Application Note

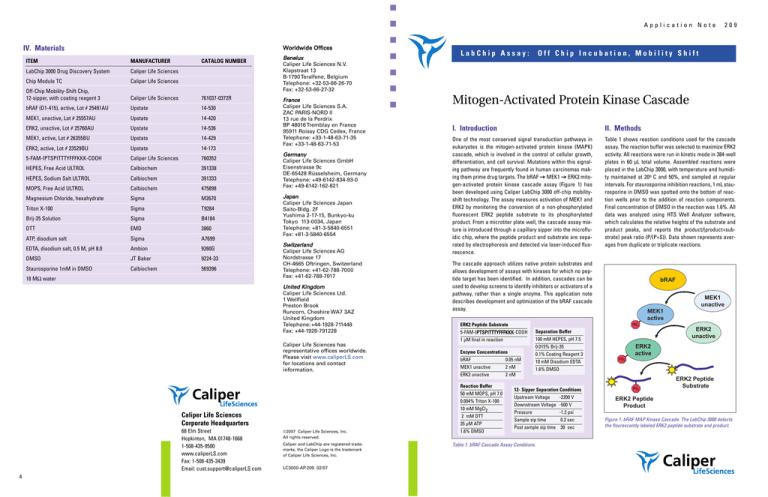

IV. Materials

Worldwide Offices

ITEM

MANUFACTURER

CATALOG NUMBER

LabChip 3000 Drug Discovery System

Caliper Life Sciences

Chip Module TC

Caliper Life Sciences

Off-Chip Mobility-Shift Chip,

12-sipper, with coating reagent 3

Caliper Life Sciences

761037-0372R

bRAF (D1-415), active, Lot # 25491AU

Upstate

14-530

MEK1, unactive, Lot # 25557AU

Upstate

14-420

ERK2, unactive, Lot # 25760AU

Upstate

14-536

MEK1, active, Lot # 26355BU

Upstate

14-429

ERK2, active, Lot # 23529BU

Upstate

14-173

5-FAM-IPTSPITTTYFFFKKK-COOH

Caliper Life Sciences

760352

HEPES, Free Acid ULTROL

Calbiochem

391338

HEPES, Sodium Salt ULTROL

Calbiochem

391333

MOPS, Free Acid ULTROL

Calbiochem

475898

Magnesium Chloride, hexahydrate

Sigma

M2670

Triton X-100

Sigma

T9284

Brij-35 Solution

Sigma

B4184

DTT

EMD

3860

ATP, disodium salt

Sigma

A7699

EDTA, disodium salt, 0.5 M, pH 8.0

Ambion

9260G

DMSO

JT Baker

9224-33

Staurosporine 1mM in DMSO

Calbiochem

569396

18 MΩ water

Benelux

Caliper Life Sciences N.V.

Klapstraat 13

B-1790 Teralfene, Belgium

Telephone: +32-53-66-26-70

Fax: +32-53-66-27-32

France

Caliper Life Sciences S.A.

ZAC PARIS-NORD II

13 rue de la Perdrix

BP 48016 Tremblay en France

95911 Roissy CDG Cedex, France

Telephone: +33-1-48-63-71-35

Fax: +33-1-48-63-71-53

Germany

Caliper Life Sciences GmbH

Eisenstrasse 9c

DE-65428 Rüsselsheim, Germany

Telephone: +49-6142-834-93-0

Fax: +49-6142-162-821

Japan

Caliper Life Sciences Japan

Saito-Bldg. 2F

Yushima 2-17-15, Bunkyo-ku

Tokyo 113-0034, Japan

Telephone: +81-3-5840-6551

Fax: +81-3-5840-6554

Switzerland

Caliper Life Sciences AG

Nordstrasse 17

CH-4665 Oftringen, Switzerland

Telephone: +41-62-788-7000

Fax: +41-62-788-7017

United Kingdom

Caliper Life Sciences Ltd.

1 Wellfield

Preston Brook

Runcorn, Cheshire WA7 3AZ

United Kingdom

Telephone: +44-1928-711448

Fax: +44-1928-791228

Caliper Life Sciences has

representative offices worldwide.

Please visit www.caliperLS.com

for locations and contact

information.

4

©2007 Caliper Life Sciences, Inc.

All rights reserved.

Caliper and LabChip are registered trademarks, the Caliper Logo is the trademark

of Caliper Life Sciences, Inc.

