Safety clothing

for masonry work

Avoid fines, hassles, and injuries by

dressing appropriately for the job

By Kenneth A. Hooker

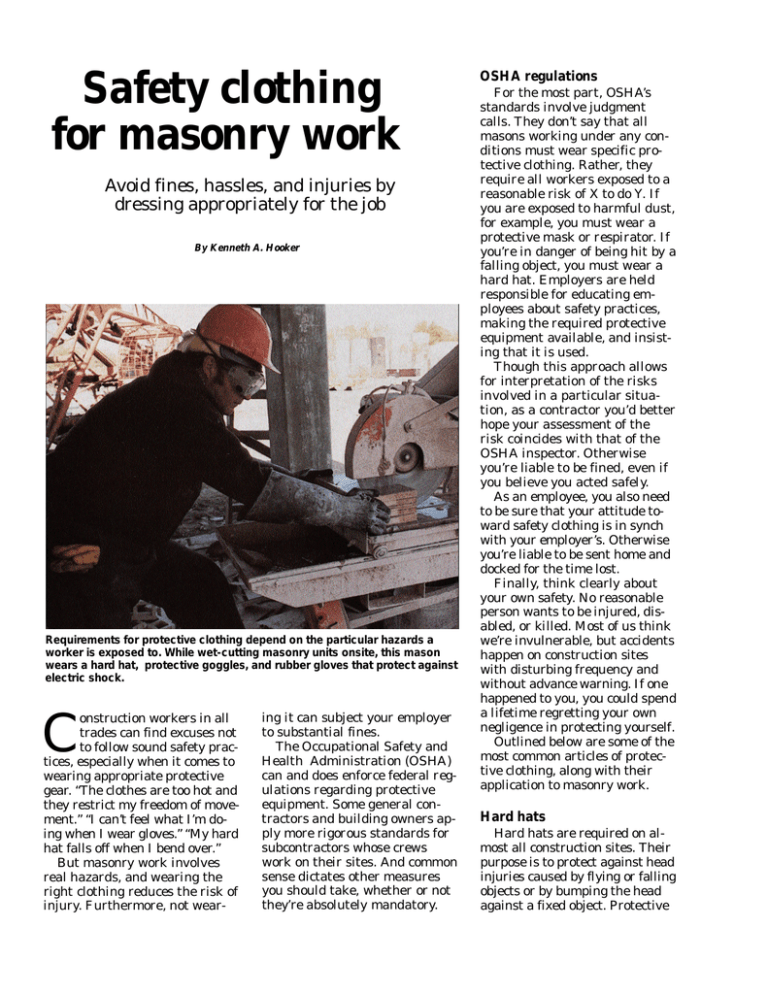

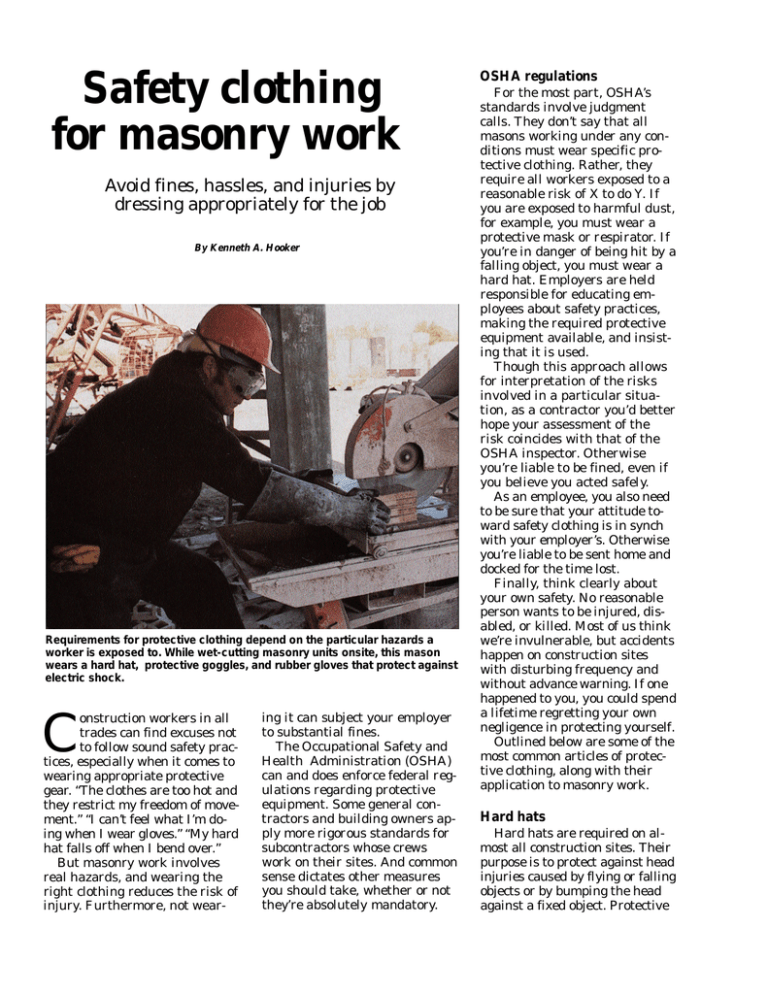

Requirements for protective clothing depend on the particular hazards a

worker is exposed to. While wet-cutting masonry units onsite, this mason

wears a hard hat, protective goggles, and rubber gloves that protect against

electric shock.

C

onstruction workers in all

trades can find excuses not

to follow sound safety practices, especially when it comes to

wearing appropriate protective

gear. “The clothes are too hot and

they restrict my freedom of movement.” “I can’t feel what I’m doing when I wear gloves.” “My hard

hat falls off when I bend over.”

But masonry work involves

real hazards, and wearing the

right clothing reduces the risk of

injury. Furthermore, not wear-

ing it can subject your employer

to substantial fines.

The Occupational Safety and

Health Administration (OSHA)

can and does enforce federal regulations regarding protective

equipment. Some general contractors and building owners apply more rigorous standards for

subcontractors whose crews

work on their sites. And common

sense dictates other measures

you should take, whether or not

they’re absolutely mandatory.

OSHA regulations

For the most part, OSHA’s

standards involve judgment

calls. They don’t say that all

masons working under any conditions must wear specific protective clothing. Rather, they

require all workers exposed to a

reasonable risk of X to do Y. If

you are exposed to harmful dust,

for example, you must wear a

protective mask or respirator. If

you’re in danger of being hit by a

