Title page

Digital Energy

Multilin

URC Reference Guide

URC revision: A1

Document part number: 1601-9200-A1

GE publication code: GEK-113472

Copyright © 2011 GE Multilin

RE

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

ISO9001:2000

I

N

EM

G

GE Multilin

D

T

GIS ERE

U LT I L

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

UL # A3775

© 2011 GE Multilin Incorporated. All rights reserved.

GE Multilin URC Universal Recloser Control reference guide for revision A1.

URC Universal Recloser Control, EnerVista, EnerVista Launchpad, EnerVista URC Setup, and

FlexLogic are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9200-A1 (August 2011)

Digital Energy

Multilin

URC Universal Recloser Control

Table of contents

INTRODUCTION

Overview ..........................................................................................................................1

SPECIFICATIONS

F60 specifications...........................................................................................................3

URC specifications..........................................................................................................3

URC PANEL

INTERFACE

Front panel indicators ...................................................................................................6

Status indicators...............................................................................................................................................6

Event cause indicators...................................................................................................................................6

User-programmable indicators.................................................................................................................7

Recloser status indicators............................................................................................................................8

Front panel pushbuttons ..............................................................................................8

Reset pushbutton .............................................................................................................................................8

Control pushbuttons .......................................................................................................................................8

User-programmable pushbuttons ...........................................................................................................8

Pushbuttons unlock ........................................................................................................................................ 9

MCBs and fuses.............................................................................................................10

Front panel MCBs .......................................................................................................................................... 10

Front panel fuses........................................................................................................................................... 10

HARDWARE

Connections...................................................................................................................11

Enclosure .......................................................................................................................13

Grounding of the enclosure...................................................................................................................... 14

Connecting the battery ...............................................................................................15

Connecting three-phase currents.............................................................................15

Connecting three-phase voltages.............................................................................16

Metering check .............................................................................................................16

Phase rotation...............................................................................................................17

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

iii

TABLE OF CONTENTS

WIRING AND

SCHEMATIC

DIAGRAMS

Schematic diagrams ....................................................................................................19

Wiring diagrams ...........................................................................................................21

COMMUNICATIONS

RS232 serial port...........................................................................................................25

RS485 serial port...........................................................................................................26

Ethernet communications ..........................................................................................26

RECORDS

Event record ..................................................................................................................27

Fault reports..................................................................................................................28

Oscillography record ...................................................................................................29

TRIP/OPEN AND

CLOSE FUNCTIONS

Issuing a trip/open command....................................................................................31

Issuing a close command............................................................................................32

Enabling and disabling the hot line tag function ...................................................33

Local/remote control...................................................................................................34

PROTECTION

FUNCTIONS

Phase instantaneous overcurrent settings .............................................................35

Phase time overcurrent...............................................................................................36

Recloser curves.............................................................................................................36

Ground and neutral overcurrent ...............................................................................37

Disabling ground/neutral protection .......................................................................37

CONTROL

FUNCTIONS

Autoreclose....................................................................................................................41

Factory settings ..............................................................................................................................................43

Enabling and disabling autoreclosing..................................................................................................46

Setting groups...............................................................................................................48

Changing setting groups............................................................................................................................48

BATTERY

MANAGEMENT

SYSTEM

Charger controller........................................................................................................52

Charger controller operation .....................................................................................52

Battery safety information .........................................................................................53

Cautions and warnings ...............................................................................................................................53

Replacement procedure for batteries..................................................................................................54

Battery disposal guidelines ........................................................................................55

iv

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 1: Introduction

Introduction

Overview

This reference guide provides information needed to help you test, install, set and

communicate with the URC Universal Recloser Control (URC). The URC is based on the URseries F60 Feeder Protection System. The UR-series F60 device has default settings

required for three-phase recloser control.

The URC Universal Recloser Control is designed for use with various manufacturer’s threephase reclosers (for example G&W, Cooper, ABB, three-phase reclosers with 24 V DC trip

and close circuits). The F60 device provides protection, control, metering and

communication functions required for distribution automation of distribution feeders for

line and substation application. The URC has factory default settings that includes phase

overcurrent, neutral overcurrent, and ground overcurrent protection as well as threephase four-shot autoreclosing.

If the phase current, neutral current, or ground current exceeds its pre-set pick-up value

for corresponding definite or time-curve timing, the controller will execute the

programmed tripping and reclosing operations. If the fault is temporary, autoreclosing is

reset after a pre-set time delay. If the fault is permanent, the URC will perform a complete

programmed autoreclosing sequence and will lock-out the recloser in the open position.

Lock-out can be reset by manual close if the recloser is closed for pre-defined time or by

automatic reset from lockout logic.

The protection and control can be reconfigured by the end user to meet specific

application requirements. Protection and control parameters can be programmed through

the front panel keypad of the device or (preferably) through a computer connected to the

front panel RS232 port or the Ethernet port.

The URC operates on 25 Hz, 50 Hz, and 60 Hz power systems, and is designed to work with

standard recloser bushing current transformers with a 1000/1 ratio. The controller may

work with all other non-standard current transformers with secondary currents of 1 A or

5 A, and also may be connected to optional potential (voltage) transformers.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

1

OVERVIEW

CHAPTER 1: INTRODUCTION

In addition to basic autoreclosing control and phase and ground overcurrent protection

functions, the URC provides undervoltage, overvoltage, underfrequency, overfrequency,

directional overcurrent, reverse power, sensitive ground fault, negative-sequence

overcurrent protection functions. It also provides for synchrocheck, recloser failure, event

recording, oscillography, data logger, event recorder and fault locator functionality.

The URC is available with optional high-impedance fault (Hi-Z) protection.

Metering functions on a per-phase basis include instantaneous current and voltage and

per phase and total basis power, power factor and energy measurement. Current and

power demand, symmetrical components and harmonics up to 25th are also provided.

2

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 2: Specifications

Specifications

F60 specifications

Refer to the reference guide for the F60 Feeder Protection System available online at

http://www.GEmultilin.com.

URC specifications

BATTERY CONTROLLER

Maximum charger current: ............................10 amps

Bulk (fast) mode on voltage: ..........................12.8 V / 25.6 V

Top-off voltage:....................................................14.7 V / 29.4 V

Float mode voltage:...........................................13.6 V / 27.2 V

Low voltage disconnect:..................................10.0 V / 20.0 V

Low voltage reconnect: ...................................12.0 V / 24.0 V

Self-consumption: ..............................................2.9 mA / 3.3 mA

Temperature compensation:.........................–3 mV/°C/cell

Operating temperature:...................................–40 to 60°C

Pluggable connectors:......................................10 AWG maximum wire size

Maximum input voltage:..................................40 V

FUSES

Battery fuse: ..........................................................10 A / 250 V

GFCI fuse:................................................................15 A / 250 V

3 VT's (PT's) fuses:................................................0.5 A / 250 V

BATTERIES

Nominal voltage:.................................................12 V each

Operating temperature:...................................–40°C (–40°F) to 45°C (113°F)

URC TYPE TESTS

Dielectric voltage withstand:.........................EN60255-5, 2.2 kV

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

3

URC SPECIFICATIONS

4

CHAPTER 2: SPECIFICATIONS

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 3: URC panel interface

URC panel interface

The URC panel interface consists of the following features:

•

F60 LCD display.

•

Status and event cause panel LEDs on the F60 faceplate.

•

User-programmable LEDs on the F60 faceplate.

•

Reset, control and user-programmable pushbuttons on the F60 faceplate.

•

F60 keypad.

•

RS232 port on the F60 device faceplate.

•

Ethernet (RJ45) port.

•

Four large pushbuttons (ground block, reclose block, open and close).