LC3000-AP-209 02/07

Off Chip Incubation, Mobility Shift

jáíçÖÉåJ^Åíáî~íÉÇ=mêçíÉáå=háå~ëÉ=`~ëÅ~ÇÉ

I. Introduction

II. Methods

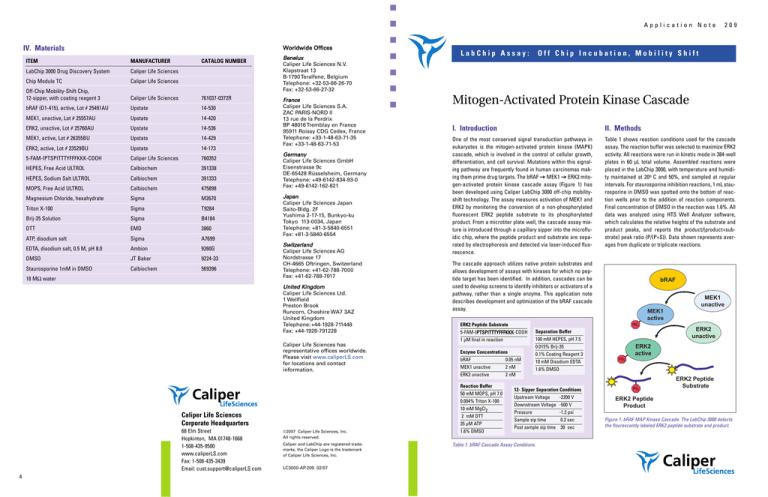

One of the most conserved signal transduction pathways in

eukaryotes is the mitogen-activated protein kinase (MAPK)

cascade, which is involved in the control of cellular growth,

differentiation, and cell survival. Mutations within this signaling pathway are frequently found in human carcinomas making them prime drug targets. The bRAF = MEK1 = ERK2 mitogen-activated protein kinase cascade assay (Figure 1) has

been developed using Caliper LabChip 3000 off-chip mobilityshift technology. The assay measures activation of MEK1 and

ERK2 by monitoring the conversion of a non-phosphorylated

fluorescent ERK2 peptide substrate to its phosphorylated

product. From a microtiter plate well, the cascade assay mixture is introduced through a capillary sipper into the microfluidic chip, where the peptide product and substrate are separated by electrophoresis and detected via laser-induced fluorescence.

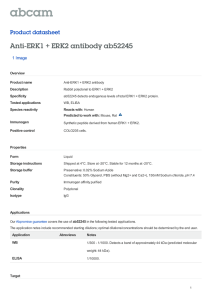

Table 1 shows reaction conditions used for the cascade

assay. The reaction buffer was selected to maximize ERK2

activity. All reactions were run in kinetic mode in 384-well

plates in 60 μL total volume. Assembled reactions were

placed in the LabChip 3000, with temperature and humidity maintained at 20o C and 50%, and sampled at regular

intervals. For staurosporine inhibition reactions, 1 mL staurosporine in DMSO was spotted onto the bottom of reaction wells prior to the addition of reaction components.

Final concentration of DMSO in the reaction was 1.6%. All

data was analyzed using HTS Well Analyzer software,

which calculates the relative heights of the substrate and

product peaks, and reports the product/(product+substrate) peak ratio (P/(P+S)). Data shown represents averages from duplicate or triplicate reactions.

The cascade approach utilizes native protein substrates and

allows development of assays with kinases for which no peptide target has been identified. In addition, cascades can be

used to develop screens to identify inhibitors or activators of a

pathway, rather than a single enzyme. This application note

describes development and optimization of the bRAF cascade

assay.

ERK2 Peptide Substrate

5-FAM-IPTSPITTTYFFFKKK-COOH

1 μM final in reaction

Enzyme Concentrations

bRAF

0.05 nM

MEK1 unactive

2 nM

ERK2 unactive

2 nM

Reaction Buffer

50 mM MOPS, pH 7.0

0.004% Triton X-100

10 mM MgCl2

Caliper Life Sciences

Corporate Headquarters

68 Elm Street

Hopkinton, MA 01748-1668

1-508-435-9500

www.caliperLS.com

Fax: 1-508-435-3439

Email: cust.support@caliperLS.com

LabChip Assay:

209

2 mM DTT

35 μM ATP

1.6% DMSO

bRAF

MEK1

unactive

MEK1

active

PO3

Separation Buffer

100 mM HEPES, pH 7.5

0.015% Brij-35

0.1% Coating Reagent 3

10 mM Disodium EDTA

1.6% DMSO

12- Sipper Separation Conditions

Upstream Voltage

-2200 V

Downstream Voltage -500 V

Pressure

-1.2 psi

Sample sip time

0.2 sec

Post sample sip time 30 sec

Table 1. bRAF Cascade Assay Conditions.

