DG2 Series

advertisement

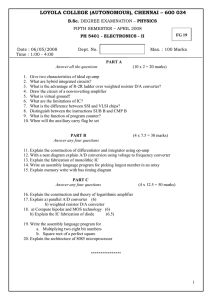

Installation & Operating Procedures DG2 Series SINGLE PHASE CONVERTERS 18 Neville Street, Unit C New Hamburg, ON N3A 4G7 Tel: 519-662-6489 Fax: 1-866-280-5247 1/4HP - 7.5HP 120/240/277 VOLTS 50/60HZ www.safdrives.com email: answers@safdrives.com (Replies given within 24 hours) TABLE OF CONTENTS 1.0 DESCRIPTION .................................................... Pg. 1 2.0 INSTALLATION AND START-UP ...................... Pg. 3 3.0 DRAWING INDEX .............................................. Pg. 7 1.0 DESCRIPTION 1.1 GENERAL DG2 Series thyristor controllers are designed to control the speed of wound field or permanent magnet DC motors from ¼ HP to 7.5 HP. The controllers are available as complete, totally enclosed units suitable for wall-mounting, or as kits suitable for custom applications. When supplied as self-contained units, the converters are provided with transparent, high-impact resistant polycarbonate covers, in a totally-enclosed, non-ventilated format. The following controls are mounted on this cover: - ON/OFF switch or circuit breaker - Speed control pot - STOP/START pushbutton or spring-loaded rocker switch The transparent cover allows visual indication of "POWER ON" and "RUN" LED's. 1.2 FEATURES - - - NEMA 1 enclosure (polycarbonate transparent) ON/OFF switch, AC line fuses (½ through 2 HP) ON/OFF 2 pole AC circuit breaker (3 HP and above) START/STOP pushbutton or spring-loaded rocker switch Speed pot 2 Amp field supply Adjustments: - Min speed - Max speed - Current limit - IR compensation - Speed stability - Current stability LED indication: - Power "ON" - Run relay "ON" Tachometer or armature feedback Full wave bridge 2 isolated pulse transformer outputs to allow the use of different SCR bridge configurations. Page - 1 1.3 SPECIFICATIONS DIMENSIONS - Inches (mm) Model Volts Max. 50/60 Hz HP L NEMA 1 W D L CHASSIS W AC D DC Current Current DG2-7.5-1 120 3/4 12 (305) 8.5 (216) 7 (178) 7.5 (191) 5 (127) 5 (127) 11A 7.5A DG2-7.5-2 240 1.5 12 (305) 8.5 (216) 7 (178) 7.5 (191) 6 (152) 5 (127) 11A 7.5A DG2-10-2 DG2-15-2 240 240 2 2 12 (305) 8.5 (216) 7 (178) 7.5 (191) 6 (152) 5 (127) 12 (305) 8.5 (216) 7 (178) 12 (305) 8.5 (216) 6 (152) 14A 21A 10A 15A DG2-25-2 240 3 12 (305) 8.5 (216) 7 (178) 12 (305) 8.5 (216) 6 (152) 34A 25A DG2-30-2.7 277 5 12 (305) 8.5 (216) 7 (178) 12 (305) 8.5 (216) 6 (152) 42A 30A TABLE 1 1.3.1 Operating Temperature Range 10oC to +40oC (50oF to 104oF) 1.3.2 Short-Circuit Protection For 240V models: HRC line fuses for chassis models, circuit breaker for Nema 1 models. 1.3.3 Speed Control Range 10:1 with armature voltage feedback 30:1 with tachogenerator voltage feedback Page - 2 2.0 INSTALLATION AND START-UP WARNING! Equipment is at line voltage when AC power is connected to the converter. All phases must be disconnected before it is safe to touch any internal parts. 2.1 INSTALL THE CONVERTER AND DC MOTOR IN AN AREA WHERE THE FOLLOWING CONDITIONS EXIST: a) b) c) d) 2.2 Ambient temperature does not exceed 40oC. (104oF) Ambient temperature is not less than 10oC. (50oF) Altitude above sea level is below 2,000 meters (6500 ft.) Ambient air is clean and dry. It must be free of flammable or combustible vapors, steam or corrosive gases. CONSIDERATIONS FOR EXTERNAL CABLING OF THE CONVERTER It is most important that the AC supply to the unit is of the correct voltage and current rating. It should be kept in mind that where the specified drive voltages and/or currents are not available, a matching transformer will be necessary. All external connections must be made according to the Engineering Drawing supplied. All power cabling and control cabling ratings should be referred to Cable Current Rating, TABLE 1. Rate incoming AC line and armature cabling for AC current rating. Field cabling should be 15A rated. 2.3 START-UP Your DG2 converter has been factory adjusted to perform optimally with the DC motor supplied. Just connect the unit as per relevant drawing and switch "ON". In the event that the unit must be readjusted, use the following procedure. 