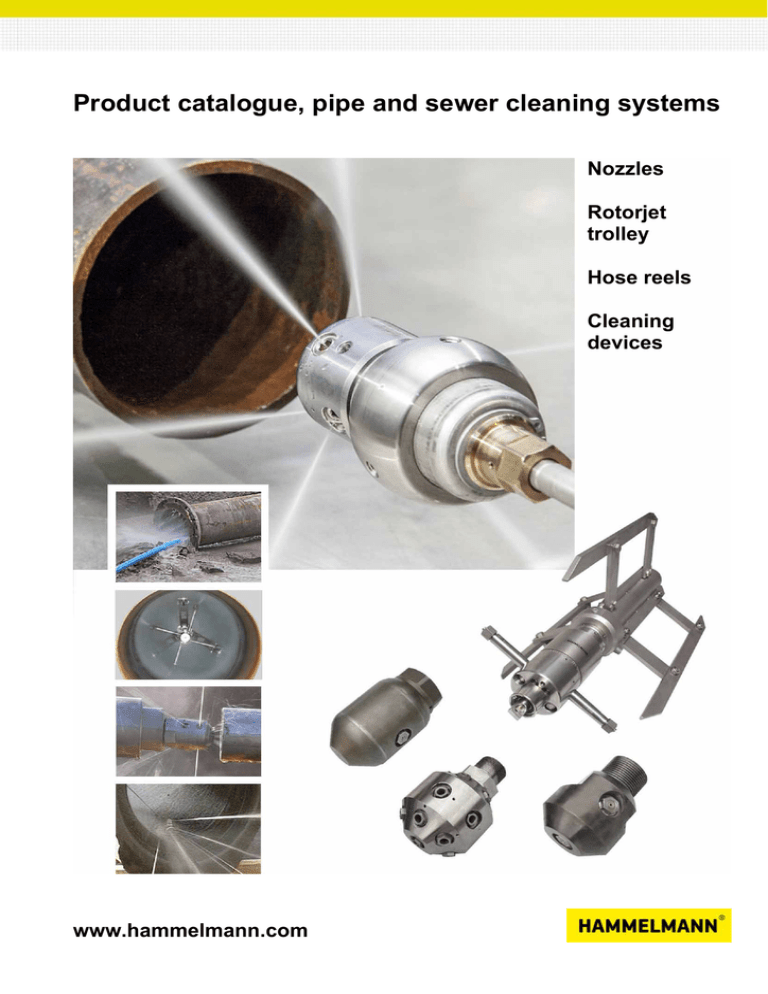

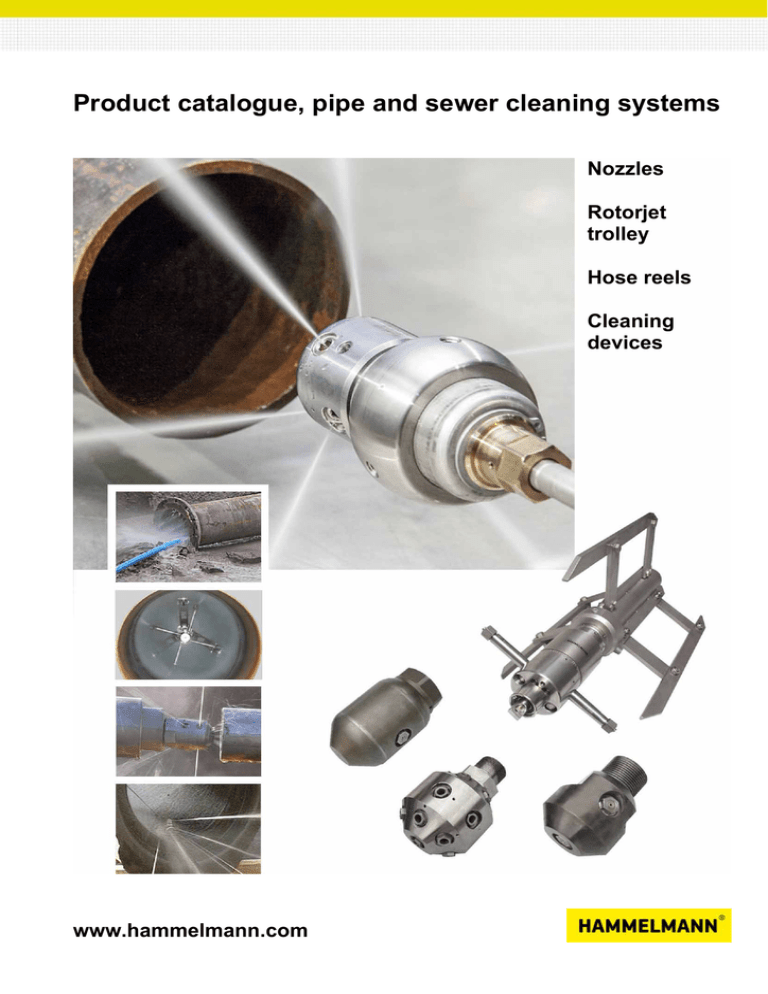

Product catalogue, pipe and sewer cleaning systems

Nozzles

Rotorjet

trolley

Hose reels

Cleaning

devices

www.hammelmann.com

Contents

(Navigation via Bookmarks)

Rotorjet trolley

Rotary joints, spray pipes and extensions blasting arms

Sledges for rotor jets

Rotor jets for pipe cleaning

Hydraulically driven hose reels

Pipemaster / Hose rotating system

Interchangeable nozzle heads

Pipe and sewer cleaning nozzles

Connectors

Hammelmann application engineering overview

Carriage

15.A.1 – 10/13

Description

HAMMELMANN stainless steel carriage as pipe cleaning

deployment device for a rotorjet or rotary joint with extension blasting

arms.

The carriage is smoothly adjustable for pipe internal diameters from

between 400 mm and 1400 mm.

It comprises the following main components:

Code no.

00.06112.0097

Guide pipe,

12 mm i/d high pressure hose with M 24 x 1,5 DKO-S-fittings,

scissors arms with moving jopints and wheels.

Rotary joint, spray pipes and extension blasting arms are not

included and must be selected separately.

Description

Code no.

The 00.06112.0097 carriage can be extended by 300 mm to 400 mm

with this adapter set.

00.05810.0036

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

Rotary joint, spray pipes and

extension blasting arms

15.A.2 – 10/13

Rotary joint, spray pipes and extension blasting arms are not included in the carriage and

must be selected separately!

The following rotary joint, spray pipes and extension blasting arms can be used:

Description

Rotary joint

Spray pipe, 15° angle

Spray pipe, 30° angle

Spray pipe, 45° angle

Quantity

1

4

4

4

Code no.