ERK2

unactive

ERK2

active

PO3

PO3

ERK2 Peptide

Substrate

ERK2 Peptide

Product

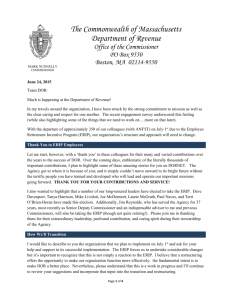

Figure 1. bRAF MAP Kinase Cascade. The LabChip 3000 detects

the flourescently labeled ERK2 peptide substrate and product.

209

Mitogen-Activated Protein Kinase Cascade

III. Results

Cascade Proof of Principle

Figure 1 illustrates the bRAF MAP kinase cascade. Activated

ERK2 adds a phosphate group to the fluorescently labeled ERK2

peptide. The phosphorylated peptide product migrates faster

through the chip than the non-phosphorylated substrate

(Figure 2). The presence of multiple enzymes and phosphorylation steps did not impede the sampling, separation or detection

of non-phosphorylated and phosphorylated ERK2 peptide.

substrate

only

Mitogen-Activated Protein Kinase Cascade

These results verify that data from assays containing active

bRAF, unactive MEK1, and unactive ERK2 (the full cascade)

represent independent activities of all three enzymes.

209

For the full and partial cascade reactions, staurosporine IC50

values increased with increasing ATP concentration (Figure 7

and Table 2). This is consistent with an ATP-competitive mode

of inhibition. At all ATP concentrations, the IC50 values for the

full cascade increased relative to those for the partial cascade

(Table 2), indicating that bRAF was less sensitive to staurosporine than MEK1. The change in IC50 values between the

full cascade and half cascade reflected the difference in the

final molar concentration of MEK1 in the two reactions (2 nM

vs. 0.4 nM).

bRAF Enzyme Titration

Increasing concentrations of bRAF were added to reactions

containing 2 nM unactive MEK1 and 2 nM unactive ERK2 (Figure

4). The concentration of bRAF affected both the lag time before

phosphorylated product was observed, and the linear rate of

product formation. This showed that the downstream targets of

bRAF were sufficiently in excess to act as indicators of bRAF

activity. The bRAF concentration resulting in approximately

30% conversion of ERK2 peptide substrate to product in 45 min

(0.05 nM) was chosen for further studies.

substrate

Figure 5. ATP Km for ERK2 active.

Figure 6 shows product accumulation in cascade reactions

containing 0.05 nM bRAF, 2 nM MEK1 unactive, 2 nM ERK2

unactive, and increasing concentrations of ATP. ATP concentration affected both the lag time before phosphorylated product was observed, and the rate of product formation. The ATP

concentration giving the half-maximal rate during the linear

phase of the full cascade reaction (27 μM) was consistent with

the measured ERK2 ATP Km (32 μM).

product

Figure 2. LabChip 3000 Data Signature. The signal from 6 channels of a

12-sipper chip are shown. The differing product peak heights reflect

differences in product accumulation due to variations in ATP concentration in different reaction wells.

Reactions were assembled containing various combinations of

active and unactive enzymes, and the accumulation of ERK2

peptide product was monitored for 75 minutes (Figure 3).

Product accumulation was observed only in reactions containing either active or activated ERK2. For reactions showing

product formation, reaction kinetics varied based on the concentration of ERK2 and the time required for activation of ERK2

by its upstream activator(s).

Figure 4. Effect of bRAF enzyme concentration on rate of phosphorylated peptide product accumulation.

ATP Titrations

ATP Km for ERK2 was measured by adding increasing amounts

of ATP to reactions containing 0.4 nM ERK2 and 1 μL peptide

substrate. Initial reaction rates were plotted vs. ATP concentration, and the Vmax and Km (32 μL) were determined via nonlinear regression analysis using the Michaelis-Menten Equation

(Figure 5).

