Acta Materialia 100 (2015) 377–391

Contents lists available at ScienceDirect

Acta Materialia

journal homepage: www.elsevier.com/locate/actamat

Angular-dependent interatomic potential for the Cu–Ta system and its

application to structural stability of nano-crystalline alloys

G.P. Purja Pun a, K.A. Darling b, L.J. Kecskes b, Y. Mishin a,⇑

a

b

Department of Physics and Astronomy, George Mason University, MSN 3F3, Fairfax, VA 22030, USA

US Army Research Laboratory, Aberdeen Proving Ground, MD 21005, USA

a r t i c l e

i n f o

Article history:

Received 5 June 2015

Revised 17 August 2015

Accepted 22 August 2015

Keywords:

Interatomic potential

Atomistic simulation

Immiscible alloys

Cu–Ta system

Grain boundaries

a b s t r a c t

Atomistic computer simulations are capable of providing insights into physical mechanisms responsible

for the extraordinary structural stability and strength of immiscible Cu–Ta alloys. To enable reliable simulations of these alloys, we have developed an angular-dependent potential (ADP) for the Cu–Ta system

by fitting to a large database of first-principles and experimental data. This, in turn, required the development of a new ADP potential for elemental Ta, which accurately reproduces a wide range of properties

of Ta and is transferable to severely deformed states and diverse atomic environments. The new Cu–Ta

potential is applied for studying the kinetics of grain growth in nano-crystalline Cu–Ta alloys with different chemical compositions. Ta atoms form nanometer-scale clusters preferentially located at grain

boundaries (GBs) and triple junctions. These clusters pin some of the GBs in place and cause a drastic

decrease in grain growth by the Zener pinning mechanism. The results of the simulations are well consistent with experimental observations and suggest possible mechanisms of the stabilization effect of Ta.

! 2015 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

1. Introduction

Recent years have seen a rapidly growing interest in immiscible

metallic alloys due to their favorable combination of high mechanical strength and extraordinary stability at high temperatures

[1–11]. The improved thermal stability is especially important for

nano-crystalline alloys, which are characterized by a strong

tendency for rapid grain growth at elevated temperatures. In particular, Cu–Ta has emerged as one of the most promising immiscible alloy systems for high-temperature, high-strength applications

[8,10,9,7]. Cu and Ta have different crystalline structures (FCC and

BCC, respectively) and negligible mutual solubility in the solid

state [12]. High-energy mechanical alloying is capable of forcing

a significant amount of Ta into a metastable FCC solid solution with

Cu [8,7]. During subsequent thermal processing, Ta precipitates in

a variety of structural forms ranging from atomic-level coherent

clusters to incoherent particles reaching a few nanometers and larger in size.

It is the formation of the Ta clusters that is believed to be

responsible for the extraordinary properties of the mechanically

alloyed Cu–Ta alloys. Such clusters tend to form at grain boundaries (GBs), pinning them by the Zener mechanism [13] and

preventing grain growth even in nano-crystalline alloys with a

⇑ Corresponding author.

E-mail address: ymishin@gmu.edu (Y. Mishin).

http://dx.doi.org/10.1016/j.actamat.2015.08.052

1359-6454/! 2015 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

strong capillary driving force for coarsening. In addition, the clusters themselves contribute to the strengthening of the material,

making it significantly stronger than predicted by the Hall–Petch

model of GB hardening [14,15]. While the exact mechanisms of

these effects remain the subject of active current research, it is

likely that the nanometer and sub-nanometer size clusters restrain

dislocation glide in the Cu lattice similar to the Guinier–Preston

zones [16,17] in Al(Cu) alloys. Furthermore, the cluster located at

GBs are likely to increase the resistance to GB sliding, which is

one of the important deformation and accommodation mechanisms in nano-grained materials [18].

Atomistic computer simulations offer a powerful tool for gaining deeper insights into the physical mechanisms of the Ta effect.

Such simulations typically employ the molecular dynamics (MD)

and Monte Carlo (MC) methods and rely on semi-empirical interatomic potentials to describe atomic interactions [19]. Our previous simulations of the Cu–Ta system [7] utilized an interatomic

potential [20] that had been developed with emphasis on surface

phenomena, such as wetting and dewetting of Cu thin films deposited on Ta substrates. While this potential does capture basic

trends in this system, quantitative investigations of immiscible

bulk alloys require a more accurate potential developed for a wider

range of applications. Indeed, since the development of the previous potential [20], more first-principles data became available

and potential generation and testing methods have been significantly improved. The goal of this work is to develop a new and

378

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

improved Cu–Ta potential taking advantage of the richer firstprinciples databases and more advanced fitting and testing

methodologies existing today.

