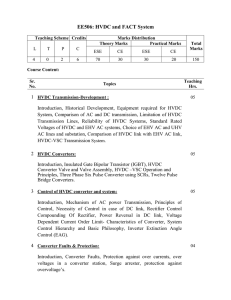

Public Utilities Board

advertisement