•

Two toggle switches (remote block and hot line tag).

•

Four red LEDs (recloser status for phases A, B, and C, as well as hot line tag indication).

•

GFCI 120 V AC / 15 A outlet for the laptop power.

•

Two-pole 15 A MCB for AC input protection.

•

Single-pole 3 A MCB for heater protection.

•

10 A battery fuse and holder.

•

15 A GFCI fuse and holder.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

5

FRONT PANEL INDICATORS

CHAPTER 3: URC PANEL INTERFACE

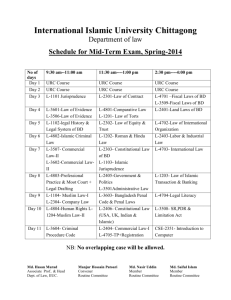

Figure 1: The URC panel interface

/RFDO5HPRWH

WRJJOHVZLWFK

)/&'GLVSOD\

*URXQGEORFNDQGUHFORVH

EORFNSXVKEXWWRQV

6WDWXVDQGHYHQW

FDXVHSDQHO/('V

8VHUSURJUDPPDEOH/('V

7KUHHSKDVHWULSRSHQ

DQGFORVHSXVKEXWWRQV

.H\SDG

&RQWUROSXVKEXWWRQV

5HFORVHUVWDWXV/('V

8VHUSURJUDPPDEOH

SXVKEXWWRQV

+RWOLQHWDJRQRIIWRJJOH

VZLWFKZLWKVWDWXV/('

56SRUW

$&LQSXWDQGKHDWHU0&%V

(WKHUQHWSRUW

%DWWHU\DQG*)&,IXVHV

$&'5

Front panel indicators

Status indicators

The following status indicators are available and are located on the F60 panel.

•

IN SERVICE: Indicates that control power is applied; all monitored inputs, outputs and

internal systems are OK; the device has been programmed.

•

TROUBLE: Indicates that the device has detected an internal problem.

•

TEST MODE: Indicates that the device is in test mode.

•

TRIP: Indicates that the selected operand serving as a trip switch has operated. This

indicator always latches; the reset command must be initiated to allow the latch to be

reset. For the URC application, the trip indicator will operate if any protection element

issued a trip command. If required, the user may create different logic or set as OFF.

•

ALARM: Indicates that the selected operand serving as an Alarm switch has operated.

This indicator is never latched. For the URC application alarm is set as OFF. If required,

the user may create customized logic.

•

PICKUP: Indicates that an element is picked up. This indicator is never latched.

Event cause indicators

Events cause LEDs are turned on or off by protection elements that have their respective

target setting selected as either “Enabled” or “Latched”. Pre-programmed URC protection

element target settings are set to “Latched”. The corresponding event cause LEDs turn on

when the operate operand associated with the element is asserted and remain on until a

reset command is issued after the condition causing the event is cleared.

All phase overcurrent elements are able to discriminate faulted phases and independently

turn off or on the phase A, B, or C LEDs.

6

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 3: URC PANEL INTERFACE

FRONT PANEL INDICATORS

•

CURRENT: Indicates current was involved.

•

PHASE A: Indicates phase A was involved.

•

PHASE B: Indicates phase B was involved.

•

PHASE C: Indicates phase C was involved.

•

NEUTRAL/GROUND: Indicates that neutral or ground was involved.

If the user enables other protection functions, then one of the following indicators may

turn on.

•

VOLTAGE: Indicates voltage was involved.

•

FREQUENCY: Indicates frequency was involved.

•

OTHER: Indicates a composite function was involved.

Figure 2: F60 status and event cause LEDs

842811A1.CDR

User-programmable indicators

The URC includes 48 amber LED indicators (three columns with 16 LEDs each) that are

provided with the F60 device. The default labels are shown below.

Figure 3: User-programmable events indicators and labels

LED BEHAVIOUR

LED LABEL

LED BEHAVIOUR

HOT LINE TAG ON

LED LABEL

BLINKING/OFF

A R BLOCKE D

BLINKING/OFF

LOC AL CONTR OL

BLINKING/OFF

A R ENA BLE D

ALTER NATIVE S ET. BLINKING/OFF

ON/OFF

LED LABEL

LED BEHAVIOUR

BAT. CHARGING

BLINKING/OFF

B ATTERY LOW

BLINKING/OFF

BLINKING/OFF

AR D ISAB LE D

ON/OFF

BAT. FUSE BLOWN

GROUND PR. BLK

BLINKING/OFF

AR C LOSE

LATCHED /OFF

BA T. TIME R BLOCK

ON/OFF

A C MCB TRIP

BLINKING/OFF

AR LOCKOU T

ON/OFF

BAT. TEST IN PROG.

ON/OFF

A R IN PROGRESS

ON/OFF

HEATER MCB TRIP BLINKING/OFF

RECLOSER CLOSED ON/OFF

AR SHOT 1

ON/OFF

P HASE TOC1 OP

ON/OFF

AR SHOT 2

ON/OFF

P HASE IOC1 OP

ON/OFF

AR SHOT 3

ON/OFF

AR SHOT 4

ON/OFF

NEUTRAL TOC1 OP

ON/OFF

NEU TRAL IOC1 OP

ON/OFF

GROUND TOC1 OP

ON/OFF

GROU ND IOC1 OP

ON/OFF

BAT. TEST PAS S

ON/OFF

BA T. TES T FAIL

ON/OFF

BATTERY OVERV OLT. ON/OFF

AC NOT OK

ON/OFF

AR BLK FRPOM MA N CLS ON/OFF

DOOR INTERLOCK

ON/OFF

The URC is shipped with the default label for the LED panel and the LEDs are preprogrammed.

The LEDs are fully user-programmable. If the user requires a different LED configuration,

then a user-printed label can replace the default label. New settings must be programmed

to match any new configuration. Refer to the User-programmable LEDs section in the

Settings chapter of the F60 instruction manual for additional details.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

7

FRONT PANEL PUSHBUTTONS

CHAPTER 3: URC PANEL INTERFACE

Recloser status indicators

If the recloser is opened, then the recloser status will be indicated by three red LEDs. For

the current URC application, all three LEDs will be ON or OFF as there is no per-phase

discrimination. In addition, user-programmable LED 23 on the F60 faceplate that will be on

if the recloser is closed.

Figure 4: URC recloser status indicators

Front panel pushbuttons

Reset pushbutton

Some events are programmed to latch the faceplate LED event indicators and the target

messages on the display. Once set, the latching mechanism will hold all of the latched

indicators or messages in the set state after the initiating condition has cleared until a

RESET command is received to return these latches (not including logic latches) to the reset

state. The RESET command can be sent from the faceplate Reset button, a remote device

via a communications channel, or any programmed operand.

When the RESET command is received by the relay, two operands are created. These

operands, which are stored as events, reset the latches if the initiating condition has

cleared. Each individual source of a RESET command also creates its individual operand

RESET OP (PUSHBUTTON), RESET OP (COMMS) or RESET OP (OPERAND) to identify the source

of the command.

Figure 5: URC reset pushbutton

Control pushbuttons

The control pushbuttons provide an easy and error-free method of entering digital state

information. Those pushbuttons are not used for URC application. If needed, the user may

program them (refer to F60 instruction manual for additional details).

User-programmable pushbuttons

The user-programmable pushbuttons provide an easy and error-free method of entering

digital state (on, off) information. There are six user-programmable pushbuttons on the F60

faceplate. Each user-programmable pushbutton has an associated LED indicator. If the

function is set as "Latched", then the pushbutton status is stored in non-volatile memory.

8

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 3: URC PANEL INTERFACE

FRONT PANEL PUSHBUTTONS

Figure 6: URC user-programmable pushbuttons

The user-programmable pushbuttons are pre-programmed for the following functionality:

•

Pushbutton 1 is used to reset recloser control from lockout.

