C4-PS3 Lightning and UHV

advertisement

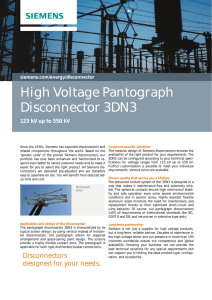

2014 Paris Session C4-202 VFTO simulation and testing for 550kV and 800kV GIS disconnectors S. SUN*, G. TREMOUILLE**, G. MARQUEZIN* T. BERTELOOT**, P. VINSON**, A. GIRODET** Alstom GRID *China & **France SUMMARY Bus-charging current switching operation by disconnectors is a sensitive point as Very Fast Transient Overvoltages (VFTO) are generated and propagate inside the whole substation. During such operations, when a disconnector is operating a section of unloaded busbar, multiple restrikes occur between contacts and one VFTO is generated for each flashover. This kind of overvoltage has very short and steep wave front and may over-stress the insulation of the GIS and the connected equipment such as power transformers. VFTO are already observed on GIS up to 550 kV but their impact is limited at these levels. From 800 kV and above, VFTO severity may become a real issue. VFTO, characterized by its waveshape and its frequency content, depends on many factors such as substation topology and location in the GIS. Moreover, the magnitude and the number of VFTO also depend on the disconnector’s inter-contact insulation properties and its operating speed. This article presents electromagnetic transient simulations of VFTO phenomena based on the recommended configuration for bus-charging current switching test of IEC standard 62271-102. A laboratory test of a 550kV gas-insulated disconnector is also presented to make comparison between simulation results and measurements. The focus is done on the consistency of the simulation with the laboratory test results including: Modelling of the bus-charging current switching test circuit including voltage generator, voltage divider, bushing, busbar and disconnector; Improvement of test circuit components and refinement of related electromagnetic transient (EMT) parameters. Then, VFTO are simulated for a compact 765 kV GIS layout considering several substation configurations. Calculations are performed with a conservative maximal trapped charge and a more realistic prospective trapped charge. It appears that a conservative trapped charge leads to a VFTO overestimation. Finally, the number of VFTO and their magnitude during full closing and opening operations of an 800 kV disconnector are discussed. Results indicate that a slow operating disconnector is safer than a fast operating disconnector from VFTO magnitudes point of view. KEYWORDS UHV, Insulation coordination, VFTO, Trapped charge, EMT, Modelling shujie.sun@alstom.com INTRODUCTION Very Fast Transient Overvoltage (VFTO) refers to high–frequency transient overvoltage with steep wave front in the range of 100 ns. When a disconnector is operating a section of unloaded busbar, multiple restrikes occur between contacts. A restrike occurs as soon as the inter-contact breakdown voltage is reached and one VFTO is generated for each arc restrike. The number of restrikes mainly depends on the disconnector’s inter-contact insulation properties and the operating speed [1] [2]. In modern substations, it is a routine operation for disconnectors to switch unloaded busbars, thus VFTO are faced frequently and may over-stress internal insulation of transformers and other equipment connected to the network. VFTO phenomenon can be easily managed up to 550 kV and the impact on insulation is limited. From 800 kV and especially in Ultra-High Voltage substations, VFTO level may become closer to lightning impulse withstand level. It is therefore necessary to keep a dielectric safety margin during bus-charging current switching and offer effective measures to reduce VFTO if necessary. This article firstly presents bus-charging current switching test on a 550 kV gas-insulated disconnector with a focus on VFTO measurement (part 1). VFTO simulations with the test circuit are also presented and comparisons are made between measurements and simulations. The study is carried out with the electrical magnetic transient simulation software PSCAD/EMTDC (part 2). Moreover, trapped charge statistical distribution is presented to prove that the maximal trapped charge of a disconnector is not necessarily 1.0 pu (part 3). Then, calculations are performed on a 765 kV substation to estimate VFTO level at different locations for several substation configurations. To do this, two scenarios of trapped charge behaviour are considered (part 4.1). Finally, the number of VFTO regarding their magnitudes during full opening and closing processes of an 800 kV disconnector is calculated for several operating speeds (part 4.2). 