Fire Lessons Learned in the Nuclear Industry S. Scott Hinds, PE

advertisement

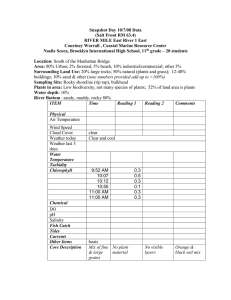

Fire Lessons Learned in the Nuclear Industry S. Scott Hinds, PE March 2011 Acknowledgements Bruce Dr. Campbell, PE – HAI Rowland Felt – Fire Consultant Dave Tomecek, PE - HAI Outline Purpose/Background Fermi Lab Wide Band Fire- 1987 Rocky Flats Fire - 1957 Cerro Grande Fire (Los Alamos) - 2000 Welding Fatality at K-25 - 1997 Outline Gaseous Diffusion Plant Fire - 1956 Paducah Chemical Fire - 1962 Rocky Flats Fire - 1969 Conclusions Purpose and Background Provide brief examples of past DOE/Nuclear related fires Provide an overview of the 1969 fire at the former Rocky Flats Plant. Discuss Discuss the Lessons Learned from these events how these lessons and events impact our professional Society Purpose and Background presentation is not all encompassing – It does present an overview of well documented facts This It is a fact of life that there are fewer and fewer of us left in the industry that retain corporate memory of these fires and in specific - the Rocky Fire of 1969 We cannot forget the lessons learned from these events FERMI Lab Wide Band Fire October 3, 1987 – Batavia Illinois. Fermi National Accelerator Laboratory focused on high energy physics research. Fire started by over-current in a 34 wire ribbon cable and spread along cable trays to eventually involve 4 particle detectors. 5 sprinklers activated. Emergency personnel were called to suppress the fire. Over $1 million in damages. FERMI Lab Wide Band Fire FERMI Lab Wide Band Fire 1957 Rocky Flats Fire Very serious plenum fire initiating in a glovebox on the floor below Gloveboxes constructed of Plexiglas Ignited by spontaneous combustion of Pu metal Spread to Plexiglas Extinguished via hose lines 1957 Rocky Flats Fire 1957 Rocky Flats Fire 1957 Rocky Flats Fire Filters – “Flammable chemical warfare system (CWS) filters” Precursor Pu to the HEPA filter release in the range of 4 to 25 grams Fire suppression measures - post 1957 fire - Use of glass-fiber filters in lieu of cellulose-asbestos filters Multiple stage filter plenums 1957 Rocky Flats Fire Cerro Grande Fire May 2000 – Los Alamos, NM Largest forest fire in New Mexico’s history –started as a controlled burn. Burned 7500 acres within Los Alamos National Laboratory’s boundary. Over 100 minor buildings were destroyed. No buildings containing nuclear material or high explosives were burned. closed from May 8 – May 22. Cost of business interruption estimated at $3 million. Laboratory Cerro Grande Fire Welding Fatality at K-25 March 11, 1997 – Oakridge, TN. Oakridge National Laboratory K-25 site. was being performed in high contamination zone – no dedicated fire watch was on duty – report indicated the welder was working alone. Work Welder unknowingly ignited his anti-contamination clothing – fully consumed in flames in < 3mins resulting in fatality. Anti-contamination outfit 100% cotton. Flame retardant version available, but not made mandatory. Gaseous Diffusion Plant Fire Gaseous Diffusion Plant Fire November 11, 1956 – Paducah, KY Fire started from a compressor gas seal leak in one of the smaller buildings in the Paducah Gaseous Diffusion Plant. Building did not have a sprinkler system. The fire ignited the underside of the roof, leading to the complete destruction of the 70,000 ft2 of roof. Despite limited damage to equipment, total cost was $2.1 million – over $20 million in todays dollars. This incident led to increased sprinkler focused fire protection systems of AEC plants. Paducah Chemical Fire December 13, 1962 – Paducah, KY An explosion followed by a chemical fire occurred at the same Paducah Gaseous Diffusion Plant, but in a much larger building. While the sprinkler system effectively extinguished the fire, the steam that formed caused most of the 2,341 sprinkler heads to activate. Losses were reported at $2.9 million. Had the sprinkler system not been in place, estimated damages >$160 million. The system supported a maximum flow rate of 40,000 gpm over 23 systems, consuming 2,800,000 gallons of water. Plutonium Primer – Interesting Facts Can be brittle as glass and malleable as aluminum Expands Silvery when it solidifies machined surface oxidizes and tarnishes in minutes – spontaneously ignites in air at room temperatures Pyrophoric 239Pu – metal –weapons; oxide – MOX reactors Ages from “outside in” – reacting vigorously with its environment, like O, H₂, and H₂O thus changing its properties from the surface to the interior. Ages from the “inside out” – continual self damaging decay