Harwell Site Timeline Brochure

advertisement

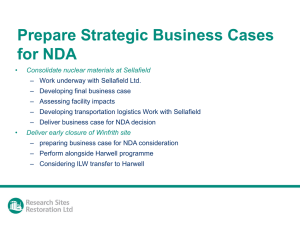

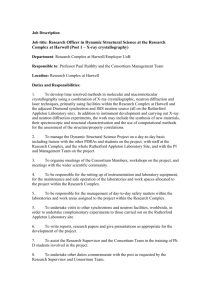

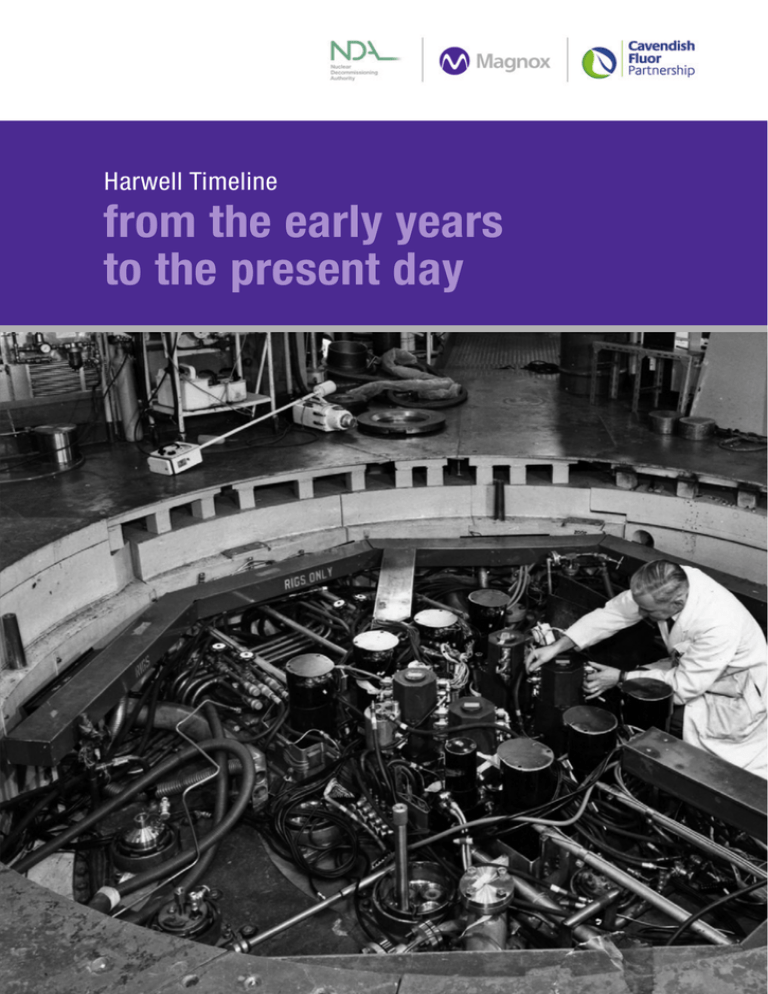

Harwell Timeline from the early years to the present day In Summary World-class excellence The Harwell site has been a centre for advanced science and technology for more than 65 years. In that time it has made enormous contributions to the development of nuclear energy, and many other major scientific and technological advances. It was in 1946 that a former RAF station in Oxfordshire became the Atomic Energy Research Establishment (AERE). By 1947 1,000 people were working on the site. From the start Harwell established a name for excellence. UKAEA then took responsibility for decommissioning and site restoration. UKAEA entered another new phase in 2005 when it began operating as a contractor to the newly created Nuclear Decommissioning Authority (NDA). Harwell produced many nuclear firsts: the first reactor in Western Europe, the first large reactor to be constructed outside the USA or USSR, and the UK’s first fast reactor. In 2009 Research Sites Restoration Limited (RSRL), successor to the AERE (albeit with a very different mission) was set up as a subsidiary of UKAEA Ltd. RSRL was the site licence company responsible for decommissioning and clearance at Harwell and its sister site at Winfrith, under contract to the NDA. In October 2009 UKAEA Ltd was sold to Babcock International Group. Competition to appoint a new parent body organisation for RSRL and Magnox began in 2012. Cavendish Fluor Partnership was announced, the preferred bidder and share transfer happened on 1 September 2014. RSRL became known as Magnox in Spring 2015. The site has adapted to changing circumstances, moving from reactor research and development into non-nuclear and commercial research, and then to decommissioning, waste management and site restoration. Throughout these periods of change, Harwell’s reputation for scientific and engineering excellence has remained as strong as ever. The organisation has undergone many changes, operating under various names and management structures. In 1954, Harwell joined other sites to become the United Kingdom Atomic Energy Authority (UKAEA). UKAEA was restructured in the 1990s, following the launch in 1989 of AEA Technology (AEAT) as its commercial arm, which was privatised in 1996. 1 Today large sections of land have been removed from nuclear regulation, paving the way for the ongoing expansion of the Harwell site as a science, innovation and business campus under the banner of Harwell Oxford, and a new chapter in Harwell’s unique history. 2 3 1 RAF buildings as seen in 1947 2 GLEEP Reactor in operation 1983 3 An early morning take off by a Handley Page Halifax 1944 5 4 6 4 Research Sites Restoration Ltd was formed 2009 5 Aerial shot of DIDO and PLUTO Reactors 1967 6 Aerial shot of Harwell site 1996 The Early Years Dawn of a new age The 1950s at Harwell were years of rapid growth. As early as 1953 more than 6,000 people were employed on site. The nuclear power industry was growing and in need of data upon which to base the design of its reactors and associated fuel cycle plant. Harwell provided much of that essential information. Reactor construction Fourteen experimental reactors were built at Harwell. GLEEP and BEPO were the first two to be constructed, initially to provide data for the Windscale reactors. GLEEP ran for an astonishing 43 years (1947-90) and was finally decommissioned and dismantled in 2005. The more powerful BEPO, the first large reactor to be constructed outside North America or the USSR, was a direct predecessor of later gas-cooled power reactors. Built in 1948, it ran for 20 years. A dozen other reactors soon followed. The most important were two large materials testing reactors, DIDO (1956) and PLUTO (1957), which played crucial parts in the development of later power reactors, as well as providing large quantities of radioactive isotopes for the medical industry. Both were in operation until 1990. 