1 – BUS-CHARGING CURRENT SWITCHING TEST ON A 550kV GIS According to IEC 62271-102 [3], bus-charging current switching test duty 1 (TD1) is described as below. In section 1, section 2 and section 3, 1.0 pu refers to 449 kVp i.e. 550 x √2 / √3. Figure 1 shows the configuration of the test circuit. DT represents the disconnector under test and DA represents the auxiliary disconnector. C1 is a lumped capacitance at power supply side. The load side is a section of busbar with a d2 length, where d2 is the distance between open contacts of DT to open contact of DA. The connection to the supply side shall be realised by another section of busbar with a d1 length, where d1 is the distance between open contacts of the DT to the bushing connection. Figure 1 – TD1 test circuit During TD1 test and for slow disconnectors, DT must perform 50 close-open operations with no flashover to the ground. Before starting a DT closing operation, the load side shall be charged by a DC voltage source U2 for one minute and disconnected by DA. Source side is connected to an AC voltage source U1. The values of U1 and U2 are as following: U1 = AC voltage [kVrms] U2 = DC voltage [kVp] U1 = 1.1 x Un / √3 U2 = 1.1 x Un x √2 / √3 U2 is a pre-charged voltage used to simulate the maximal possible trapped charged. Figure 2 shows the laboratory test circuit mentioned above where the test object is a 550 kV gas-insulated disconnector. The test circuit includes AC voltage generator, voltage dividers, bushings, busbars, DT and DA disconnectors, DC voltage generator and VFTO sensors. 1 Figure 2 – 550 kV gas-insulated disconnector during TD1 During TD1, the load side sensor is at 45 cm from the disconnector arcing contact while the source side sensor is at 15 cm from the disconnector arcing contact. The red circles in Figure 2 show the location of each sensor on the test assembly. The peak value of the first VFTO during a closing process shall not be less than 1.4pu and time to peak shall be less than 500 ns. Figure 3 shows this first VFTO at load side of the DS. The VFTO peak is 1.48 pu and the front wave is 350 ns, which meet IEC requirements. 1.6 1.4 Voltage - pu As a pre-test requirement and to verify overvoltage factor of the test circuit, the first test is be conducted with 1.0 pu AC voltage on source side while the voltage on load side is 0 kV before the closing process. 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Figure 3 – First VFTO with no DC pre-charge on load side During TD1, 50 close-open operations must be performed without reconditioning the disconnector. The closing operation is performed with an AC voltage on source side at 1.1 pu and a floating busbar pre-charged at -1.1 pu which corresponds to the maximal trapped charge possible. Then the opening operation is done with whole bus-section d2 energized at 1.1 pu. At the end of each opening process, it is possible to measure the remaining voltage on the floating busbar, called the trapped charge. 2.4 2.0 1.6 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Voltage - pu Voltage - pu The first VFTO of the closing process were measured on source and load side. They are presented in Figure 4. 