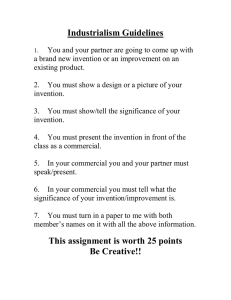

Test connector

advertisement

United States Patent [19] [m 3,997,231 Sherwood [45] Dec. 14, 1976 [54] TEST CONNECTOR 1,395,734 5/1975 United Kingdom ........ .. 339/75 MP [75] Inventor: Theodore R. Sherwood, Sunnyvale, Cahf‘ OTHER PUBLICATIONS Twin-Contact Connector, IBM Technical Disclosure [73] Bulletin, VOl- 14, n0- 9, 2-1972, Colletti et al Assignee: The United States of America as represented by the Secretary of the 22 [ F] l I Navy, Washington, D-C‘ Primary Examiner—-Roy Lake D _ 8, 1975 Assistant Examiner—E. F. Desmond l ed ec Attorney, Agent, or Firm-R. S. Sciascia; Charles D. B. [21] Appl- No; 638,385 Curry; Elliott N. Kramsky [52] [51] US. Cl. .................... .. 339/75 M; 339/176 MP lm. C1.2 ...................................... .. I-IOlR 13/54 1571 [58] held of Search ------ -- 339/17 L’ 17 LC’ 75 MP, 339/75 M, 75 R, 176 MP A compact test connector having a slim design to per mit side to side installation on a master interconnect [56] ABSTRACT References Cited board, allowing simultaneous testing of multiple mod UNITED STATES PATENTS faces. A simple and compact camming device acts in 12/1975 conjunction with the contact board to impart zero de ules. A contact board contains redundant contact sur 3,924,916 Vcnaleck .................... .. 339/17 LC vice insertion force and simpli?ed replacement of the most degradable components‘ FOREIGN PATENTS OR APPLICATIONS l,l25,990 3/1962 Germany .................. t. 339/l76 MP 7 Claims, 4 Drawing Figures |5 11 l7 l9 *7‘ 29 /— f; 43 \\ /65 US. Patent 35 Dec. 14,1976 Sheet10f2 37 3,997,231 1 3,997,231 TEST CONNECTOR BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates to electrical test con 2 Another object of this invention is to provide an electrical connector especially adapted to achieve the ‘ above object and remain operable through repeated insertions and removals of electrical devices. Yet another object of this invention is to achieve the above objects with a device which provides maximum nectors. More particularly, it relates to easily repair contact area. able test connectors of compressible design which exert A further object of this invention is to achieve the above objects by means of a design which allows for further simpli?ed miniaturization of the invention. A still further object of this invention is to achieve the above objects in an electrical connector especially adapted to accommodate an electrical device having zero insertion force on the contacts of devices to be tested. ' 2. Description of the Prior Art Low insertion force electrical connectors have been necessitated by the increased miniaturization of elec tronic devices and their attendant delicacy. Often a elongated contacts. camming device has been the means employed to 15 Futher objects, advantages and novel features of the achieve Zero insertion force. See, for instance, Sitzler, invention will become apparent from the following US. Pat. No. 3,744,005 and Wycheck, US. Pat. No. detailed description of the invention when considered 3,426,313._ Prior art devices have mainly dealt with in conjunction with the accompanying drawings solving the problems caused by direct insertion of the wherein: edge of a printed circuit board into a connector to join it electrically to another device and have not dealt Brief Description of the Drawings extensively with miniaturized electronic devices having FIG. 1 is a perspective view of the test connector of elongated contacts. Miniaturization has been limited in many camming devices which utilize a knob control. the present invention; required than for coupling the edge of a miniaturized present invention. FIG. 2 is a vertical sectional view of the present in Such control may only be reduced to a limited extent 25 vention taken along line 2—2 of FIG. 1; and remain manually operable. FIG. 3 is a vertical sectional view of the present in When one deals with the elongated leads of a minia vention taken along line 3-3 of FIG. 1; turized device, even ?ner control of insertion force is FIG. 4 is an exploded partial perspective view of the board. At all times, however, a reliable electrical con 30 nection must be assured between the devices to be DESCRIPTION OF THE PREFERRED coupled. Prior art teachings are generally not adaptable EMBODIMENT to the special problems involved in coupling miniatur With reference to FIG. 1, there is shown in perspec ized devices having small elongated contacts and- do an embodiment of the present invention. A plural not recognize the further problems attendant in design 35 tive ity of contact receptacles 11 are arrayed upon device of a connector to interface with test equipment or con interface 13. The receptacles are adapted to receive soles. Such equipment is intended to repeatedly test elongated contacts from an electronic device and are different devices and must allow for insertion an re arrayed to accommodate a multiplicity of such contacts. It is seen in FIG. 2 that the receptacles 11 may be funnel shaped as a further precaution against out. . insertion force deformations. One hundred contact The present invention solves these and other related receptacles 11 are shown in the embodiment illus problems by providing a small cam actuated zero inser trated, although such number is not intended as a limit tion force electrical test connector. The cam is de signed to be activated by manipulation of its major 45 ing'aspect of the present invention. The size of the receptacles l 1 will vary according to the transverse size dimension, thus allowing maximum potential miniatur of the elongated contacts to be inserted and are de ization. A removable and easily replaceable card hav signed to accord a loose, zero insertion force, ?t for ing redundant electrical contact surfaces assures simple such contacts. The