•

Pushbuttons 2 and 3 are not used.

•

Pushbutton 4 is used to change setting groups

•

Pushbutton 5 is used for battery test.

•

Pushbutton 6 is used for pushbuttons unlock operation.

The URC has the following pushbutton labels:

Figure 7: Fig.6: URC labels for user-programmable pushbuttons

Pushbuttons unlock

The following steps are required to be able to perform any operation with pushbuttons

(except TRIP/OPEN):

1.

User-programmable pushbutton 6 has to be pressed and held for 2 seconds.

2.

The second pushbutton has to be operated during the pre-programmed 5 second

auto-reset delay.

3.

The amber LED associated with user-programmable pushbutton 6 will turn on when

unlock in enabled.

If the auto-reset delay time must be changed, open the Product Setup > Userprogrammable pushbuttons menu and change the Prog Pushbutton 6 Auto-reset Delay

setting to desired time (refer to the F60 Instruction manual for additional details).

Figure 8: URC pushbutton unlock programmable pushbutton 6 settings

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

9

MCBS AND FUSES

CHAPTER 3: URC PANEL INTERFACE

MCBs and fuses

There are two mini circuit breakers (MCBs) and five fuses installed in the URC.

Front panel MCBs

On the URC swing door there are two MCBs used for protection of the AC part of battery

charger and for protection of the heater. The MCB that protects the battery charger is twopole with operating current of 15 A. The MCB that protects the heater is single-pole and

with an operating current of 3 A.

Figure 9: Battery charger input AC and heater protection MCBs

Front panel fuses

There are two fuse holders on the front of URC swing door. They are labeled as battery fuse

and GFCI fuse. The battery fuse is rated for 10 A and GFCI fuse is rated for 15 A.

Figure 10: Battery DC and GFCI protection fuses

If the voltage option is chosen, three 0.5 A fuses for protection of the secondary PT(VT)

circuits will be installed (shown below).

Figure 11: PT(VT) protection fuses

10

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 4: Hardware

Hardware

Connections

Connect the three-phase voltages, three-phase currents, and the 115 V AC power in the

URC, as well as the radio antenna and control via connections at the bottom of the

enclosure.

The URC uses the same control cables for connection with three-phase reclosers from

different manufacturers if they use the same connection pins.

Figure 12: The URC connections at the bottom of the enclosure

At the bottom of the enclosure, there are up to five Amphenol receptacle connections

designated as AM1 to AM5. The number of available connectors is dependent on the order

code.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

11

CONNECTIONS

CHAPTER 4: HARDWARE

Figure 13: Controller AC supply

AM1

OR

The AM1 connector is a two-pin or three-pin Amphenol connector used for the URC AC

supply. Pin A must be connected to 115 V L, pin B must be connected to 115 V N, and if the

three-pin connector is chosen, then pin C must be connected to ground.

Figure 14: Controller PT (VT) connections

AM2

The AM2 connector is an optional eight-pin Amphenol connector used to connect voltage

transformers if the PT (VT) option is chosen. Pins A, B and C are used for phase A, B and C

respectively, and pin D is used for neutral. Pins E, F, G and H are not wired, but if required

they can be used for connection of the other voltages (for example, synchrocheck).

Figure 15: Recloser AC supply

AM3

The AM3 connector is an optional two-pin Amphenol connector used for the recloser AC

power supply. Pin A must be connected to 115 V L and pin B must be connected to 115 V.

The AM4 connector is an optional connector used for radio antenna connection.

12

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 4: HARDWARE

ENCLOSURE

Figure 16: Recloser current and control connections

AM4

The AM5 connector is a 14-pin or 24-pin Amphenol connector used for connection

between the recloser and the recloser controller. The 14-pin Amphenol connector

connections used for Cooper and G&W reclosers are as follows:

NOTE

•

Pin A: +24 V DC.

•

Pin B: jumper to pin D.

•

Pin C: trip.

•

Pin D: jumper from pin B.

•

Pin E: close.

•

Pin F: 52b+69 status.

•

Pin G: current phase A.

•

Pin H: current phase B.

•

Pin J: current phase C.

•

Pin K: current neutral, grounded.

•

Pin L: from Pin K ground.

•

Pin M: from pin L ground.

•

Pin N: not used or 52b status if required.

•

Pin P: not connected.

The URC batteries are charged from user’s 115 V AC power source. As some reclosers have

an internal battery charging transformer, those reclosers will have this charging

transformer electrically shorted at the control cable, grounding pins K and L.

For the ABB recloser connection option, a 24-pin control cable is used. Refer to the

appendix for additional detail.

NOTE

Do not disconnect the control cable if the recloser is energized, as the CTs may generate

very high voltages that are dangerous and may cause injury or death.

NOTE

Enclosure

The URC enclosure is accessible from the front. The F60 device, pushbuttons, and fuses are

mounted on the swing door. The swing door and enclosure door are hinged on the left side.

The URC dimensions are 24” (height) × 24” (width) × 14” (depth).

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

13

ENCLOSURE

CHAPTER 4: HARDWARE

Figure 17: URC door dimensions

The mounting drill plan for the pole mounting bracket is provided in the figure below.

Figure 18: Pole mounting bracket

The enclosure has ventilation.

NOTE

Grounding of the enclosure

All devices interfacing with URC must be connected to the same pole ground. Use

applicable IEEE or IEC grounding standards.

14

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 4: HARDWARE

CONNECTING THE BATTERY

Connecting the battery

The URC has two 12 V DC batteries connected in series to obtain 24 V DC. The batteries are

shipped inside the battery holder, fastened and secured, with the battery fuse taken out

and shipped separately. Insert the 10 A battery fuse into the enclosure’s fuse holder to

connect the battery circuit.

Figure 19: Battery fuse

The battery is fully charged prior to shipment and is ready for use.

When batteries need to be replaced, dispose of the old batteries in an environmentally

responsible way. If required, contact your local regulator for instructions for proper

disposal.

Connecting three-phase currents

The URC has four current input terminals (Ia, Ib, and Ic) and a common return. The Ia, Ib and

Ic current inputs are used to connect the recloser three-phase CTs. The factory setting for

the CT ratio is 1000 / 1 A. The In current input of the F60 may be used for ground protection

and is not pre-wired.

Figure 20: Phase and ground CT settings

For more details refer to the F60 Instruction manual. Changes to the phase current and

ground current settings are performed in the System Setup > AC Inputs > Current menu.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

15

CONNECTING THREE-PHASE VOLTAGES

CHAPTER 4: HARDWARE

Connecting three-phase voltages

The URC has four voltage inputs terminals (Va, Vb, Vc and Vx). The Va, Vb and Vc voltage

inputs are used for connection of three-phase voltages, either phase to ground (wye

connection) or phase-to-phase voltages (delta connection). The Vx voltage input is used for

the synchrocheck function.

Figure 21: PTs (VTs) settings

For more details refer to the F60 Instruction manual. Changes to the phase VT and

auxiliary VT settings are performed in the System Setup > AC Inputs > Voltage menu.

Metering check

When the recloser is closed, it is possible to check measurements of primary currents and

symmetrical components. If the system is balanced, then the magnitudes of the negativesequence and zero-sequence current components should be low compared to the phase

current magnitudes. If the negative-sequence or zero-sequence component values are

high or the phase rotation is incorrect, then verify the wiring.

Figure 22: Current and voltage cut-off level settings

The factory default setting for current cut-off is 2% (or 20 A primary for 1000/1A CTs). If the

load current is less than 20 A then modify the Current Cutoff Level setting.

