2008 SG cover:2006 Cover

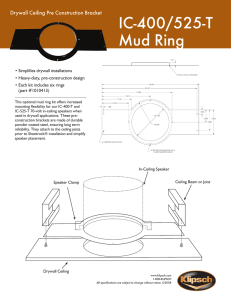

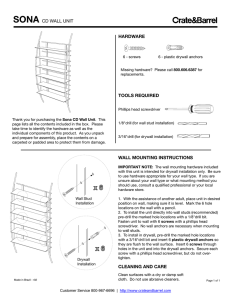

advertisement