The strategy for achieving this goal is as follows. We will adopt

the existing embedded-atom method (EAM) [21] potential for Cu

[22], which has been successfully tested in many materials applications. A new potential will be constructed for Ta. The previously

developed angular-dependent potential (ADP) [23] had a flaw:

due to an error in the fitting program, some of the elastic constants

of Ta are different from those reported in the paper. In addition, the

melting temperature of Ta predicted by that potential is significantly higher than experimental. Several other potentials have

been developed for Ta [24–28], the most recent ones being the

EAM potentials by Li et al. [27] and Ravelo et al. [29]. The Ravelo

EAM potential [29] is especially accurate and transferable as will

be discussed below. However, we prefer the ADP potential format

[30,23,20,31,32], which we believe to be more appropriate for BCC

transition metals than the regular EAM. We therefore set the goal

of constructing a new ADP potential for Ta, and along the way to

improve on some of the properties of the Ravelo potential [29],

such as the melting temperature, the surface energies and the

interstitial formation energies.

The development of the ADP Ta potential will be described

in Sections 2 and 3 and the testing results will be reported in

Section 4. We compare the predictions of the new potential with

first-principles calculations and the potentials by Li et al. [27]

and Ravelo et al. [29]. Having a Ta potential, we then cross it with

EAM Cu [22] by fitting the mixed-interaction functions in the ADP

format. The fitting and testing results for the binary Cu–Ta potential are presented in Section 5. The ability of the new potential to

model the Cu–Ta system is demonstrated in Section 6 by studying

structural stability of nano-crystalline Cu–Ta alloys. Two types of

alloys are tested, one modeling the highly non-equilibrium state

with a random dispersion of Ta atoms created by mechanical alloying, and the other mimicking the heat-treated alloys containing Ta

clusters. The results of this study are well consistent with experimental observations and reveal some interesting effects such as

the strong pinning of GBs by the Ta clusters and the formation

and growth of Ta clusters in random alloys by the mechanism of

GB diffusion.

2. Potential format

In the ADP formalism [30,23,20,31,32], the total energy of a system is expressed by

Etot ¼

%

m

2

i;

lai ¼

kai b ¼

mi ¼

j–i

qsj ðrij Þ;

X

wsi sj ðrij Þraij r bij ;

j–i

ð4Þ

X aa

ki :

ð5Þ

a

3. Fitting of the ADP potential for Ta

The pair-wise interaction function UTaTa ðrÞ, the host electron

density qTa ðrÞ, and the quadrupole interaction function wTaTa ðrÞ

were represented by cubic splines. For each spline, not only the

values of the function but also positions of the nodes were adjustable parameters. Each function was parameterized by five nodes,

giving a total of 30 fitting parameters. To impose a smooth cutoff

at a distance r c , the splines were multiplied by the truncation function wððr % rc Þ=hÞ, were

wðxÞ ¼

(

x4

1þx4

0

if x < 0;

if x P 0:

ð6Þ

The truncation introduces two more parameters r c and h, bringing the total number of fitting parameters to 32. In this work, we

did not use the dipole term. It was found that it did not improve

the potential quality enough to warrant its inclusion.

! Þ was obtained by inverting Eq. (1)

The embedding energy F Ta ðq

to ensure that the energy E per atom of BCC Ta follows Rose’s equation of state postulated in the form

!

"

EðaÞ ¼ E0 1 þ ax þ f 3 a3 þ f 4 a4 e%ax ;

x¼

a¼

X

ð3Þ

In these equations, usi sj ðrÞ and wsi sj ðrÞ are additional potential

functions of the radial distance between atoms. For the binary

Cu–Ta system, the construction of an ADP potential requires 13

potential functions: UCuCu ðrÞ; UTaTa ðrÞ, UCuTa ðrÞ; qCu ðrÞ; qTa ðrÞ,

! Þ; F Ta ðq

! Þ; uCuCu ðrÞ, uTaTa ðrÞ; uCuTa ðrÞ; wCuCu ðrÞ, wTaTa ðrÞ, and

F Cu ðq

wCuTa ðrÞ. In this work, the ADP potential functions for pure Ta will

be constructed separately and then crossed with an existing EAM

potential for pure Cu developed in [22] to obtain a binary potential.

where indices i and j enumerate atoms and superscripts

a; b ¼ 1; 2; 3 represent Cartesian components of vectors and tensors. In Eq. (1), Usi sj ðrij Þ is the pair interaction energy between an

atom i of chemical species si located at position r i and an atom j

of chemical species sj located at position r j ¼ r i þ r ij . The second

term is the energy of embedding an atom of chemical species si in

! i induced at site i by all other atoms.

the host electron density q

The host electron density is given by

q! i ¼

usi sj ðr ij Þr aij ;

where the trace of kiab is

and

i

j–i

and quadrupole tensors

ð1Þ

6

X

ð7Þ

where

X

1 X

1 X a 2 1 X ab 2

!iÞ þ

Usi sj ðr ij Þ þ

F si ð q

ðl Þ þ

ðk Þ

2 i;jði–jÞ

2 i;a i

2 i;a;b i

i

1X

The remaining terms in Eq. (1) represent the non-central character of bondings and include the dipole vectors