00.00062.0155

00.03567.9147

00.03567.9148

00.03567.9149

Extension blasting arms

Length in mm

50

75

100

200

300

Quantity

4

4

4

4

4

Code no.

00.03544.0010

00.03544.0011

00.03544.0012

00.03544.0013

00.03544.0014

The standard length fitted is 100 mm.

Example:

Rotary joint 00.00062.0155 with

spray pipe 00.03567.9147

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

Sledges for RDM series Rotorjets

Pipe dia.

min. / max.

[mm]

Length *

[mm]

Rotorjet **

Code no.

300

RDM 200

RDM 250

RDM 300

00.01355.0003

450

RDM 200

RDM 250

RDM 300

00.01355.0005

450

RDM 200

RDM 250

RDM 300

00.01355.0004

450

RDM 200

RDM 250

RDM 300

RDM 400

00.01355.0007

1190

RDM 200

RDM 250

RDM 300

00.01355.0006

1190

RDM 200

RDM 250

RDM 300

00.01355.0008

Smoothly adjustable

working diameter

270 to 400

without high-pressure

extension arms

Working diameter

variable in 9 steps

125 / 150 / 200 / 250 /

300 / 350 / 400 / 450 / 500

without high-pressure

extension arms

with leg sets

Working diameter

variable in 9 steps

125 / 150 / 200 / 250 /

300 / 350 / 400 / 450 / 500

with high-pressure

extension arms

with leg sets

Working diameter

200

without high-pressure

extension arms

without leg sets

Working diameter

variable in 9 steps

125 / 150 / 200 / 250 /

300 / 350 / 400 / 450 / 500

with high-pressure

extension arms

with leg sets

Working diameter

variable in 2 steps

600 / 800

with high-pressure

extension arms

with leg sets

* length without rotorjet

** not included in the sub-assembly of the sledges

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

15.B.1 – 10/13

Sledge and trolley with externally

driven Rotorjet

Length*

[mm]

Pipe dia.

min. / max.

