VOL-II-Final Technical Tender

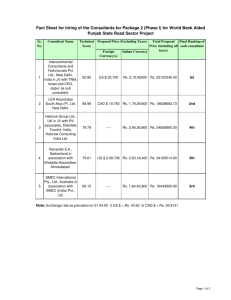

advertisement