Modelling and analysis of wind-excited vibrations of transmission lines

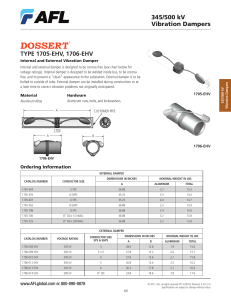

advertisement