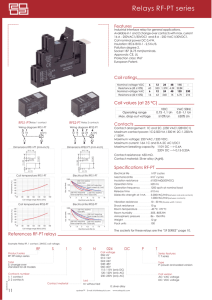

relays - AmpsLab.com

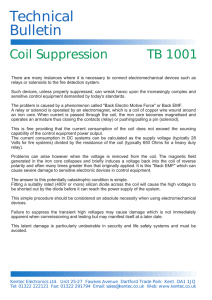

advertisement