[mm]

Connection

thread

Working diameter

variable in 9 steps

125 / 150 / 200 / 250 /

300 / 350 / 400 / 450 / 500

Working diameter

variable in 3 steps

Nozzle type

A/B

M 48 x 2

max. 1000 bar

827 / 924

4 x RD 2500

700 / 1000 / 2800

Nozzle type

G/H

with high-pressure

extension arms

with leg sets

Code no.

4 x 90° radial

1332

with high-pressure

extension arms

with leg sets

Accessories

00.06035.0342

00.06035.0468**

max. 2500 bar

M 30 x 2

* length without rotorjet

** incl. oil hydraulically driven rotary joint

Example of use: Hose reel with various pipe cleaning devices

Pipe Ø 1400 mm

Hose reel with

hydraulic unit

Pipe Ø 700 mm

Pipe Ø 400 mm

Nozzle holder to feed in the

high pressure hose

Pipe Ø 300 mm

Note!

The hose reel can be electrically, hydraulically or pneumatically driven.

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

15.B.2 – 10/13

Rotor jets for pipe cleaning

15.C.1 – 10/13

The rotor jets are outfitted with threaded nozzle inserts. The rotation of the rotor jet and the axial motion

within the pipe is effected by the reaction force of the water jets.

Max. Ø

rotor jet

[mm]

32

Max.

Operating

pressure

[bar]

600

Max.

flow

rate

[l/min]

Nozzles

Connection

thread

Code no.

Quantity

Type

80

2 x 35° push

2 x 90° radial

2 x 125° pull

(rotating)

+

6 x 140° pull

(static)

S

G 3/8

female

00.00786.0082

S

G 3/8

female

00.00786.0081

38

600

80

2 x 35° push

2 x 90° radial

2 x 125° pull

(rotating)

+

6 x 140° pull

(static)

53

1000

60

4 x 90° radial

(rotating)

G

H

G 3/8

female

09.00530.2525

200

2 x 30° push

2 x 90° radial

2 x 135° pull

(rotating)

+

3 x 135° pull

3 x 165° pull

(static)

G

H

M 36 x 2 DKO

male

09.00530.0072

50

2 x 30° push

2 x 90° radial

2 x 135° pull

(rotating)

G

H

M 14 x 1,5 LH

female

09.00530.2782

32

2 x 30° push

2 x 90° radial

2 x 135° pull

(rotating)

G

H

M 14 x 1,5 LH

female

09.00530.2870

80

4 x 45° push

4 x 95° pull

(rotating)

+

6 x 140° pull

(static)

S

M 14 x 1,5 LH

female

09.00530.4685

58

78

78

35

1600

1500

2500

1500

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

Rotor jets for pipe cleaning

15.C.2 – 10/13

The rotor jets are outfitted with threaded nozzle inserts. The rotation of the rotor jet and the axial motion

within the pipe is effected by the reaction force of the water jets.

Max. Ø

rotor jet

[mm]

Max.

Operating

pressure

[bar]

Max.

flow

rate

[l/min]

80

1500

90

128

Nozzles

Connection

thread

Code no.

Quantity

Type

120

2 x 50° push

2 x 90° radial

2 x 125° pull

A

(B)

M

G1

female

09.00530.2059

1000

180

4 x 90° radial

(rotating)

A

(B)

M

M 36 x 2

male

00.00786.0128

1000

180

2 x 105° pull

2 x 135° pull

(rotating)

A

(B)

M

M 36 x 2

male

00.00786.0091

120

2 x 27° push

2 x 90° radial

2 x 135° pull

(rotating)

A

(B)

M

M 24 x 1,5

DKO

male

09.00530.2050

G

H

(P)

M 30 x 2

female

09.00530.2058

128

1500

128

2500

(3000)

60

2 x 27° push

2 x 90° radial

2 x 135° pull

(rotating)

130

1500

200

4 x 90° radial

(rotating)

A

(B)

M

M 36 x 2

male

00.00786.0120

L

M 36 x 2

male

00.00786.0108

I

M 30 x 2

female

00.00786.0147

166

1600

400

2 x 45° push

2 x 90° radial

2 x 120° pull

(rotating)

275

2500

100

2 x 90° radial

(rotating)

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Technische Änderungen vorbehalten.