falling object, you must wear a

hard hat. Employers are held

responsible for educating employees about safety practices,

making the required protective

equipment available, and insisting that it is used.

Though this approach allows

for interpretation of the risks

involved in a particular situation, as a contractor you’d better

hope your assessment of the

risk coincides with that of the

OSHA inspector. Otherwise

you’re liable to be fined, even if

you believe you acted safely.

As an employee, you also need

to be sure that your attitude toward safety clothing is in synch

with your employer’s. Otherwise

you’re liable to be sent home and

docked for the time lost.

Finally, think clearly about

your own safety. No reasonable

person wants to be injured, disabled, or killed. Most of us think

we’re invulnerable, but accidents

happen on construction sites

with disturbing frequency and

without advance warning. If one

happened to you, you could spend

a lifetime regretting your own

negligence in protecting yourself.

Outlined below are some of the

most common articles of protective clothing, along with their

application to masonry work.

Hard hats

Hard hats are required on almost all construction sites. Their

purpose is to protect against head

injuries caused by flying or falling

objects or by bumping the head

against a fixed object. Protective

headgear must do two things—

resist penetration and absorb the

shock of a blow. OSHA-approved

hard hats conform to ANSI standard Z89.1-1969 (Ref. 1).

A properly fitting hard hat

should be raised slightly off the

head so it can cushion and absorb blows. The bands inside the

hat should be adjusted so that

the hat fits properly and rests in

a fairly level position.