fundamentally changes its properties over time. Plutonium Primer – Fire Facts Burning Plutonium – glows like a charcoal briquette Ignition Temperature – 560 degrees C Melting Temperature – 650 degrees C Rate of Combustion - ~240 grams/hour or 4 grams/minute Massive metal chunks – hard to ignite - 5.2 BTU/gram Surface area to weight ratios critical to proper handling Ignition transition area between 0.05 – 0.2 mm thickness or 7 – 25 cm2/gram specific surface area – higher end 500 degree C – lower end 150-200 degree C Pu Nuclear criticality potential high with improper design Obviously – nuclear containment required Water and Plutonium Roland Felt reported that: The Rocky Flats fire was the first known fire where water was used on burning plutonium It had been hypothesized that a hydrogen explosion could occur if water was used on burning Pu, none occurred during the fire The burned Pu was confined in the fire areas in welldefined piles “Burning Plutonium” Basics of Fire Protection – Fuel – Temperature – Oxidizer: The Fire Triangle We know from our primer that burning plutonium is missleading - Pu metal simply reacts with oxygen to produce heat and form a plutonium oxide (the oxidation process) Pu oxide is a nonvolatile substance - converts to a full oxide if agitated, generally remains a sub-oxide that is still pyrophoric The greater the surface area to mass ratio, the greater the chances of oxidation Non-alloyed oxidation Pu – pure metal - is also more prone to “Burning Plutonium” Rocky Flats Rocky Flats Rocky Flats was a former nuclear weapons production facility. Previously manufactured various nuclear weapon components and one of the key facilities within the DOE for this purpose Opened 6,000 All in 1953 acres facilities were demolished in late 2005 Largest D&D project in the nation, several billion dollars. 21 tons of nuclear material, 3 million square feet of structures, 30K liters of Pu solutions, 1500+ gloveboxes, 600,000 cubic meters of waste. Rocky Flats Rocky Flats – Why we are here… Site of two large nuclear fires, one in 1957 and the other in 1969 1966 brought an end to the dual capability to provide weapon materials between Hanford and Rocky – Rocky won the “competition” Used 16Kg ingots and no water permitted in the process Rocky capable of very high throughput Economic production factors were favorable for relative low cost of Rocky Flats – Pre 2002 Rocky Flats – February 2005 Rocky Flats – September 2005 Rocky Flats – Before the Fire From 1955 to March 1971: 602 reported fires 374 in Plutonium areas 228 in other areas “Although these figures look high, many of these were small fires from metal chips or turnings…” In the Plutonium business – fires are expected Rocky Flats – Before the Fire 1969 Fire - Overview May 11, 1969, 2:27 PM (Mother’s Day Sunday) The fire started as a fully involved glovebox fire in Building 776 - one of the main production buildings– moved through conveyors overhead Initial alarm from a heat detector Firefighters instructed to never use water prior to that fire 1969 Rocky Flats Fire Heavy smoke conditions Plexiglas® biggest smoke factor Benelex® also involved - 1% was combusted – 600 tons 60-gloves involved in the initial line 10 minutes before the fire, Stationary Operating Engineers and Security had made a walk-thru of the area – no issues Shielding, Plexiglas and Benelex – WHY Due to the increased throughput, shielding enhancements were initiated – the plant was experiencing unacceptable exposures of workers Radiation Protection – Primary was alpha radiation 60 KeV gamma from 241Am Neutron from spontaneous fission of 240Pu Shielding – Alpha – gloves Gamma – lead sheets Neutron – plastic/wood composite – Benelex 401 (Masonite Corp) and Plexiglas (Rohm & Hass) Shielding, Plexiglas and Benelex 1967 - Installation of 600 tons of Benelex and Plexiglas Workers could stay longer and “increase their time” in the work zone Cost – $3.5M neutron shielding effort Required due to unacceptable exposure of the employees However, this increased exposure 40% Neutrons where thermalized to detection range of the dosimeters – neutrons where slowed down - increased exposure resulted Conveyors overhead were also a radiation source Shielding, Plexiglas and Benelex Solution Move – shielding into the glovebox Develop Benelex/Plexiglas chests for storage of the compacted machine turnings Plutonium briquettes were stored in the gloveboxes and provided with “flower pot” heat detectors Briquettes were pressed Pu chips - briquette is 3inches in diameter and 1-inch thick ~1500 grams Benelex and Plexiglas – Fire