 0 °C

0.0064 °C

T 0 °C

0.0064 °C + (0.0043% of

absolute value T)

T < 0 °C

0.016 °C

T 200 °C

0.023 °C – (0.0036% of T)

T < 200 °C

0.007 °C

T 0 °C

0.007 °C – (0.003% of absolute

value T)

T < 0 °C

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0.001% of

span

0 to 2000

-200 to 800

Other Input Types

Millivolt Input

-10 to 100

mV

0.0005 mV

2-, 3-, 4-wire Ohm

0 to 2000

0.0084

Entire Sensor Input

Range

Entire Sensor Input

Range

0.001% of

span

0.001% of

span

(1) Change in ambient is with reference to the calibration temperature of the transmitter 68 °F (20 °C) from factory.

(2) Does not apply to FOUNDATION fieldbus.

Temperature Effects Example (HART devices)

When using a Pt 100 ( = 0.00385) sensor input with a 0–100 °C span at 30 °C ambient temperature:

Digital Temperature Effects: 0.003 °C x (30 - 20) = 0.03 °C

D/A Effects: [0.001% of 100] x (30 - 20) = 0.01 °C

Worst Case Error: Digital + D/A + Digital Temperature Effects +

D/A Effects = 0.15 °C + 0.03 °C + 0.03 °C + 0.01 °C = 0.22 °C

Total Probable Error:

18

0.15 2 + 0.03 2 + 0.03 2 + 0.01 2 = 0.16C

www.rosemount.com

Rosemount 644

August 2012

Temperature Effects Examples (FOUNDATION fieldbus devices and Profibus PA)

When using a Pt 100 ( = 0.00385) sensor input at 30 °C span at 30 °C ambient temperature:

Digital Temperature Effects: 0.003 °C x (30 - 20) = 0.03 °C

D/A Effects: No D/A effects apply

Worst Case Error: Digital + Digital Temperature Effects = 0.15

°C + 0.03 °C = 0.18 °C

Total Probable Error:

0.15 2 + 0.03 2 = 0.153C

Table 7. Transmitter Accuracy when ordered with option code P8

Sensor Options

Sensor Reference

2-, 3-, 4-wire RTDs

Minimum

Span(1)

Digital

Accuracy(2)

°F

–328 to

1562

–328 to

1562

–328 to

1562

°C

°F

°C

°F

10

18

± 0.10

± 0.18

10

18

± 0.22

10

18

± 0.14

–328 to 572

10

18

± 0.10

10

18

± 0.10

10

18

± 0.22

Input Ranges

°C

±0.02% of

span

±0.02% of

± 0.40

span

±0.02% of

± 0.25

span

±0.02% of

± 0.18

span

±0.02% of

± 0.18

span

±0.02% of

± 0.40

span

±0.02% of

± 0.14

span

±0.02% of

± 1.80

span

±0.02% of

±0.36

span

±0.02% of

±0.18

span

±0.02% of

±0.61

span

±0.02% of

±0.61

span

±0.02% of

±0.31

span

±0.02% of

±0.31

span

Pt 100 ( = 0.00385)

IEC 751

–200 to 850

Pt 200 ( = 0.00385)

IEC 751

–200 to 850

Pt 500 ( = 0.00385)

IEC 751

–200 to 850

Pt 1000 ( = 0.00385)

IEC 751

–200 to 300

Pt 100 ( = 0.003916)

JIS 1604

–200 to 645

JIS 1604

–200 to 645

Ni 120

Edison Curve No. 7

–70 to 300

–94 to 572

10

18

± 0.08

Cu 10

Edison Copper Winding No.