ð2Þ

where qsj ðr ij Þ is the atomic electron density function of a neighboring

atom j of chemical species sj . The first two terms in Eq. (1) constitute

the standard embedded-atom method (EAM) format [21].

a

%1

a0

ð8Þ

#

$1

%9V 0 B 2

:

E0

ð9Þ

Here, a is the cubic lattice parameter and E0 ; a0 and V 0 are the equilibrium values of the cohesive energy, lattice parameter and atomic

volume, respectively. In Eq. (7), the coefficients f 3 and f 4 could also

be treated as adjustable parameters. However, in this work we used

the values f 3 ¼ %0:035744 and f 4 ¼ %0:020879 optimized by

Ravelo and co-workers [29]. Note that this parameterization of

the potential functions guarantees an exact fit to E0 ; B and a0 .

The potential parameters were fitted to the elastic moduli,

vacancy formation energy and energies of low index surfaces of

BCC Ta and energies of several alternate crystalline structures of

Ta. The parameters were optimized by minimizing the sum of

weighted mean-squared deviations of computed properties from

379

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

the respective experimental and/or first-principles values. A twostep optimization process was applied. First, a preliminary optimization was implemented utilizing a genetic algorithm developed

in our previous work [31], followed by a more refined fit using a

simulated annealing method.

2.0

Energy (eV)

1.5

4. Testing results for the Ta potential

obtained by Q ¼ Evf þ Em

v . The generalized stacking fault energies

were computed in the gamma-surface mode [38]. Namely, two

half-crystals were translated with respect to each other in a given

direction parallel to a chosen crystal plane. After each increment

of translation, the structure was relaxed with respect to atomic

displacements in the x direction normal to the fault plane while

keeping the y and z components of atomic coordinates fixed.

Most of the computations reported here used the LAMMPS simulation program [39].

Table 1 shows that the ADP potential accurately reproduces the

elastic constants c11 and c12 but slightly overestimates c44 . Fig. 2

presents phonon dispersion relations for BCC Ta computed at

300 K by MD simulations [40] with the ADP potential. In this

method, the dynamical matrix is reconstructed from correlations

between atomic displacements and is subject to a Fourier transformation in high-symmetry directions in the reciprocal space. The

simulations were performed in a periodic supercell containing

16&16&16 primitive unit cells. The phonon dispersion curves are

in qualitative agreement with experimental measurements by

neutron scattering [41]. While low phonon frequencies are reproduced by the potential accurately, the maximum phonon frequency at point H of the zone boundary is underestimated while

the frequencies at points P and N are overestimated. Similar deviations were found with other potentials. For example, the maximum frequency in the phonon density of states predicted by the

present ADP potential and the two EAM potentials developed by

Ravelo et al. [29] are, respectively, 5.05, 4.56 and 4.25 THz. The

experimental value is 5.03 THz. Note that phonon frequencies were

not included when fitting the potentials.

The vacancy migration energy predicted by the ADP potential

(0.82 eV) overestimates the accepted experimental value of

0.7 eV but falls within the range of first-principles calculations.

The activation energy of self-diffusion is consistent with experimental measurements and first-principles calculations. For interstitials, the potential underestimates the first-principles

formation energy for the h1 0 0i dumbbell orientation, as do all

other potentials [29,27]. However, the energies of the h1 1 0i and

h1 1 1i interstitials are reproduced more accurately than with other

potentials. The energy ctw of the f2 1 1gtwin boundary is in

0.0

−0.5

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

Distance (Å)

(a)

Electron density

0.10

0.08

0.06

0.04

0.02

0.00

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

(b)

Distance (Å)

25.0

20.0

Energy (eV)

of vacancies (Evf ) and interstitials (Eif ) were computed for a set

of different system sizes, plotted against the inverse of the number of atoms and extrapolated to the infinite size [35]. The

vacancy migration energy Em

v was calculated in a periodic supercell containing 1024 atoms using the nudge elastic band (NEB)

method [36,37]. The activation energy of self-diffusion was

0.5

15.0

10.0

5.0

0.0

(c)

−5.0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

ρ (arbitrary units)

0.40

0.35

Energy (eV/Å2)

