Asymptotic homogenization of 3-D microstructures

advertisement

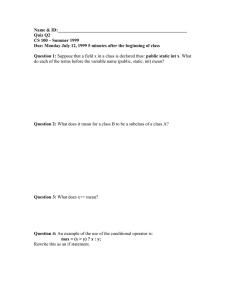

Asymptotic Homogenization of 3-D Microstructures Simulated Either by the Multi-phase Field Method or by Cellular Automata G. Laschet1, M. Spekowius2, M. Apel1 and Ch. Hopmann2 1ACCESS 2Institute e.V, RWTH Aachen University, Germany of Plastics Processing, RWTH Aachen University, Germany 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Multiscale Simulation of Manufacturing Processes – Linepipe Tube Heating Multi-Pass Rolling Cooling U-O-Forming UP-Welding 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Calibration Multiscale Analysis Tools asymptotic expansion interface tools microscale homogenization HOMAT Mesh2Homat Mesh2XXX effect. thermoelastic properties: ● Hooke matrix, eigenstrain, ● thermal expansion coeff effect. thermal conductivity Mesh2Abaqus effect. Darcy permeability virtual uniaxial tests ■ 3-D microstructures simulated by: ● ABAQUS multi-phase field method for metals ● cellular automata for semi-crystalline plastics effect. elastoplastic flow curves ■ real 3-D microstructures digitalized via CT ■ synthetic 3-D microstructures 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Features of HOMAT version 5.1 ● Several homogenizations in one run: f. ex. at different specified T ● Multilayer or monolayer homogenization for selected layers ● different homogenization analyses can be achieved in one run: thermal, mechanical, … ● homogenization models: 3-D (default), 2-D (plane strain) or 2-D (plane stress) ● Output: - microscopic displacements and implicit fluxes / forces on the initial or deformed RVE (VTK files viewed in Paraview ) - effective properties in Abaqus format (.mat file) ● HOMAT detects automatically the double, period. nodes on the wedges and fixes directly the rigid body motions ● Localization analysis in critical macroscale regions 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Application 1: Austenite to Ferrite Transformation Austenite Ferrite High temperature phase fcc-Fe (austenite) transforms into bcc-Fe (ferrite) during cooling C diffusion and/or interface kinetics controls the process rate The molar volume of ferrite is larger than austenite (low C steels) 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Austenite to Ferrite Transformation - Problem Definition (I) low carbon steel: Fe-0.023C-0.17Mn-0.009Si [wt %] ■ Cooling curve extracted from the thermal analysis of sand casting of a graded steel disk TC 1 ■ Statistical homogenization procedure1 determines the RVE size of a random grain microstructure with no specific texture ■ RVE: microstructure generated by Voronoi tesselation: 1543cells, non-uniform cooling 213 grains with - cell spacing: ∆x = 0.5 µm - mean grain size: <rgrain = 8 µm> quasi-isotropic, random orientation distribution via a novel procedure 1G. Laschet, P. Hul and M. Apel, WCCM-14, Barcelona, July 2014 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Austenite to Ferrite Transformation: Problem Definition (II) ■ Phase properties: ● temperature dependent surfacial energies and mobilities: cm4/(Js) = austenite: µ0 = 35 cm4/(Js) ; ferrite: µ0 =150 cm4/(Js) ● temp. and conc. dependent elastic constants (cubic symmetry)1, density2 and mole volume Zener anisotropy factor: - austenite: 3.723 - ferrite: 1Ghosh 2.389 and Olson, Act. Mat., vol. 50 (2002) 2655-75. 2Cho et al, Met. And Mat. Trans. A, vol. 42 (2011) 2094-2106 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Multi-Phase Field Simulation Results on the RVE T= 1000°C, fα=0% t=0 s ■ austenite ■ ferrite T= 862°C, fα=9.2% T= 844°C, fα=49.5% T= 699°C, fa=99.6% t = 38 s t = 42 s t = 120 s ■ transformation kinetics is simulated as C diffusion process ■ due to low carbon content, the austenite phase transforms into ferrite without cementite formation but with residual austenite (high C concentration) final state: 981 ferrite + 98 residual austenite grains 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc <r>=4.47 µm Variation of Effective Young and Shear Modules During Phase Transformation Ehom Ghom ■ Ehom (T) and Ghom(T) decrease strongly in the range 826°C -856°C ■ Eii(T) / Gij(T) present max. deviation from Em / Gm for pure austenite state: ∆Em,2= -0.95% ; ∆Gm,13= -1.80% quasi-isotropic global behaviour predicted ■ Em (T) and Gm (T) ) transferred to the macrosimulation result of practical interest 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Effective Volumetric Eigenstrain and Thermal Expansion Coefficients αhom κhom ■ T >860°C: eigenstrain κii decreases due to thermal contraction of austenite (slope = αii) ■ 860°C < T< 825°C: phase transformation κii increases as Vmol,fer > Vmol,aust ■ T < 825°C: κii diminishes again due to αfer ■ residual orthotropy of αhom: Dα11 max. for pure austenite (-16.88%); reduces to -5.43% for ferrite 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Variation of Effective Poisson Coefficients During Phase Transformation ■ mean Poisson coeff. varies strongly from austenite (νm ≈0.341) to ferrite (νm ≈ 0.280) 