present inventive concept is not maintenance and maximum contact area. moval with minimal degradation of contact areas, the portion of any electrical connector most prone to wear limited to accommodate only electrical devices having SUMMARY OF THE INVENTION Brie?y, the present invention relates to a compact test connector having a slim design to permit side to elongated contacts but is also adaptable to electrical devices having one or more contact areas coincident with a circuit board edge or other surface, for example. An upper portion casing is formed of the device in side installation on a master interconnect board. A contact board contains redundant contact surfaces. A 55 terface 13 and paired ridge panels 15, plateau panels simple and compact camming device acts in conjunc 17, angled panels 19 and side panels 21 which are joined and culminate in a pair of end pieces 23. An abrupt constriction 25 is grooved the length of side tion with the contact board to provide zero insertion force and simpli?ed replacement of the most degrad panels 21 as shown in FIGS. 2 and 3 which shall be further discussed hereinafter. A cam activator 27 for adjusting a plurality of spring contacts 29 (shown in FIGS. 2, 3 and 4) to either an open or closed position is shown in FIG. I to consist of a pair of locking bar sides 31 joined to a pair of end able components. The board is contained within a matched pair of camming blocks which vary the dis tance between the contact parts upon activation caused by moving sliding exterior surfaces. Cone-shaped aper tures permit positioning of elongated electrical contacts in the variable space. Objects of the Invention An object of the present invention is to provide a zero insertion force electrical connector. 65 pieces 33 by plurality of standard fastening means 35. The abrupt constrictions 25 matching side panels 21 permit a slidable engagement between the cam activa tor 27 and side panels‘ 21. 3 3,997,231 top of the inclines formed in inclined slots 37. This shift of the cam activator 27 causes simultaneous and identi cal vertical movements of rods 39. FIG. 2 illustrates the inclined recesses 45 of split camming block 42 and the The rods 39 and inclined slots 37 are so arranged that the axes of the rods 39 describe a horizontal plane at all times. The height of each rod relative to anchor plane seating of the spring contacts 29 therein. In FIG. 3 it is 41 is determined by the rod’s relative position in its inclined slot which, in turn, is determined by the posi tion of the cam activator 17 relative to the side panels 21. FIG. 3 illustrates a cross section of the invention taken along line 3—3 of FIG. 1. It is seen that rod 39 sits in a notch formed in paired camming blocks 42. FIG. 2, a cross section of the invention taken along line 2—2 of FIG. 1, shows that, between comb-like inter vening camming block- ridges 43 there exist, alternating with such ridges, a plurality of recesses 45 each having an inclined side. FIG. 4 shows the paired camming blocks 42 in perspective and illustrates their relation ship to replaceable contact board 47. ‘ seen that rods 39 are located internally in cam block 42 and sit in a vertical slot 63 which exists in connector side panels 21. Lower contact spring 65 completes electrical contact between console contact pins 61 and plane contacts 49 and exerts a retaining force on contact board 47. Thus, vertical movement of rods 39, causing an upward movement of cam block 42, will 5 cause the spring contacts 29 of contact board 47 toward one another. This is due to the inclined internal surface of the cam block 42 against which the spring contacts 29 are seated. The pinching movement caused thereby brings the spring contacts 29 into electrical 20 Contact board 47 is constructed of a non-conductive connection with the elongated contact of the ?rst de vice protruding through contact receptacle 11. This completes the electrical connection of the device joined‘ to contact pins 61 with that joined to contact receptacles 11. If the ?rst device does not posses elon material. On each side of the board exist alternating plane contacts 49. The contacts 49 consist of strips of a conducting material and may be so arranged that, as illustrated in ‘FIG. 2, a strip is located along the projec tion of receptacle 11. With each plane contact 49 there 4 contact with one or more of the pins 16 by moving the cam activator 27 to such position that rods 39 sit at the A pair of inclined slots 37 exists in each locking-bar side 31. A rod 39 is associated with each slot 37, each rod spanning the internal width of the test connector. 25 is paired a spring contact 29 made of a resilient con gated contacts, obvious adaptations of the present in vention, such as removal of interface 13 may be made in accord with the present invention. Due to the loose ?t of the elongated contacts in the ducting material. Each spring contact 29 and plane receptacles 11 and the relatively large gap existing contact 49 are joined by standard means such as solder between spring contacts 29- and contact board 47 be fore rods 39 achieve their upper position, no force is ing at a flat junction 51. contact board 47 has a lip 53 at each end. Each lip 53 sits in a notch 55 formed at the junction of the paired In operation with an electronic device of the type exerted upon the elongated contacts until they are in place and fully aligned. Also, due to the unique con struction of the invention and particularly the split nature of camming block 42, the contact board 47 may be replaced independent of other parts of the invention by a simple disassembly seen clearly in FIG. 4. This is a particularly useful feature of the invention when uti having at least one elongated contact the contact is lized as an interface for an electrical test console. The blocks 