XV. PROCEDURES FOR STORING CHEMICALS IN LABORATORIES

advertisement

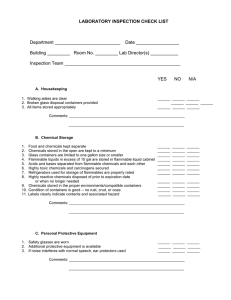

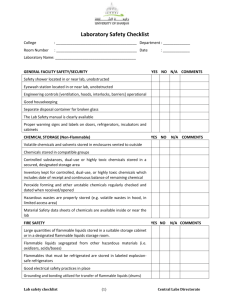

XV. PROCEDURES FOR STORING CHEMICALS IN LABORATORIES GENERAL CONSIDERATIONS Every chemical in the laboratory must have a definite storage place and must be returned to that location after each use. Please review MSDS or SOP’s or consult with EHRS at 2-2520 for instructions on the use handling and storage of specific chemicals. The quantities and volume of material stored in a lab must be kept to a minimum. Numerous regulatory agencies are responsible for regulating the exact volume and quantities of material allowed in one are. The Fire Marshal must be consulted in regards to limitations required for chemical storage. The storage of chemicals on bench tops is undesirable; in such locations, they are unprotected from potential exposure to fire and are also more readily knocked over. Storage in hoods is also inadvisable because this practice interferes with the air flow in the hood, clutters up the working space, and increases the amount of materials that could become involved in a hood fire. All chemicals must not be stored on the floor. Prior approval and specific instruction are required when working with regulated materials. Contact EHRS at 215-707-2520 for additional information. Regulated materials consist of explosives, controlled substances (drugs), toxics, radioisotopes, etiologic agents, select agents and carcinogens. Storage trays or secondary containers should be used to minimize the distribution of material should a container break or leak. Chemicals must be stored in approved storage cabinets (ex. Corrosives cabinets). All incompatible chemicals must be physically separated. Care must be taken to avoid exposure of chemicals to heat or direct sunlight and to observe precautions regarding the proximity of incompatible substances. Approved laboratory refrigerators are to be used for the storage of chemicals only; food must not be placed in them. All containers placed in the refrigerator must be properly labeled (identification of contents and owner, date of acquisition or preparation, and nature of any potential hazard) and, if necessary, must be sealed to prevent escape of any corrosive vapors. Household grade refrigerators in labs should be labeled: "No food or flammable liquid storage". Flammable liquids must not be stored in laboratory refrigerators unless the unit is an approved, explosion-proof, fire proof or laboratory-safe type (NFPA Standards 45 and 56D). The chemicals stored in the laboratory must be inventoried at least annually, and unneeded items must be given to EHRS for recycling or disposal. All chemical containers (including beakers and flasks) must be labeled with contents and hazard information. Abbreviations and chemicals formula are unacceptable. All chemical containers that have legible labels and chemicals that appear to have deteriorated must be disposed of through EHRS. Funnels must not be left in containers. All water reactive chemicals must be stored away from water and water vapor. The Principal Investigator (PI) or chemical owner is required to ensure that all their chemicals in their labs are examined annually for replacement, deterioration, expiration, container integrity and overall condition of the chemical. This annual evaluation must be documented. The best method of documentation is utilizing the evaluation function in CEMS. Other acceptable documentation methods include writing the evaluation date on the chemical bottle itself or 1 2/3/2011 creating a log book or spreadsheet that list the every chemical present and the respective evaluation date. On termination, transfer, graduation, or such of any laboratory, the PI must submit Certificate of Vacancy (EHRS Handbook 1.5) to EHRS. Use common sense in planning chemical storage areas. Carefully read the label before storing a hazardous chemical. The MSDS will also provide any special storage information and incompatibilities. Do not store unsegregated chemicals in alphabetical order or incompatible chemicals in close proximity to each other. The amount of space that can be placed between different chemical classes depends on the amount of storage area available in the laboratories. Do not segregate chemical classes into separate rooms unless they will only be used in that room. Segregation that disrupts normal workflow or requires more frequent transport of hazardous chemicals between labs will increase the probability of a chemical spill. Store dry reagents, liquid reagents and solutions and compressed gases in separate areas. Within each of these chemical forms, segregate the chemicals into hazard classes. Segregate dry reagents as follows: • • • • Oxidizing solids; Flammable solids; Water reactive solids; and All others solids. Segregate liquid reagents and solutions as follows: • • • • • • Acid liquids; Caustic liquids; Oxidizing liquids; Perchloric acid solutions; Flammable or combustible liquids; and All other liquids. Segregate compressed gases as follows: • Toxic gases; • Flammable gases; and • Oxidizing and inert gases. Incompatibilities amongst the above mentioned hazards class can exist. Consult MSDS for exceptions to the above mention hazard classes. Please review the table below for additional guidelines on chemical compatibility Number 1 2 3 4 5 6 7 Chemical Group Inorganic acids Organic acids Caustics Amines and alkanolamines Halogenated compounds Alcohols, glycols, glycol ethers Aldehydes 2 Do Not Store With Group #’s 2-8, 10,11,13,14,16-19, 21-23 1,3,4,7,14, 16-19,22 1,2,5,7,8,13-18, 20,22,23 1,2,5,7,8, 13-18,23 1,3,4,11,14,17 1,7,14,16,20,23 1-4,6,8,15-17,19,20,23 2/3/2011 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 