15

–50 to 250

–58 to 482

10

18

±1.00

Pt 50 (=0.00391)

GOST 6651-94

–200 to 550

10

18

±0.20

Pt 100 (=0.00391)

GOST 6651-94

–200 to 550

10

18

±0.10

Cu 50 (=0.00426)

GOST 6651-94

–50 to 200

–58 to 392

10

18

±0.34

Cu 50 (=0.00428)

GOST 6651-94

–185 to 200

–301 to 392

10

18

±0.34

Cu 100 (=0.00426)

GOST 6651-94

–50 to 200

–58 to 392

10

18

±0.17

Cu 100 (=0.00428)

GOST 6651-94

–185 to 200

–301 to 392

10

18

±0.17

100 to 1820

212 to 3308

25

45

± 0.75

± 1.35

–200 to

1000

–328 to

1832

–292 to

1400

–292 to

2501

25

45

± 0.20

± 0.36

25

45

± 0.25

± 0.45

25

45

± 0.25

± 0.45

Pt 200 ( = 0.003916)

–328 to

1193

–328 to

1193

–328 to

1022

–328 to

1022

D/A

Accuracy(3)(4)

Thermocouples(5)

Type B(6)

Type E

Type J

Type K(7)

www.rosemount.com

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

–180 to 760

–180 to

1372

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

19

Rosemount 644

August 2012

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

NIST Monograph 175, IEC

584

–200 to

1300

–328 to

2372

25

45

± 0.40

± 0.72

0 to 1768

32 to 3214

25

45

± 0.60

± 1.08

0 to 1768

32 to 3214

25

45

± 0.50

± 0.90

–200 to 400

–328 to 752

25

45

± 0.25

± 0.45

DIN Type L

DIN 43710

–200 to 900

25

45

± 0.35

± 0.63

DIN Type U

DIN 43710

–200 to 600

25

45

± 0.35

± 0.63

Type W5Re/W26Re

ASTM E 988-96

0 to 2000

32 to 3632

25

45

± 0.70

± 1.26

GOST Type L

GOST R 8.585-2001

–200 to 800

–392 to

1472

25

45

± 0.25

± 0.45

Type N

Type R

Type S

Type T

–328 to

1652

–328 to

1112

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

±0.02% of

span

Other Input Types

Millivolt Input

–10 to 100 mV

3 mV

±0.015 mV

2-, 3-, 4-wire Ohm Input

0 to 2000 ohms

20 ohm

±0.35 ohm

±0.02% of

span

±0.02% of

span

(1) No minimum or maximum span restrictions within the input ranges. Recommended minimum span will hold noise within accuracy specification with damping at zero

seconds.

(2) Digital accuracy: Digital output can be accessed by the Field Communicator.

(3) Total Analog accuracy is the sum of digital and D/A accuracies.

(4) Applies to HART / 4-20 mA devices.

(5) Total digital accuracy for thermocouple measurement: sum of digital accuracy +0.25 °C (0.45 °F) (cold junction accuracy).

(6) Digital accuracy for NIST Type B is ±3.0 °C (±5.4 °F) from 100 to 300 °C (212 to 572 °F).

(7) Digital accuracy for NIST Type K is ±0.50 °C (±0.9 °F) from –180 to –90 °C (–292 to –130 °F).

Reference Accuracy Example (HART only)

When using a Pt 100 (= 0.00385) sensor input with a 0 to 100

°C span: Digital Accuracy would be ±0.10 °C, D/A accuracy

would be ±0.02% of 100 °C or ±0.02 °C, Total = ±0.12 °C.

20

Differential Capability Exists Between Any Two Sensor

Types (dual-sensor option)

For all differential configurations, the input range is X to Y where:

X = Sensor 1 minimum – Sensor 2 maximum and

Y = Sensor 1 maximum – Sensor 2 minimum.

www.rosemount.com

Rosemount 644

August 2012

Product Certifications

Rosemount 644 with HART

E5

European Directive Information

The EC declaration of conformity can be found in the Rosemount

644 Temperature Transmitter Quick Installation Guide. The

most recent revision can be found at

www.emersonprocess.com.