42. The height of the lips 53 in conjunction with the depth of notch 55 determines the maximum depth at which contact board 47 may be seated within cam ming blocks 42. plugged manually into device interface 13. Anchor continual insertion and removal of the devices to‘ be plane 41 serves as the base of the present invention and 40 tested degrades the spring contacts 29 more severely adjoins a second electronic device. A pair of holes 57 than another portion of the invention. Simple replace ment or repair of the contact board 47 will assure long provide points of attachment of the invention to the other electrical device, such as a test console. The term performance of the invention. Thus there is provided a durable no-force connector holes extend through anchor plane 41 and through a pair of shoulders 59 which serve as end portions for the 45 in which an electrical device may be plugged into the invention causing minimal device degradation and al lowing. easy replacement of degradable parts for long portion of the chamber formed side panels 21 below the cam activator 27. An electrical connection is made between the second device and the contact pins 61 located at the bottom of the anchor plane 41 by any of variety of methods well recognized in the art, such as wire winding. The locking bar sides 31 are moved to such a position that rods 39 lie at the lowest point of term ef?ciency of operation. inclined slots 37 (the position illustrated in FIG. 1) and the device, having at least one elongated contact, has such contact or contacts inserted through one or more 55 of contact receptacles 11. With rods 39 in their low positions, a relatively large gap exists between the semi circular portion of spring contacts 29 and contact ~ a. an upper portion for receiving at least one contact from a ?rst electrical device; b. a lower portionvfor receiving at least one contact from a second electrical device; c. a contact board located between said upper and 1 lower portions, said board having at least one elec trical contact thereon, said at least one electrical spring portion, said strip portion consisting of elec 60 tacles 11, allows the insertion of an elongated contact trically conductive material located on the face of the board and said spring portion, in contact with said strip portion, consisting of resilient electrically encountering little, if any opposing force. In complex conducting material attached to said board at one and miniaturized arrays, such contacts may be of slight end and projecting therefromat the other end; transverse dimension as a packaging consideration and subject to hann from relatively minor insertion forces. After the insertion of the elongated contacts of the device, the operator may complete the electrical con nection of the ?rst device with the electrical device in > contact comprising a strip portion joined to a board 47, shown most vividly in FIG. 2. The gap, cou pled with the loosely designed ?tting of contact recep ‘ What is claimed is: 1. An electrical connector which comprises: 65 (I. a camming apparatus located in said upper por tion; e. said camming apparatus comprises a matched pair of blocks surrounding said contact board; 5 3,997,231 f. each block having a top portion and a bottom por tion and each having at least one cavity in its in 6 3. An electrical connector as described in claim 2 wherein said connector additionally comprises: a. a pair of shoulders which join said top portion to said bottom portion; and b. each of said shoulders has a pair of notches to accommodate the sides of said camming apparatus. ward-facing side; g. said at least one cavity is larger at said top portion than at said bottom portion; whereby h. an electrical connection may be made between 4. An electrical connector as described in claim 3 said ?rst and second devices said connection being completed and undone according to the position ing of said contact board within said camming ap which additionally comprises: a. attachment means to join the lower portion of said electrical connector to a surface located at the paratus. bottom of each of said shoulders; b. said means being removable, so that, upon removal 2. An electrical connector as described in claim 1 wherein said electrical connector further comprises: a. said camming apparatus has a pair of sides each side having parallel inclined slots and each side located in a notch in said upper portion of said electrical connector; b. a pair of end pieces joined to said sides to maintain of said attachment means and said rods said electri cal connector is suf?ciently disassembled to allow manual removal of said contact board. 5. An electrical connector as described in claim 4 wherein said upper portion has at least one opening to admit an elongated electrical contact from said ?rst electrical device. a parallel spaced positioning therebetween; c. a pair of rods projecting through said matched pair 6. An electrical connector as described in claim 5 of blocks and seated in said inclined slots and in a wherein said opening in said upper portion is of funnel vertical slot in said upper portion of said electrical shape. connector of vertical dimension at least as great as 7.‘ An electrical connector as described in claim 6 wherein: that when said pair of sides of said camming appa a. said contact spring portion further has a straight ratus are shifted in position within said joint in said 25 lower portion adapted to the shape of said at least the vertical displacement of said inclined slot so upper portion of said electrical connector, said one cavity of said camming block; and rods are caused to be displaced in a vertical direc b. an upper portion having a bend toward said tion thereby causing said matched pair of blocks to undergo vertical movement. contact board. * 35 40 45 55 60 65 * * * *