How do ventilation Controllers communicate with variable speed fans?

advertisement

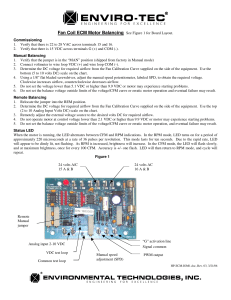

How do ventilation Controllers communicate with variable speed fans? Why do we use Variable Speed Fans? Example: 24 crate farrowing room – Needs 480 cfm for minimum – Smallest fan available is about 1000 cfm Example: 1000 head finisher Jay D. Harmon, Ph.D., P.E. Professor & Extension Ag Engineer Agricultural & Biosystems Engineering Iowa State University Ph: (515) 294294-0554 Email: jharmon@iastate.edu Review Controller Setting for VS – Needs 7000 cfm for minimum (large pigs) – One fan will do this, but too localized 1 Variable Variable--Speed & 3 Single Single--Speed Fans Airflow rate 6 Minimum speed (%) – motor curve 7 Stage 4 Stage 3 5 Bandwidth 8 – Temperature T t difference diff between b t minimum i i and maximum speed (ramp length) Stage 2 4 9 Stage 1 2 Minimum 3 10 1 Temperature Bandwidth 1 Differential 2 Differential 3 Differential 4 Temperature Set Point Common Questions Associated with Variable Speed Fans What minimum speed do I use? Does the percent reading on my controller mean percent capacity of the fan? Wh does Why d my system t behave b h diff differently tl after I replaced a fan motor? What are the consequences of using improper minimum ventilation settings? – Too Low? Too High? Learning Objectives Refresh understanding of terminology Increase knowledge of variable speed fan p performance Understand how the controller read out and fan performance are related Improve ability to select minimum speed and bandwidth settings 1 8,000 7,000 6,000 5,000 4,000 3,000 2,000 1,000 0 8,000 7,000 6,000 5,000 4,000 3,000 2,000 1,000 0 0.30 0.00 BESS Labs Volts Motor Controller RPM Fan CFM % 0.15 0.20 0.25 0.30 Variable-Speed Controllers 100 80 60 Actual Ideal 40 20 0 0 10 ? 0.10 Static pressure (inches of water) 0 Why are Variable Speed Fans Complicated? 0.05 10 0.25 80 90 0.20 60 70 0.15 50 0.10 Static pressure (inches of water) 30 40 0.05 % F u lll-sc a le a irflo w 0.00 BESS Labs 230V 200V 180V 160V 140V 120V 100V 20 230V 200V 180V 160V 140V 120V 100V cfm m Why are Variable Speed Fans Complicated? cfm m Why are Variable Speed Fans Complicated? Controller variable-speed setting Results from the Air Dispersion Lab, ISU Motor Curves Fan Delivery vs Motor Speed CFM M Example At 0.05 inches static pressure 1400 1200 1000 800 600 400 200 0 Threshold 0 Motor RPM 200 Fan CFM 400 600 800 1000 1200 1400 1600 1800 Relationship between voltage supplied to the motor and the resulting RPM Varies with motor make and size. Different motor curves exist for different motors Must select the right one in the controller to make the ventilation rate increase smoothly with temperature change RPM Volts Controller Motor Curves RPM 2 Volts Prudent PS-12 Fan with Marathon 1/6 hp motor APP--12F APP 2000 Volts Motorr RPM 1500 700 RPM 1000 Volts Motor Curve RPM 10 volts 500 0 0 20 40 60 80 Motor Curve 100 120 140 Input Voltage to Motor 230 135 119 115 112 111 109 107 105 104 103 102 101 99 RPM } } 95 V 16 V } 10 V 1765 1675 1575 1475 1375 1275 1175 1075 975 875 775 675 575 475 RPM CFM w/o Cone } } 100 rpm 100 rpm } 400 rpm 1432 1351 1251 1133 983 964 780 700 590 520 445 380 310 242 } 81 cfm } 100 cfm } 471 cfm f } } } 10 V APP-12F 700 rpm 538 cfm APP--24F APP 2000 Volts RPM CFM WO/Cone CFM W/Cone 1750 230 194 176 157 143 130 115 103 CFM or RPM 1500 1250 1000 750 Volts RPM Motor Curve 500 Fan CFM 250 0 80 100 120 140 160 180 200 220 1040 940 840 33 v 740 640 540 27 v 440 340 