Soneplex

USER MANUAL

FIBER LOOP CON

VERTER

DS3/OSS

INTERFACE

ACCESS

PANEL

QFLC

F6312-20

ENABLE

MAJOR

MINOR

RMT/HSKP

MOD FAIL

LOS Y

OPT OOF R

FORCE SW Y

APS LKOUT R

ONLINE G

STDBY Y

DS1

LOS/LPBK

1 RLB

NORMAL

UNEQPT

2

G=IN SERV

R=LOS

Y=PBK

PT

OFF=UNEQ

3

4

LMPTST/

FORCE SW

RMT ALM

DISPLAY

RESET

7

5

8

6

4

3

2

1

ALM

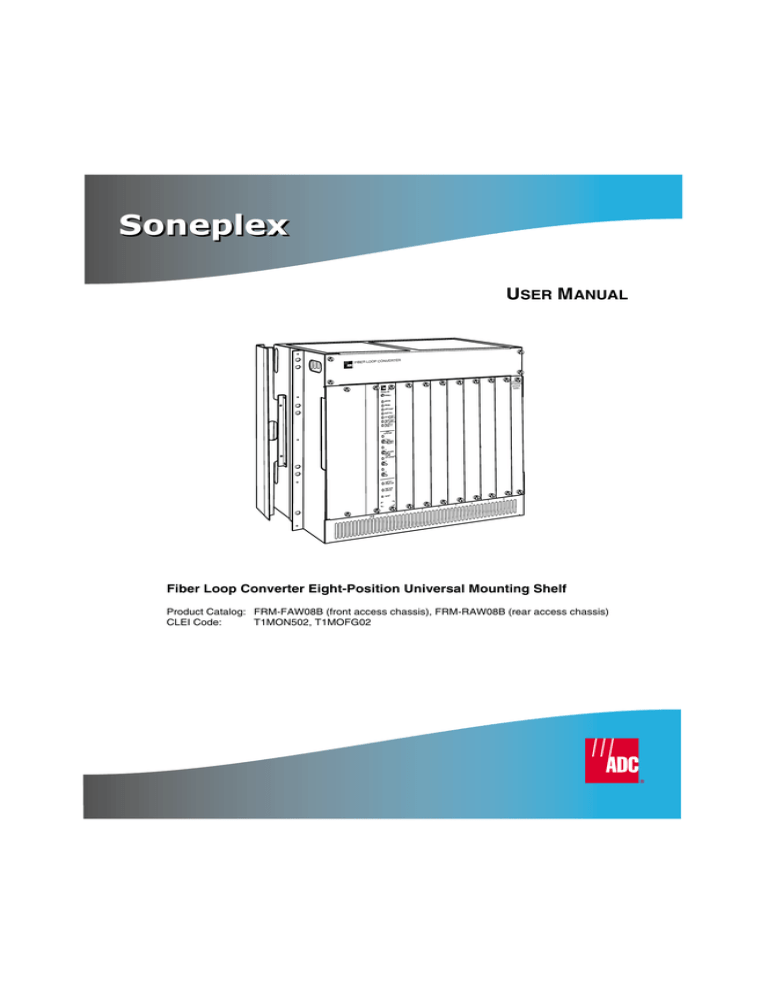

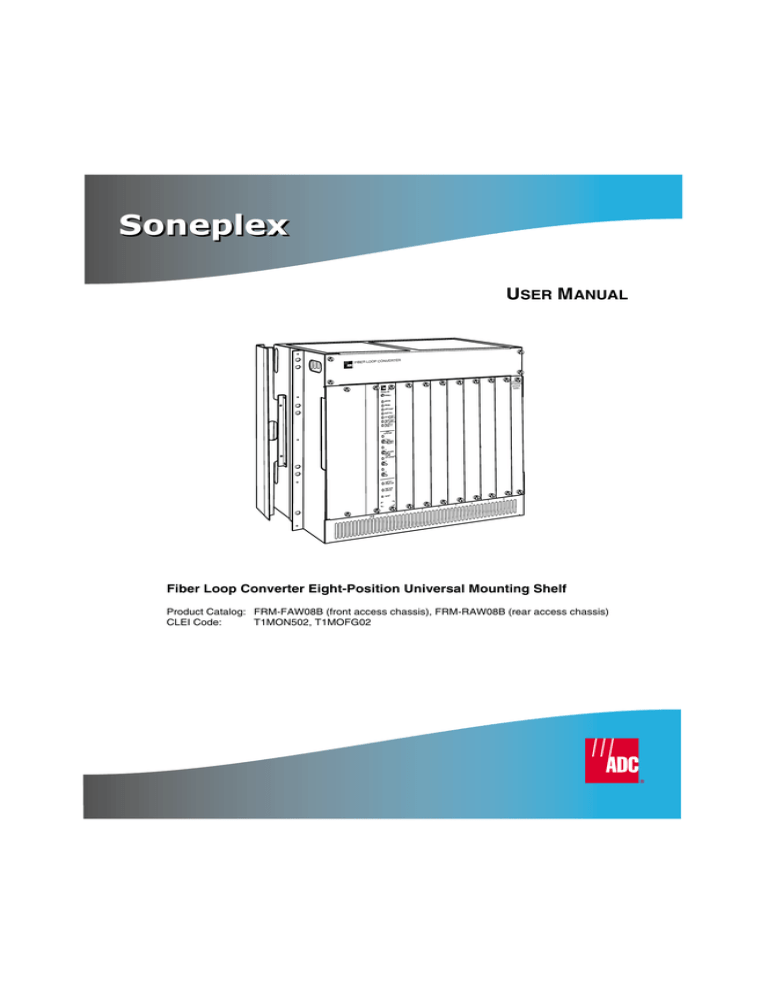

Fiber Loop Converter Eight-Position Universal Mounting Shelf

Product Catalog: FRM-FAW08B (front access chassis), FRM-RAW08B (rear access chassis)

CLEI Code:

T1MON502, T1MOFG02

Copyright

March 4, 2002

© 2002 ADC DSL Systems, Inc. All rights reserved.

Trademark Information

ADC and Soneplex are registered trademarks and LX.5 is a trademark of ADC Telecommunications, Inc. No right, license, or

interest to such trademarks is granted hereunder, and you agree that no such right, license, or interest shall be asserted by you with

respect to such trademark.