When voltage measurement is available, it is possible to check measurements of primary

voltages (phase voltages, auxiliary voltage) and symmetrical components. The factory

default setting for voltage cut-off is 1 V secondary.

16

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 4: HARDWARE

PHASE ROTATION

Phase rotation

Phase rotation is handled through the Phase Rotation setting under System Setup >

Power System menu has a factory default value of “ABC”. For an ACB phase rotation,

change this setting from “ABC” to “ACB”.

Figure 23: Power system settings

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

17

PHASE ROTATION

18

CHAPTER 4: HARDWARE

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 5: Wiring and schematic

diagrams

Wiring and schematic diagrams

Schematic diagrams

$&0&%,/

$&0&%,1

&+*1'

Figure 24: URC AC schematic diagram

/ 1 *

2XWSXW

65*

,1387

$0$

$0%

$0&

/ 1 *

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

&6/

$&'&

1

/

*

9²

9²

9

9

$&0&%21

$&0&%2/

&+*1'

'&7%

52*6/5

%06

3D

$&'5

19

SCHEMATIC DIAGRAMS

CHAPTER 5: WIRING AND SCHEMATIC DIAGRAMS

Figure 25: URC DC schematic diagram

'&7%

'&7%

9'&

6833/<

)

%

%D

&+*1'

32:(56833/<

%E

%E

%E %D

%D %E

%E

/2

%E

+,

%D

*

(7+(51(7

%DVH7

&20

1250$/

%DVH)

&3802'8/(

(7+(51(75(&(37$&/(

3,1$0

&20

56

'D

'D

'D

$0$

$0%

$0%

$0&

$0&

$0'

$0'

$0(

$0(

$0)

$0)

$01

$01

5$',2&20

5$',2&20

5$',2&20

,5,*%

,1387%1&

287387%1&

'E'D

75,3&2,/

3

7+,5'$1*/(352-(&7,21

6,202'8/(

3,1$0

$0$

6:E

3D

3E

3E

3E

$0&

3E'&7%

6:D

75,3

3F

6:

3D

3D

3E

3E

&+*1'

3E3E

3F

3F

$0(

&/26(

',/2&.

&/26(&2,/

3D

&6/'&

3E

56/5

3F

3D

3E

%06

3F

5/2$'

3D

3E

3E3E

3F

3D

3E

3E3E

3F

/('$/('%/('&

&223(55(&/26(5

$0)E

3D

$01E

3F

+

',202'8/(

+D

+F

+E

+E

7*/5%/.

7*/+/7+7//('

+D

3%&/26(

+F

+E

3%23(1

+D

3%*1'

+F

+E

3%

+E+E

+F

+E

+750&%

+D

+F

+E

E+E+E

85&5(&/26(5&21752//(5

+D

$&0&%

+D

%06

+F

+E

%06

+D

%06

+F

+E

%06

+G'&7%

+D

%06

+F

+E

%06

&+*1'

20

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 5: WIRING AND SCHEMATIC DIAGRAMS

WIRING DIAGRAMS

Wiring diagrams

Figure 26: URC wiring diagram, back and side walls

CH.GND

DC-TB

H6a

H6c

H7a

H7c

H8a

H8c

17

1

2

3

4

5

6

7

8

9

10

11

12

16

15

13

14

28

27

26

25

24

23

22

21

20

19

18

BMS

CSL+DC

DC+TB

P2b,ROG+LD

DC-TB

ROG-LV

BATT+FS

P2c

R-LOAD

DC-TB

DC-TB

BATT-FS

B6a

HLT-LED

DC-TB

P7b

H7b

RADIO-

P3b

CSL-DC

R-LOAD

R-SLR

ROG-LD

BMS-4

BMS-10

ROG+SLR

BMS-26

D-ILOCK

DC+TB

B6b

HTR+MCB

P6b

AC+MCB

BMS-2

D-ILOCK

GND

TGL-RBLK

AM1-7

TGL-HLT

PB-CLOSE

RADIO+

SOLAR

DC LOAD

ROG

LVALERT

PB-79

BMS-5

BATTERY

PB-GND

P8b

DC-TB

PB-OPEN

UR.GND

BMS-28

G

LEFT

CSL-DC

N

BATT-FS

L

CSL-SRG

R-SLR

BATT+FS

+-+-

GFCI-SRG

BMS-3

SRG-SRG

BATT-

AM-S

TB-btm-IN

ROG-B

-

CH GND

+

AC-M CB-IN

POWER

AC M CB-IL

DC+TB

D3a

D1a

COM

123456789

D2a

ANT

ANTENNA

DC-TB

H8b

+-

RIGHT

CSL

OUTPUT

ISD-SRG

-

B8a

+

-

+

AC/DC

INPUT

L

AM 1-B

GNDSTUD

AM 1-A

SRGOUTL

SRG

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

N

AM 1-C

B8b

G

N

ACMCB-ON

BATT1

L

BATT2

ACMCB-OL

G

CHGND

V-

DC-TB

V-

ROG-SLR

V+

BMS-1

V+

P3a

21

WIRING DIAGRAMS

CHAPTER 5: WIRING AND SCHEMATIC DIAGRAMS

Figure 27: URC wiring diagram, swing door

22

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 5: WIRING AND SCHEMATIC DIAGRAMS

WIRING DIAGRAMS

Figure 28: URC wiring diagram, F60 wiring diagram

NORMA

CPU

(P6b,P2b)

IRIG-B

Output

48VDC

OUTPUT

CONTROL

POWER

SURG

FILTER

(P5b,P7b)

(LED-A,LED-B,LED-C)

(F2b)

8A/8B/8F/8G/8L/8M

IRIG-B

Input

(TB-BTM-Ia)

(F3b,F1b)

CURRENTINPUTS

(DC+TB)

(DC-TB)

(CH.GND)

(CH.GND)

(BMS-3)

(R-LOAD)

COM

RS485

COM2

CRITICAL

FAILURE

+

HI+

LO+

-

(P1b,P5b)

(AM5-E)

(CSL+DC)

(R-SLR)

COMMO

BNC

BNC

(P2b)

(AM5-C)

CONTACTIN

1

D1a +

D2a D3a COM

D4b +

D4a -

6S

9N

CONTACTIN

SURG

10BaseT

(RADIO+COM)

(RADIO-COM)

(RADIOCOM)

CONTACTIN

POWERSUPPLY

(CH.GND)

DIGITALI/O

CONTACTIN

6D

(D-ILOCK)

(P6b,DC-TB)

+

+

+

+

-

DIGITALI/O

(AM5-F)

(TB-BTM-Ib)

(TB-BTM-InC,F2b)

(TB-BTM-Ic)

(TGL-RBLK)

(TGL-HLT,HTL+LED)

(PB-CLOSE)

(PB-OPEN)

(H3b)

+

+

+

+

-

CONTACTIN

(PB-GND)

(PB-79)

(AC-MCB)

(HTR-MCB)

(H5b,H1b)

+

+

+

+

-

CONTACTIN

CONTACTIN

(BMS-22)

(BMS-19)

(H3b,H7b)

+

+

+

+

+

+

+

+

-

CONTACTIN

CONTACTIN

IG

CONTACTIN

COMMO

IG1

CONTACTIN

VA

CONTACTIN

CONTACTIN

VA

COMMO

CONTACTIN

CONTACTIN

CONTACTIN

COMMO

VOLTAGEINPUTS

(BMS-18)

(BMS-17)

(BMS-16)

(BMS-15)

(H5b,DC-TB)

(CH.GND)

IG5

CONTACTIN

(FS-BTM-Va)

(F6c)

(FS-BTM-Vb)

(F7c,F5c)

(FS-BTM-Vc)

(TB-BTM-Vn,F6c)

CONTACTIN

CONTACTIN

CONTACTIN

COMMO

SURG

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

23

WIRING DIAGRAMS

CHAPTER 5: WIRING AND SCHEMATIC DIAGRAMS

Figure 29: URC wiring diagram, amphenol connectors

24

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 6: Communications

Communications

Actual values (measurements, status of inputs and outputs) can be viewed, settings viewed

or changed, and oscillography, fault report and sequence of events obtained through the

F60 front panel or via Ethernet.