Rotating and swivelling hose reel

15.D.1 – 10/13

(for pipe cleaning)

Description

for 12 mm i/d hose,

operating pressure 1600 bar,

including hydraulic motor with brake, gear and chain drive to rotate

the reel to wind off / wind on the hose,

including hydraulic motor with brake, gear and ball turning support

with external teeth to swivel the reel on its axis,

all completely mounted on a completely enclosed mobile frame,

00.06035.0387

suitable for horizontal and vertical (top to bottom) operation,

without hydraulic power pack and installation material,

swivel water connection to enable unwinding and rewinding of

pressurised HP hose,

max. 180 m hose capacity.

for 20 mm i/d hose,

operating pressure 1600 bar,

without hydraulic power pack

including hydraulic motor with brake, gear and chain drive to rotate

the reel to wind off / wind on the hose,

including hydraulic motor with brake, gear and ball turning support

with external teeth to swivel the reel on its axis,

all completely mounted on a completely enclosed mobile frame,

Code no.

suitable for horizontal and vertical (top to bottom) operation,

00.06035.0367

with hydraulic power pack

without hydraulic power pack and installation material,

swivel water connection to enable unwinding and rewinding of

pressurised HP hose,

00.06035.0374

max. 100 m hose capacity.

Hydraulic power pack

Description

Code no.

electric motor: 5,5 kW, 400 V, 25 l/min, 100 bar,

dimensions of all (H x W x L): 1500 x 1050 x 700 mm,

oil tank capacity 160 litre,

weight without oil approx. 235 kg,

all on a mobile frame with casters.

04.00028.0051

control unit for hydraulic power pack

00.06700.0713

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipemaster /

Hose rotating system

15.D.2 – 10/13

The Pipemaster is a manually operated, high pressure hose rotating system. It is used to remove both soft

and very hard deposits from the insides of pipes and pipelines including those with bends and vertical

sections.

As an alternative to self rotating nozzles the rotary action is achieved by rotating the high pressure hose.

The slow rotation speed results in increased cleaning/

removal rates.

Powered deployment and retraction can remove pipe

blockages.

Positioningdevice

Increased operational safety due to the remote control.

Cleans pipeline bends.

Suitable for hoses 8, 12 and 20 mm i/d.

Operates in conjunction with Hammelmann nozzle

holders.

Hose

deployment

unit

Hose rotating unit

The pipe inside cleaning system consists of:

Rotating unit

Hose deployment unit to deploy or retract the hose, incl. remote control

Triple hose (air pressure hose from deployment unit to rotating unit, length: 10 m)

Guide and protective hose, length: 10 m

Positioning device and hose guide (mounting on (heat exchanger) pipe)

Hose rotating unit

A high pressure supply hose line is fixed between the pump and the

rotary joint on the hose rotating unit.

A second hose is connected to the rotary joint and runs via the deployment unit into a protective hose to the positioning device at the work

piece.

The rotation of the second high pressure hose around its’ longitudinal

axis is effected by a chain drive from a pneumatic motor to the rotary

joint.

The rotation speed can be smoothly adjusted by throttle check valves.

The rotating unit is driven by 120 Nm³ / hr. of compressed air at 4 bar.

Consisting of:

Pneumatic motor with gearbox

- rotation speed can be smoothly adjusted by throttle check valves; nmax = 32 1/min.

Pneumatic maintenance unit

consisting of filter, pressure reducer, lubricator and upstream manual shut-off valve, pressure

regulation range 0 - 8 bar

High pressure rotary joint

Pneumatic control system

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipemaster /

Hose rotating system

15.D.3 – 10/13

Hose deployment unit

Actuating the control lever of the unit causes the hose to start rotating which

in turn produces the forward (deployment) motion.

The deployment speed is 1.6 m/min. and it is smoothly adjustable by means

of the control lever.

Changing the angle of the three wheels that press onto the hose will cause

the hose to move forward (deploy) or backward (retract).

The hose deployment unit is mounted on a sturdy base plate and comprises

the height adjustable control lever to deploy or retract the hose which incorporated the remote control to operate the hose rotating unit.

Positioning device

A non rotating protective hose is fitted between the hose deployment unit and the

positioning device. This enables operation in pipes that are difficult to access.

The positioning device enables easy and secure insertion of the hose into the pipe.

The blasting guard prevents a pressurised nozzle from being accidentally pulled out

of the pipe.

The positioning device shown here is for use with pipes up to 40 mm i/d.