2.4 2.0 1.6 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Figure 4 – VFTO measurements during TD1: source side on the left and load side on the right 2 2 – VFTO SIMULATION Digital simulation based on the simplified GIS modelling in PSCAD/EMTDC simulation software is a well-accepted method to evaluate the VFTO magnitudes. This solution can be recommended to ensure convenient insulation coordination and by consequence no disruptive discharge on equipment. Due to the travelling nature of the VFTO, GIS components can be modelled as electrical equivalent circuits composed by lumped capacitors and lines with distributed parameters including damping resistance, surge impedance and travelling time. The quality of the simulation depends on the accuracy of the model’s components. Main components of the IEC bus-charging current switching test assembly are disconnectors, bushings, T-junctions and busbar elements. According to IEC 60071-4 [4], test circuit components can be modelled as surge impedance combined with related capacitances. Parameters such as surge impedances, capacitances and damping resistances can be calculated based on GIS geometry. Figure 5 shows the EMT models used for GIS components. L1 S1 L1 L2 L1 L2 L2 C1 C2 C C2 a) Disconnector model C b) Bushing model c) T-junction model Figure 5 – PSCAD/EMTDC modeling components Figure 6 shows PSCAD/EMTDC simulation of the first VFTO during a pre-test closing process with no DC pre-charged voltage. The voltage peak is 1.58 pu while time to peak is 340 ns. It is pretty close to measurement where voltage peak was 1.48 pu and time to peak was 350 ns. Voltage - pu 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Voltage - pu Figure 6 – Comparison between simulation (green curve) and measurement (blue curve) of pre-test VFTO 2.4 2.0 1.6 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Figure 7 shows VFTO at source side and load side during a TD1 closing process. With -1.1 pu on load side, the simulated first VFTO magnitude during the closing operation reach 2.07 pu on source side and 2.41 pu on load side. In both cases, the peak values of the simulated VFTO are close to the measurements which were 2.14 pu on source side and 2.26 pu on load side. Voltage - pu 1.6 2.4 2.0 1.6 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -2.0E-07 2.0E-07 6.0E-07 1.0E-06 1.4E-06 1.8E-06 2.2E-06 Time - s Figure 7 – Comparison between simulation (green curves) and measurement of the first VFTO during a TD1 closing 3 3 – TRAPPED CHARGE VOLTAGE A DC voltage called trapped charge remains on the load side after each opening operation once restrike scenario is over. Its value comes from the last breakdown event between disconnector’s contacts. The trapped charge value after an opening process will determine among other factors the value of the first VFTO magnitude of the next closing process. Indeed, the peak value of the VFTO magnitude is according to formula (1) where K is a factor depending on the circuit, ΔU is the intercontact breakdown voltage at breakdown instant and Q is the load side voltage before the flashover [5]. VFTO = K(x,t) * ΔU + Q (1) The worst VFTO magnitude for a closing operation happens when the voltage on the power source side is at the positive crest value while the trapped charge on the floating busbar is at the negative crest value. This worst VFTO is obtained for each closing process during TD1 where ΔU = 2.2 pu and Q = -1.1 pu. The trapped charge is always different from an opening to the other. Its amplitude depends on the disconnector’s characteristics such as opening speed, gas nature and pressure [6]. However, trapped charged statistical distribution can be estimated thanks to laboratory tests. Indeed, laboratory must conduct 50 disconnector close-open operations to complete TD1 for slow motion disconnectors and for each opening operation the trapped charge on the load side is recorded. Probability As an example, Figure 8 shows the trapped charge distribution of the 550 kV GIS disconnector. It can be found that the trapped charge value distribution for 50 times tests is closed to a Gaussian distribution. The mean trapped charge observed is 0.58 pu and the standard deviation is 0.074 pu. From the simplified statistical method of insulation coordination point of view [7], the 2 % overvoltage value Ue2, the value having a 2 % probability of being exceeded, is 0.66 pu. Therefore, during the 550 kV gas-insulated disconnector TD1, 98% of the trapped charges are under 0.66 pu. 24% 22% 20% 18% 16% 14% 12% 10% 8% 6% 4% 2% 0% -0.30 -0.36 -0.42 -0.48 -0.54 -0.60 -0.66 -0.72 -0.78 Measured trapped charge value in pu Figure 8 – Trapped charge distribution and comparison with Gaussian distribution law. In the network simulations, the assumption of a maximal trapped charge of 1.0 pu is therefore too conservative and not representative of real disconnector behaviour on the grid. It would lead to overestimate the VFTO magnitudes inside the GIS substation for that particular disconnector as we will explain in the next chapter. 