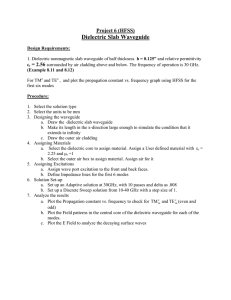

Transmission Line and Components

advertisement