Other product names mentioned in this practice are used for identification purposes only and may be trademarks or registered

trademarks of their respective companies.

Disclaimer of Liability

Information contained in this document is company private to ADC DSL Systems, Inc., and shall not be modified, used, copied,

reproduced or disclosed in whole or in part without the written consent of ADC.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits, and ADC further disclaims any

and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of liability applies to all

products, publications and services during and after the warranty period.

INSPECTING SHIPMENT

Upon receipt of the equipment:

•

Unpack each container and inspect the contents for signs of damage. If the equipment has been damaged in

transit, immediately report the extent of damage to the transportation company and to ADC DSL Systems,

Inc. Order replacement equipment, if necessary.

•

Check the packing list to ensure complete and accurate shipment of each listed item. If the shipment is short

or irregular, contact ADC DSL Systems, Inc. If you must store the equipment for a prolonged period, store

the equipment in its original container.

ADCP-UM-61-118-11

Issue 11, March, 2002

Fiber Loop Converter

Eight-Position Universal Mounting Shelf

User Manual

Content

Page

INTRODUCTION ........................................................................... 1

Revision History ....................................................................... 1

Related Publications .................................................................... 2

Admonishments ....................................................................... 2

1. GENERAL ............................................................................ 3

2. PHYSICAL DESCRIPTION ................................................................ 4

3. FUNCTIONAL DESCRIPTION.............................................................. 5

A.

Major, Minor, and Remote Alarm........................................................ 7

B.

Housekeeping Alarm ................................................................. 7

4. SPECIFICATIONS ...................................................................... 8

5. INSTALLATION ........................................................................ 9

A.

Protect/Non-Protect and Unprotected DS3 FLC Options...................................... 9

B.

DS3 FLC Options................................................................... 12

C.

Terminal Block and Connector Access .................................................. 14

D.

Shelf Mounting .................................................................... 15

E.

Wire Power and Alarms.............................................................. 15

F.

Wire DS1 Lines .................................................................... 17

G.

Install Optical Fiber ................................................................. 21

H.

FLC Module Installation ............................................................. 24

6. CLEANING AND MATING INSTRUCTIONS................................................... 25

7. PRODUCT SUPPORT................................................................... 27

INTRODUCTION

This manual describes the ADC Fiber Loop Converter Eight-Position Universal Mounting Shelf

and provides installation instructions for the shelf.

Revision History

ISSUE

DATE

REASON FOR CHANGE

Issue 8

12/93

Adds DS3 FLC and other changes

Issue 9

02/96

Change photographs to line art and add Unprotected QLX Adapter Kit.

Issue 10

10/98

Update to current format standards, update customer support information and corporate address.

Issue 11

03/02

Update customer support information, remove references to DFLC and SFLC modules

Page 1

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Related Publications

This format can be used for listing related manuals to the current document. Listed below are all

of the related manuals and their publication numbers. These publications can be downloaded

from the ADC website at www.adc.com or hard copies can be obtained by contacting your sales

representative.

Title

ADCP Number

Quad DS1 Fiber Loop Converter (B2/B3/D3 Versions) User Manual

ADCP-61-135

DS3 Fiber Loop Converter User Manual

ADCP-61-128

Model FLC A10MPU FLC Micro Processor Unit

ADCP-61-129

FLC Eight Position Universal Mounting Shelf

DS3 Adapter Kit Instruction Sheet

ADCP-61-140

Fiber Loop Converter Installation, Operation

and Maintenance Quick Reference Guide

ADCP-61-124

FLC Eight-Position Universal Mounting Shelf Unprotected DS3 Adapter Kit

ADCP-61-164

Admonishments

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what may

happen if the hazard is not avoided. The admonishments — in the form of Dangers, Warnings,

and Cautions — must be followed at all times. These warnings are flagged by use of the

triangular alert icon (seen below), and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe

personal injury, death, or substantial property damages if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe

personal injury, death, or substantial property damages if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause

minor personal injury or property damage if the hazard is not avoided.

Page 2

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

1. GENERAL

1.01

This manual provides the description and installation instructions for ADC’s Fiber Loop

Converter Eight-Position Universal Mounting Shelf. Changes made to the technical content of

this document since the previous issue is included in the List of Changes table located in the

preface.

1.02

The shelf accommodates a variety of ADC’s Fiber Loop Converter modules. The

modules make electrical connection with associated equipment through connectors at the rear of

the mounting shelf while the optical interface is provided by optical transmit and receive

connectors mounted on the module.

1.04

The following admonishments are applicable to this mounting shelf.

Warning: This equipment generates, uses and can radiate radio frequency energy when

populated with circuit cards and if not installed in accordance with the user manual,

may cause interference to radio communications. It has been tested and found to comply

with the limits for a Class A computing device pursuant to Subpart B of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference to TV and radio reception in which case

the user at their own expense will be required to take whatever measure may be required

to correct the interference.

This equipment does not exceed Class A limits for radio noise emission for digital

apparatus, set out in the radio interference regulation of the Canadian Department of

Communication. Operation in a residential area may cause unacceptable interference to

TV and radio reception requiring the owner or operator to take whatever steps are

necessary to correct the interference.

Caution: To prevent damage to circuit cards by static electrical discharge, Electrostatic

Discharge (ESD) protection must always be used while handling circuit cards. An ESD

ground jack is provided on the lower left front corner of the shelf. Whenever circuit

cards are being installed or removed, always place the cards on a grounded, approved

anti-static mat. Stored circuit cards should also be wrapped in anti-static material

This product conforms to all applicable standards of 21 CFR 1040.

Caution: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Page 3

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

2. PHYSICAL DESCRIPTION

2.01

The FLC Eight-Position Universal Mounting Shelf accommodates the following ADC

Fiber Loop Converters:

•

DS3 Fiber Loop Converter

•

Quad DS1 Fiber Loop Converter

Figure 1 shows the cabinet containing one QFLC.