4 4 – 800kV GIS substation VFTO simulation As described before, switching operation of floating busbar is common for disconnector in GIS substations. For 800 kV GIS and above, VFTO simulation is therefore important to ensure enough safety margin regarding dielectric strength. Figure 9 shows a 3D view of a compact 800 kV GIS arrangement where circuit-breakers, disconnectors, current transformers and busbar elements are visible. Figure 9 – 800 kV GIS arrangement (single phase view) 4.1 – Simulation of the first VFTO during a closing process VFTO simulations were performed based on the 765 kV GIS substation single line diagram shown in Figure 10. In this section, 1.0 pu refers to 625 kVp i.e. 765 x √2 / √3. Out going line1 Out going line2 Line Reactor DS114 DS104 DS101 DS111 DS102 DS112 CB10 Based on the GIS layout, component’s geometries and PSCAD/EMTDC modelling methodology, VFTO caused by disconnector operations can be simulated in all parts of the GIS substation like illustrated in chapter 2. Based on formula (1), VFTO level depends on K factor. It appears that K value depends on substation configuration (type of equipment submitted to wave propagation) but also on measurement position due to reflexion and transmission coefficient at the discontinuities. For instance, for a same substation configuration, K value at disconnector position is different from K value at power transformer entrance. 765kV BUS 1 DS105 DS115 AUXBUS CB11 DS11 DS41 DS71 CB01 CB04 CB07 DS12 DS42 DS72 DS21 DS51 DS81 CB02 CB05 CB08 DS22 DS52 DS82 DS31 DS61 DS91 CB03 CB06 CB09 DS32 DS62 DS93 DS92 765kV BUS 2 DS33 DS64 DS34 DS63 AUXBUS 765/400kV Transformer 1 765/400kV Transformer 2 Bus Reactor Figure 10 – 765 kV GIS substation single line diagram To calculate the maximal VFTO, the maximal trapped charge of 1.0 pu is often used. However, we saw that it is not a real case as some disconnectors may induce maximal trapped charge much lower than 1.0 pu. For the 765 kV substation study, two cases were considered: a trapped charge of 1.0 pu, which is the most critical case, and a more realistic trapped charge of 0.66 pu which should be close to the maximal trapped charge of the 800 kV gas-insulated disconnector whose design derived from the 550 kV disconnector one. 5 In following simulations, four substation configurations according to Figure 11 are simulated to investigate VFTO values. For each configuration, the first VFTO of a closing operation is calculated at four different locations. The operated disconnectors are inside green squares. Out going line1 Out going line1 Out going line1 Out going line1 DS101 DS101 Out going line2 Line Reactor DS104 DS101 DS101 DS114 DS111 DS102 DS112 CB11 CB10 765kV BUS 765kV BUS DS42 DS51 DS51 CB05 DS41 DS71 CB04 CB07 DS72 DS42 CB05 DS52 DS52 DS61 DS63 DS63 DS51 DS51 DS81 CB05 CB05 CB08 DS52 DS52 DS82 DS61 DS61 DS91 CB09 CB06 DS32 765kV BUS 2 765kV BUS DS63 DS63 765/400kV Transformer 2 a) Case 1 765/400kV Transformer 2 DS93 DS92 DS62 765/400kV Transformer 2 765/400kV Transformer 2 Bus Reactor b) Case 2 c) Case 3 d) Case 4 Figure 11 – Simulation cases: operated disconnectors are into the green squares Table 1 sums up simulation configurations and VFTO values, as well as the K value for the different locations. Among all simulated configurations, the maximum simulated VFTO magnitude is 2.62 pu at bushing location (case 3), where DS32 is connected by a long busbar and far away from source side. A first point to notice is that the distance between the operated disconnector and the main transformer