medium-voltage metal-enclosed switchgear

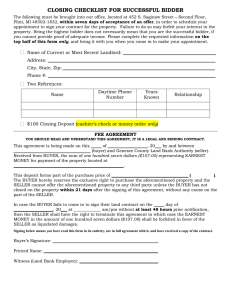

advertisement