1 Several zero and low energy experimental reactors were built, including ZEPHYR and NEPTUNE. In addition, Harwell was home to the DIMPLE and LIDO reactors. ZETA was built to advance understanding of fusion power, work which later moved to Culham, UKAEA’s fusion laboratory. Research facilities A range of other ground-breaking research facilities were built to support the nuclear programme. Harwell’s radiochemistry laboratories, opened in 1949, were the most advanced in the world, allowing the safe handling of a wide range of radioactive materials. Van de Graaff accelerators, a Tandem generator and a cyclotron were built to probe into the atom. Pioneering research continued in purpose-built chemistry, chemical engineering and materials research laboratories, and a post irradiation examination facility. Waste management facilities were constructed to treat active and non-active solid and liquid radioactive waste from these activities. 2 3 1 GLEEP Reactor construction 1947 2 BEPO Reactor in operation 1962 3 Radiochemistry building 220 1950 5 4 6 4 LIDO Reactor swimming pool 1956 5 Experimentation in ZEPHYR Reactor 1955 6 Liquid Effluent Treatment Plant (LETP) 1961 Harwell 1950s – 2000s The Timeline 1950s – 2000s Sir Winston Churchill tours Harwell 1950 1960 1970 1951 1961 1971 1952 110 inch diameter synchrocyclotron - Hangar 7 1962 1953 1963 1954 1964 1972 1973 1974 Margaret Thatcher visits site DIDO Reactor Construction HM The Queen and HRH The Duke of Edinburgh Isotope production unit 1955 1965 1975 1956 1966 1976 1967 1977 1968 1978 1969 1979 1957 PLUTO Reactor top 1958 1959 Tandem Van-de-Graaff Generator is built Cockcroft-Walton particle accelerator – Hangar 8 Chemical Engineering 1950s 1960s 1970s Following the establishment of AERE in 1946 at RAF Harwell, GLEEP, BEPO, ZEPHYR, DIDO, PLUTO and other reactors are built. Radiochemistry laboratories and other facilities are constructed. Sir Winston Churchill tours the site in 1954 and HM The Queen and HRH The Duke of Edinburgh in 1957. Tandem Generator is built in 1958. The research programme is at its zenith, some of it in converted RAF hangars. Early research into fusion energy and fast reactors takes place. Harwell begins to undertake new roles in non-nuclear scientific research. Harwell makes the transition from being government-funded to a partly commercial research organisation. Spin-off technologies are used throughout industry in chemical engineering, computer programming, oil and gas exploration and many others. It establishes a name for excellence in safety research and environmental science. 1980 1990 1981 1991 1982 Intermediate waste store 1992 2000 2001 GLEEP decommissioning 2002 2003 1983 1993 2004 1984 Laser beams used in laser isotope separation Ground water treatment plant before it was replaced 1994 Tandem Van-de-Graaff Generator demolition 1985 1995 1986 1996 2005 2006 2007 50m long Harwell Pipeline facility 1987 1997 DIDO and PLUTO in care and maintenance 2008 2009 1988 1998 1989 Calorimetric surveys – cold fusion 2010 1999 Chemical engineering building 351 demolition 2011 RAF Water Tower demolition 1980s 1990s 2000s Laser beams are used to investigate aspects of the basic science and technology of laser isotope separation. The examination of liquid flows of gas and sand for the oil industry is carried out in the Harwell pipeline facility. Scientists debunk ‘cold fusion’ claims through careful measurements. AEA Technology is created in 1989 as a commercial organisation, later privatised. Harwell concentrates on the work of decommissioning its nuclear plant and disposing of waste. A major programme of decommissioning begins. GLEEP, DIDO and PLUTO reactors are closed down. Redundant facilities are decommissioned. Waste recovery and processing plant are