ST_240-56062752 Rev 2

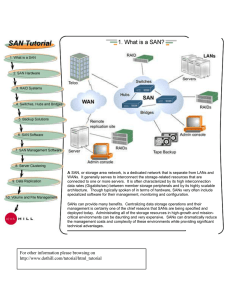

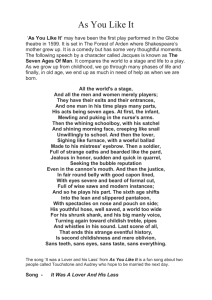

advertisement