Markings:EXPLOSIONPROOF FOR CL. I, DIV. 1, GP BCD

DUST-IGNITIONPROOF FOR CL. II & III, DIV. 1, GP EFG

NON-INCENDIVE FOR CL. I, DIV 2, GP ABCD

WHEN INSTALLED PER ROSEMOUNT DRAWING

00644-1049

CONDUIT SEAL NOT REQUIRED;

ENCLOSURE TYPE 4X

Ordinary Location Certification from FM

Approvals

As standard, the transmitter has been examined and tested to

determine that the design meets basic electrical, mechanical,

and fire protection requirements by FM Approvals, a nationally

recognized testing laboratory (NRTL) as accredited by the

Federal Occupational Safety and Health Administration (OSHA).

Explosion-Proof and Dust Ignition Proof

Certificate No: 3006278

Applicable Standards: FM Class 3600 – 1998, FM Class

3615 – 2006, FM Class 3810 – 2005, ANSI/NEMA 250 2003

Special Conditions for Safe Use (X)

The surface resistivity of the non-metallic enclosure materials

is greater than one gigaohm. Care must be taken to avoid

electrostatic charge build-up. Do not rub or cleaned with

solvents or a dry cloth.

The Model 644 optional enclosures may contain aluminum

and are considered a potential risk of ignition by impact or

friction. Care must be taken into account during installation

and use to prevent impact and friction.

Hazardous Locations Certifications

North American Certifications

FM Approvals

I5

Intrinsically Safe and Non-Incendive

Certificate No: 3044581

Applicable Standards: FM Class 3600 – 1998, FM Class

3610 – 2010, FM Class 3611 – 2004,

FM Class 3810 – 2005, ANSI/NEMA 250 - 2003

Markings (without enclosure):

INT. SAFE CL I, GP ABCD, T4

IS CL I Zone 0, AEX ia IIC; T4 Ga

NI CL I, DIV.2, GP ABCD T5

INSTALL PER DRAWINGS 00644-2071

CSA Group

I6

Markings (without enclosure):

Ex ia

INTRINSICALLY SAFE, CLASS I, GROUPS A, B, C, D, T4/T5/T6

CLASS I, ZONE 0, IIC

SUITABLE FOR CLASS I DIV 2, GROUPS A, B, C, D

INSTALL PER DRAWING 00644-2072.

Markings (with enclosure):

IS CL I,II,III, GP ABCDEFG T4/T5/T6

NI CL I, DIV.2, GP ABCD

INSTALL PER DRAWINGS 00644-2071

ENCLOSURE TYPE 4X

Special Conditions for Safe Use (X)

The surface resistivity of the non-metallic enclosure materials

is greater than one gigaohm. Care must be taken to avoid

electrostatic charge build-up. Do not rub or cleaned with

solvents or a dry cloth.

The Model 644 optional enclosures may contain aluminum

and are considered a potential risk of ignition by impact or

friction. Care must be taken into account during installation

and use to prevent impact and friction.

www.rosemount.com

Intrinsically Safe

Certificate No.: 1091070

Applicable Standards: CSA Std. C22.2 No. 142 – M1987,

CSA Std. C22.2 No. 157 – 92

Markings (with enclosure):

Ex ia

CLASS I, GRPS A,B,C,D, T4/T6, CLASS I, ZONE 0, IIC

WHEN INSTALL PER DRAWING 00644-1064 or 0644-2072

SUITABLE CLASS I DIV 2, WITH NON-INCENDIVE OUTPUT

WHEN INSTALL PER DRAWING 00644-2072

ENCLOSURE TYPE 4X

K6

Explosion-Proof, Dust Ignition Proof, Intrinsically Safe and

Suitable for Class I Division 2

Certificate No.: 1091070

Applicable Standards: CSA Std. C22.2 No. 142 – M1987,

CSA Std. C22.2 No. 30 – M1986, CSA std. C22.2 No

157-92, CSA Std. C22.2 No. 213 – M1987

21

Rosemount 644

Markings:CL I, GRPS. B,C,D;