VERTER

FIBER LOOP CON

DS3/OSS

INTERFACE

ACCESS

PANEL

QFLC

F6312-20

ENABLE

MAJOR

MINOR

RMT/HSKP

MOD FAIL

LOS Y

OPT OOF R

FORCE SW Y

APS LKOUT R

ONLINE G

STDBY Y

DS1

LOS/LPBK

1 RLB

NORMAL

UNEQPT

2

G=IN SERV

R=LOS

Y=PBK

PT

OFF=UNEQ

3

4

LMPTST/

FORCE SW

RMT ALM

DISPLAY

RESET

7

5

8

6

4

3

2

1

ALM

7018-C

OPTIONAL

CABLE SHIELD

QUAD FLC

Figure 1. Fiber Loop Converter Eight-Position Universal Mounting Shelf

(front access shelf shown)

2.02

The shelf accommodates the FLC A10MPU FLC Micro Processor Unit (MPU). The

MPU is a controller module designed to monitor system configurations and facilitate Telemetry

Byte Oriented Serial (TBOS) communications link/protocol that functions with the QFLC and

DS3 FLC modules.

2.03

The Eight-Position Universal Mounting Shelf is rectangular in shape and designed with no

protruding parts on either the top or bottom. This permits the vertical stacking of shelves in a relay

rack. The shelf is constructed of heavy gauge steel with an integrated baffle on the bottom. A 2.8inch (7.1-cm) high area above the slot provides for fiber entry and routing to the modules. An

optional moveable cable shield can be attached to each side of the shelf to provide protection for the

fibers entering the shelf. The shelf is designed to provide either front or rear access for all

installation connections. Blank panels are provided to cover vacant module mounting spaces. An

Electrostatic Discharge (ESD) ground jack is provided on the front lower left corner of the cabinet.

Page 4

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Note: On some units, the ESD ground jack is located behind the upper front cover.

2.04

Total height of the shelf is 15.7 inches (39.9 cm) and it is 11.7 inches (29.7 cm) deep.

Reversible mounting flanges permit the shelf to be installed in either a 19- or 23-inch (48.3 or

58.4 cm) relay rack. Pre-drilled holes on each side of the shelf allow the mounting brackets to be

positioned so that the front of the shelf can extend 4 or 5 inches (10.2 or 12.7 cm) beyond the

front of the relay rack.

3. FUNCTIONAL DESCRIPTION

Warning: ADC Fiber Loop Converter chassis are designed to be used with ADC Fiber

Loop Converters. When used together, the chassis and module assemblies form a Class 1

Laser Kit that conforms to the applicable standards of 21 CFR 1040. If the equipment is

used in any other way, compliance to the above standard is not guaranteed.

The following required labels appear on the back panel of the shelf.

THIS PRODUCT CONFORMS TO ALL

APPLICABLE STANDARDS OF

21 CFR 1040

DANGER

2954-A

INVISIBLE LASER RADIATION

AVOID DIRECT EXPOSURE TO BEAM

ADC TELECOMMUNICATIONS, INC.

113311 K-TEL DRIVE

MINNETONKA, MINNESOTA 55343

Manufactured:

2953-A

1971-A

3.01

Two terminal blocks are located inside the left-most compartment of the shelf. (See

Figure 2.) Power and ground screw down terminals and alarm wire-wrap pins are provided on

one terminal block while DS1 line transmit and receive pair wire-wrap terminations are located

on another terminal block. Shield wire and cable drain wire terminations are provided in the

terminal block compartment. DS1 terminations are provided by either wire-wrap pins or 50-pin

Amp Champ connectors, depending on the model. Installation connections to the shelf are made

from the front or rear of the shelf, depending on the orientation of the terminal blocks. A baffle

at the bottom provides ventilation for cooling.

Page 5

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

WIRE WRAP

T1 LINE

TERMINAL

7722-A

BATTERY, GROUND,

AND ALARM

TERMINALS

Figure 2. T1 Lines, Battery, Ground, Shield Ground and Alarm Terminals

3.02

A DS3 FLC Interface Panel, FLC Micro Processor Unit (MPU) with Interface Panel, and

Unprotected DS3 FLC Interface panel are options that are available for the shelf. The DS3 FLC

Interface Panel mounts into the right-most slot and contains connector pins for the TBOS

interface line. Likewise, the Unprotected DS3 FLC Interface panel contains connector pins for

the TBOS interface line but mounts in the left-most slot and replaces the two terminal blocks

inside the left compartment of the shelf. The MPU module mounts into the slot labeled 0, ALM,

or MPU near the left side of the shelf.

3.03

Module electrical interface at each slot is provided by a backplane-mounted, 20-pin

card-edge connector and a 96-pin DIN connector. The QFLC and DS3 FLC modules connect to

both connectors. Fiber patch cords connect the modules to other network equipment.

3.04

In a protected QFLC or DS3 FLC system, the Working System module installs in an odd

numbered slot while the associated Protect System module installs in the even numbered slot to

the right. The protect/non-protect jumper board on the back panel is placed in the Protect

position to strap the four DS1 lines (or one DS3 line) of the Working System to the Protect

System. The Unprotected DS3 Adapter Kit supports two Working System modules in a slot pair

with a dual I/O module and protect jumper board in the non-protect position.

3.05

Figure 3 shows a QFLC module partially inserted in the shelf with the transmit and

receive fibers connected to the module. Fibers enter the shelf through one of four entry holes

located on the sides and route through the area above the slots.

Page 6

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

A. Major, Minor, and Remote Alarm

3.06

Major, Minor and Remote Alarm Normally Open (NO) and Common (COM) wire-wrap

terminals appear on a terminal block (see Figure 2) for connection to local alarm surveillance

equipment. An alarm condition causes the normally open dry relay contacts on the FLC module

to furnish a closed (loop) condition. The eight slot connectors are wired to provide one

termination for each Major and Minor alarm for the entire shelf. Each slot provides a separate

pair of Remote Alarm NO and COM terminals appearing on the terminal block.

B. Housekeeping Alarm

3.07

Housekeeping input alarm terminals are provided for any alarm conditions the user may

wish to input. A Housekeeping alarm condition is activated by a closed circuit (loop) provided

by customer equipment. Each slot has one pair of Housekeeping alarm terminals (see Figure 2)

appearing on the terminal block.

FLC

TRANSMIT

FLC

RECEIVE

3126-A

Figure 3. Fiber Connected to QFLC Module

Page 7

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

4. SPECIFICATIONS

4.01

Specifications are listed in Table 1.