RS232 serial port

A nine-pin RS232C serial port is located on the F60 faceplate for programming with a local

PC. All that is required to use this interface is a personal computer running the EnerVista

UR Setup software provided with the relay. Cabling for the RS232 port is shown in the

following figure for both 9-pin and 25-pin connectors. The baud rate for this port is fixed at

19200 bps.

Figure 30: RS232 connections

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

25

RS485 SERIAL PORT

CHAPTER 6: COMMUNICATIONS

RS485 serial port

RS485 data transmission and reception are accomplished over a single twisted pair with

transmit and receive data alternating over the same two wires. Through the use of these

ports, continuous monitoring and control from a remote computer, SCADA system or PLC is

possible. To minimize errors from noise, the use of shielded twisted pair wire is

recommended. Correct polarity must also be observed.

If the radio option is installed, the RS485 port is used as the communication interface from

the F60 to the radio.

NOTE

Ethernet communications

The F60 used in the URC has one 10/100Base-T Ethernet port and is wired to the Ethernet

port on the swing door for easy and fast communication with a computer.

Figure 31: Ethernet port

26

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 7: Records

Records

Event record

The following events are enabled:

•

Events from the following protection functions:

–

Phase time overcurrent.

–

Phase instantaneous overcurrent.

–

Neutral time overcurrent.

–

Neutral instantaneous overcurrent.

–

Ground time overcurrent.

–

Ground instantaneous overcurrent.

•

Events from control functions (autoreclosing).

•

Digital inputs

•

Virtual inputs (from SCADA or DCS).

•

Digital outputs.

If any other events are required or if new functions are enabled, then it is possible to enable

additional events. Enable events in the setting screen for any protection element, control

element, input, or output where event reports are required.

The event record displays up to the last 1024 events listed in chronological order from the

most recent to the oldest. If all event records are filled, then the oldest event record will be

removed each time a new record is added.

To read event records, connect to the F60 using communications or through the front

panel and navigate to the Actual Values > Records > Event Record section.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

27

FAULT REPORTS

CHAPTER 7: RECORDS

Figure 32: Event record

For additional details on the event recorder feature, refer to the F60 instruction manual.

Fault reports

The URC can calculate distance to the fault if the phase voltage option is installed. If this

feature is required, enable fault reporting by programming the Fault Report Trigger

setting to “TRIPBUS 1 OP” and enter the line characteristics through the Product Setup >

Fault Report window.

Figure 33: Fault report settings

The fault report trigger is set by trip bus 1 function through the Control Elements > Trip

Bus > Trip Bus 1 window as shown:

28

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 7: RECORDS

OSCILLOGRAPHY RECORD

Figure 34: Fault report triggering

If required, add more inputs to trigger the fault report. For additional details on the fault

report feature, refer to the F60 instruction manual.

Oscillography record

The oscillography is pre-configured to be triggered by trip bus 2 with the following settings.

The oscillography can record most digital signals as well as all currents and voltages.

Figure 35: Oscillography settings

The oscillography trigger is set by trip bus 2 function at Control Elements > Trip Bus > Trip

Bus 2 window as shown below:

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

29

OSCILLOGRAPHY RECORD

CHAPTER 7: RECORDS

Figure 36: Oscillography triggering

If required, additional inputs can be added to trigger the oscillography. For additional

details on oscillography, refer to the F60 instruction manual.

The oscillography record displays up to 20 records. A new oscillography record may

automatically overwrite an older record, since the Trigger Mode setting is pre-programmed

to “Automatic Overwrite”. The URC is pre-configured to record 108 cycles per record. All

pre-configured values for the number of records, number of samples per cycle, and trigger

mode may be changed, if required.

To read oscillography records, connect to the F60 and navigate to the Actual Values >

Records > Oscillography menu item.

Figure 37: Oscillography records

30

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 8: Trip/open and close

functions

Trip/open and close functions

Issuing a trip/open command

The URC will issue a trip command for any of the following conditions:

•

Phase instantaneous overcurrent and phase time overcurrent.

•

Neutral instantaneous overcurrent and neutral time overcurrent.

•

Ground instantaneous overcurrent and ground time overcurrent (if the Ig current input

is wired).

•

Local open.

•

Remote open.

•

User open.

For additional details on the phase, neutral, and ground protection functions, refer to

Protection functions on page 35. The recloser can be opened locally with the green TRIP

pushbutton on the swing door inside the enclosure.

Figure 38: Three-phase trip/open pushbutton

&ORVHSXVKEXWWRQUHG

7ULSSXVKEXWWRQJUHHQ

$&'5

The recloser can be opened remotely if remote operation is enabled and a communication

input from remote control is received. Remote open will issue a 50 ms opening pulse. The

duration of this pulse is defined by FlexLogic™ timer 1 Dropout Delay setting.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

31

ISSUING A CLOSE COMMAND

CHAPTER 8: TRIP/OPEN AND CLOSE FUNCTIONS

Figure 39: Three-phase trip/open logic

3+$6(,2&23

3+$6(72&23

*5281',2&23

*5281'72&23

25

23(192

1(875$/,2&23

1(875$/72&23

/2&$/3%23121+&

/$7&+21

5(027(23(1219,

PV

$1'

PV

7,0(5

$1'

25

23(192

$&'5

The opening signal is not supervised.

NOTE

Issuing a close command

The URC will issue a closing command if the hot line tag function is off and if any of the

following conditions are present:

•

Closing command from autoreclosing function.

•

Local close.

•

Remote close.

For additional information on the autoreclosing function, refer to Autoreclose on page 41.

The recloser can be closed locally with the red CLOSE pushbutton on the swing door inside

the enclosure.

Figure 40: Close pushbutton

&ORVHSXVKEXWWRQUHG

7ULSSXVKEXWWRQJUHHQ

$&'5

For local closing, refer to the following steps:

32

1.

The remote block toggle switch must be in the disabled position (local control).

2.

User-programmable pushbutton 6 must be pressed and held for 2 seconds.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 8: TRIP/OPEN AND CLOSE FUNCTIONS

ENABLING AND DISABLING THE HOT LINE TAG FUNCTION

3.

The CLOSE pushbutton must be pressed before its auto-reset delay time has expired

(refer to Pushbuttons unlock on page 9 for additional details).

The recloser can be closed remotely if remote operation is enabled and a communication

input (virtual input 2) from remote control is received. Remote close will issue a 50 ms

closing pulse. The duration of this pulse is specified by the FlexLogic™ timer 2 Dropout

Delay setting.

Figure 41: URC closing logic

386+%8772121

/$7&+2))

$1'

/2&$/3%&/621+$

$1'

/$7&+21

5(027(&/26(219,

PV

$1'

25

PV

7,0(5

$1'

$1'

23(192

$5&/26(

25

+27/,1(7$*2))+&

$1'

&/26(92

$&'5

NOTE

Contact SW2 (69) stays open when the external manual operating lever is in lockout. If this

contact is open, then it is not possible to close the recloser. Only when the manual

operating lever is reset and SW2 (69) is closed will it be possible to close the recloser.