DUST-IGNITION PROOF, CL II, GRPS E,F, CL. III;

SUITABLE FOR CL I, DIV. 2, GROUPS A,B,C,D, WITH

NON-INCENDIVE OUTPUT

INSTALL PER DRAWING 00644-1059

ENCLOSURE TYPE 4X; CONDUIT SEAL NOT REQUIRED, Ex ia

CLASS I, GROUPS A, B, C, D, T4/T5/T6CLASS I, ZONE 0, IIC.

INSTALL PER DRAWING 00644-1064 or 00644-2072.

SUITABLE FOR CLASS I DIV 2, GROUPS A, B, C, D, WITH

NON-INCENDIVE OUTPUT

INSTALL PER DRAWING 00644-2072.

August 2012

N1

Specific Conditions for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V

insulation test required by Clause 6.8.1 of EN 60079-15:2005.

This must be taken into account when installing the apparatus.

NC

European Certifications

I1

ATEX Intrinsic Safety

Certificate No.: Baseefa 12ATEX0101X

Applicable Standards: IEC 60079-0: 2011, EN60079-11:

2007

Markings:

II 1 G, Ex ia IIC T6…T4 Ga;

See Certificate (Table 8)

1180

Special Conditions for Safe Use (X)

The apparatus must be installed in an enclosure which affords a

degree of protection of at least IP20.

Non-metalic enclosures must have a surface resistance of less

than 1Gohm.

Light alloy or zirconium enclosures must be protected from

impact and friction when installed.

Special Conditions for safe use (x):

The component must be installed in a suitably certified

enclosure such that it is afforded a degree of protection of at

least IP54 in accordance with IEC 60529, IEC 60079-0 & EN

60079-15.

E1

Loop

Ta < 60°

Ta < 70°

Ta < 80°

T6 (-60 °C ≤ Ta ≤ 40 °C), T5 (-60 °C ≤ Ta ≤ 50 °C)

T5 (-60 °C ≤ Ta ≤ 40 °C), T4 (-60 °C ≤ Ta ≤ 80 °C)

ATEX Flameproof

Certification No.: KEMA 99ATEX8715X

Applicable Standards: EN60079-0: 2006, EN60079-1:

2007

Markings:

II 2 G, Ex d IIC T6 Gb (-50°C ≤ Ta ≤ 65°C)

1180

Special Conditions for Safe Use (X):

For information on the dimensions of the flameproof joints the

manufacture shall be contacted.

ND

Sensor

Uo = 13.6 V

Io = 80 mA

Po = 80 mW

Ci = 0.075 μF Co = 0.816 μF Group IIC

Co= 5.196 μF Group IIB

Co = 18.596 μF Group IIA

Li = 0

Lo = 5.79 mH Group IIC

Lo = 23.4 mH Group IIB

Lo= 48.06 mH Group IIA

ATEX Type n (without enclosure)

Certificate No.: Baseefa12ATEX0102U

Applicable Standards: IEC 60079-0: 2011, EN60079-15:

2005

Markings:

II 3 G, Ex nA IIC T6…T5 Gc

Vmax = 45 volts max

Temperature limitations – T6 (-60 °C ≤ Ta ≤ 40 °C), T5 (-60

°C ≤ Ta ≤ 85 °C)

Table 8. Input Parameters

Ui = 30 V

Ii = 150 mA

= 170 mA

= 190 mA

Pi = 0.67 W

= 0.8 W

Ci = 3.3 nF

Li = 0

ATEX Type n (with enclosure)

Certification No.: BAS 00ATEX3145

Applicable Standards: EN 60079-0: 2006, EN60079-15:

2005

Markings:

II 3 G, Ex nA IIC T5 Gc (-40 °C ≤ Ta ≤ 70 °C)