Table 1. Specifications

PARAMETER

SPECIFICATIONS

REMARKS

Singlemode 9/125 µm

Nominal

Optical

Fiber Optical Cable

Power

Supply Voltage

–42.0 to –56.0 Vdc

Supply Current

QFLC Module

250 mA typical @ –48 V

DS3 FLC Module

250 mA max. @ –48 V

Four DS1 lines on one module with

simplex current enabled on all four

lines, 490 mA typical, 600 mA max

Alarm Relay Contacts (Module) 1A

Contact rating

Connectorized Shelf

Four 50-pin Amp Champ

Connectors (Female)

0° to +50° C

(+32° to +122° F)

For all standard FLC modules.

–40° to +65° C

(–40° to +149° F)

For extended temperature range

modules

Environmental

Operating Temperature

Storage Temperature

–40° to +70° C

(–40° to +158° F)

Operating Humidity

20 to 80%

No condensation

Storage Humidity

10 to 95%

No condensation

Dimensions

Size

15.7 H × 11.7 D inches

(39.9 × 29.7 cm)

Relay Rack Mounting

19.0 or 23.0 inches

(48.3 or 58.4 cm)

Page 8

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

5. INSTALLATION

Warning: Never install Fiber Loop Converter equipment in a wet location or during a

lightning storm. When installing or modifying telephone lines, disconnect lines at the

network interface before working with uninsulated lines or terminals.

Caution: To prevent damage to circuit cards by static electrical discharge, Electrostatic

Discharge (ESD) protection must always be used while handling circuit cards. An ESD

ground jack is provided on the lower left front corner of the shelf. Whenever circuit

cards are being installed or removed, always place the cards on a grounded, approved

antistatic mat. Stored circuit cards should also be wrapped in anti-static material.

5.01

This section covers the procedures for installing the shelf. The installation includes:

•

Protect/Non-protect option.

•

DS3 FLC options - Protect/Non-protect and Unprotected.

•

Terminal block and connector access.

•

Shelf mounting.

•

Connecting power and alarm circuits.

•

Placing electrical cable or wires and optional fibers.

5.02

When installing the shelf, the backplane jumper board must be properly mounted for

protect/non-protect systems, and the mini-jumpers set for the QFLC/DS3 FLC module. Also, the

shelf must be configured properly for the electrical and T1 line entry and connections.

Installation and setup procedures for the FLC modules may be found in the FLC User Manuals

listed in the preface to this manual.

A. Protect/Non-Protect and Unprotected DS3 FLC Options

5.03

Module slots are configured for protect/non-protect operation by the position of the

associated jumper boards located on the module side of the backplane (see Figures 4 and 5). The

shelf contains four jumper boards. Each jumper board options two slot locations paired as

follows: 1 - 2, 3 - 4, 5 - 6, and 7 - 8. Each slot pair can be configured independently for either

protect or non-protect operation.

5.04

In a Protect System configuration, the Working System module occupies the odd

numbered slot and the Protect module occupies the even-numbered slot (for example, Working

in slot 3, Protect in slot 4). The shelf is factory configured for Protect System operation in all slot

pairs. In non-protect configuration, a slot pair may be occupied by QFLC modules. When the

Unprotected DS3 FLC Adapter Kit is used, any or all of the eight slots can be populated with

DS3 FLC modules.

Page 9

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

PROTECT

POSITION HOLE

WHEN OVER

WHITE POST

NON-PROTECT

POSITION HOLE

WHEN OVER

WHITE POST

PROTECT

POSITION HOLE

WHEN OVER

WHITE POST

NON-PROTECT

POSITION HOLE

WHEN OVER

WHITE POST

1253-A

Figure 4. Jumper Board

CONFIGURED AS

PROTECT

SYSTEM

CONFIGURED AS

NON-PROTECT

SYSTEM

SLOT 8

SLOT 1

PROT

PROT

PROT

PROT

J19

21

UNPROT

UNPROT

UNPROT

UNPROT

J16

J15

J12

J11

J8

J7

J4

J3

J17

ABC

J14

ABC

J13

ABC

J10

ABC

J9

ABC

J6

ABC

J5

ABC

J2

ABC

J23

J24

21

21

PRESSURE

SNAPS

J20

21

34 33 34 33

34 33 34 33

J27

J32

J30

J28

J33

J36

J34

2

2

26

26

J35

1

J29

1

25

1

J31

25

1241-A

NOTE:

SLOTS 1-2 AND 5-6 ARE CONFIGURED FOR NON-PROTECTION SYSTEM OPERATION.

SLOTS 3-4 AND 7-8 ARE CONFIGURED AS PROTECTED SYSTEMS.

Figure 5. Backplane Jumper Boards

Page 10

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

5.05

When the jumper board is in the Protect System position, the white mounting posts on

the backplane pass through the left side upper and lower holes of the jumper board (see Figure

5). When the jumper board is in the Non-Protect System position, the white mounting posts on

the backplane pass through the right side upper and lower holes of the jumper board.

5.06

The mini-jumpers located on the backplane side of the Protect/Non-protect jumper board

(see Figure 6) configure the associated slots for QFLC/DS3 FLC modules. The upper minijumper configures the odd-numbered slot of the slot pair and the lower mini-jumper configures

the even-numbered slot of the pair. When a slot contains a QFLC or DS3 FLC module, place the

associated mini-jumper across the center and right pins (Q side) of the three configuration pins.

QFLC and DS3 FLC modules may be configured as Protected or Non-Protected systems.

P2

P1

REAR VIEW OF

JUMPER BOARD

P2

P1

S/D SIDE OF

MINI-JUMPER

DFLC JUMPER

REAR VIEW OF

JUMPER BOARD

S

Q

ODD NUMBERED

SLOT MINIJUMPER

MINIJUMPERS

D

P3

EVEN NUMBERED

SLOT MINIJUMPER

2034-A

2033-A

Figure 6. Jumper Board Mini-Jumpers

Setting Jumper and Mini-Jumper Configuration

5.07

To configure a slot pair as protect or non-protect and/or set the mini-jumper

configuration, proceed as follows:

a.

Release the snap at the top of the board and pull out the top of the board slightly.

b.