Operating

pressure

Hose

i/d

Pipemaster

Hose rotating

unit

Connection

thread

Hose deployment unit

Nozzle holder

1600 bar

DN 20

00.03138.0013

00.06023.0036

M 36 x 2

DKO-S

00.01330.0014

see chapter

15.D.4

1800 bar

DN 12

00.03138.0012

00.06023.0031

M 24 x 1,5

DKO-S

00.01330.0013

see chapter

15.D.4

3000 bar

DN 8

00.03138.0011

00.06023.0035

M 14 x 1,5

LH

00.01330.0013

00.01599.0301*

00.01599.0357*

00.01599.0449*

* The corresponding M4 nozzles must be selected according to the product handbook.

Accessories

Description

Code no.

Catching device,

for protection against hp water and

removed deposit.

Mainly for horizontal pipes.

For pipe-Ø of 100 – 300 mm

00.06025.0006

Guidance frame,

for adjusting the hose in front oft he

heat exchanger tubes.

Modified according heat exchanger

requirements.

Hammelmann

Maschinenfabrik GmbH

00.03371.0031

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipemaster /

Hose rotating system

15.D.4 – 10/13

Schlauchvorschubgerät

Hose feed tool

Schlauch-Zentriereinheit

Hose centring guide

Druckluftmotor mit Getriebe

Air motor with gear

Anschlüsse Schlauchvorschubgerät

Connectors for

hose feed control

Drehanschluss

Rotary joint

Wartungseinheit

Air service unit

Druckluftversorgung

Compressed air supply

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipe cleaning nozzle holders

15.D.5 – 10/13

Pipe Cleaning Nozzle Holders

Nozzle type „A“, „B“, „M“

max. op.

pressure

[bar]

1600

Nozzles

Ø x length

[mm]

Quantity

80 x 125

4

80 x 135

6

Protection disc

Adjustment

Connection

thread

4 x pull

Code no.

00.01599.0397

M 36 x 2

DKO-S

6 x pull

90 x 106

19

6 x pull, 6 x push,

1 x central, 6 x radial

51 x 95

2

2 x pull

55 x 110

5

2 x pull, 2 x radial,

1 x central

55 x 120

7

2 x pull, 2 x push,

1 x central, 2 x radial

2

1 x pull, 1 x central

00.01599.0260

M 33 x 2

20 low

00.01599.0414

00.01599.0273

M 33 x 2

20 low

00.01599.0272

00.01599.0405

01.01599.0235

M 24 x 1,5

DKO-S

65 x 100

4

3 x pull, 1 x central

01.01599.0234

2

2 x radial

00.01599.0262

2

2 x pull

00.01599.0263

65 x 110

5

2 x pull, 2 x radial,

1 x central

65 x 120

7

2 x pull, 2 x push,

1 x central, 2 x radial

00.01599.0406

70 x 122

special

design

2 x pull, 2 x push

00.01599.0388

65 x 110

M 33 x 2

20 low

00.01599.0264

1800

4

4

76 x 152

special

design

4

special

design

3 x pull, 1 x central

00.01599.0395

M 24 x 1,5

DKO-S

3 x pull

00.01599.0396

00.01599.0389

80 x 110

7

2 x pull, 2 x push,

1 x central, 2 x radial

90 x 147

4

2 x pull, 2 x push

00.01599.0387

M 33 x 2

20 low

138 x 147

4

2 x pull, 2 x push

00.01599.0390

144 x 147

4

2 x pull, 2 x push

00.01599.0386

Hammelmann

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Maschinenfabrik

GmbH

13-21 • Germany Telefax (0 25 22) 76-444

Nozzles, plugs and

sealsZum

see Sundern

chapter 12.J

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipe cleaning nozzle holders

15.D.6 – 10/13

Accessories

Description

Code no.

Banjo bolt

M 18 x 1,5, max. 1500 bar

01.04732.0171

Banjo bolt

M 18 x 1,5, max. 1800 bar

01.04732.0191

Cylinder ring in addition

01.00742.0142

Double nipple red.

M 33 x 2 und M 36 x 2, max. 1650 bar

01.02981.0495

Double nipple red.

M 33 x 2 und M 24 x 1,5, max. 1800 bar

01.02981.0490

Cylinder ring in addition

04.00742.0057

Additional double nipples see chapter 16.C.

Pipe Cleaning Nozzle Holders

Nozzle type „G“ and „H“

max. op.