ATEX Dust

Certification No.: KEMA 99ATEX8715X

Applicable Standards: EN 61241-0:2006, EN

61241-1:2004

Markings:

II 1 D, Ex tD A20 IP66 T95°C

1180

Special Conditions for Safe Use (X): None

IECEx Certifications

I7

IECEX Intrinsic Safety

Certificate No.: IECEx BAS 12.0069X

Applicable Standards: IEC 60079-0: 2011, IEC 60079-11:

2007

Markings: Ex ia IIC T6…T4 Ga

See Certificate (Table 8)

Special Conditions for Safe Use (X)

The apparatus must be installed in an enclosure which affords a

degree of protection of at least IP20

22

www.rosemount.com

Rosemount 644

August 2012

Non-metalic enclosures must have a surface resistance of less

than 1Gohm

Light alloy or zirconium enclosures must be protected from

impact and friction when installed

N7

NG

IECEX Type n (with enclosure)

Certification No.: IECEx BAS 07.0055

Applicable Standards: IEC 60079-0: 2004, EN60079-15:

2005

Markings:

Ex nA IIC T5 Gc (-40 °C ≤ Ta ≤ 70 °C)

IECEX Type n (without enclosure)

Certificate No.: IECEx BAS 12.0070X

Applicable Standards: IEC 60079-0: 2011, IEC 60079-15:

2010

Markings: Ex nA IIC T6…T5 Gc

Vmax = 45 volts max

Temperature limitations – T6 (-60 °C ≤ Ta ≤ 40 °C), T5 (-60

°C ≤ Ta ≤ 85 °C)

Special Conditions for safe use (x):

The component must be installed in an enclosure which meets

the impact test requirements of IEC 60079-15:2005 and

provides the component with a degree of protection of at least

IP54.

E7

IECEx Flameproof

Certification No.: IECEx KEM 09.0015X

Applicable Standards: IEC 60079-0: 2004, IEC 60079-1:

2007

Markings: Ex d IIC T6 Gb (-40 °C ≤ Ta ≤ 65 °C)

Special Conditions for Safe Use (X):

For information on the dimensions of the flameproof joints the

manufacture shall be contacted.

NK

IECEX Dust

Certification No.: IECEx KEM 09.0015X

Applicable Standards: IEC 61241-0:2004, IEC

61241-1:2004

Markings: Ex tD A20 IP66 T95°C

Special Conditions for Safe Use (X): None

Chinese Certifications

E3

NEPSI Flameproof and Dust Ignitionproof

Certification No.: GYJ111385X

Applicable Standards: GB3836.1-2000, GB3836.2-2000,

GB12476.1-2000

Markings: Ex d IIC T6

DIP A20 TA 95°C IP66*

Special Conditions for Safe Use (X):

(See Manual)

Japanese Certifications

E4

TIIS Flameproof

Certification No.: TC15744 – 644H with meter, no sensor

TC15745 – 644H without meter, no sensor

TC15910 – 644H without meter, thermocouple sensor

TC15911 – 644H with meter, thermocouple sensor

TC15912 – 644H without meter, RTD sensor

TC15913 – 644H with meter, RTD sensor

Markings: (TC 1591x) d IIB+H2 T4

(TC1574x) IIC T6

Combinations of Certifications

Stainless steel certification tag is provided when optional

approval is specified. Once a device labeled with multiple

approval types is installed, it should not be reinstalled using any

other approval types. Permanently mark the approval label to

distinguish it from unused approval types.

