Operations and Maintenance

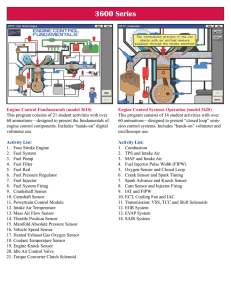

advertisement