Facts - 9,900 BTU’s per pound to 11,600 BTU’s per pound Plexiglas Ignition Some temperature of 775° F “fire retardant” methacrylate was used Benelex - Burning characteristics more closely approach those of the dense hardwoods 8240 BTU’s per pound Ignition temperature of 795° F Prolonged exposure at 4-hours at 475° F also causes ignition Volrath Can Storage Flower Pot Detector Rocky Flats Fire Continued Over 800,000 gallons of water existed to “fight” the fire First attempts to extinguish the fire were via multiple 50pound CO2 wheeled extinguishers (not successful) Water utilized within 7-minutes via 1 ½ inch lines Decision by the fire captain to use water - was later commended for this decision 776 Area not sprinklered or provided with emergency power 41,000 Fire gallons per hour were used to fight the fire re-ignited due to burning plutonium Fire Damage Fire Damage Rocky Flats Fire A total of 33 firefighters and security guards fought the fire No outside firefighting units were called or assisted Some No self-contained breathing apparatus was borrowed action was initiated to contact local authorities or to establish road blocks outside the plant perimeter Fire Damage - Roof Rocky Flats Fire Why was there no criticality? in sheep dips – a design feature of these gloveboxes that resulted in voids below the glovebox base floor Water Short bursts of water around the Volrath cans – Consolidation of the cans - luck Fog streams directed at the top of the glovebox Small blue flames were seen, later found to be magnesium carriers – scraped off ingots will volatize as blue color Pu “crusting” slowed the oxidation Rocky Flats Fire fire spread from Building 776 to 777 – another production building - within 25-minutes (via the conveyor line system) The About 2-hours into the fire the sprinklers on the second floor were operating It took nearly 6-hours to get the fire under control was estimated that 100 x 106 BTU of heat was liberated during the fire – what does that equal??? It About an average heat release rate of 4884 Kw or a fully engaged – out of control – burning super Wal-Mart About 2000 BTU is a burning couch Fire Damage Fire Damage Rocky Flats Fire – Water versus Pu After the fire it was noted that the Pu Oxide was crusty instead of powdery The utilization of water had the effect of forming a moist oxide coating over the burning metal which baked to a rigid crust This crust prevented the loose oxide from being dispersed This also contributed to the lack of a criticality Rocky Flats Fire – Root Cause No evidence of arson Started in the North Foundry line of 776 Self ignition of a briquette ignited shielding material Had been burning for a long time prior to discovery Initiated inside the glovebox Rocky Flats Fire – Root Cause “With the installation of the Benelex-Plexiglas storage container in 1968, the heat detection system was nullified” The type of briquette that self ignited had occurred previously at Rocky Flats, however the storage configuration was different (shielding which provided insulation), thus a self ignited fire was plausible About one-half of the heat released during the fire was from the Plexiglas glovebox windows Less The than 5% was from the Pu remainder was from the shielding material and gloves Rocky Flats Fire – Root Cause “The fact that the building structure, including the roof was not breached by the fire, that most of the ventilation system continued to operate, and only a part of the final stage of one set of filters was damaged appear to have been the controlling factor in limiting the amount of Pu release” “Although the area subjected to fire damage was relatively small, the damage to equipment and the building due to contamination was very extensive” The A conveyor system contributed to the extent of the loss fire truck hit an electrical pole that took out the ventilation by mistake – saved the day Rocky Flats Fire – Damages No serious physical injuries to personnel fighting the fire Initial estimate; $50M in 1969 dollars, ($315M in 2011 dollars) Final Fist tally was “only” about $26M ($165M in 2011 dollars) floor of Building 776/777 grossly contaminated Second floor of Building 776/777 highly contaminated An estimated 1-kg of oxidized Pu was on the floor of the glovebox of origin (Glovebox 134-39 in building 776) Significant number of other briquettes oxidized within their containers in multiple gloveboxes Total Pu in Building 776/777 was 3,400-kg Rocky Flats Fire – Damages 1,400-kg was in the area of origin Most damaged Pu was oxidized, some was chemically damaged due to the loss of inerting