Release the snap at the bottom of the board and pull out the bottom of the board, (see

Figure 5).

c.

With both snaps released, pull the board out of the connector.

Page 11

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

d.

Locate the mini-jumpers at the bottom of the jumper board (see Figure 6). Position the

upper mini-jumper (associated with the odd-numbered slot) across the center and right

pins for a QFLC or DS3 FLC module. Repeat this procedure with the lower mini-jumper

for the even-numbered slot. If a position has no mini-jumper, it accommodates only

QFLC or DS3 FLC modules.

e.

Reinstall the jumper board by first positioning either the left side holes over the white

posts for a protect configuration of the slot pair, or the right side holes over the white

posts for a non-protect or unprotected configuration.

f.

Press in the top of the board until the snap catches.

g.

Press in the bottom of the board until the snap catches.

h.

Press in the board evenly until it is firmly seated in the connector.

Note: If the Protect/Non-Protect configuration is not the same at both ends, all four

LOS/LPBK LEDs on the QFLC module will blink.

B. DS3 FLC Options

5.08

Using DS3 FLCs in the shelf requires one of two available adapter kits to be installed in

the chassis. One option is the DS3 Adapter Kit (catalog number FRM-DS3KIT-8) Interface

Panel and cable/splitter assembly to connect the DS3 input and output signals to the mounting

shelf and shelf backplane (see Figure 7 on page 13). This adapter kit is used for protected DS3

FLC operation with up to four protected DS3 FLCs. The other option is the Unprotected DS3

FLC Adapter Kit (catalog number FRM-DS3KIT8UN) interface panel and cable/splitter

assembly. This kit adapts the shelf so it can be loaded with up to eight Unprotected DS3 FLCs

(see Figure 8 on page 14). The MPU/TBOS connector and cable assembly is not used unless an

MPU module is installed in the shelf. Mounting and installation instructions are included with

the kits.

Page 12

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

COAXIAL CABLES

1

1-RCV

1-XMT

2-RCV

2

4

3

1

2

2-XMT

3

3-RCV

CONNECTOR

MOUNTING

PLATE

PRINTED CIRCUIT BOARDS

3-XMT

4

4-RCV

4-XMT

PORT 1

RX

+

GD

TX

+

TX

RX

PORT 2

MPU/TBOS

CONNECTOR

1073-C

Figure 7. DS3 Adapter Kit Interface Panel and Cable Assembly

Page 13

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

COAXIAL

CABLES

1&2

DS3 1

(SLOT 1)

3&4

DS3 2

(SLOT 2)

DS3 3

(SLOT 3)

DS3 4

(SLOT 4)

5&6

DS3 5

(SLOT 5)

DS3 6

(SLOT 6)

DS3 7

(SLOT 7)

7&8

DS3 8

(SLOT 8)

OUT

(FROM FLC)

IN

(TO FLC)

PORT 1

RX

+

–

GD

7706-C

TX

+

–

PRINTED

CIRCUIT

BOARDS

TX

RX

PORT 2

MPU/TBOS

CONNECTOR

Figure 8. Unprotected DS3 Adapter Kit Interface Panel and Cable Assembly

C. Terminal Block and Connector Access

5.10

The Alarm Terminal block and 50-Pin T1 Line Connector Block may be configured for

front or rear access depending on the model number of the Eight-Position shelf. However, the

terminal block and connector block may be reversed for opposite access using the following

procedure.

Note: The Unprotected DS3 Adapter Kit supports only rear access configuration of the

terminal and connector blocks.

a.

Remove the front (see Figure 2 on page 6) and rear panels that cover the terminal block

and connectors.

b.

Remove the two top and two bottom corner hex extender screws that fasten the T1

Connector Block to the mounting tabs.

Page 14

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

c.

Turn the block sideways (90 degrees), either toward the left or right. Move the block

toward the back or front of the mounting tabs while carefully feeding the wire cables

connected to it along the side of block until there is sufficient slack to completely turn

the block around. Position the block against the mounting tabs.

Note: The internal wiring from the terminal block to the eight slots is connectorized on

the back of the terminal block.

d.

Fasten the block to the mounting tabs with the four screws removed in step (b).

e.

Repeat steps (b), (c), and (d) for the battery and Alarm Terminal block. Note that the

internal wire cables connecting the terminal block to the slots feed over the top of the

terminal block and not along the side as they do with the T1 Connector Block.

f.

Reinstall the front and rear panels.

D. Shelf Mounting

5.11

When installing the mounting shelf in a 23-inch (58.4 cm) relay rack, no changes to the

mounting brackets are necessary. When installing in a 19-inch (48.3 cm) relay rack, remove the

mounting brackets from the shelf (see Figure 9 on page 16) and place each bracket so the wide

side of the bracket is flat against the shelf; reattach the brackets to the shelf.

5.12

Align the mounting bracket holes on each side of the shelf with the threaded holes in the

relay rack. Secure shelf to the rack with 12 x 24 machine screws.

E. Wire Power and Alarms

5.13

Route power leads into the shelf via front or back entry holes located on each side to the

Alarm Terminal block. On the Alarm Terminal block, battery and ground terminations are

provided by screw down terminals. Two (A and B) –48 Vdc battery terminations provide for a

redundant power source to the FLCs. Connect as indicated in Table 2 on page 16. The shelf must

be grounded before any FLC modules are installed and power is applied. The power and Alarm

Terminal block is shown in Figure 10 on page 17.

Note: A fully equipped shelf of eight QFLC modules with each module furnishing

60 mA simplex current on all the DS1 lines has a 3.9 Amp maximum current drain. (150

watts max.) A shelf with eight QFLC modules not furnishing 60 mA of simplex current,

has a 2.0 Amp maximum current drain. Connect the –48V battery supply with 18 gauge

wire and separately fuse each 48V supply in the mounting shelf bay with a fuse size to

be determined locally, but not to exceed 5.0 Amps.

Warning: Before making any connections to the mounting shelf, ensure that the power is

off (fuse removed at the fuse and alarm bay) and all modules are removed. Modules

should only be installed after they are optioned and the wiring is completed.

