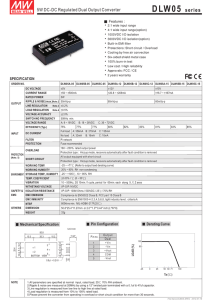

Selection and Application

advertisement