Enabling and disabling the hot line tag function

The hot line tag function can be enabled and disabled with toggle HOT LINE TAG ENABLE

switch. User-programmable LED 1 on the F60 faceplate indicates that the hot line tag

function is enabled. The red LED next to HOT LINE TAG ENABLE switch also indicates that

the hot line tag function is enabled.

Figure 42: Hot line tag switch and indication

+27/,1(7$*(1$%/(

WRJJOHVZLWFK

+RWOLQHWDJ/('21 HQDEOHG

$&'5

The hot line tag function is provided for live line work applications. When the hot line tag

function is enabled, the autoreclosing function is disabled, closing is supervised, and it is

not possible to close the recloser locally nor remotely. The hot line tag function only

prevents the recloser from closing — it does not open the recloser. If required, the user may

change the logic and create independent time overcurrent protection that will perform the

trip operation for certain applications. The factory programmed logic will only activate the

hot line tag function from the URC toggle switch. If required, the logic can be

reprogrammed by the user to accommodate activation via communications (SCADA, DCS).

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

33

LOCAL/REMOTE CONTROL

CHAPTER 8: TRIP/OPEN AND CLOSE FUNCTIONS

Local/remote control

Remote control can be enabled and disabled by the REMOTE BLOCK toggle switch. Userprogrammable LED 2 on the F60 faceplate indicates that Remote Control is blocked. All

control functions (with the exception of open/trip operation and the hot line tag function)

are supervised by this control. It is not possible to perform any local operation of

supervised functions if remote operation is enabled.

Figure 43: Local/remote switch

5(027(%/2&.(1$%/(

WRJJOHVZLWFK

$&'5

Leaving the remote control in the blocked state may create a problem if the crew leaves

the site with the URC in local control mode. The REMOTE BLOCK switch controls nonvolatile latch 6.

Figure 44: Local/remote latch gate

34

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 9: Protection functions

Protection functions

The URC Universal Recloser Control uses the following protection functions:

•

Phase instantaneous overcurrent and phase time overcurrent.

•

Neutral instantaneous overcurrent and neutral time overcurrent.

•

Ground instantaneous overcurrent and ground time overcurrent (if Ig current input is

wired).

All phase, neutral, and ground time overcurrent and instantaneous overcurrent protection

elements have separate settings for main and alternate settings.

NOTE

All the other protection functions (for example, directional elements, reverse power, etc.)

from F60 relay can be enabled if required. For additional details, refer to the F60 Instruction

manual.

Phase instantaneous overcurrent settings

The phase instantaneous overcurrent element may be used as an instantaneous element

with no intentional delay or as a definite time element. The input current is the

fundamental phasor magnitude.

Figure 45: Phase instantaneous overcurrent settings

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

35

PHASE TIME OVERCURRENT

CHAPTER 9: PROTECTION FUNCTIONS

If the phase instantaneous overcurrent function is not required, then change the Function

setting to “Disabled”. If this function is used, then the Pickup setting must be set according

to a protection coordination study. If required, a time delay or reset delay can also set. The

phase instantaneous overcurrent function can be blocked if the cold load pickup function

is enabled.

For additional details, refer to the F60 Instruction manual.

Phase time overcurrent

The inverse time overcurrent curves used by the time overcurrent elements are the IEEE,

IEC, GE Type IAC, and I2t standard curve shapes. This allows for simplified coordination with

downstream devices.

If none of these curve shapes are adequate, then FlexCurves™ may be used to customize

the inverse time curve characteristics. The definite time curve is also an option that may

be appropriate if only simple protection is required.

Recloser curves

The F60 uses the FlexCurve™ feature to facilitate programming of 41 recloser curves. Refer

to the FlexCurve™ section in the F60 instruction manual for additional details.

Figure 46: Phase time overcurrent settings

A time dial multiplier setting allows selection of a multiple of the base curve shape (where

the time dial multiplier = 1) with the Curve (curve shape) setting. Unlike the

electromechanical time dial equivalent, operate times are directly proportional to the TD

Multiplier (time multiplier) setting value. For example, all times for a multiplier of 10 are 10

times the multiplier 1 or base curve values. Setting the multiplier to zero will result in an

instantaneous response to all current levels greater than pickup.

Two methods of resetting operation are available: “Timed” and “Instantaneous”. When the

element is blocked, the time accumulator will reset according to the reset characteristic.

For example, if the element reset characteristic is set to “Instantaneous” and the element is

blocked, the time accumulator will be cleared immediately.

36

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 9: PROTECTION FUNCTIONS

GROUND AND NEUTRAL OVERCURRENT

For additional details, refer to the F60 instruction manual.

Ground and neutral overcurrent

The ground or neutral instantaneous overcurrent element may be used as an

instantaneous element with no intentional delay or as a definite time element. The input

current is the fundamental phasor magnitude.

If the ground or neutral instantaneous overcurrent protection functions are not required,

then change the Function setting to “Disabled”. If those functions are required, then the

Pickup setting must be specified according to a protection coordination study. If

necessary, a time delay or reset delay can also be specified. The ground or neutral

instantaneous overcurrent protection functions can be blocked if the cold load pickup

function is enabled.

The inverse time ground or neutral overcurrent curves used by the time overcurrent

elements are the IEEE, IEC, GE Type IAC, and I2t standard curve shapes. This allows for

simplified coordination with downstream devices. If none of these curve shapes is

adequate, then FlexCurves™ may be used to customize the inverse time curve

characteristics. The definite time curve is also an option that may be appropriate if only

simple protection is required.

For additional details on these functions, refer to the F60 Instruction manual.

All ground and neutral time overcurrent and instantaneous overcurrent elements will be

blocked if the ground/neutral protection function is disabled.

Figure 47: Ground time overcurrent settings

Disabling ground/neutral protection

Ground fault protection can be enabled and disabled both locally and remotely.

Ensure the steps below are followed for local control.

1.

The REMOTE BLOCK toggle switch must be in enable position (local control).

2.

The F60 user-programmable pushbutton 6 must to pressed.

3.

The GROUND BLOCK pushbutton must then be pressed during the auto-reset delay

time (refer to Pushbuttons unlock on page 9 for details).

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

37

DISABLING GROUND/NEUTRAL PROTECTION

CHAPTER 9: PROTECTION FUNCTIONS

Figure 48: GROUND BLOCK pushbutton

Ensure the steps below are followed for remote control.

1.

The REMOTE BLOCK toggle switch must be in disable position (remote control) for the

SCADA input to be received.

2.

Program virtual input 3 to “GROUND BLOCK”.

3. Program virtual input 4 to “GROUND ENABLE”.

The FlexLogic™ for enabling and disabling ground fault protection is shown below:

Figure 49: Ground disabling logic

Figure 50: Ground enabling logic

This logic controls non-volatile latch 2. The blinking user-programmable LED 4 on the F60

faceplate indicates that ground protection is disabled.

38

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 9: PROTECTION FUNCTIONS

DISABLING GROUND/NEUTRAL PROTECTION

Figure 51: Ground block latch gate

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

39

DISABLING GROUND/NEUTRAL PROTECTION

40

CHAPTER 9: PROTECTION FUNCTIONS

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 10: Control functions

Control functions

The URC controller ships from the factory with the following control functions:

NOTE

•

Autoreclose.

•

Setting groups.

All the other control function (for example synchrocheck, cold load pickup, etc.) from the

F60 relay can also be enabled if required. For additional details, refer to the F60 instruction

manual.

Autoreclose

The autoreclosure feature is intended for use with distribution lines, in three-pole tripping

schemes for single breaker applications. Up to four selectable reclosure ‘shots’ are possible

prior to locking out. Each shot has an independently specified dead time. The protection

settings can be changed between shots if so desired, using FlexLogic™.