K1 Combination of E1, I1, N1, and ND

K2 Combination of E2 and I2

K5 Combination of E5 and I5

K6 Combination of E6 and I6

K7 Combination of E7, I7, and N7

KA Combination of E1, I1, E6, and I6

KB Combination of E5, I5, I6, and E6

KC Combination of E5, E1, I5, and I1

KD Combination of E5, I5, E6, I6, E1, and I1

Other Certifications

Brazil Certifications

Shipboard

E2

SBS American Bureau of Shiipng (ABS)

Certificate No.: 00-HS145383/1-PDA

Applicable Standards: ABS Rules:2008 Steel Vessels Rules

1-1-4/7.7, 4-8-3/1.7

Intended Service: Measurement of Pressure, Flow and

Level for Liquid, Gas and Vapor Applications on ABS

Classed Vessels, Marine and Offshore Installations

INMETRO Flameproof

Certification No.: CEPEL 02.0095X

Applicable Standards: ABNT NBR IEC 60079-0:2008, ABNT

NBR IEC 60079-1:2009,

ABNT NBR IEC 60079-26: 2008, ABNT NBR IEC

60529:2009,

Markings: d IIC T6 Ga/Gb IP66* Tamb : -20 °C a +65 °C

www.rosemount.com

23

Rosemount 644

August 2012

Rosemount 644 with FOUNDATION

Fieldbus and Profibus PA

Temperature code: T4 (Tamb = – 50 °C to 60 °C);

Suitable for Class I, Division 2, groups A, B, C, and D (must

be installed in a suitable enclosure)

Hazardous Locations Certificates

North American Certifications

K6

Factory Mutual (FM) Approvals

I5

FM Intrinsically Safe

Intrinsically Safe FISCO for use in Class I, II, III, Division 1,

Groups A, B, C, D, E, F, and G; when installed per control

drawing 00644-2075.

Temperature Code: T4A (Tamb = – 50 °C to 60 °C).

Temperature Code: T4 (Tamb = – 50 °C to 60 °C);

T5 (Tamb = – 50 °C to 85 ° C)

Nonincendive for use in Class I, Division 2, Groups A, B, C,

and D.

Temperature Code: T5 (Tamb = – 50 °C to 85 °C);

T6 (Tamb = – 50 °C to 70 ° C)

When installed per Rosemount control drawing

00644-2075

E5

FM Explosion Proof

Explosion Proof for Class I, Division 1, Groups B, C, and D.

Nonincendive for use in Class 1, Division 2, Groups A, B, C,

and D.

Temperature Code: T5 (Tamb = – 50 °C to 85 °C)

When installed per Rosemount control drawing

00644-1049

Dust Ignition Proof for Class II/III, Division 1, Groups E, F, G.

Temperature Code: T5 (Ta = – 50 °C to 85 ° C)

When installed per Rosemount drawing 00644-1049.

(J5, J6, and J8 options only.)

Canadian Standards Association (CSA) Approvals

I6

24

CSA Intrinsically Safe, Explosion-proof

Includes Intrinsically Safe “I6” and Explosion-Proof for Class

I, Division 1, groups B, C, and D.

Dust-Ignition Proof for Class II, Division 1, Groups E, F, and

G. Dust-Ignition Proof for Class III, Division 1

Seal not required.

CSA Enclosure Type 4X

NOTE:

(For J5 and J6 enclosure options only)

European Certifications

E1

ATEX Flame-Proof

Certificate Number: KEMA99ATEX8715X

ATEX Marking:

II 2 G

1180

Ex d IIC T6 (–50 °C Tamb 65 °C)

U = 32 Vdc

Special Conditions for Safe Use (X):

For information on the dimensions of the flameproof joints

the manufacturer shall be contacted.