No evidence of Pu-Water explosions (due to H₂) The Plexiglas windows in the primary burn area were almost completely consumed In some of the primary burn area, the Benelex and Plexiglas shielding was heavily charred “The capability to produce and assemble plutonium pits for War Reserve weapons was lost for a period of several months and production of special devices for the weapons laboratories was interrupted”. Fire Damage Pu and Plexiglas Plutonium Metal Fire Damage Fire Damage Rocky Flats Fire – Conclusions Building 776/777, a vital nuclear weapons production facility did not even meet the minimum AEC fire safety standards Plexiglas Benelex Long windows most significant contributor also a contributor (only 1% burned) interconnected conveyor system – highway for fire Recycling Storage of turnings, chips and skull material of Pu briquettes without lids If there had not been the Benelex-Plexiglas storage container, the fire would not have ignited the windows The Benelex-Plexiglas container also impaired the use of storage container heat detectors Volrath Can Storage Rocky Flats Fire – Conclusions The Benelex and Plexiglas shielding also made fire fighting and clean-up efforts difficult No loss time injuries firefighters who fought the fire were hero’s and they clearly prevented a much more serious and catastrophic fire The Combustible The loading was the primary contributor lack of automatic sprinklers, sufficient detection and fire barriers were also a major contributors Rocky Flats Fire – Lessons Learned Facility wide automatic sprinkler protection Non-combustible containers with tight fitting lids for the storage of all forms of Pu Eliminate unnecessary storage of combustibles within gloveboxes - Combustible loading was the primary contributor Glovebox overheat detection system was upgraded and fixed detectors which monitor air temperatures were added Quicker processing of pyrophoric forms of Pu having a large surface to mass ratio such as turnings, slag, to PuO2 Rocky Flats Fire – Lessons Learned Production areas eliminated Plexiglas and Benelex shielding The use of plastics as glovebox structural components were eliminated The use of gloveboxes and conveyor lines for long-term storage of Pu was eliminated, storage accomplished via storage vaults which were nitrogen inerted Fire stops were provided for gloveboxes and conveyor lines. Dampers were automatic Rocky Flats Fire – Lessons Learned Ventilation systems for Pu processing lines were changed to supply & exhaust air from GB’s and conveyor lines o At the time of the fire, air was drawn into the GB’s from the room and exhausted through the conveyor system. Using the conveyor system contributed to the fire spread Areas with pyrophoric Pu were N2 inerted o It was found that O2 of less than 5% inhibits the ignition of Pu (plus all other combustibles) Rocky Flats Fire – Lessons Learned All room air exhaust plenums were equipped with a cooling chamber and two stages of HEPA filters Cooling is achieved by automatic water sprays which provide an amount of water calculated to reduce 1000º F inlet air to approximately 200º F, system activated by 190º F heat detectors All glovebox air exhaust plenums and inert plenums were provided with 4-stages of HEPA in lieu of 2-stages Glovebox Exhaust Plenums Rocky Flats Fire – Lessons Learned Manually operated deluge systems were provided for the first stage of HEPA filters All exhaust filter plenums were designed to prevent direct impingement on the face of the HEPA filters Accomplished via baffles or directional air changes Heat detectors were provided upstream of filters Directional Air Change Baffle Rocky Flats Fire – Lessons Learned Fire rated walls and doors were provided to limit fire spread Including upgrading of exterior walls and roofs Rooms were subdivided to limit the spread of fire Two 2500 gpm fire pumps and Two 500,000 gallon suction tanks New fire alarm system Emergency The generators – Lighting - Ventilation lack of automatic sprinklers, sufficient detection and fire barriers were also a major contributors Rocky Flats Fire – Lessons Learned Sprinklers, sprinklers, sprinklers… Combustible loading Fixed suppression systems Fixed detection systems Fire An separations adequately staffed on-site professional fire department is critical Rocky Flats Fire – Lessons Learned “While Rocky Flats does have fire protection experts and they provide advice to line management when called upon, there is no one centralized safety organization with appropriate responsibility to assure that overall safety evaluations are performed.” Final Look