Ketones Saturated Hydrocarbons Aromatic hydrocarbons Olefins Petroleum Oils Esters Monomers, polmerizable esters Phenols Alkylene oxides Cyanohydrins Nitriles Ammonia Halogens Ethers Elemental Phosphours Acid anhydrides 1,3,4,7,19,20 20 1,20 1,5,20 20 1,3,4,19,20 1-6,15,16,19-21,23 3,4,7,14,16,19,20 1-4, 16,23 1-2,7,8,13-17,20,23 3, 6-15,19,21,22 1-2,7,8,13-17, 20,23 3, 6-15,19,21,22 1,14,20 1-3,20 1,3,4,6,7,14, 16-19 Once separated into hazard classes, the compatible chemicals may be stored alphabetically. Incompatibilities amongst segregated chemical can exist. For example, Nitric acid must be stored separately away from all acids. Use approved storage containers and safety cans for flammable liquids. Use spill trays under containers of strong corrosive reagents. Do not store liquids above eye level. Dispose of old chemicals promptly. Ensure that all containers are properly labeled. All hazardous chemicals received must be labeled with the date received, the date of initial opening and, when available, expiration date. For more information on hazardous chemical storage, contact EHRS at 2-2520. FLAMMABLE & COMBUSTIBLE LIQUIDS The storage of flammable and combustible liquids in a laboratory must be kept to the minimum amount needed for research and operations. Flammable-liquids storage cabinets are not intended for the storage of highly toxic materials, acids, bases, compressed gases or pyrolytic chemicals. All chemical storage cabinets must be compatible with the chemical stored within it. Storage of flammable liquids outside of a storage cabinet should be avoided when possible. Flammable liquids that are not in use should be stored in an appropriate cabinet. Flammable liquids should not be stored in a refrigerator unless the refrigerator is UL approved for flammable liquid storage. Storage of flammable liquids in household grade refrigerators is a fire hazard. OSHA regulations for the laboratory storage of flammable and combustible liquids are not based on fire prevention and protection principles but rather address the types and sizes of containers allowable. Whenever feasible, quantities of flammable liquids greater than 1 liter must be stored in metal containers. Portable approved safety cans are one of the safest methods of storing flammable liquids. These cans are available in a variety of sizes and materials. They have spring-loaded spout covers that can open to relieve internal pressure when subjected to a fire and will prevent leakage if tipped over. Some are equipped with a flame arrester in the spout that will prevent flame propagation into the can. If possible, flammable liquids received in large containers must be repackaged into safety cans for distribution to laboratories. Such cans must be properly labeled to identify their contents. 3 2/3/2011 The storage of flammable materials in wooden cabinets in existing laboratories is prohibited. Other considerations in the storage of flammable liquids in the laboratory include ensuring that aisles and exits are not blocked in the event of fire; that accidental contact with strong oxidizing agents such as chromic acid, permanganates, chlorates, perchlorates, and peroxides is not possible; and that sources of ignition are excluded. REGULATED MATERIALS Regulated materials consist of explosives, controlled substances (drugs), toxics, radioisotopes, etiologic agents, select agents and carcinogens. Regulated materials must be stored in ventilated storage areas in unbreakable chemically resistant secondary containers. Access to regulated materials must be secured and controlled. Select chemical agents require additional security measures. Storage areas for regulated materials must exhibit a sign warning of the hazard, have limited access, and are adequately ventilated. Adequate ventilation is of particular concern for hazardous materials that have a high vapor pressure (such as bromine, mercury, etc.). Prior approval and specific instruction are required when working with regulated materials. Contact EHRS at 215-707-2520 for additional information. COMPRESSED GASES Carefully read the label before using or storing compressed gas. The MSDS will provide any special hazard information. Always use the minimum size cylinder required to perform the work. Cylinders of compressed gases must be handled as high-energy sources. When storing or moving a cylinder, have the cap securely in place to protect the stem. Use suitable racks, straps, chains or stands to support cylinders. Care must be taken to keep them away from sources of heat or ignition. Compressed gas cylinders pose a crush hazard to hands and feet. Do not expose cylinders to temperature extremes. Do not store cylinders or lecture bottles with the regulator in place. If the regulator fails, the entire contents of the gas cylinder may be discharged. Always use the correct regulator. Do not use a regulator adapter. Oil or grease on the high-pressure side of an oxygen cylinder can cause an explosion. Do not lubricate an oxygen regulator. Empty cylinder must be labeled as such. Cylinders of toxic, flammable or reactive gases should be stored and used in a fume hood or with local ventilation. Never bleed a cylinder completely empty. Cylinder must be stored according to their proper hazard class. Always leave slight pressure to keep contaminants out. Always wear safety glasses when handling compressed gases. A method for detecting an unintentional release of a gas from a compressed gas cylinder may need be implemented. This may apply in an area where highly hazardous chemicals are present or in an area where there is the potential (large volume of cylinders, gas generators, etc..) for a cylinder to deplete the oxygen content in an area. Please contact EHRS for additional information. 4 2/3/2011