Hard hats should be available

at all times, but they need not

be worn under certain circumstances. When working on garden walls or other projects isolated from other trades, masons

may not be required to wear

hard hats. Some contractors allow masons to go without hard

hats if they’re working at the

top of the wall and no work is in

progress overhead.

Safety shoes

Leather work boots offer more

protection than gym shoes or

sneakers and are required on

most jobsites. Safety boots protect against injuries caused by

dropping heavy objects on the

foot, or by stepping on sharp objects or scraps of masonry materials. Boots also help protect the

ankles from scrapes and bruises.

Eye protection

OSHA requires eye protection

equipment whenever there is a

reasonable probability that an injury could be prevented by its use.

In normal brick- and block-laying,

eye protection generally is not required. Certain operations, though,

present distinct risks of eye injury

and thus call for the use of protective goggles or other eye protection.

Among these activities are:

■ sawcutting units or walls

■ grinding or chipping out mortar joints for tuckpointing

■ splitting stone

■ any other work that presents a

danger of chips or dust flying

into the eyes

OSHA-approved eye protection

must conform to ANSI Z 87.1-

1968 (Ref. 2). Individuals who

wear corrective glasses must wear

face shields, goggles, or spectacles

of one of the following types:

the trauma to the hands caused

by using a chip hammer or other

device that produces prolonged

and violent vibrations.

■ glasses with protective lenses

that provide optical correction

■ goggles worn over corrective

spectacles without disturbing

the adjustment of the spectacles

■ goggles that incorporate corrective lenses mounted behind

the protective glasses

Other protective clothing

Respiratory protection

Respiratory protection is required to prevent occupational

diseases caused by breathing air

contaminated with harmful dust,

smoke, mist, gases, and vapors.

Again, masonry work results in

such exposure only when certain

tasks are performed. Masons and

laborers should wear dust masks

or other approved respiratoryprotective devices when they are

engaged in grinding or sawcutting operations.

When using any chemical

agents, mortar additives, cleaning chemicals, and the like,

follow the manufacturer’s recommendations with regard to protective equipment and other safety

measures. Mixing and spraying

certain chemicals can put you at

risk of respiratory damage, so

take any necessary precautions.

Gloves

Work gloves protect hands

from cuts and scrapes caused by

handling rough-textured masonry

units. They also can help prevent

chemical burns from exposure to

fresh mortar. Though gloves are

not ordinarily required for masonry work, they often are useful.

In some cases, work gloves of

specific types are required.

Rubber gloves and boots should

be worn to reduce the risk of electric shock when wet-sawing or

working with other power tools in

the vicinity of water.

Protective gloves with vibration-deadening silastic in the

palms and fingers can help ease

Though OSHA generally does

not require it, sensible work

clothes can help prevent injuries

and contribute to a safer jobsite.

Mason and author Richard T.

Kreh makes specific recommendations in his book, Safety for

Masons (Ref. 3):

■ Wear long pants of medium- or

heavyweight material to protect legs from scrapes and cuts.

Avoid cuffs that can catch on

scaffolding.

■ Wear a shirt for protection

from welding sparks and flying

masonry chips. Keep sleeves

rolled up or buttoned so they

don't catch on objects.

■ Dress appropriately for the

weather, but avoid loose or

bulky garments that can restrict free movement and catch

on objects.

Besides these safety concerns,

some contractors and building

owners prohibit masons from

working in shorts or without a

shirt for the sake of decorum.

References

1. ANSI Z89.1-1969, “Requirements for Industrial Head Protection,” American

National Standards Institute, 1430 Broadway, New York, NY 10018.

2. ANSI Z87.1-1968, “Practice for Industrial

and Educational Eye and Face Protection,”

ANSI.

3. Richard Kreh, Sr., Safety for Masons,

Delmar Publishers Inc., Box 15-015, Albany, NY 12212.

PUBLICATION #M920136

Copyright © 1992, The Aberdeen Group

All rights reserved