NeXLev™ Parallel Interconnect System

Telcordia GR-1217-CORE Compliance Report

Note: This is an outline of the Telcordia Compliance Report providing the scope of testing. For copies of

the report, please contact your local Teradyne Sales Representative.

Teradyne, Inc.

Connection Systems Division

44 Simon Street

Nashua, NH 03060

603.879.3000

www.teradyne.com/tcs

HD+, HDM, GbX, VHDM, VHDM-HSD, and NeXLev, are trademarks or

registered trademarks of Teradyne, Inc. While the information in this document

is reliable at the time of publication, it is subject to change without notice.

Copyright © Teradyne, Inc. 2002 • All rights reserved

NeXLev™ Parallel Interconnect System

Telcordia GR-1217-CORE Compliance Report

Revision 2

The NeXLev parallel interconnect system was tested for compliance to Telcordia specification GR-1217CORE, “General Requirements For Separable Electrical Connectors Used In Telecommunications

Hardware” per the following test plan:

NeXLev Bellcore GR-1217-CORE

Test Plan

Sample Preparation

Note: Each Test Group will require 5 Samples Mated to Test Boards to

obtain a minimum of 300 monitoring sites per group.

Copyright © Teradyne, Inc. 2002 • All rights reserved

Page 2 of 4

NeXLev™ Parallel Interconnect System

Telcordia GR-1217-CORE Compliance Report

Revision 2

Test Descriptions:

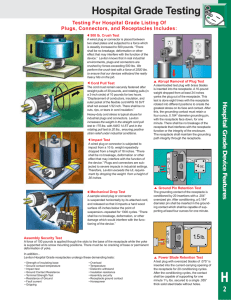

1. Mating/Unmating Force: EIA-364 TP13

The plug module and the receptacle module shall be mounted to test boards. The force required to mate

and unmate the plug and receptacle modules shall be measured.

2. Low Level Contact Resistance: GR-1217-CORE, Section 6.2.1 Low-Level Contact Resistance

(LLCR) & EIA-364 TP23. The test set up requires that the plug and receptacle modules be soldered onto

test boards that allow a four-wire measurement to the backplane and daughtercard module mating

interface through the test pwb ( the four-wire measurement nulls out the probe and pwb etch bulk

resistances).

The measurement energy shall be restricted to no more than 20 millivolts and 100 milliamperes. There

shall be no instance where the change in bulk resistance through the mated pair is greater than 10

milliohms.

3. Durability: GR-1217-CORE, Section 9.1.1.2 & EIA-364 TP09.

The backplane plug module and the daughtercard receptacle module shall be mounted to test boards.

The plug and receptacle modules shall be mated and unmated for 100cycles at a rate of <500

cycles/hour.

4. Dust: Dust and fiber contamination test module shall be conducted per GR-1217-CORE, Sections

9.1.1.1. The plug and receptacle modules shall be mounted to test boards and the LLCR measured while

plug and receptacle are mated. The connector shall be unmated, exposed to dust, mated once, and

LLCR again measured.

5. Vibration, sinusoidal: GR-1217-CORE, Section 9.1.2.1 Vibration and Mechanical Shock. The

verification method for vibration shall be EIA-364-TP28B, Test Condition II – 10.0g RMS sinusoidal

excitation.

Test set up requires the use of the same test boards using the four-wire measurement method. Test

duration of vibration shall be 2 hours on each of three mutually perpendicular axes. The LLCR shall be

less than 1 milliohm.

6. Mechanical Shock: GR-1217-CORE, Section 9.1.2.1 Vibration and Shock. The verification method for

mechanical shock shall be EIA-364-TP27B, Test Condition I, 30g Sawtooth excitation.

The test set up uses the four-wire test boards. The test sample shall be subjected to three shocks in each

direction along each of the three mutually perpendicular axes of the sample. In all, the shock test shall

employ 18 shock impulses. The test sample is secured in a mounting fixture for both vibration and shock.

The low-level contact resistance shall not exceed 1 milliohm.

7. Thermal Shock: Plug and receptacle modules shall be mounted to test pwb’s and initial LLCR

measurements taken. The mated modules shall then be subjected to five thermal shock cycles. The cyclic

temperature variation shall be from –55ºC to 85ºC per EIA-364-TP32B, Test Condition I and GR-1217CORE, Section 6.3.3.

8. Humidity: Humidity testing is to be performed per EIA-364-TP31, Method II, Test Condition A (500

hours steady state 90-95% relative humidity at 40ºC +/-2ºC) and GR-1217-CORE, Section 9.1.1.1.

9. Temperature Life: Mated plug and receptacle modules shall be elevated to 85ºC for a minimum of 500

hours per EIA-364-TP17, Test Method A, Condition 3.

Copyright © Teradyne, Inc. 2002 • All rights reserved

Page 3 of 4

NeXLev™ Parallel Interconnect System

Telcordia GR-1217-CORE Compliance Report

Revision 2

10. Four Gas MFG Testing: EIA-364 TP 65.

The recommended MFG procedure, gas analyses procedures, and corrosion monitoring procedures are

defined in the ASTM B827-92 and ASTM B810-91. The four gas mixture for MFG Testing:

Gas

NO2

Cl2

H2S

SO2

Concentration

200 ppb

10 ppb

10 ppb

100 ppb

The test temperature shall be 30“-ê½”©C and the relative humidity 70%. Modules mounted to the four

wire test boards shall be exposed to twenty days of the MFG to evaluate the risk to the significant number

of telecommunications connectors, including backplane pins and headers, which are unmated for some

years before being put into service.

The low-level contact resistance is measured initially and every 5 days during the test. The samples shall

be stabilized at room ambient for at least 1 hour before the final observations or measurements are

made. The low-level contact resistance shall not exceed 1 milliohm.

Test Results:

Results for test groups 1, 2, 3, and 4 are reported in Contech Research, Inc.

test report #201160, Rev. 1.1

Results for test group 6 are reported in Analytical Answers test report #39442.

Reports are available upon request.

The NeXLev parallel interconnect system met or exceeded all requirements specified in Telcordia

GR-1217-CORE.

Copyright © Teradyne, Inc. 2002 • All rights reserved

Page 4 of 4