built. Harwell International Business Centre is established in 1996. GLEEP and the Tandem generator tower are gone. 160 redundant facilities and buildings are removed and historic chemical storage areas cleaned up. DIDO, PLUTO and BEPO are put in long-term care and maintenance. In 2005 Harwell becomes a contractor to the NDA. In 2009, RSRL was formed. By 2012 more than 1.6m sq ft of land is cleaned up and approximately one fifth of the site delicensed. The Middle Years Applying expertise By the late 1960s the nuclear industry was starting to mature; there was not the same requirement for fundamental nuclear research. This led to decades of change, as Harwell’s focus moved towards applied nuclear and non-nuclear research. Diversification Drawing on existing expertise, Harwell diversified into many new areas, such as non-destructive testing, water desalination, materials technology, and electronics. Applied nuclear work included the development of nuclear instrumentation used throughout the industry. Elsewhere, medical, chemical engineering, computer programming, battery and the offshore oil and gas industries were among the fields to benefit from spin-off technologies born at Harwell. At this time the site was involved in several high profile projects: detecting metal fatigue in Big Ben; measuring cosmic ray doses on Concorde; contributing to the investigation into the King’s Cross underground fire; carbon dating various ancient artefacts, including the Winchester Round Table; and debunking the discovery of so-called ‘cold fusion’. Harwell was also prominent in the field of safety and environmental science, establishing research centres to 1 2 3 4 1MTR fuel rods cooling off in storage pond 1982 2 Non-destructive testing 1975 deal with chemical emergencies, environmental safety and environmental pollution, among others. In 1974 the Government set up a new, expert advisory agency, the Energy Technology Support Unit (ETSU). ETSU provided policy support and programme management in renewables, energy efficiency, clean coal, combined heat and power, and sustainable transport. The need for more powerful computers grew. In 1987, Harwell achieved another first when it took delivery of what at the time was the world’s most powerful computer, the CRAY-2 supercomputer. Restructuring In the 1970s, major restructuring meant some responsibilities were transferred from UKAEA to other newly created organisations. Even so, throughout the 1970s and 80s, some 4,000 people were employed inside the Harwell security fence. 6 5 3 Desalination plant ‘Gibraltar’ 1973 4Great clock of Westminster ‘Big Ben’ 1983 7 5 CRAY-2 Supercomputer 1987 6Scientists at work building 220 1976 7 Air sampling 1981 The Later Years A time of change The 1990s brought perhaps the biggest change of all. Reactors and laboratories across UKAEA sites, including Harwell, ceased operations and attention was switched to decommissioning and environmental restoration. Alongside decommissioning activities, Harwell began to develop part of the site as an international business centre. Era of decommissioning With the ending of publicly-funded civil nuclear research in the UK, all three of Harwell’s remaining reactors were closed down. From now on, many of the engineers and scientists who helped build and run Harwell’s experimental facilities would concentrate their skills on decommissioning, radioactive waste management, and site restoration. The task of decommissioning began in earnest. During this period UKAEA completed more decommissioning than any other organisation in Europe. After an exceptionally long operational life, GLEEP was shut down in 1990, and the fuel, control rods and external equipment removed. Major decommissioning work was carried out on DIDO and PLUTO and by 1997 they were in a condition suitable for long term care and maintenance, pending final decommissioning. 