Operations Manual Model - 16DC

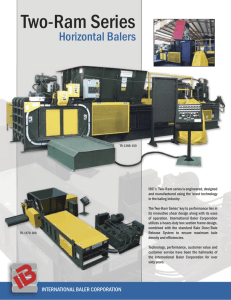

advertisement