2.3.1 Ensure that the wiring is according to the appropriate drawing. 2.3.2 Measure and confirm that the AC supply voltage is as per DG2 converter nameplate. 2.3.3 Confirm that the AC current supply is adequate, (see TABLE 1). Page - 3 2.3 START-UP - Continued... 2.3.4 Switch power "ON" and confirm: - that field voltage is correct - that the power "ON" LED lights up 2.3.5 Switch power "OFF" and set all trim adjustments fully counter clockwise. Remove one field wire, and physically clamp the motor shaft. Insert a DC ammeter in series with the motor armature. Set the external speed control pot to 50% full speed. 2.3.6 Apply power. Connect an ungrounded oscilloscope across A+ and A-. Press the "START" pushbutton. Confirm that the "RUN" LED goes ON. Slowly turn "I MAX" trimpot clockwise until the armature current is 100% of motor nominal current. To ensure current stability, turn the "I STAB" trimpot slightly clockwise. 2.3.7 Switch power "OFF". Disconnect the ammeter, and reconnect the field. Turn "SPEED POT" to "0". 2.3.8 Switch power "ON", and press "START" pushbutton. - Adjust the "MIN SPEED" trimpot until the motor turns at the desired minimum speed. - Slowly turn the external speed pot to position 10 and watch out for instability. It is usually necessary to adjust the "V STAB" trimpot slightly clockwise to achieve stable operation with good response. - At position 10, adjust the "MAX SPEED" pot until the motor's rated RPM is achieved. Alternatively, connect a DC voltmeter across A+ and A- and adjust the "MAX SPEED" pot for appropriate DC voltage as follows: Input AC Volts 120V 90V 240V 180V 277V 240V Max DC Output Volts Page - 4 2.3.9 IR Compensation This control is used to even out speed variations due to load changes. If your load is of a variable nature, observe the motor RPM under light load and full load conditions at 25% full speed. Slowly adjust the "IR COMP" trimpot until the speed changes disappear or are minimized. WARNING! Do not adjust this control beyond 30% of full clockwise setting as this may result in unstable drive operation. 2.3.10 Tachogenerator Feedback Remove the "ARM" link. Connect the "TACH" link. Go through Start-up steps 2.3.1 through 2.3.4. IMPORTANT To prevent drive run away, be very careful to establish tachogenerator polarity with the motor rotating in the desired direction. Then, connect tach + to terminal 12, and tach - to terminal 13. When the tachogenerator is connected for the first time, do not start the drive unless the external speed pot is set at "0", and the "MIN SPEED" pot is full counter clockwise. Set the "I MAX" pot slightly clockwise. Start the drive and slowly turn the speed pot clockwise. Confirm that the motor's speed increases to a low speed, but does not run away. Switch the drive "OFF" and go through Start-up steps 2.3.5 through 2.3.7. IMPORTANT The "IR COMP" trimpot is not used with tachogenerator feedback and must remain fully counter clockwise. Page - 5 2.4 TERMINAL DESIGNATIONS FIGURE 1 FIGURE 2 2 NOTES: 1. For constant torque control, link shown in Fig. 2 above. 4 to 5 and connect torque pot to terminals 3, 6 and 7 as Page - 6 3.0 DRAWING INDEX NUMBER CA185-3 TITLE Control Card Drawing DG2-10-1 DG2 Converter ¼ - 1 HP, 120 VAC DG2-10-2 DG2 Converter ¼ - 2 HP, 240 VAC DG2-10-2.7 DG2 Converter ¼ - 2 HP, 277 VAC DG2-15-2 DG2 Converter 3 HP, 240 VAC DG2-25-2 DG2 Converter 5 HP, 240 VAC DG2-30-2.7 DG2 Converter 7.5 HP, 277 VAC CP71 Drawing Notes Page - 7 CA185-3 CONTROL CARD DRAWING Page - 8 DG2-10-1 CONVERTER 1/4 - 1HP, 120VAC Page - 9 DG2-10-2 CONVERTER 1/4 - 1HP, 240VAC Page - 10 DG2-15-2 CONVERTER 3HP, 240VAC Page - 11 DG2-25-2 CONVERTER 5HP, 240VAC Page - 12 DG2-30-2.7 CONVERTER 7.5HP, 277VAC Page - 13 Installation & Operating Procedures DG2 Series SINGLE PHASE CONVERTERS 18 Neville Street, Unit C New Hamburg, ON N3A 4G7 Tel: 519-662-6489 Fax: 1-866-280-5247 1/4HP - 7.5HP 120/240/277 VOLTS 50/60HZ www.safdrives.com email: answers@safdrives.com (Replies given within 24 hours)