affects VFTO value. For instance, between case 1 and case 2, substation configuration is almost the same as the only difference is the operated disconnector. In case 1, operated disconnector DS61 is closer to the transformer than DS42, operated in case 2. It results in a lower VFTO at power transformer entrance for the shorter distance: 1.56 pu for case 1 vs. 1.67 pu for case 2. Second point to notice is the fact that with a -0.66 pu trapped charge, the VFTO are much lower than VFTO with a -1.0 pu trapped charge. Overestimation in this case is up to 17.4 %. For a VFTO magnitude assessment, a -1.0 pu trapped charge is a too conservative assumption. Table 1 – VFTO simulation cases of 765 kV GIS substation VFTO value (pu) Case No Operated DS DS Load side DS source side Transformer entrance Bushing 1.78 1.35 1.34 1.71 -1. 2.56 1.70 1.67 2.43 -0.66 2.30 1.58 1.56 2.19 1.66 1.31 1.27 1.57 -1 2.36 1.61 1.54 2.14 -0.66 2.12 1.59 1.51 1.46 1.49 1.29 1.95 1.81 -1 2.17 1.92 1.58 2.62 -0.66 1.99 1.78 1.77 1.33 1.48 1.31 2.23 1.77 -1 2.58 1.65 1.62 2.54 -0.66 2.31 1.55 1.52 2.29 K 1 DS61 Trapped charge (pu) K 2 DS42 Trapped charge (pu) K 3 DS32 Trapped charge (pu) K 4 DS61 Trapped charge (pu) 6 4.2 – VFTO magnitude and number for full opening and closing processes A solution to decrease the trapped charge value is to decrease the opening speed of the disconnector [6]. However, a lower speed implies more restrikes during both opening and closing processes. The aim of this part is to estimate VFTO amplitude and occurrence for complete opening and closing processes of an 800 kV disconnector versus different operating speeds. Dielectric strength of the gap is estimated to assess the restrike mechanism leading to a complete VFTO pattern. This dielectric strength depends on the disconnector’s geometry, gas type and gas pressure. Therefore, presented results are specific to the considered geometry but are illustrating global tendencies. In this section, 1.0 pu refers to 653 kVp i.e. 800 x √2 / √3 a. Opening processes During the opening process, flashovers occur when the positive or the negative inter-contact breakdown voltage of the gap ΔU is reached. A thousand opening processes are simulated for three different speeds: 0.10 m/s, 0.80 m/s and 1.60 m/s while 653 kVp AC voltage is applied on the fixed side of the disconnector. For each simulation, all the ΔU and Q value are listed to calculate VFTO values. The K factor is fixed at 2.0 which is a conservative value used to cover most cases possible inside the GIS. Figure 12 shows the trapped charge statistical distribution as well as the number of VFTO for the 1000 opening processes. The VFTO values are compared to the 800 kV GIS lightning impulse withstand level (LIWL) from IEC standard i.e. 2100 kVp. TC max 0.61 pu 1.60 m/s 0.80 m/s 0.10 m/s 15 TC max 0.92 pu 10 5 TC max 1.00 pu -1.0 -0.5 1479 0 0 0 0 0.0 0.5 Trapped charge - pu 1.0 4406 1.60 m/s 0.80 m/s 0.10 m/s Number of VFTO Probability - % 20 90% LI to 100% LI 285 389 332 15 22 0 110 118 80% LI to 90% LI 70% LI to 80% LI 60% LI to 70% LI 805 460 50% LI to 60% LI VFTO level - K = 2.0 Figure 12 – Trapped charges (TC), VFTO number and VFTO level for 1000 opening operations of an 800 kV disconnector Over the 1000 opening simulations, the maximal trapped charge is 0,61 pu for a 0.10 m/s opening speed, 0.92 pu for a 0.80 m/s opening speed and 1.00 pu for 1.60 m/s opening speed. With the K=2.0 assumption, the maximal VFTO is 2.55 pu for 0.10 m/s, 2.79 pu for 0.80 m/s and 2.88 pu for 1.60 m/s opening speed. From 1.60 m/s to 0.10 m/s, the maximal VFTO is decreased by 11.5 %. The lower the speed, the lower the trapped charge, the lower the maximal VFTO during opening process. Considering the number of VFTO with respect to their magnitudes, a 0.10 m/s opening speed ensures no VFTO above 80 % of 800 kV GIS LIWL on the considered disconnector geometry. On the contrary, faster opening speeds lead to several VFTO above 80 % of 800 kV GIS LI. Furthermore, a 0.10 m/s opening speed induces more VFTO above 50 % of 800 kV GIS LI – about 6 VFTO per process – compared to faster speeds – about 1 VFTO per process for 0.80 m/s and 1.60 m/s. The number of VFTO above 50 % of 800 kV GIS LIWL stay small for both slow and fast operating disconnectors but faster disconnectors can lead to VFTO magnitudes closer to the withstand level of the substation. 