Inhibition Assays

Staurosporine, a known ATP competitive inhibitor, was selected

to demonstrate use of the cascade assay to identify a pathway

inhibitor and determine its mechanism of action. Staurosporine

titrations were run at 4 different ATP concentrations with reactions containing:

Full Cascade

0.05 nM bRAF, 2 nM unactive MEK1, 2 nM unactive ERK2

Partial Cascade 0.4 nM active MEK1, 2 nM unactive ERK2

ERK2 Only

0.4 nM

Reactions containing ERK2 only progressed at the same rate

across all staurosporine concentrations (data not shown) indicating that ERK2 is not sensitive to this inhibitor.

Figure 7. Staurosporine inhibition curves for reactions containing the

full cascade (A) or the partial cascade (B).

[ATP]

IC50

Full Cascade

Partial Cascade

ERK2 Only

1000 mM

236 nM

67.2 nM

no effect

333 mM

44.6 nM

12.3 nM

no effect

111 mM

12.0 nM

3.8 nM

no effect

37 mM

2.9 nM

1.3 nM

no effect

Table 2. Staurosporine IC50 values at varying ATP concentrations.

2

Figure 3. Accumulation of phosphorylated peptide product is dependent upon the activity of ERK2. The legend summarizes which combinations of

active enzyme at 0.4 nM (A) and unactive enzyme at 2 nM (U) resulted in peptide product formation.

Figure 6. Effect of ATP concentration on rate of phosphorylated

product accumulation in cascade reactions.

3

209

Mitogen-Activated Protein Kinase Cascade

III. Results

Cascade Proof of Principle

Figure 1 illustrates the bRAF MAP kinase cascade. Activated

ERK2 adds a phosphate group to the fluorescently labeled ERK2

peptide. The phosphorylated peptide product migrates faster

through the chip than the non-phosphorylated substrate

(Figure 2). The presence of multiple enzymes and phosphorylation steps did not impede the sampling, separation or detection

of non-phosphorylated and phosphorylated ERK2 peptide.

substrate

only

Mitogen-Activated Protein Kinase Cascade

These results verify that data from assays containing active

bRAF, unactive MEK1, and unactive ERK2 (the full cascade)

represent independent activities of all three enzymes.

209

For the full and partial cascade reactions, staurosporine IC50

values increased with increasing ATP concentration (Figure 7

and Table 2). This is consistent with an ATP-competitive mode

of inhibition. At all ATP concentrations, the IC50 values for the

full cascade increased relative to those for the partial cascade

(Table 2), indicating that bRAF was less sensitive to staurosporine than MEK1. The change in IC50 values between the

full cascade and half cascade reflected the difference in the

final molar concentration of MEK1 in the two reactions (2 nM

vs. 0.4 nM).

bRAF Enzyme Titration

Increasing concentrations of bRAF were added to reactions

containing 2 nM unactive MEK1 and 2 nM unactive ERK2 (Figure

4). The concentration of bRAF affected both the lag time before

phosphorylated product was observed, and the linear rate of

product formation. This showed that the downstream targets of

bRAF were sufficiently in excess to act as indicators of bRAF

activity. The bRAF concentration resulting in approximately

30% conversion of ERK2 peptide substrate to product in 45 min

(0.05 nM) was chosen for further studies.

substrate

Figure 5. ATP Km for ERK2 active.

Figure 6 shows product accumulation in cascade reactions

containing 0.05 nM bRAF, 2 nM MEK1 unactive, 2 nM ERK2

unactive, and increasing concentrations of ATP. ATP concentration affected both the lag time before phosphorylated product was observed, and the rate of product formation. The ATP

concentration giving the half-maximal rate during the linear

phase of the full cascade reaction (27 μM) was consistent with

the measured ERK2 ATP Km (32 μM).

product

Figure 2. LabChip 3000 Data Signature. The signal from 6 channels of a

12-sipper chip are shown. The differing product peak heights reflect

differences in product accumulation due to variations in ATP concentration in different reaction wells.

Reactions were assembled containing various combinations of

active and unactive enzymes, and the accumulation of ERK2

peptide product was monitored for 75 minutes (Figure 3).

Product accumulation was observed only in reactions containing either active or activated ERK2. For reactions showing

product formation, reaction kinetics varied based on the concentration of ERK2 and the time required for activation of ERK2

by its upstream activator(s).