Page 15

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Table 2. Battery and Ground Connections

CONNECT

TO

–48 Vdc battery

–48 V A

–48 Vdc battery

–48 V B

Battery Return A

RET A

Battery Return B

RET B

Frame Ground

GND

Major and Minor Alarms

5.14

Route alarm leads into the shelf via front or back entry holes located on each side (see

Figure 9). Wire-wrap terminals provide the Major Alarm (MAJ) and the Minor Alarm (MIN)

terminations. All slots are wired to provide one termination for the Major Alarm and one

termination for the Minor Alarm. Connect the VISUAL ALARM MAJ and MIN Normally Open

and Common dry contact alarm terminals (see Figure 10) to local alarm surveillance equipment.

VERTER

FIBER LOOP CON

FIBER

ENTRY HOLE

QFLC

F6312-20

ENABLE

OPTIONAL

SIDE PANEL

CABLE SHIELD

MAJOR

MINOR

RMT/HSKP

MOD FAIL

LOS Y

OPT OOF R

FORCE SW Y

APS LKOUT R

ONLINE G

STDBY Y

DS1

LOS/LPBK

1 RLB

NORMAL

UNEQPT

MOUNTING

BRACKET

2

G=IN SERV

R=LOS

Y=PBK

PT

OFF=UNEQ

3

4

LMPTST/

FORCE SW

RMT ALM

DISPLAY

ELECTRICAL

FACILITIES

ENTRY HOLE

RESET

3

2

ALM

1

2036-B

ESD JACK

Figure 9. Side Panel Shield and Entry Holes

Page 16

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Remote Alarm

5.15

The Remote alarm leads, from slots 1 through 8, that connect to local alarm surveillance

equipment appear on wire-wrap pins. A pair of Remote Alarm REM is the NO contact) and

COM dry contact alarm terminals (see Figure 10) connect, as required, to each of the eight FLC

slots.

Note: If the shelf is equipped with an FLC-A10MPU system, the major, minor and

remote audible NO wire-wrap pins are provided on the bottom of the Alarm Terminal

block. Also provided are ACT wire-wrap pins to connect an external alarm cut-off key

and IND wire-wrap pins to connect an external visual ACO indicator.

VISUAL ALARM

MAJ

MIN

1 2 3 4 5 6 7 8

MAJOR AND MINOR

ALARM NO AND COM

TERMINALS

-48V A

REM

-48V B

COM

RET A

HSKP

HSKP

RET B

NO AND COM REMOTE

ALARM TERMINALS

HOUSEKEEPING ALARM

INPUT TERMINALS

AUDIBLE ALARM

MAJ

MIN

REM

FRAME GROUND

GND

FLC MPU ALARM TERMINALS

ALARM CUTOFF

ACT

IND

FLC MPU EXTERNAL ALARM

CUTOFF AND ACO INDICATOR

TERMINALS

1111-D

Figure 10. Battery Ground and Alarm Terminal

Housekeeping Alarm

5.16

The Housekeeping Alarm input is by a dry contact closure (loop) furnished from

customer equipment selected to originate Housekeeping Alarms. A pair of housekeeping input

leads connect to a pair of wire-wrap pins designated HSKP (see Figure 10) for each slot.

F. Wire DS1 Lines

5.17

Route the paired wire or cables into the shelf via front or back entry holes located on

each side (see Figure 9). Four DS1 lines connect to each slot via a terminal block or four 50-pin

Amp Champ female connectors. Connect T1 lines with 22 AWG shielded wire, ABAM, or

equivalent cable. If cable is used, the transmit and receive pair should be in separate cables. Wire

shield and cable drain wire terminations are provided near the terminal block. Twisted pair shield

and cable shield (drain wire) in the transmit and receive cables must be grounded to a shelf

(frame) ground at one end, preferably the equipment end.

Page 17

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Wire DS1 Lines Non-Connectorized Protect Systems

5.18

A shelf with four QFLC Protected systems requires up to 16 DS1 lines. The DS1 lines

connect to odd numbered slots that are occupied by the Working System modules as follows:

•

4 DS1 lines in slot 1 (Group 1)

•

4 DS1 lines in slot 3 (Group 3)

•

4 DS1 lines in slot 5 (Group 5)

•

4 DS1 lines in slot 7 (Group 7)

The T1 ACCESS wire-wrap terminal block is shown in Figure 11. EQ IN pins provide the

terminations for the DS1 lines input to a QFLC and the EQ OUT pins provide the terminations

for the DS1 lines receiving an output from a QFLC.

T1

LINES

T1 ACCESS

EQ IN (TO QFLC)

1

2

3

4

T

R

T

R

T

R

T

R

T

R

T

R

T

R

T

R

1

2

3

4

GROUP

5

6

7

8

SLOT

NUMBER

EQ OUT (FROM QFLC)

1

2

3

4

T

R

T

R

T

R

T

R

T

R

T

R

T

R

T

R

1

2

3

4

GROUP

5

6

7

8

1724-C

Figure 11. DS1 Wire-Wrap Pins

Wire DS1 Lines Connectorized Protect System

5.19

The DS1 line terminations for the working systems are connected to two 50-pin Amp

Champ connectors designed J51 and J53. DS1 EQ IN lines to the odd-numbered slots (input to

the QFLC module) connect to J53 and EQ OUT lines to the odd-numbered slots (DS1 output

from the QFLC module) connect to J51 as indicated in Table 3. The 50-pin connector locations

are shown in Figure 12 on page 20.

Page 18

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Table 3. Installer T1 Line Connections to 50-Pin Amp Champ Female Connectors