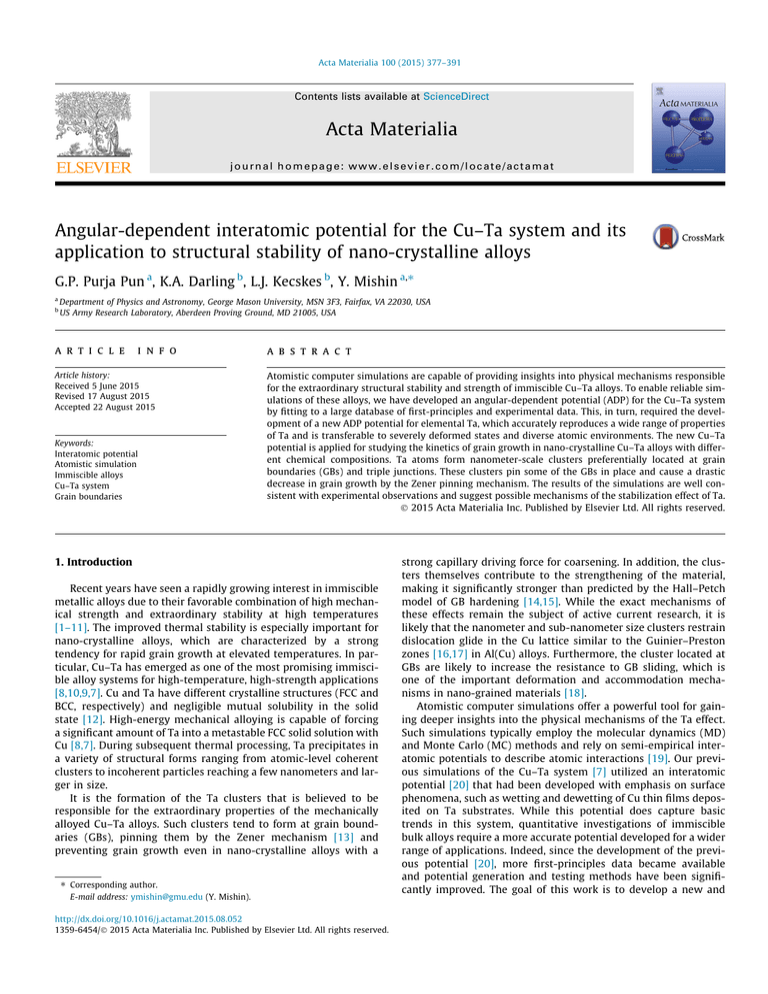

The optimized potential functions are plotted in Fig. 1. The pair

potential and embedding energy function are plotted in the effec! has

tive pair format [33,34], although the host electron density q

not been scaled and the minimum of the embedding energy occurs

! ¼ 1:074599.

at q

Some of the properties of BCC Ta predicted by the potential

are summarized in Table 1 in comparison with experimental data,

first-principles calculations and predictions of EAM potentials

[29,27]. All properties, except for the melting point, were computed at absolute zero temperature. For defect energies, the

structures were relaxed and the results were tested for convergence with respect to the system size. The formation energies

1.0

0.30

0.25

0.20

0.15

0.10

0.05

0.00

(d)

−0.05

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

Distance (Å)

Fig. 1. Potential functions of the ADP Ta potential: (a) pair interaction, (b) electron

density, (c) embedding energy, and (d) quadrupole interaction function.

good agreement with the first-principles value (no experimental

data is available). The energies cs of low-index surfaces were

included in the potential fit and are in good agreement with

first-principles calculations. The ranking of the surface

energies is also consistent with first-principles calculations:

380

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

Table 1

Properties of BCC Ta computed with the present ADP potential in comparison with experimental data, first-principles calculations and previously

developed EAM potentials [29,27]. The properties marked by an asterisk were included in the potential fit. The values marked by a dagger were

computed in this work using the published potentials.

Property

⁄

Experiment

q

Ab initio

l

a0 (Å)

3.3026 ; 3.3039

E0 (eV)⁄

B (GPa)

%8.1r

194.2a; 198l

c11 (GPa)⁄

266.3a 266.0v

c12 (GPa)⁄

158.2a 160.94v

c44 (GPa)⁄

87.4a 82.47v

Evf (eV)⁄

2.2–3.1s

Em

v (eV)

0.7s

Q (eV)

3.8–4.39s

Eif h100i (eV)

Eif h110i (eV)

Eif h111i

(eV)

T m (K)

ctw (J/m2)

cus (J/m2):

f110gh111i

f110gh110i

f110gh100i

f211gh110i

f211gh111i

cs (J/m2):

f100g'

f110g'

f111g'

f211g

3293

p

i

3.26 ; 3.3086

3.315e; 3.3k

3.27864f; 3.311m

195.58k; 194f

190.95j; 196m

265; 259.6c; 258.7k

249.68j 257t

159i; 165.2c; 168.8k

161.59j 163t

74t; 64.2c; 67.8k

70.26j 71t

3.22b; 2.99h; 2.95g

2.91d 3.14u

0.76b; 0.83h

0.86 1.48u

3.98b

7.00u

ADP

EAM1

EAM2

EAM3

3.304

3.304

3.304

3.3026

%8.1

194.7

%8.1

194.7

%8.1

195.9

%8.089

179.2

268.9

263

267

247.5y

157.6

161

160

143.6y

90.4

82

86

86.5

3.06

2.43

2.00

2.76

0.82

0.99

1.08

1.24

3.88

5.86

3.42

5.34y

3.08

5.89y

4.00

5.12y

6.38u

5.65

4.55y

5.83u

5.62

4.44y

5.05y

0.304b

3296

0.28

3033

0.29y

3080

0.30y

0.840b

1.947b

1.947b

4.079b

0.947b

0.782

2.041

2.041

3.927

0.918

0.864

2.181y

2.194

3.422y

1.017

0.803

2.182y

2.208

3.312y

0.975

2.991

2.755

3.236

3.113

2.28

1.97

2.53

2.32y

2.40

2.04

2.74

2.48y

3.142b;

2.881b;

3.312b;

3.270b;

3.097n; 2.97p

3.087n; 2.58p

3.455n

3.256n

0.42y

2.03

1.77

2.20y

2.02y

1;2

Ref. [29].