Figure 4. Effect of bRAF enzyme concentration on rate of phosphorylated peptide product accumulation.

ATP Titrations

ATP Km for ERK2 was measured by adding increasing amounts

of ATP to reactions containing 0.4 nM ERK2 and 1 μL peptide

substrate. Initial reaction rates were plotted vs. ATP concentration, and the Vmax and Km (32 μL) were determined via nonlinear regression analysis using the Michaelis-Menten Equation

(Figure 5).

Inhibition Assays

Staurosporine, a known ATP competitive inhibitor, was selected

to demonstrate use of the cascade assay to identify a pathway

inhibitor and determine its mechanism of action. Staurosporine

titrations were run at 4 different ATP concentrations with reactions containing:

Full Cascade

0.05 nM bRAF, 2 nM unactive MEK1, 2 nM unactive ERK2

Partial Cascade 0.4 nM active MEK1, 2 nM unactive ERK2

ERK2 Only

0.4 nM

Reactions containing ERK2 only progressed at the same rate

across all staurosporine concentrations (data not shown) indicating that ERK2 is not sensitive to this inhibitor.

Figure 7. Staurosporine inhibition curves for reactions containing the

full cascade (A) or the partial cascade (B).

[ATP]

IC50

Full Cascade

Partial Cascade

ERK2 Only

1000 mM

236 nM

67.2 nM

no effect

333 mM

44.6 nM

12.3 nM

no effect

111 mM

12.0 nM

3.8 nM

no effect

37 mM

2.9 nM

1.3 nM

no effect

Table 2. Staurosporine IC50 values at varying ATP concentrations.

2

Figure 3. Accumulation of phosphorylated peptide product is dependent upon the activity of ERK2. The legend summarizes which combinations of

active enzyme at 0.4 nM (A) and unactive enzyme at 2 nM (U) resulted in peptide product formation.

Figure 6. Effect of ATP concentration on rate of phosphorylated

product accumulation in cascade reactions.

3

Application Note

IV. Materials

Worldwide Offices

ITEM

MANUFACTURER

CATALOG NUMBER

LabChip 3000 Drug Discovery System

Caliper Life Sciences

Chip Module TC

Caliper Life Sciences

Off-Chip Mobility-Shift Chip,

12-sipper, with coating reagent 3

Caliper Life Sciences

761037-0372R

bRAF (D1-415), active, Lot # 25491AU

Upstate

14-530

MEK1, unactive, Lot # 25557AU

Upstate

14-420

ERK2, unactive, Lot # 25760AU

Upstate

14-536

MEK1, active, Lot # 26355BU

Upstate

14-429

ERK2, active, Lot # 23529BU

Upstate

14-173

5-FAM-IPTSPITTTYFFFKKK-COOH

Caliper Life Sciences

760352

HEPES, Free Acid ULTROL

Calbiochem

391338

HEPES, Sodium Salt ULTROL

Calbiochem

391333

MOPS, Free Acid ULTROL

Calbiochem

475898

Magnesium Chloride, hexahydrate

Sigma

M2670

Triton X-100

Sigma

T9284

Brij-35 Solution

Sigma

B4184

DTT

EMD

3860

ATP, disodium salt

Sigma

A7699

EDTA, disodium salt, 0.5 M, pH 8.0

Ambion

9260G

DMSO

JT Baker

9224-33

Staurosporine 1mM in DMSO

Calbiochem

569396

18 MΩ water

Benelux

Caliper Life Sciences N.V.

Klapstraat 13

B-1790 Teralfene, Belgium

Telephone: +32-53-66-26-70

Fax: +32-53-66-27-32

France

Caliper Life Sciences S.A.

ZAC PARIS-NORD II

13 rue de la Perdrix

BP 48016 Tremblay en France

95911 Roissy CDG Cedex, France

Telephone: +33-1-48-63-71-35

Fax: +33-1-48-63-71-53

Germany

Caliper Life Sciences GmbH

Eisenstrasse 9c

DE-65428 Rüsselsheim, Germany

Telephone: +49-6142-834-93-0

Fax: +49-6142-162-821

Japan

Caliper Life Sciences Japan

Saito-Bldg. 2F

Yushima 2-17-15, Bunkyo-ku

Tokyo 113-0034, Japan

Telephone: +81-3-5840-6551

Fax: +81-3-5840-6554

Switzerland

Caliper Life Sciences AG

Nordstrasse 17

CH-4665 Oftringen, Switzerland

Telephone: +41-62-788-7000

Fax: +41-62-788-7017

United Kingdom

Caliper Life Sciences Ltd.