The user-programmable LEDs on the F60 faceplate indicate the state of the autoreclose

scheme as follows:

•

RECLOSE BLOCKED: User-programmable LED 17 indicates that autoreclosing is

blocked (that is, reclosing is disabled or hot line tag is enabled).

•

RECLOSE ENABLED: User-programmable LED 18 indicates that autoreclosing is

enabled and may reclose if initiated.

•

RECLOSE DISABLED: User-programmable LED 19 indicates that autoreclosing is

disabled.

•

RECLOSE CLOSE: User-programmable LED 20 indicates that a close signal from

autoreclosing has been issued. A reset command is required to clear this LED.

•

RECLOSE LOCKED OUT: User-programmable LED 21 indicates that the reclosing

scheme has generated the maximum number of breaker closures allowed and, as the

fault persists, will not close the breaker again. The scheme may also be sent in lockout

when the incomplete sequence timer times out or when a block signal occurs while in

reclose in-progress. The scheme must be reset from lockout in order to perform

reclose for subsequent faults.

•

RECLOSE IN-PROGRESS: User-programmable LED 22 indicates reclose-in-progress

(RIP), when a reclosing cycle begins following a reclose initiate signal.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

41

AUTORECLOSE

CHAPTER 10: CONTROL FUNCTIONS

•

RECLOSER CLOSED: User-programmable LED 23 indicates the recloser status.

•

RECLOSE SHOT 1, 2, 3, and 4: User-programmable LEDs 24 through 27 indicates

reclosing shots 1 through 4, respectively.

•

RECLOSE BLOCK UPON MANUAL CLOSE: User-programmable LED 28 indicates that

autoreclosing is blocked upon manual closing.

The autoreclosure scheme is considered enabled when all of the following conditions are

true:

1.

The autoreclose Function setting is “Enabled”.

2.

The autoreclosure scheme is not in the lockout state.

3.

The operand assigned to the Block input is not asserted.

4. The Block Time Upon Manual Close timer is not active.

The autoreclose scheme is initiated by a trip signal from any selected protection feature

operand. The scheme is initiated provided the circuit breaker is in the closed state before

protection operation.

The reclose-in-progress (RIP) is set when a reclosing cycle begins following a reclose initiate

signal. Once the cycle is successfully initiated, the RIP signal will seal-in and the scheme will

continue through its sequence until one of the following conditions is satisfied:

•

The close signal is issued when the dead timer times out, or

•

The scheme goes to lockout.

While RIP is active, the scheme checks that the breaker is open and the shot number is

below the limit, and then begins measuring the dead time.

Each of the four possible shots has an independently specified dead time. Two additional

timers can be used to increase the initial set dead times 1 to 4 by a delay equal to Delay 1

or Delay 2 or the sum of these two delays depending on the selected settings. This offers

enhanced setting flexibility using FlexLogic™ operands to turn the two additional timers on

and off. These operands may possibly include AR1 SHOT CNT = 1, SETTING GROUP ACT 1,

etc. The autoreclose feature provides a maximum of 4 selectable shots. The maximum

number of shots can be dynamically modified through the Reduce Max to 1, Reduce Max

to 2, and Reduce Max to 3 settings, using the appropriate FlexLogic™ operand.

The scheme lockout blocks all phases of the reclosing cycle, preventing automatic

reclosure, if any of the following occurs:

•

The maximum shot number was reached.

•

A block input is in effect.

•

The incomplete sequence timer times out.

The recloser will be latched in the lockout state until a ‘reset from lockout’ signal is

asserted, either from a manual close of the breaker or from a manual reset command

(local or remote). The reset from lockout can be accomplished by operator command, by

manually closing the breaker, or whenever the breaker has been closed and stays closed

for a preset time.

After the dead time elapses, the scheme issues the close signal. The close signal is latched

until the breaker closes or the scheme goes to lockout.

A reset timer output resets the recloser following a successful reclosure sequence. The

reset time is based on the breaker ‘reclaim time’ which is the minimum time required

between successive reclose sequences.

42

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 10: CONTROL FUNCTIONS

AUTORECLOSE

Figure 52: Autoreclose settings

Factory settings

The autoreclose factory settings are described below.

•

Function: The autoreclose function is enabled for the URC application.

•

Initiate: This settings selects the operand that initiates the autoreclose scheme. For

the URC application, autoreclose will be initiated by any phase, neutral, or ground

instantaneous or time overcurrent protection element.

Figure 53: Autoreclosing initiating logic

•

Block: This setting selects the operand that blocks the autoreclose initiation. For the

URC application The AR DISABLED signal (latch 1) or HOT LINE TAG ENABLED signal will

block autoreclosing. Autoreclose will be unblocked when both the AR ENABLED and

HOT LINE TAG DISABLED signals are present.

User-programmable LED 17 indicates that reclose is blocked.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

43

AUTORECLOSE

CHAPTER 10: CONTROL FUNCTIONS

Figure 54: Autoreclosing blocking logic

•

Max Number Of Shots: This setting specifies the number of reclosures that can be

attempted before reclosure goes to lockout because the fault is permanent. For the

URC application this value is left at "4" but may be changed as required.

•

Reduce Max To 1, Reduce Max To 2, Reduce Max To 3: These settings select the

operand that changes the maximum number of shots from the initial setting to 1, 2, or

3, respectively. For the URC application all of these values are set to "OFF" but may be

changed as required.

•

Manual Close: This setting selects the logic input when the breaker is manually closed.

For the URC application this logic input is set for local or remote close commands and

is configured as shown below. This logic may be changed according to the user’s

specific autoreclosing logic. The Reset Lockout On Manual Close setting is left as OFF

but may be changed as required.

Figure 55: Autoreclosing manual closing logic

•

Manual Reset from LO: This setting selects the operand that resets the autoreclosure

from lockout condition. For the URC application reset from lockout is performed locally

by user-programmable pushbutton 1 on the F60 faceplate, remotely, or automatically

after a programmable time delay.

The following procedure describes how to reset from lockout locally:

44

1.

The URC must be in the local control mode (ensure the REMOTE BLOCK toggle

switch is in the ON position).

2.

User-programmable pushbutton 6 must be pressed and held for 2 seconds before

its auto-reset delay time has expired (refer to Pushbuttons unlock on page 9 for

details).

3.

User-programmable pushbutton 1 (with the LO RESET label) must be pressed.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 10: CONTROL FUNCTIONS

AUTORECLOSE

Figure 56: Autoreclosing lockout reset logic

The reset from lockout can be performed remotely. Ensure that the REMOTE BLOCK

toggle switch is in the off position (remote control) for an input from SCADA to be

received. Virtual input 10 (VI10) is set for remote reset from lockout.

The reset from lockout can also be performed automatically after a pre-set time delay

(FlexLogic™ timer 3). If this reset is not required, then latch 4 must be disabled.

Figure 57: Autoreclosing automatic lockout reset latch gate

•

Reset Lockout If Breaker Closed: This setting allows the autoreclose scheme to reset

from lockout if the breaker has been manually closed and stays closed for a preset

time. In order for this setting to be effective, the next setting (Reset Lockout On

Manual Close) should be disabled. For the URC application this value is set to "OFF"

but may be changed as required.

•

Reset Lockout On Manual Close: This setting allows the autoreclose scheme to reset

from lockout when the breaker is manually closed regardless if the breaker remains

closed or not. This setting overrides the previous setting (Reset Lockout If Breaker

Closed). For the URC application this value is set to "OFF" but may be changed as

required.

•

Block Time Upon Manual Close: The autoreclose scheme can be disabled for a

programmable time delay after the associated circuit breaker is manually closed. This

prevents reclosing onto a fault after a manual close. This delay must be longer than

the slowest expected trip from any protection not blocked after manual closing. If no

overcurrent trips occur after a manual close and this time expires, the autoreclose

scheme is enabled. This setting has to be changed by the user according to the

particular application if autoreclosing reset lockout on manual close is used. For the

URC application this value is set to "10 seconds".