5798 5160 4784 200 rpm3830 2875 2072 200 rpm 823 368 } 46 v } 100 rpm }638 cfm } } } } } } 1909 cfm 1704 cfm 7386 6353 5648 4688 3842 2902 1596 331 240 Volts RPM CFM WO/Cone C CFM 24-inch AP Fan MC #4 6500 6000 5500 5000 4500 4000 3500 3000 2500 2000 1500 1000 500 0 Volts RPM Motor Curve Fan CFM Which Motor Curve in the Controller do we pick? Controller Voltage % 80 100 120 140 160 180 200 220 240 Volts RPM CFM WO/Cone 3 MC 1 MC 3 MC 5 MC 7 MC 9 Voltag ge Output 120 100 Motor Curves MC 2 MC 4 MC 6 MC 8 MC 10 Motor curve recommendations for various fan sizes from Aerotech controller 80 60 40 Controller 20 Volts RPM Motor Fan CFM % 20 40 60 % scale 80 100 Motor curve recommendations for various fan sizes from Airstream controller Controller Volts Motor RPM Generally, minimum speed is ~50% of voltage Fan CFM % RPM cfm 20 30 40 % scale 50 60 Controller 70 Volts 80 2000 1750 1500 1250 1000 750 500 250 0 90 100 Motor RPM Fan CFM 140 Volts 120 RPM 100 CFM Nearly full capacity at 40 % Reading 80 60 40 20 % Scale 0 0 20 40 60 Controller 80 Volts 100 Motor 2000 1800 1600 1400 1200 1000 800 600 400 200 0 120 RPM RPM / CFM Volts Volltage 140 120 100 80 60 40 20 0 Motor Curve 5 RPM M/CFM Volts V Motor Curve 1 Fan CFM 4 What Changes the % Scale on the controller? 100% Reading – 70 F Setpoint –2FB Bandwidth d idth – 50 % minimum speed 71 F 75% Reading 120 110 100 90 80 70 60 50 40 30 20 10 0 69.8 70 F 2000 % Scale Voltage RPM CFM 1800 1600 1400 1200 1000 800 600 RPM / CFM 72 F % Scale & Voltage Temperature! Example: 1oF Bandwidth for MC7 400 200 0 70 70.2 70.4 70.6 70.8 71 71.2 Te mpe rature (F) 50% Reading 1oF and 2oF Bandwidths for MC1 1600 100 1400 – Curve and Motor Dependent 1200 80 1000 60 % Scale 1 deg Volts 1 deg 40 % scale 2 deg 20 800 600 volts 2 deg 400 RPM 1 deg 200 RPM % sca ale, Volts Proper Minimum Speed? 1800 120 How Can I Use this? Avoid less than half voltage g if book values are unavailable Use volt meter to measure voltage to fan rpm 2 deg 0 69.5 0 70 70.5 71 71.5 72 72.5 Temperature How Can I Use this? What if my fan isn’t shown in the motor curve recommendations or I have no book? Procedure: 1. Set the setpoint high so the fan will operate at a minimum speed. 2. Set the Minimum Speed to 100%, measure the rpm using a tachometer. Approximately 110 V for 220 V fans Approximately 55 to 60 V for 110 V fans How Can I Use this? Procedure: 3. Set the Minimum Speed to 90%, measure the rpm using a tachometer. 4 Continue in 10% increments until the fan 4. stops moving air. 5. Does the fan rpm steadily increase over the range? 6. Switch motor curve number and go back to step 2. 5 So, this is what you want from your 1,000 1,000--cfm VS fan… Conclusions A total lack of understanding for everyone involved. The percentage readout does not correlate to fan output or fan rpm rpm. A 50% minimum reading recommendation may or may not be correct. Motor response (rpm) over a bandwidth may or may not be linear. % Full-scale airflow If you had to live with nonnon-linear VS fan output, which situation would be most/least acceptable? 100 80 60 40 A B C Actual Ideal 20 0 Controller variable-speed setting cfm 1,000 800 600 400 200 0 60 70 72 80 Temp. Quiz Yourself What minimum speed should I use? Does the percent reading on my controller mean percent capacity of the fan? Wh does Why d my system t behave b h diff differently tl after I replaced a fan motor? What are the consequences of using improper minimum ventilation settings? – Too Low? Too High? Thank you for your time! What questions do you have? 6