1 Wellfield

Preston Brook

Runcorn, Cheshire WA7 3AZ

United Kingdom

Telephone: +44-1928-711448

Fax: +44-1928-791228

Caliper Life Sciences has

representative offices worldwide.

Please visit www.caliperLS.com

for locations and contact

information.

4

©2007 Caliper Life Sciences, Inc.

All rights reserved.

Caliper and LabChip are registered trademarks, the Caliper Logo is the trademark

of Caliper Life Sciences, Inc.

LC3000-AP-209 02/07

Off Chip Incubation, Mobility Shift

jáíçÖÉåJ^Åíáî~íÉÇ=mêçíÉáå=háå~ëÉ=`~ëÅ~ÇÉ

I. Introduction

II. Methods

One of the most conserved signal transduction pathways in

eukaryotes is the mitogen-activated protein kinase (MAPK)

cascade, which is involved in the control of cellular growth,

differentiation, and cell survival. Mutations within this signaling pathway are frequently found in human carcinomas making them prime drug targets. The bRAF = MEK1 = ERK2 mitogen-activated protein kinase cascade assay (Figure 1) has

been developed using Caliper LabChip 3000 off-chip mobilityshift technology. The assay measures activation of MEK1 and

ERK2 by monitoring the conversion of a non-phosphorylated

fluorescent ERK2 peptide substrate to its phosphorylated

product. From a microtiter plate well, the cascade assay mixture is introduced through a capillary sipper into the microfluidic chip, where the peptide product and substrate are separated by electrophoresis and detected via laser-induced fluorescence.

Table 1 shows reaction conditions used for the cascade

assay. The reaction buffer was selected to maximize ERK2

activity. All reactions were run in kinetic mode in 384-well

plates in 60 μL total volume. Assembled reactions were

placed in the LabChip 3000, with temperature and humidity maintained at 20o C and 50%, and sampled at regular

intervals. For staurosporine inhibition reactions, 1 mL staurosporine in DMSO was spotted onto the bottom of reaction wells prior to the addition of reaction components.

Final concentration of DMSO in the reaction was 1.6%. All

data was analyzed using HTS Well Analyzer software,

which calculates the relative heights of the substrate and

product peaks, and reports the product/(product+substrate) peak ratio (P/(P+S)). Data shown represents averages from duplicate or triplicate reactions.

The cascade approach utilizes native protein substrates and

allows development of assays with kinases for which no peptide target has been identified. In addition, cascades can be

used to develop screens to identify inhibitors or activators of a

pathway, rather than a single enzyme. This application note

describes development and optimization of the bRAF cascade

assay.

ERK2 Peptide Substrate

5-FAM-IPTSPITTTYFFFKKK-COOH

1 μM final in reaction

Enzyme Concentrations

bRAF

0.05 nM

MEK1 unactive

2 nM

ERK2 unactive

2 nM

Reaction Buffer

50 mM MOPS, pH 7.0

0.004% Triton X-100

10 mM MgCl2

Caliper Life Sciences

Corporate Headquarters

68 Elm Street

Hopkinton, MA 01748-1668

1-508-435-9500

www.caliperLS.com

Fax: 1-508-435-3439

Email: cust.support@caliperLS.com

LabChip Assay:

209

2 mM DTT

35 μM ATP

1.6% DMSO

bRAF

MEK1

unactive

MEK1

active

PO3

Separation Buffer

100 mM HEPES, pH 7.5

0.015% Brij-35

0.1% Coating Reagent 3

10 mM Disodium EDTA

1.6% DMSO

12- Sipper Separation Conditions

Upstream Voltage

-2200 V

Downstream Voltage -500 V

Pressure

-1.2 psi

Sample sip time

0.2 sec

Post sample sip time 30 sec

Table 1. bRAF Cascade Assay Conditions.

ERK2

unactive

ERK2

active

PO3

PO3

ERK2 Peptide

Substrate

ERK2 Peptide

Product

Figure 1. bRAF MAP Kinase Cascade. The LabChip 3000 detects

the flourescently labeled ERK2 peptide substrate and product.