DS1

LINE

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

PIN #

T/R

SLOT

POS

EQ IN

CONN #

EQ OUT

CONN #

SLOT

POS

EQ IN

CONN #

EQ OUT

CONN #

1

R

1

J53

J51

2

J52

J50

26

T

1

J53

J51

2

J52

J50

2

R

1

J53

J51

2

J52

J50

27

T

1

J53

J51

2

J52

J50

3

R

1

J53

J51

2

J52

J50

28

T

1

J53

J51

2

J52

J50

4

R

1

J53

J51

2

J52

J50

29

T

1

J53

J51

2

J52

J50

5

R

3

J53

J51

4

J52

J50

30

T

3

J53

J51

4

J52

J50

6

R

3

J53

J51

4

J52

J50

31

T

3

J53

J51

4

J52

J50

7

R

3

J53

J51

4

J52

J50

32

T

3

J53

J51

4

J52

J50

8

R

3

J53

J51

4

J52

J50

33

T

3

J53

J51

4

J52

J50

9

R

5

J53

J51

6

J52

J50

34

T

5

J53

J51

6

J52

J50

10

R

5

J53

J51

6

J52

J50

35

T

5

J53

J51

6

J52

J50

11

R

5

J53

J51

6

J52

J50

36

T

5

J53

J51

6

J52

J50

12

R

5

J53

J51

6

J52

J50

37

T

5

J53

J51

6

J52

J50

13

R

7

J53

J51

8

J52

J50

38

T

7

J53

J51

8

J52

J50

14

R

7

J53

J51

8

J52

J50

39

T

7

J53

J51

8

J52

J50

15

R

7

J53

J51

8

J52

J50

40

T

7

J53

J51

8

J52

J50

16

R

7

J53

J51

8

J52

J50

41

T

7

J53

J51

8

J52

J50

Note 1.

EQ IN – Input to QFLC module

EQ OUT – Output from QFLC module.

Note 2.

Protect System mode - wire to connectors J53 and J51 for the odd numbered slots.

Non-Protect System mode - wire to the connectors J53, J51, J52, and J50 for all slots.

Page 19

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

J50

J51

J52

J53

2038-A

Figure 12. 50-Pin T1 Line Connectors

Wire DS1 Lines Non-Connectorized Non-Protect System

5.20

The T1 ACCESS terminal block (see Figure 11 on page 18) provides wire-wrap pins for

connecting up to 32 non-protected DS1 lines four lines to each of the eight slots. EQ IN pins

provide the terminals for the DS1 lines that furnish the input to a QFLC. EQ OUT pins provide

the terminals for the DS1 lines that receive an output from a QFLC. Group number is the same as

slot number.

Wire DS1 Lines Connectorized Non-Protect System

5.21

Installer connections for 32 DS1 EQ IN (input to the QFLC module) are made at

connector J53 for the odd-numbered slots and a J52 for the even-numbered slots (see Table 3).

Connections for the DS1 EQ OUT (output from the QFLC module) are made at connector J51

for the odd-numbered slots and at J50 for the even-numbered slots.

Page 20

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

G. Install Optical Fiber

Danger: Do not look into the ends of any optical fiber. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify that the optical

fibers are not active.

5.22

Route optical fiber into the shelf through one of the two entry holes located on each side

(see Figure 9 on page 16). Selection of the front or rear entry hole depends on how the shelf is

mounted and where the fiber is routed to the shelf.

5.23

Remove the top front panel by loosening the four captive screws.

5.24

Remove the blank panels from the slot to be used.

5.25

Be sure protective covers are on the fiber-optic connectors to prevent dust and damage to

the fiber ends. Be sure the fibers are tagged for identification.

Caution: Always allow sufficient fiber length to permit routing without severe bends.

The minimum bend radius for optical fibers is typically 1.5 inches (3.8 cm). Avoid

making any sharp bends in the fiber.

Warning: Before connecting the fibers, do not insert the plug-in module card edge

connector into the backplane connector. Exposure to invisible laser radiation may occur

if power is applied to the module before the fibers are attached.

Rear Entry Hole Fiber Installation

5.26

When the fibers enter the shelf through a rear, side panel entry hole, it may be necessary

to use the fiber hook that is attached inside the front panel (see Figure 13 on page 22). Place the

fiber as follows:

a.

Determine the slot that the fiber is to be routed to.

b.

Place the fiber connectors through the entry hole and catch them from the inside with the

fiber hook. (See Figure 14 on page 23.)

c.

Carefully draw the fibers out through the front of the shelf above the slots while feeding

the fiber through the entry hole, until the connectors extend 10 to 12 inches in front of

the destination slot.

d.

If fiber-fanning guides are provided, route the fibers through the guides above the

destination slot.

e.

Remove the fiber from the hook.

f.

Secure the fiber hook to the back of the front panel with the hook and pile strips.

g.

Secure the fibers near the entry hole with a releasable tie wrap so they can slide freely

through the wrap. Do not tighten the tie wrap around the fibers.

h.

If FLC modules are not installed at this time, the ends of the fibers routed into the shelf

should be arranged in the slots.

Page 21

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

DS3/OSS

INTERFACE

ACCESS

PANEL

QFLC

F6312-20

ENABLE

MAJOR

MINOR

RMT/HSKP

MOD FAIL

LOS Y

OPT OOF R

FORCE SW Y

APS LKOUT R

ONLINE G

STDBY Y

DS1

LOS/LPBK

1 RLB

NORMAL

UNEQPT

2

G=IN SERV

R=LOS

Y=PBK

T

OFF=UNEQP

3

4

LMPTST/

FORCE SW

RMT ALM

DISPLAY

RESET

7

5

8

6

4

3

2

ALM

1

FIBER

HOOK

TOP FRONT

PANEL

1710-A

Figure 13. Top Front Panel Removed

Page 22

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

FIBER HOOK

2039-A

Figure 14. Fiber Installed with Fiber Hook

Page 23

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Front Entry Hole Fiber Installation

5.27

When the fibers enter the mounting shelf through a front entry hole, proceed as follows:

Danger: Do not look into the ends of any optical fiber. Exposure to invisible laser

radiation may result. An optical power meter should be used to verify that the optical

fibers are not active.

a.

Carefully feed the fibers through the front entry hole and out through the front of the

shelf until they extend 10 to 12 inches beyond the destination slot.

Note: Fiber must be connected Working-To-Working and Protect-To-Protect. If

mismatched, the four QFLC LOS/LPBK LEDs will blink.

Caution: Electrostatic Discharge (ESD) protection must always be used while handling

circuit packs. An ESD ground jack is provided on the lower left front corner of the shelf

for connection of ESD wrist bands. Whenever circuit cards are being installed or

removed, always place the cards on ground, approved anti static mat. Stored cards

should also be wrapped in anti static material.

Warning: Before connecting the fibers, do not insert the plug-in module card edge

connector into the backplane connector. Exposure to invisible laser radiation may occur

if power is applied to the module before the fibers are attached.

b.

If fiber-fanning guides are provided, route the fibers through the guides above the

destination slot.

c.