1 Many redundant facilities, including accelerators, R&D laboratories and waste processing plant were also decommissioned; new stores and plant were constructed for the recovery and processing of waste. Restructuring in the 1990s brought the number of employees on site to around 2,500. International business centre UKAEA brought new commercial life to its former nuclear sites with the creation of new technology parks, such as the Harwell International Business Centre, since developed as Harwell Oxford, a science, innovation and business campus – now home to some 100 high-tech and research organisations, employing 4,500 people. 2 3 1 Building 220 decommissioning success 2000 2 Intermediate Level Waste (ILW) operations 2009 3 Waste Encapsulation Plant (WEP) 2008 5 4 6 4 Chemical engineering building 351 demolition 1997 5 Waste Retrieval Machine 1 2001 6 Aerial shot of Harwell Campus 2009 The Present Day 2000 onwards The new millennium saw the pace of decommissioning and restoration step up another gear. In 2009 RSRL (now known as Magnox) was set up to complete the decommissioning and site clearance. By 2012 large areas of the site had been delicensed and removed from the controls of the Nuclear Installations Act and the security fence was realigned. Decommissioning and restoration Harwell’s decommissioning and restoration programme was well underway by 2000. Harwell became part of the NDA’s decommissioning programme in 2005. ‘temporary’ buildings from the 1950s. A number of facilities including the DIDO, PLUTO, and BEPO reactors remain in care and maintenance. The NDA has brought even greater focus on disciplined project management and coordination with other sites around the country. Research Sites Restoration Ltd was created in 2009 (now known as Magnox) to complete Harwell’s decommissioning programme. More than 160 unused buildings and research facilities have been demolished, clearing more than 1.6 million square feet of land. In 2011, Harwell’s site boundary fence moved reducing the size of the secure part of the site. To date, almost 18 hectares of land has been delicensed. This land will eventually be de-designated by the NDA and form part of the wider Harwell Oxford Campus. Since the turn of the century, Harwell has completed dismantling of the GLEEP reactor. The Tandem Generator, many purpose built laboratories, a post irradiation examination facility, and workshops have been decommissioned and demolished. The extensive drain system throughout the site is being cleaned and removed as necessary. Clean-up work has removed a number of the RAF structures from the 1930s and 1 Harwell’s history is one of constant change. What hasn’t changed over the decades is its unrelenting focus on worldclass science and technology, which began with the birth of the nuclear age in the 1940s and continues today. 2 3 1 GLEEP pile during dismantling 2004 2 Tandem Van-de-Graaff Generator demolition 2005 3 Ground Water Treatment Plant 2007 5 4 6 4 Retrieval Machine 2 5 RAF Water Tower demolition 2009 6 Medical and Health Physics Facility building 364 demolished 2010 For further information Visit us at www.magnoxsites.com Telephone us at 01235 820220 We have gone to considerable trouble to ensure that the facts presented in this brochure are correct. We recognise that the achievements we have outlined are simply a snapshot of some of the events at the Harwell site. They are not intended to be a comprehensive report of work carried out over the decades. Magnox is owned and operated by Cavendish Fluor Partnership (CFP) on behalf of the Nuclear Decommissioning Authority (NDA). The NDA works with CFP, the Magnox management team and other stakeholders to oversee the delivery of programmes, building confidence amongst Government and others that the nuclear legacy is being tackled effectively, safely and responsibly. Harwell Site Harwell Oxford Didcot Oxfordshire OX11 0DF Images reproduced by kind permission of the NDA photographic library.