7 b. Closing processes Regarding closing process, 1000 opening-closing processes were simulated which allows taking into account the actual trapped charge statistical distribution from the opening processes. VFTO are still calculated with a factor K= 2.0. Figure 13 shows the number of VFTO for the 1000 opening-closing operations distributed according to the 800 kV GIS LIWL. Number of VFTO 8720 1.60 m/s 0.80 m/s 0.10 m/s 8 0 0 2198 1469 466 719 1002 390 533 70 79 1 208 90% LI to 80% LI 70% LI to 60% LI 50% LI to 100% LI to 90% LI 80% LI to 70% LI 60% LI VFTO level - K = 2.0 Figure 13 – VFTO number and VFTO level for 1000 opening-closing processes of an 800 kV disconnector On the 1000 opening/closing processes, the maximal VFTO at closing is 3.00 pu for 1.60 m/s, 2.92 pu for 0.80 m/s and 2.61 pu for 0.10 m/s. From 1.60 m/s to 0.10 m/s, the maximal VFTO is decreased by 13%. As per opening process, the lower the speed, the lower the trapped charge, the lower the maximal VFTO during closing process. A low operating speed at 0.10 m/s induces obviously more VFTO than faster disconnector. However, the number of VFTO above 50 % of the LIWL is small for all the speeds: about 11 VFTO per process (O/C operation) for 0.10 m/s, 3 VFTO per process for 0.80 m/s and 2 VFTO per process for 1.60 m/s. Finally, a 0.10 m/s opening speed ensures almost no VFTO above 80 % of 800 kV GIS LIWL according to the simulation which is not the case for faster disconnector. To conclude, a slow 0.10 m/s opening disconnector is safer than a faster disconnector since it ensures almost no VFTO above 80 % of the 800 kV GIS LIWL for the full opening-closing operation. CONCLUSION With development and application of UHV networks, 800 kV and above, VFTO produced by the GIS disconnector operation needs more attention regarding to the insulation level of equipment. In this paper, VFTO phenomenon for a 550 kV disconnector are observed during test and simulated in PSCAD. As the simulation methodology is valid, extension is proposed for a realistic 765 kV GIS architecture. The most important VFTO values are always obtained when the remaining trapped charge on the busbar is at its maximum. Beside this, the application of a more realistic trapped charge value reduces the expected VFTO peak values. We also have shown that beyond the design, the operating speed plays an important role on the trapped charge and finally on the VFTO magnitudes. On the considered 800 kV disconnector design, it appears that a slow acting disconnector is safer than a fast acting disconnector as it ensures almost no VFTO above 80% of the LIWL for both closing and opening operation. Entering UHV levels, costs of overdesign are growing exponentially and it may be of great interest to consider the real trapped charge behaviour of the disconnector for the insulation co-ordination, as this will lead to more realistic insulation co-ordination calculations. 8 BIBLIOGRAPHY [1] CIGRÉ Working Group 15.03, GIS Insulation Properties in Case of VFT and DC Stress (Paris, 1996) [2] CIGRÉ Working Group 33/13.09, Monograph on GIS Very Fast Transients (Brochure 35, 1989) [3] IEC 62271-102, High-voltage switchgear and controlgear – Part 102: Alternating current disconnectors and earthing switches – Annex F (2003) [4] IEC TR 60071-4, Insulation Co-ordination – Part 4: Computational Guide to Insulation Coordination and Modeling of Electrical Networks (2004) [5] N. Fujimoto, F.Y. Chu, S.M. Harvey, G.L. Ford, S.A. Boggs, V.H. Tahiliani, M. Collod, Developments in improved reliability for gas-insulated substations (CIGRÉ, Paris, 1988) [6] T. Berteloot, A. Girodet, P. Vinson, M. Bernard, Development of a Gas Insulated Disconnector for UHV Networks (CIGRÉ, New Delhi, 2013) [7] IEC TR 60071-2, Insulation Co-ordination – Part 2: Application guide (2004) 9