Secure the fiber near the entry hole with a releasable tie wrap so they can slide freely

through the wrap. Do not tighten the tie wrap around the fibers.

d.

If the FLC modules are not being installed at this time, the ends of the fibers routed into

the shelf should be arranged in the slots.

H. FLC Module Installation

5.28

To install an FLC module, follow the installation instructions in the applicable user

manual listed in the Related Publications (page 2).

5.29

Reinstall the front panels covering the top of the shelf and unused slots.

Page 24

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

CLEANING AND MATING INSTRUCTIONS

Cleanliness affects the performance of an optical fiber system. Perform the following

procedures prior to installation. Clean all connectors, adapters, and attenuators before

making any connections. The following cleaning materials are recommended and may form

part of your cleaning kit:

• Lint-free laboratory wipes

• Isopropyl alcohol in pressurized dispenser

• Lint-free pipe cleaners

• Clean, dry, oil-free compressed air

Warning: Handle, use, and dispose of chemicals in accordance with the manufacturer's

instructions.

Note: When using canned compressed air, clear the nozzle with a short air blast before

blowing any parts clean. Do not shake the compressed air can. When using, keep the can

level to prevent liquid in the can from entering the air stream.

I.

Cleaning

Connectors/Terminators

1. Fold a clean, new wipe into a 2-inch by 2-inch square pad.

2. Moisten, but do not saturate, the pad with alcohol, making a spot approximately 1/2-inch

in diameter.

TM

Open the protective door (LX.5 only).

3. Press the ferrule end face into a wet spot on the wipe. Press and twist the ferrule so that a

hard wiping action takes place. Repeat twice, using a clean alcohol-moistened area each

time.

4. Press the ferrule end face into a dry spot on the wipe. Press and twist the ferrule so that a

hard wiping action takes place.

5. Close door (LX.5 only).

6. Discard the used pad.

Attenuators

1. For an exposed ferrule (in-line type), see the connector cleaning procedure; blow the

other end dry with clean compressed air.

2. Clean the bulkhead attenuators only by blowing with clean compressed air.

Adapters

1. Moisten one end of a lint-free pipe cleaner with alcohol.

2. Remove excess alcohol from the pipe cleaner with a clean wipe.

3. Insert the moistened pipe cleaner into either end of the adapter and scrub in and out so

that the inside surface of the adapter is wiped by the pipe cleaner. (For LX.5, lift the

adapter door using a second smaller pipe cleaner.) Repeat this step for the opposite end.

Page 25

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

4. Insert the dry end of the pipe cleaner into either end of the adapter to remove any

residual alcohol. For oversized adapters (biconic), slightly bow the middle of the pipe

cleaner for better surface contact. Repeat this step for the opposite end.

5. Blow the adapter dry with clean compressed air.

J. Mating

SC, E-2000

1. For the SC, align the housing key with the slot in the adapter.

2. Push the connector into the adapter until a click is heard or felt indicating the latching

system is engaged. When fully engaged, the white stripes on the sides of the SC housing

should be hidden inside the adapter.

FC, SMA, D4

1.

2.

3.

4.

Insert the ferrule tip into the adapter.

For D4 and FC types, align the key with the slot in the adapter.

Push the connector into the adapter until the coupling nut reaches the adapter housing.

Screw the coupling nut clockwise onto the adapter to complete the connection.

LX.5

1. Close the protective door.

2. Align slots with key on adapter.

3. Push the connector into the adapter until it clicks.

Biconic

1. Grasp the threaded cap of the connector and insert the ferrule into the adapter. For keyed

biconic, align the key on the connector with the arrow on the adapter/buildout.

2. Screw the cap clockwise in the adapter/buildout (finger tight only).

ST

1.

2.

3.

4.

Align the ferrule hub key with the slot in the adapter.

Insert the connector into the adapter until the coupling nut reaches the adapter housing.

Align the bayonet slots on the coupling nut with the pins on the outside of the adapter.

Push the coupling nut onto the adapter while rotating the coupler nut clockwise to lock

the bayonet and secure the connection.

Page 26

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

6. PRODUCT SUPPORT

ADC Customer Service Group provides expert pre-sales and post-sales support and training

for all its products.

Technical support is available 24 hours a day, 7 days a week by contacting the ADC

Technical Assistance Center (TAC).

Sales Assistance

800.366.3891 extension 73000

•

•

•

Quotation Proposals

Ordering and Delivery

General Product Information

•

Complete Solutions (from concept to

installation)

Network Design and Integration Testing

System Turn-Up and Testing

Network Monitoring (upstream or downstream)

Power Monitoring and Remote Surveillance

Service/Maintenance Agreements

Systems Operation

(USA and Canada)

952.917.3000

Fax: 952.917.3237

Systems Integration

800.366.3891, extension 73000 (USA

•

and Canada)

•

952.917.3000

•

•

•

•

Email: technical@adc.com

•

•

•

•

•

•

Technical Information

System/Network Configuration

Product Specification and Application

Training (product-specific)

Installation and Operation Assistance

Troubleshooting and Repair/Field Assistance

Online Technical Support

•

www.adc.com/Knowledge_Base/index.jsp

Online Technical Publications

•

www.adc.com/library1/

Product Return Department

•

ADC Return Material Authorization (RMA)

number and instructions must be obtained

before returning products.

ADC Technical Assistance Center

800.366.3891, ext.73223

952.917.3223

Fax: 952.917.3244

800.366.3891 ext. 73748 or

952.917.3748

Fax: 952.917.3237

Email: repair&return@adc.com

All 800 lines are toll-free in the USA and Canada.

© 2002, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

Page 27

© 2002, ADC Telecommunications, Inc.

ADCP-UM-61-118-11

Issue 11, March, 2002

Page 28

© 2002, ADC Telecommunications, Inc.

ADC DSL Systems, Inc.

14402 Franklin Avenue

Tustin, CA 92780-7013

Tel: 714.832.9922

Fax: 714.832.9924

Technical Assistance

Tel: 800.366.3891 x73223

Tel: 952.917.3223

Fax: 952.917.3244

ISO 9001/TL 9000

DOCUMENT: ADCP-UM-61-118-11, ISSUE 11

´,1[¶0w¨

DNV Certification, Inc.

REGISTERED FIRM

1217590