Ref. [64]

Ref. [23]

c

Ref. [65]

d

Ref. [66]

e

Ref. [67]

f

Refs. [68,69]

g

Ref. [70]

h

Ref. [71]

i

Ref. [72]

j

Ref. [73]

k

Ref. [74]

l

Ref. [75]

m

Ref. [76]

n

Ref. [77]

p

Ref. [78]

q

Ref. [79]

r

Ref. [80]

s

Ref. [81]

t

Ref. [82]

u

Ref. [83]

v

Ref. [84]

3

Ref. [27]

a

b

cs h1 1 0i < cs h1 0 0i < cs h2 1 1i < cs h1 1 1i. The EAM potentials

[29,27] significantly underestimate the surface energies.

Generalized stacking faults energies for the f1 1 0g and

f2 1 1gfault planes are displayed in Fig. 3. The first-principles

gamma-surfaces [29,23] are shown for comparison. For the sake

of completeness, we also include the earlier first-principles calculations by Frederiksen and Jacobsen [42] for the h1 1 1if1 1 0g fault,

which are unrelaxed and thus predictably overestimate the recent

relaxed calculations [29,23]. The maxima along the gamma surfaces represent unstable stacking fault energies cus , which are summarized in Table 1. The ADP predictions are in excellent agreement

with first-principles calculations, even though the latter were not

included in the potential fit. Unstable stacking fault energies are

important for simulations of core effects in dislocation glide.

Equilibrium energies DE of several alternate structures of Ta relative to the BCC ground state are summarized in Table 2. The

agreement between the ADP energies and first-principles data is

reasonable. To facilitate comparison with other potentials, we plot

the energies predicted by the ADP and EAM potentials versus the

first-principles data (Fig. 4). The bisecting line in this plot is the line

of perfect agreement. Despite the scatter of the points, all potentials show a strong correlation with first-principles results. The

381

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

Frequency (THz)

6

5

4

3

2

1

0

Γ

[ζ,0,0]

H

[ζ,ζ,ζ]

P

[ζ,ζ,ζ]

Γ

[0,ζ,ζ]

N

Fig. 2. Phonon dispersion relations for BCC Ta computed with the ADP potential at

300 K (solid lines). The circles (() and triangles (M) represent experimental data

from Ref. [41].

scatter is more significant for the potential by Li et al. [27]. The

alternate structures were included in this analysis as a test of

transferability of the potentials to various atomic environments

different from the BCC structure. It is important to note that both

the ADP and EAM potentials correctly predict the metastable b-U

and b-W structures to be closest in energy to the BCC ground state.

The b-phase of Ta (b-U prototype) is often observed experimentally

2.0

2.5

DFT

DFT

ADP

Energy (J/m2)

2

Energy (J/m )

2.5

1.5

1.0

0.5

0.0

0.0

in deposited thin films [26,43,44]. The proposed ADP potential

should be suitable for thin film simulations involving the b-phase.

We next discuss the performance of the potential under large

structural distortions. The pressure–volume relation computed

for BCC Ta at 0 K is in good agreement with experiment and

first-principles calculations up to 1 TPa (Fig. 5). As a further test

beyond the limits of linear elasticity, we performed a static uniaxial compression of BCC Ta at 0 K in three different directions.

Stress–strain relations under such conditions are relevant to shock

wave propagation and were computed by Ravelo et al. [29]. The

material was compressed in a chosen x-direction up to e ¼ 40%

while keeping fixed dimensions in the y and z directions. The

results are shown in Fig. 6 in comparison with first-principles calculations [29]. While marked deviations are observed under compressions exceeding 20%, the overall agreement with firstprinciples calculations is good and on the same level of accuracy

as with the EAM potentials [29].

Several other tests were conducted to evaluate the transferability of the potential to highly distorted configurations. One of them

involved homogeneous twinning and anti-twinning deformation

paths, which are relevant to mechanical behavior of Ta. This deformation carries a BCC crystal back to itself but with a twinning or

anti-twinning orientation relative to the initial state. A detailed

crystallographic description of this path can be found in Ref. [23].

