edilon)(sedra Filler Blocks

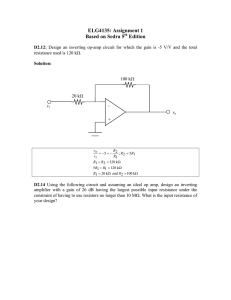

advertisement

edilon)(sedra Filler Blocks edilon)(sedra SDS and SDS-M type for tram tracks Headquarters edilon)(sedra GmbH Nijverheidsweg 23 NL-2031 CN Haarlem P.O. Box 1000 2003 RZ Haarlem T +31 / (0)23 / 531 95 19 F +31 / (0)23 / 531 07 51 mail@edilonsedra.com www.edilonsedra.com Schoßbergstraße 19 D-65201 Wiesbaden T +49 / (0)611 / 928 01-0 F +49 / (0)611 / 928 01-15 02-2014 watch us on edilon)(sedra group bv green solution Always a step ahead in rail systems! www.edilonsedra.com General information concerning edilon)(sedra Filler Blocks edilon)(sedra SDS and SDS-M type for tram tracks Elastomeric rail web Filler Blocks are invented and patented by edilon)(sedra. edilon)(sedra is offering a wide range of Filler Block designs for many different types of grooved and vignol rails and for various application fields such as in-street running track, turf track, special track work, depots, level crossings as well as for crane tracks. All kind of installation accessories, well tested and proven, to perfectly insulate/isolate the track, such as rail foot profiles, tiebar isolation profiles, factory isolated tie-bars, plastic cover caps, rail anchors, mats and strips, electrical insulating adhesives and pasty fillers and many others are provided by edilon)(sedra. Expertise where it matters Features )( Vibration dampening (dBv) in vertical and lateral axis )( Noise damping (dBA), depending on type of track construction Various rail transportation is an indispensable part of and proven, including the resilient rail joint sealant material )( Constructive function, elastic component to fill the rail web and to create a rail joint modern society, which has to meet environmental regula- in case of an embedded in-street track system providing to )( Electrical insulation of the track ( DIN 50122-2, DIN VDE 0100-610, DIN IEC 60093, BOStrab.) tions for noise and vibrations. Not only can edilon)(sedra match the max. vertical track deflection under operational )( Aeration ( reduction of corrosion in turf tracks) provide resilient solutions to meet noise and vibration limits, track conditions. )( Possibility for covering the track (e.g. turf track up to the top of the rail) the products and systems are designed for durability and sustainability. edilon)(sedra SDS and SDS-M type Filler Blocks are an integral part to form a resilient system; Filler Blocks acting edilon)(sedra has invented the elastomeric (recycled rub- as a spring to reduce sound emissions. ber based) rail web Filler Blocks to form the internationally well-known edilon)(sedra SDS (Sound Damping System), The Filler Blocks are highly compacted and bounded by becoming a more and more global technical standard for the use of polyurethane material to ensure very low water modern tramway track building, for electrical track insu- absorption ( ≤ 1 %, mass related) and to ensure a high lation and vibration and sound dampening. edilon)(sedra amount of electrical insulation (DIN 50122-2). This also Filler Blocks have been recognized for its accurate fit to the ensures a high degree of vibration (dBv) damping and noise rail, easy handling and easy and swipe installation with no (dBA) reduction. requirement of expensive specialized heavy duty machinery. edilon)(sedra Filler Blocks are supplied as part of the edilon)(sedra SDS advanced track systems, fully tested 2 3 edilon)(sedra Filler Blocks Improvement in design, function and performance Material development of edilon)(sedra Filler Blocks General advantages: Years of development, extensive testing, laboratory and )( Good damping features (dBv, dBA) field tests established the unique edilon)(sedra elastomeric )( Good electrical insulation properties (DIN 50122-2) composite (plastic / elastic) material compound, based on )( Providing defined bedding modules (N/mm³) specially pre-selected SBR rubber granules bounded by )( Corrosion protection using high grade polyurethane material. Meanwhile being )( Temperature resistance up to 280°C a technical standard the Filler Blocks provide excellent )( Fully proven to latest technical standard (DIN 45673-8) properties in terms of vertical and lateral stability, vibration )( Absorption of track deformations caused by horizontal & sound damping as well as electrical insulation of the track. and vertical forces )( Fitting accuracy )( High compressive strength in vertical and lateral axis edilon)(sedra Filler Block features / advantages / application fields: )( Compatibility with the track (hot and/or cold joint sealing )( In-street running/road embedded track application )( Wide spectrum of application (in-street track, turf track, )( Turf track application )( Special track work (switches, junctions) application )( Depot application compounds) special track works (switches), depots, level crossings, crane rails) )( Quick installation )( Easy handling )( Onsite and offsite fitting to the rails feasible )( Easy to cut on site, when necessary Research and Testing Testing, test equipment, approvals edilon)(sedra Filler Blocks have been extensively tested to the latest international technical standard such as DIN 45673-8, DIN 50122-2 and many others. )( )( )( )( Stability in lateral and vertical axis Compressive strength Water absorption (EN ISO 62) Electrical insulation properties, DIN EN 50122-2 (VDE 0115-4), DIN IEC 60093 (VDE 0303-30) )( )( )( )( )( )( )( )( )( Weather resistance Freeze-thaw resistance Resistance against acids, bases, oil & grease Damping properties (dBv, dBA) Temperature resistance (up to 280°C) Classification of flammability (DIN 4102-1) Skid resistance (DIN EN 13036-4) Environmental impact (Evaluation of physiological acceptability) Tested and proven as a fully track according to the latest technical standard of DIN 45673-8 (test specimen type 1, 2 and 3). )( )( Resistance against micro-organism and bacteria Standard of DIN 45673-8 (test method 2 and 3) )( Durability / long lasting )( Cost effectiveness )( 100 % Recycable 4 5 edilon)(sedra Filler Blocks Installation, Tools & Equipment edilon)(sedra rail web Filler Blocks stand for economic installation and do The world is our workplace not require any special heavy duty machinery for the installation. Quality assurance References, track record edilon)(sedra has available all necessary test equipment, edilon)(sedra Filler Blocks have successfully proven, many edilon)(sedra Services state-of-the-art, to provide extensive in-house QA control. times even under harsh climate conditions, since decades All edilon)(sedra Filler Blocks as components as well all around the world with some thousends of km of track as completed systems have been extensively tested in service with a none-failure track record to date. Extract at various numerous test laboratories and technical of edilon)(sedra global reference-list of Filler Blocks: all universities, e.g. TU Munich, TU Louvain, TU Berlin, TU over Western Europe, Eastern Europe, MENA (region Dresden, TU Prag, Györ Budapest, TAW Wuppertal and Middle East and Africa) and many other countries. edilon)(sedra is also offering comprehensive services such as: - Engineering - Consultancy - Vibration attenuation & insertion loss (dB) prognosis acoustic studies - Implementation / installation - Installation training - Supervision others against the latest technical standards such as DIN 50122-2, DIN 45673-8. - Professional project management - High degree of logistic service 6 7