I1

ATEX Intrinsic Safety

Certificate Number: Baseefa03ATEX0499X

ATEX Marking:

II 1 G

1180

Ex ia IIC T4 (-50 °C Tamb 60 °C)

CSA Intrinsically Safe

Intrinsically Safe and FISCO for Class I, Division 1, groups A,

B, C, and D when connected per Rosemount drawing

00644-2076.

www.rosemount.com

Rosemount 644

August 2012

Table 9. Entity Parameters

I.S. Loop/Power Terminals

Ui = 30 V

Ii = 300 mA

Pi = 1.3 W

Ci = 2.1 nF

Li = 0

FISCO Loop/Power Terminals

Ui = 17.5 V

Ii = 380 mA

Pi = 5.32 W

Ci = 2.1 nF

Li = 0

IECEx Certifications

E7

IECEx Flameproof and Dust

Certificate Number: IECEx KEM 09.0015X

Ex d IIC T6 (Flameproof) -40 °C < Tamb < 65 °C

Ex tD A20 IP 66 T 95 °C (Dust)

Vmax = 42.4 V

Special Conditions for Safe Use (X):

For information on the dimensions of the flameproof joints

the manufacturer shall be contacted.

Table 10. Electrical Data

Transmitter

Sensor

Vmax = 32 Vdc

Imax = 24.0 mA

Umax = 5 Vdc

Imax = 2.0 mA

Sensor Terminals

I7

Uo = 13.9 V

Io = 23 mA

Po = 79 mW

Ci = 7.7 nF

Li = 0

Table 11. Temperature Classification

Special Conditions for Safe Use (X):

The apparatus must be installed in an enclosure which

affords it a degree of protection of at least IP20.

Non-metallic enclosures must have a surface resistance of

less than 1G, light alloy or zirconium enclosures must be

protected from impact and friction when installed.

N1

NC

ATEX Type n

Certificate Number: BAS00ATEX3145

ATEX Marking:

II 3 G

Ex nL IIC T5 (-40 °C Tamb 70 °C)

Max Input Voltage: Ui = 42.4 Vdc

IECEx Intrinsic Safety

Certificate Number: IECEx BAS 07.0053X

Ex ia IIC T4/T5/T6

Pi (W)

Tamb

T4

T4

-50 °C to 60 °C

-60 °C to 60 °C

1.3

5.32 (FISCO Group IIC)

Special Conditions for Safe Use (X):

1. The apparatus must be installed in an enclosure which

affords it a degree of protection of at least IP20.

2. Non-metallic enclosures must have a surface resistance of

less than 1 G; light alloy or zirconium enclosures must be

protected from impact and friction when installed.

Table 12. Entity Parameters

ATEX Type n Component

Certificate Number: BAS99ATEX3084U

ATEX Marking:

II 3 G

Ex nL IIC T5 (-40 °C Tamb 70 °C)

Max Input Voltage: Ui = 42.4 Vdc

NOTE:

The equipment must be installed in an enclosure meeting the

requirements of IP54 and the requirements of the impact tests

described in EN60079-15.

Temperature

Class

N7

Transmitter

(I.S.)

Transmitter

(FISCO)

Sensor

Ui = 30 Vdc

Ii = 300 mA

Pi = 1.3 W

Ci = 2.1 nF

Li = 0 mH

Ui = 17.5 Vdc

Ii = 380 mA

Pi = 5.32 W

Ci = 2.1 nF

Li = 0 mH

Uo = 13.9 Vdc

Io = 23 mA

Po = 79 mW

Ci = 7.7 nF

Li = 0 mH

IECEx Type n

Certificate Number: IECEx BAS 07.0055

Ex nA nL IIC T5 (-40 °C Tamb 70 °C)

Table 13. Electrical Data

ND ATEX Dust Ignition-Proof

Certificate Number: KEMA99ATEX8715X

ATEX Marking:

II 1 D

Ex tD A20 T95°C (-50 °C Tamb 85 °C)

1180

IP66

Special Conditions for Safe Use (X):

For information on the dimensions of the flameproof joints

the manufacturer shall be contacted.

www.rosemount.com

Transmitter

Sensor

Ui = 32 V

RTD

Ui = 5 V

Thermocouple

Ui = 0

NG IECEx Type n Component

Certificate Number: IECEx BAS 07.0054U

Ex nA nL IIC T5 (-40 °C Tamb 75 °C)

Input Parameter: Ui = 32 Vdc

25

Rosemount 644

August 2012

Combination Approvals

Schedule of Limitations:

The component must be housed in a suitably certified

enclosure that provides a degree of protection of at least

IP54.