(110)⟨100⟩

0.2

0.4 0.6 0.8

Displacement

2.0

1.5

1.0

0.5

0.0

0.0

1.0

DFT

ADP

(110)⟨110⟩

0.2

0.4 0.6 0.8

Displacement

(a)

1.0

0.8

(b)

5.0

ADP

DFT

DFT

DFT

Energy (J/m2)

2

Energy (J/m )

1.2

0.6

0.4

0.2

0.0

0.0

(110)⟨111⟩

0.2

0.4

0.6

0.8

4.0

3.0

2.0

1.0

0.0

0.0

1.0

DFT

ADP

(211)⟨110⟩

0.2

0.4

0.6

Displacement

Displacement

(c)

(d)

1.2

Energy (J/m2)

1.0

1.0

0.8

0.8

1.0

DFT

DFT

ADP

0.6

0.4

0.2

0.0

0.0

(211)⟨111⟩

0.2

0.4 0.6 0.8

Displacement

1.0

(e)

Fig. 3. Cross-sections of gamma surfaces for BCC Ta computed with the present ADP potential in comparison with first principles (DFT) calculations (( [23], ! [29] and

M [42]): (a) h1 0 0if1 1 0g, (b) h1 1 0if1 1 0g, (c) h1 1 1if1 1 0g, (d) h1 1 0if2 1 1g, (e) h1 1 1if2 1 1g. The displacements are normalized by the period in the respective direction.

382

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

Table 2

Equilibrium energies DE per atom (relative to the cohesive energy of BCC Ta) and the respective lattice parameters a0 of alternate structures of Ta computed with the ADP

potential in comparison with EAM potentials [29,27] and first-principles calculations [23]. SH is the simple hexagonal phase and L12 is the FCC structure with one unrelaxed

vacancy per cubic unit cell. The structures marked by an asterisk were included in the potential fit.

Structure

Ab initio

BCC (A2)*

b-U (Ab)

b-W (A15)

x (C32)

FCC (A1)*

HCP (A3)*

SH (Af)*

SC (Ah)

Cu3Au (L12)

DC (A4)*

EAMa

ADP

EAMb

EAMc

DE (eV)

a0 (Å)

DE (eV)

a0 (Å)

DE (eV)

a0 (Å)

DE (eV)

a0 (Å)

DE (eV)

a0 (Å)

0

0.041

0.060

0.249

0.303

0.385

0.757

1.137

1.116

3.128

3.2398

9.9974

5.1805

4.7611

4.1256

2.9112

2.7715

2.6710

3.9120

5.9096

0

0.073

0.075

0.143

0.124

0.151

0.811

1.064

1.246

2.931

3.304

10.2441s

5.3482

4.7197r

4.2456

2.9841l

2.7010

2.5920

3.9801

6.2362

0

0.038y

0.035y

0.148y

0.134y

0.139y

0.920y

1.134y

1.113y

2.867y

3.304

10.1505y,s

5.2670y

4.7442y,!

4.1850y

2.9632y,l

2.7284y

2.5958y

3.8903y

5.4476y

0

0.076

0.086y

0.215y

0.137

0.137y

1.127y

1.382y

1.138y

2.274y

3.3026

10.1097y,s

5.2727y

4.6898y,m

4.2039y

2.9726y,l

2.9032y

2.6638y

4.1057y

6.2665y

0

0.026y

0.029y

0.166y

0.167y

0.176y

0.932y

1.153y

1.016y

3.075y

3.304

10.1084y,s

5.2716y

4.7530y,a

4.1556y

2.9452y,l

2.7453y

2.6374y

3.8370y

5.5242y

a;c

Ref. [29].

Ref. [27].

ideal c/a

a

c/a = 0.5790.

m

c/a = 0.5792.

!

c/a = 0.5827.

r

c/a = 0.5876.

y

computed in this work.

s

c/a = 0.5290.

b

3.5

3.0

2.5

EAM1

EAM2

EAM3

ADP

1000

Pressure (GPa)

EAM and ADP energy (eV)

l

2.0

1.5

1.0

0.5

0.0

0.0

ADP

DFT

DFT

Exp

Exp

800

600

400

200

0.5

1.0

1.5

2.0

2.5

3.0

3.5

DFT energy (eV)

Fig. 4. Energies of alternate structures of Ta predicted by ADP and EAM potentials

versus the results of first-principles (DFT) calculations [23]. Potentials: EAM1 [29],

EAM2 [29], EAM3 [27] and ADP (present work). The bisecting dashed line is the line

of perfect correlation. Details of the structures are given in Table 2.

The deformation is described by a shear parameter which is zero in

pffiffiffi

pffiffiffi

the initial state and attains the values of 1= 2 and % 2 for the

twin and anti-twin orientations, respectively. The energy along this

paths computed with the ADP potential is shown in Fig. 7 in comparison with first-principles calculations [23]. The potential accurately reproduces the maximum anti-twinning energy (1.04 eV/

atom) and slightly underestimates the maximum twinning energy

(0.15 eV/atom).

The potential was also tested for three volume-conserving

deformation paths: orthorhombic, tetragonal and trigonal.