Pressure

[bar]

Øx

length

[mm]

50 x 70

Nozzles

Quantity

Adjustment

2

1 x pull, 1 x central

Connection

thread

Code no.

01.01599.0212

M 24 x 1,5

DKO-S

1800

50 x 90

Hammelmann

Maschinenfabrik GmbH

3

2 x pull, 1 x central

01.01599.0211

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Pipe and sewer cleaning nozzles

Drawing

Description

15.F.1 – 10/13

Code no.

Reversible pipe cleaning nozzle (G ½”)

for cleaning partly or fully clogged pipes from

50 – 500 mm diameter, manually adjustable from pull to

push. Operating pressures up to 400 bar

Connection thread ½ “ female

09.00511.xxxx

Automatic reversible pipe cleaning nozzle AF 100

(G ½”)

for cleaning pipes with bends and gates, for pipe and

sewer diameters of 50 – 500 mm, remotely controlled

from pull to push by pressure impulse, therefore the hose

cannot jam in the pipe line. Operating pressures up to

200 bar. Connecting thread ½” female

09.00521.xxxx

Automatic reversible pipe cleaning nozzle AF 500

(G ½”)

for cleaning pipes with bends and gates, for pipe and

sewer diameters of 50 – 1000 mm, remotely controlled

from pull to push by pressure impulse, additionally

manually reversible from maximum cleaning efficiency to

maximum traction. Operating pressures up to 200 bar.

Connecting thread ½” female

09.00522.xxxx

Sewer cleaning nozzle (G 1”)

suitable for pipe and sewers from 500 to 2000 mm ,

flow rates of 180 to 300 l/min.,

operating pressures of 80 to 150 bar.

Connection thread 1” female

Without nozzles (suitable screw-in nozzle Type C + D)

09.00510.xxxx

Sewer cleaning nozzle (G 1”)

for outputs up to 350 l/min. and

operating pressures up to 150 bar.

Connection thread 1” female

Sewer cleaning nozzle (G 1”)

the nozzle inserts are exchangeable, for outputs up to

500 l/min. and operating pressures up to 150 bar.

Connection thread 1” female

Spray angle: 20°

Without nozzles (suitable screw-in nozzle Type C + D)

04.00795.0034

Sewer leaning nozzle for large diameters (G 1”)

the nozzle inserts are exchangeable, for outputs up to

500 l/min. and operating pressures up to 150 bar.

Connection thread 1” female

Without nozzles (suitable screw-in nozzle Type C + D)

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

04.00795.0055

Pipe and sewer cleaning nozzles

adapters

Inner diameter

DN

Operating pressure

bar

15.G.1 – 10/13

Dimensions

Code no.

10

550

½“ to M 18 x 1,5 male thread

DKL

04.05402.0060

10

850

½“ to M 22 x 1,5 male thread

DKO

01.02981.0285

12

470

½“ to M 22 x 1,5 male thread

DKL

04.05402.0061

10

1100

½“ to M 24 x 1,5 male thread

DKO

01.02981.0505

12

1040

½“ to M 30 x 1,5 male thread

DKM

01.02981.0057

10

940

½“ to M 36 x 2 male thread

DKO

01.02981.0312

20

350

1“ to M 30 x 1,5 male thread

DKM

04.05402.0067

25

300

1“ to M 38 x 1,5 male thread

DKM

04.05402.0068

12

1040

½“ to M 38 x 1,5 male thread

DKM

01.02981.0092

Hammelmann

Maschinenfabrik GmbH

Postfach 3309 • D-59282 Oelde Telefon (0 25 22) 76-0

Zum Sundern 13-21 • Germany Telefax (0 25 22) 76-444

eMail: mail@hammelmann.de • Internet: www.hammelmann.de

© Copyright Hammelmann Maschinenfabrik GmbH, Oelde, Germany. Rights reserved to modify design.

Application engineering

Standard

Surface blasting

Tank cleaning

Tube bundle cleaning

Pipe and sewer cleaning

Water hydraulic

Abrasive cutting

Hammelmann GmbH

Carl-Zeiss-Straße 6-8

59302 Oelde• Germany

mail@hammelmann.de

Telefon (0 25 22) 76-0

Telefax (0 25 22) 76-140

www.hammelmann.de

© Copyright Hammelmann GmbH, Oelde, Germany. Rights reserved to modify design.