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc macroscale Example 2: Integrative Multiscale Simulation of the Injection Moulding Process structural analysis with effective local material properties with ABAQUS Multi-phase flow and heat transfer σ, ε simulation with COMSOL microscale T, v, p homogenisation 3-D prediction of PP with HOMAT microstructure with Eh, νh, αh, λh SphaeroSim ΦS, κ R. Spina et al., Jnl. of Mater. Forming, 2014 Spekowius et al, WCCM-14, Barcelona, July 2014 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Zoom in the Structural Composition of a Semi-Crystalline Thermoplastic crystalline/amorphous lamella folded molecular chain molecular chain: a,b,c: dimensions of the crystalline mono-bloc spherulite sample 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Mechanical Behaviour of the Amorphous and Crystalline Phases ■ Difficulties: - amorph and crystalline phases are inseparable - it is impossible to produce a pure amorphous / crystalline phase quasi-impossibility to characterize each phase separetely ■ Spherulite of a 3 mm PP plate amorphous phase: assumed to be in a rubbery state at 20°C G = 0.3 Mpa ; E = 0.9 Mpa et ν = 0.49993 ■ crystalline phase: ● Tashiro & al. (2002) achieve molecular dynamic calculations ● Sakurada & Kaji (70, 75): X-ray diffraction measurements 1.26 1.27 0 0.8 0 2.8 1.26 − 0.36 3.1 1.15 0 0 1.82 1.95 − 0.57 0 0 21.4 cr = HPP − 0 0 0 1.85 0 0.12 [Gpa] 0.8 − 0.36 − 0.57 0 1.735 0 − 0 0 0 0.12 0 1.75 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Two-Level Homogenization Scheme of Semi-Crystalline Thermoplastics ■ Model: successive homogenizations at different scales: ● nanoscale: homogenization of the amorphous-crystalline bilamina ● microscale: spherulite homogenization with a radial distribution of equivalent bilamina around the spherulite center ■ F.E. discretization of the spherulites ● two random numbers specified per spherulite ● in each Gauss point: r r r - the eff. Hooke matrix of the bilamina is adopted with PG − C = e1 r r r - e2 ,e3 defined with the random numbers perpendicularly to e1 3 Euler angles: θ, φ, ψ ■ HOMAT ● the orientation discontinuity at the spherulite interfaces ● the variation of the bilamina orientation in each spherulite 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Microstructure Prediction of an Injected Moulded 2mm PP Plate ■ Injection moulding process parameters: tool = 80°C ; melt = 280°C larger spherulites below the thin microstructure at the skin ΦS 5 elements ■ Mould filling and heat transfer analysis: model almost homogeneous microstructure with 124264 elements spherulite diameter ■ 3-D Sphaerosim simulations for the selected 5 elements also larger spherulites below the very thin skin microstructure 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Homogenization of the Bilamina of isotactic PP at the Nanoscale ■ Definition of the bilamina RVE: ● length ≈ 1500 nm; thickness = 15 nm (X-ray measurements) ● width: wc = 60 nm; cristallinity degree: 46 % wa= 62.5 nm ● 2D periodic B.C are applied - 2nd degree hexahedron elements ● challenging problem due to incompressibiliy of amorphous phase and strong anisotropy of the crystalline phase ■ r r r Effective Hooke matrix [GPa] is nearly monoclinic in the local axis system e1, e 2 , e 3 eff H bila = [Mpa] 10268 1910 1780 − 0.007 − 185.7 2151 1923 − 0.006 − 76.18 2469 - 0.008 342.1 62.07 0.007 S Y 795.5 M 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc 0.008 0.009 − 5.4 − 0. 48.55 0.004 2mm PP Plate: Effective Young Modules over the Thickness ■ Reference: uniaxial test on an extracted bar: EX = 1860. ; EY = 1650. ■ Em = 1755 MPa 2-level homogenization scheme predicts noticeable orthotropic effective behaviour with EY < EX < EZ same in-plane orthotropy as in unxial test ● EX,hom agrees with EX,exp but EY,hom underestimates significantly EY,exp ● EY and EX are lower in the center and max.at the borders, whereas EZ decreases over the thickness 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc 2mm PP Plate: Microscopic Fields in Z Direction at the Lower Border RVE .[N] [µm] 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc Conclusion and Outlook ■ Phase-field simulations combined with HOMAT allow the prediction of a full set of effective thermo-elastic properties of a steel microstructure during γ-α phase transformation ■ Work in progress: ● elastoplastic flow curves ● smoothing of the grain boundaries and FE remeshing of the microstructure ■ Development of a 2-level homog. scheme for semi-crystalline thermoplastics which is able to predict the observed anisotropy of the injected moulded plate ■ Outlook: ● extension to a 3-level homog. scheme by adding a third level: effect. properties of folded, helicoidal molecular chains ● molecule orientation has to be taken into account ● derivation of effective viscoelastic and viscoplastic properties Funding by the DFG as part of the Cluster of Excellence "Integrative Production Technology for HighWage Countries“ is gratefully acknowledged. 1st Int. Workshop on Software Solutions for ICME 24th-27th June 2014, Aachen / Rolduc