Orthorhombic deformation is implemented by elongation of the

BCC cubic unit cell along the ½0 0 1* direction with simultaneous

compression along the ½1 1 0* direction to preserve the equilibrium

BCC volume. The respective deformation parameter p was defined

in [45]. For the tetragonal deformation path (Bain path), the unit

cell is elongated in the ½0 0 1* direction with simultaneous compression in the ½1 0 0* and ½0 1 0* directions by equal amounts. The deformation is measured by the parameter p ¼ c=a with p ¼ 1 for the

pffiffiffi

BCC structure and p ¼ 2 for the FCC structure. Further elongation

produces a local energy minimum corresponding to a bodycentered tetragonal (BCT) structure. Finally, for the trigonal deformation we compress the BCC structure along the ½1 1 1* axis with

0

0.40

0.50

0.60

0.70

0.80

0.90

1.00

V/V0

Fig. 5. Pressure–volume relation for BCC Ta computed with the present ADP

potential in comparison with experiments (( [85], M [75,86]) and first-principles

(DFT) calculations (þ [87], r [88]).

simultaneous elongation in perpendicular directions. The deformation parameter p is the Lagrangian strain described in [46]. The

deformation starts with p ¼ 0 (BCC structure) and creates the simple cubic (SC) and FCC structures at p ¼ 2 and p ¼ 4, respectively.

Comparison of the ADP and EAM potentials with first-principles

calculations is shown in Fig. 8. Given that no information about

these deformation paths was included in the potential fit, the

agreement with first-principles data is quite reasonable. The ADP

potential demonstrates about the same level of accuracy as the

potentials by Ravelo et al. [29]. The potential by Li and coworkers [27] is somewhat less accurate. In particular, for the

tetragonal deformation path it predicts a local minimum of energy

for the FCC structure instead of a maximum.

To evaluate thermal properties predicted by the ADP potential,

the linear thermal expansion factor was computed as a function of

temperature (Fig. 9). The simulations utilized a periodic cubic

supercell containing 16000 atoms. MD simulations were executed

in the NPT (fixed temperature and pressure) ensemble in which all

three dimensions of the supercell were allowed to fluctuate independently to ensure zero components of pressure in all three directions. The cubic lattice parameter a was averaged over a 1 ns long

MD run and the linear expansion coefficient was defined as

ða % art Þ=art , where art is the lattice parameter at room temperature

383

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

Stress (GPa)

600

500

250

Pxx (ADP)

Pzz (ADP)

Pxx (DFT)

Pzz (DFT)

400

300

200

150

DFT

100

100

(c)

Energy (eV/atom)

1.0

1.4

1.6

500

450

400

350

300

250

200

150

100

50

0

0.8

1.8

2.0

ADP

EAM1

EAM2

EAM3

DFT

FCC

BCT

BCC

1.0

1.2

1.4

p

1.6

1800

Pxx (ADP)

Pzz (ADP)

Pxx (DFT)

Pzz (DFT)

1400

1200

1000

2.0

SC

800

600

1.8

ADP

EAM1

EAM2

EAM3

DFT

1600

BCC

400

FCC

200

0.05

0.10

0.15

ε⟨111⟩

0.20

0.25

0.30

Fig. 6. Stress components as functions of strain during uniaxial compression of BCC

Ta calculated with the present ADP potential in comparison with first-principles

(DFT) calculations [29]. Crystallographic directions: (a) x : ½1 0 0*; y : ½0 1 0*; z : ½0 0 1*.

! 1 0*; z : ½0 0 1*. (c) x : ½1 1 1*, y : ½1

! 1 0*; z : ½1

!1

! 2*.

(b) x : ½1 1 0*; y : ½1

1.2

(b)

E [meV/atom]

450

400

350

300

250

200

150

100

50

0

0.00

1.2

p

E [meV/atom]

450

Pxx (ADP)

400

Pyy (ADP)

Pzz (ADP)

350

Pxx (DFT)

300

Pyy (DFT)

Pzz (DFT)

250

200

150

100

50

0

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

ε⟨110⟩

0

1.0

(a)

anti-twinning

0.6

0.4

twinning

0.2

0.0

-0.2

-2.0 -1.5 -1.0 -0.5

Fig. 8. Energy along three homogeneous deformation paths of Ta computed with

interatomic potentials in comparison with first-principles (DFT) calculations [45].

(a) Orthorhombic deformation path. (b) Tetragonal deformation path. (c) Trigonal

deformation path. Potentials: EAM1 [29], EAM2 [29], EAM3 [27] and ADP (present

work). For each deformation path, the volume remains fixed at its equilibrium value

in BCC Ta.

DFT

ADP

0.8

0.0

0.5

1.0

Shear strain

Fig. 7. Energy along the homogeneous twinning and anti-twinning deformationpaths in BCC Ta calculated with the present ADP potential in comparison with firstprinciples (DFT) calculations [23].