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

45

AUTORECLOSE

CHAPTER 10: CONTROL FUNCTIONS

•

Dead Time Shot 1, Dead Time Shot 2, Dead Time Shot 3, Dead Time Shot 4: These

are the intentional delays before first, second, third, and fourth breaker automatic

reclosures (1st, 2nd, and 3rd shots), respectively, and should be set longer than the

estimated deionizing time following a three-pole trip.

This setting must be changed by the user according to the specific application.

•

Add Delay 1: This setting selects the FlexLogic™ operand that introduces an

additional delay (delay 1) to the initial set dead time (1 to 4). For the URC application,

this value is “Off” and delay 1 is by-passed.

•

Delay 1: This setting establishes the extent of the additional dead time delay 1. For the

URC application, the delay 1 is by-passed.

•

Add Delay 2: This setting selects the FlexLogic™ operand that introduces an

additional delay (delay 2) to the initial set dead time (1 to 4). For the URC application,

this value is “Off” and delay 2 is by-passed.

•

Delay 2: This setting establishes the extent of the additional dead time delay 1. For the

URC application, the delay 2 is by-passed.

•

Reset Lockout Delay: This setting specifies how long the breaker should stay closed

after a manual close command in order for the autorecloser to reset from lockout. For

the URC application, this logic is not used when the breaker is closed.

•

Reset Time: A reset timer output resets the recloser following a successful reclosure

sequence. The setting is based on the breaker ‘reclaim time’ which is the minimum

time required between successive reclose sequences. This setting must be changed

by the user according to their specific application.

•

Incomplete Sequence Time: This timer defines the maximum time interval allowed for

a single reclose shot. It is started whenever a reclosure is initiated and is active when

the scheme is in the ‘reclose-in-progress’ state. If all conditions allowing a breaker

closure are not satisfied when this time expires, the scheme goes to lockout.

This setting has to be changed by the user according to the specific application. It

must be set to a delay value less than the reset timer value.

NOTE

Enabling and disabling autoreclosing

Autoreclosing can be enabled and disabled both locally and remotely. Use the following

procedure to initiate local control mode.

1.

The REMOTE BLOCK toggle switch must be in enable position (local control).

2.

The F60 user-programmable pushbutton 6 must to pressed and held for 2 seconds.

3.

The RECLOSE BLOCK pushbutton must then be pressed during the auto-reset delay

time (refer to Pushbuttons unlock on page 9 for details).

Figure 58: Autoreclosing block pushbutton

Use the following procedure to initiate remote control mode.

46

1.

The REMOTE BLOCK toggle switch must be in disable position (remote control) for the

SCADA input to be received.

2.

Program virtual input 7 to “RECLOSE RECLOSE ENABLE”.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 10: CONTROL FUNCTIONS

AUTORECLOSE

3. Program virtual input 8 to “RECLOSE RECLOSE DISABLE”.

The FlexLogic™ for enabling and disabling autoreclosing is shown below:

Figure 59: Autoreclosing disabling logic

Figure 60: Autoreclosing enabling logic

The reclose block and enable operands are controlling non-volatile latch gate 1 as shown

below.

Figure 61: Autoreclosing enabling and disabling latch gate

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

47

SETTING GROUPS

CHAPTER 10: CONTROL FUNCTIONS

Setting groups

The F60 relay has six setting groups. For the URC application two setting groups are

enabled. They are called the main and alternate settings.

Figure 62: Setting groups settings

The setting groups function must be enabled if main and alternate setting groups to be

used. If the alternate setting group is not required, then disable the setting groups function.

If the setting groups function is disabled, then only the main setting group is enabled and

all alternate settings are by-passed.

Changing setting groups

The active setting group can be selected both locally and remotely. The main or alternate

settings are controlled by non-volatile latch 3. The user-programmable LED 3 indicates

that alternate setting is active

Figure 63: Main/alternate setting groups latch gate

Use the following procedure for local change.

1.

The REMOTE BLOCK toggle switch must be in the on position (local control).

2.

The F60 user-programmable pushbutton 6 must to pressed and held for 2 seconds.

3.

User-programmable pushbutton 4 (labeled ALT 1 SETTINGS) must then be pressed

during the auto-reset delay time (refer to Pushbuttons unlock on page 9 for details).

Use the following procedure for remote change.

48

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

CHAPTER 10: CONTROL FUNCTIONS

SETTING GROUPS

1.

The REMOTE BLOCK toggle switch must be in the off position (remote control) for the

SCADA input to be received.

2.

Program virtual input 5 for main settings control.

3.

Program virtual input 6 for alternate settings control.

Figure 64: Main setting group enabling logic

Figure 65: Alternate setting group enabling logic

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

49

SETTING GROUPS

50

CHAPTER 10: CONTROL FUNCTIONS

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

Digital Energy

Multilin

URC Universal Recloser Control

Chapter 11: Battery management

system

Battery management system

In the case of AC power failure, the system is equipped with a 24 V battery backup supply,

which kicks in upon loss of line power. This way, the recloser controller will continue to

operate, as intended, for some time after the power has been lost. This gives the operator

complete monitoring and control for the duration of the outage, assuming that power is

restored in a timely manner.

The battery is a Sealed Valve Regulated Lead Acid (SVRLA) battery. A slow “3 step charging

cycle” is recommended for optimal charging of SVRLA batteries. Improper charging is

among the most common problems of premature failure of Lead Acid batteries. The

preferred three step charging procedure is common for SVRLA batteries and consists of a

constant current step followed by two steps of constant voltage. In the first step, BULK

step, a constant current is applied to the battery until the battery voltage reaches a level of

80% State of Charge (SOC). The next step of charging is referred to as the TOP OFF or

ABSORPTION step, and holds the 80% SOC voltage constant until the battery is not

accepting any more charge (or until a pre-set timer in the controller has expired). At this

point, the voltage is dropped to a new level and held constant in what is called the FLOAT

step, so that the battery remains fully charged. This profile is optimal for most lead acid

batteries. For 24 V battery systems, the voltage (at 25°C) should be within the range of 28.4

to 30 V.

The battery backup is not like a traditional standard battery and charger. The system

implemented is in fact simpler as it splits the charger into two parts: a power supply and a

charger controller.

The main reason a traditional method cannot be implemented is because no off the shelf

charger exists that meets the wide temperature range of –40° to 60° and can withstand GE

type test requirements.

It is also important to capture the minimum and maximum voltages that the load can

withstand. The minimum turn ON voltage for the load (F60) is 20VDC. The battery should

therefore supply power down to 20VDC and then cut the load off to prevent deep

discharge.

The battery backup is part of a Battery Management System (BMS) board implemented to

optimize battery life and provide useful feedback to the F60. The BMS board will output the

following to the UR:

1.

Battery Charged Signal.

2.

Battery Low Warning (21.5 V).

3.

Battery Overvoltage (33.8 V).

4.

Battery Fuse Blown.

URC UNIVERSAL RECLOSER CONTROL REFERENCE GUIDE

51

CHARGER CONTROLLER

CHAPTER 11: BATTERY MANAGEMENT SYSTEM

5.

Power Supply Fail

6.

Critical Fail – Under voltage

The URC battery charging sequence is performed automatically. As such, user initiation is

not required.

NOTE

Charger controller

The charger controller has the following features.

•

10 Amp Capacity: The charger can facilitate a total of 10 amps to charge the battery

and power the load.

•

Temperature Compensation: The charger has an internal temperature sensor and

varies charging voltages accordingly.

•