Catalog - Multalloy

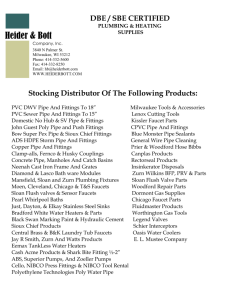

advertisement