Japanese Certifications

Stainless steel certification tag is provided when optional

approval is specified. Once a device labeled with multiple

approval types is installed, it should not be reinstalled using any

other approval types. Permanently mark the approval label to

distinguish it from unused approval types.

Japanese Industrial Standard (JIS) Approvals

E4

JIS Explosion Proof

C15744

C15745

C15749

C15750

C15751

C15752

C15910

C15911

C15912

C15913

26

644H with meter and

no sensor

644H without meter

and no sensor

644H without meter

and with RTD

644H without meter

and with

thermocouple

644H with meter and

thermocouple

644H with meter and

RTD

644H without meter

and with

thermocouple

644H with meter and

thermocouple

644H without meter

and with RTD

644H with meter and

RTD

Combination of I5 and E5.

K1

Combination of E1, I1, N1, and ND

Russian GOST Certifications

Table 14. Certificate and Description

Certificate Description

K5

Approval

Group

Temp

Code

Ex d II C

T6

Ex d II C

T6

Ex d II B

T4

Ex d II B

T4

PPC BA-13006:

0 Ex ia IIC T4/T5/T6

Kazakhstan GOST

Pattern approval Certificate for Measuring Instruments

See Certificate

Ukraine GOST

Pattern Approval for Measuring Instruments

Ex d II B

T4

Ex d II B

T4

See Certificate

Ex d II B + H2 T4

Ex d II B + H2 T4

Ex d II B + H2 T4

Ex d II B + H2 T4

www.rosemount.com

Rosemount 644

August 2012

Dimensional Drawings

644H (DIN A Head Mount)

HART device shown with captivated screw terminals

FOUNDATION fieldbus and Profibus device shown with

Standard Compression Screw Terminals

60 (2.4)

60 (2.4)

Sensor Terminals

Sensor

Terminals

33 (1.3)

33

(1.3)

Communication

Terminals

59 (2.3)

Display

Connection

Failure

Mode Switch

24 (.96)

Power Terminals

Display

Connection

Communication

Terminals

24 (1.0)

Power

Terminals

Simulation Switch

33 (1.30)

31 (1.2)

Dimensions are in millimeters (inches)

www.rosemount.com

27

Rosemount 644

August 2012

644 Rail Mount

Sensor

Terminals

82

(3.2)

Power

Terminals

36

(1.4)

104

(4.1)

Mounting Kits for 644H

644H Rail Clips

644R Rail & Walls Clips

G-Rail (asymmetric)

Top Hat Rail (symmetric)

Mounting

Hardware

Mounting

Hardware

Transmitter

Transmitter

Rail Clip

Rail Clip

G-Rail

Grooves

Top Hat Rail

Grooves

Screw Holes

for Mounting

to a Wall

Note: Kit (part number 00644-5301-0010) includes

mounting hardware and both types of rail kits.

644H Retrofit Kit

Existing Threaded Sensor

Connection Head

(former option code L1)

Kit includes replacement

bracket and screws.

(part number 03044-4103-0001)

28

Note: Kit (part number 00644-5321-0010) includes a new

mounting bracket and the hardware necessary to facilitate the

installation.

www.rosemount.com

Rosemount 644

August 2012

LCD Display Cover

Threaded-Sensor Universal Head

(Option code J5, J6, J7 or J8)

DIN Style Sensor Connection Head

(Option code R1, R2, R3 or R4)

112 (4.41)

Label

96 (3.76)

104

(4.09)

95 (3.74)

LCD

Display

Meter Cover

Standard

Cover

78 (3.07)

128 (5.04) with

LCD Display

75 103 (4.03) with LCD

(2.93) Display

316 SST “U” Bolt

Mounting, 2-inch

Pipe

100

(3.93)