(300 K). The ADP potential demonstrates a good agreement with

experimental data up to the temperature of 1200 K but

underestimates the experimental lattice constant at higher

temperatures.

The melting temperature T m of BCC Ta was computed by two

methods: the phase coexistence method and the interface velocity

method. The phase coexistence method is described in detail else-

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

p

(c)

Linear thermal expansion (%)

Stress (GPa)

Stress (GPa)

(b)

BCT

50

0

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

ε⟨100⟩

(a)

ADP

EAM1

EAM2

EAM3

200

E [meV/atom]

700

3.5

ADP

Experiment

3.0

2.5

2.0

1.5

1.0

0.5

Tm

0.0

-0.5

0

500 1000 1500 2000 2500 3000 3500

Temperature (K)

Fig. 9. Linear thermal expansion factor (%) of BCC Ta relative to room temperature

computed with the present ADP potential in comparison with experimental data

[89]. The experimental melting temperature is indicated.

where [47,48]. In short, a simulation block containing a plane

solid–liquid interface is equilibrated by a micro-canonical MD simulation and the equilibrium temperature and pressure (defined

here as the trace of the stress tensor averaged over the system)

are calculated. The simulation is repeated several times starting

384

3320

8

3315

6

Energy (eV/atom/ns)

Temperature (K)

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

3310

3305

3300

3295

3290

3285

3280

-0.2

-0.1

0.0

0.1

Pressure (GPa)

4

2

0

-2

-4

-6

-8

3000

0.2

Fig. 10. Melting temperature as a function of pressure obtained by solid–liquid

phase coexistence simulations for BCC Ta using the present ADP potential. The line

is a linear fit to find the melting point at zero pressure.

from slightly different initial states and the temperature–pressure

relation thus obtained is extrapolated to zero pressure to determine T m . In this work we used a simulation block with dimensions

49:6 & 99:9 & 47:6 Å containing 12240 atoms. The solid–liquid

interface was parallel to the (1 1 1) plane and normal to the longest

dimension of the simulation block. A linear fit to the pressure–temperature points shown in Fig. 10 gives the melting temperature of

3301 + 0:5 K. As an independent check, T m was evaluated by NPT

simulations using the same simulation block but annealed isothermally at several temperatures above and below the expected melting point. In such simulations, the solid–liquid interface migrates

until one of the two phases disappears. The rate of migration was

evaluated by the average energy change per unit time and extrapolated to zero rate (Fig. 11). This calculation gives T m ¼ 3291 + 4 K.

Both numbers are close to the experimental melting point of

3293 K. Each method has its advantages and shortcomings. In the

phase coexistence method, the state of stress is generally nonhydrostatic and the trace of the stress tensor is not an adequate

measure of residual stresses in the system [49]. This is one of the

sources of the statistical scatter of the points in Fig. 10. On the

other hand, the velocity method creates non-equilibrium states

of the system. With the information available to us, we estimate

the melting point by averaging the two numbers to obtain

3296 K. The melting temperatures predicted by the EAM potentials

[29] (3033 and 3030 K) are in less accurate agreement with

experiment.

3200 3300 3400

Temperature (K)

3500

3600

Fig. 11. Energy rate (measure of interface velocity) as a function of temperature in

MD simulations of solidification and melting of BCC Ta with the present ADP

potential. The line is a linear fit to find the melting point.

Table 3

Equilibrium formation energies (in eV per atom) of Cu–Ta compounds computed with

the present ADP potential in comparison with the first-principle calculations. The

compounds marked by an asterisks were included in the potential fit.

Phase

Structure

Ab initio

CuTa

B2⁄

L1'0

L1'1

B32

B1⁄

B3⁄

L1'2

D019

D011

D022

D0'3

A15

L1'2

D019

D011

D022

D0'3

A15

CuCuCuTaTaTa⁄

CuTaTa⁄

CuCuTa⁄

C11b

C11f

C11b

C11f

0.1920a;

0.1235a;

0.2612a;

0.4841a

0.7789a;

1.7421a;

0.3443a;

0.1653a;

0.1971a

0.1172a;

0.1161a;

0.3739a

0.1490a;

0.1822a;

0.1393a

0.1596a;

0.1833a;

0.1168a

0.387c

0.352c

0.219c

0.0959a

0.063c

0.1627a;

0.141c

Cu3Ta

Ta3Cu

Layer

Cu2Ta

Ta2Cu

a

5. ADP potential for the Cu–Ta system

3100

b

c

ADP

0.200b; 0.139c

0.260b; 0.075c

0.269b; 0.228c

0.788b

1.755b

0.372b; 0.350c

0.193b

0.193b

0.143b

0.158b; 0.126c

0.189b

0.166b

0.191b

0.046c

0.07994

0.23447

0.30669

0.35980

0.69585

1.86985

0.23956

0.18674

0.20504

0.28788

0.30295

0.43389

0.23590

0.25064

0.14615

0.27967

0.19087

0.28516

0.19685

0.17293

0.28657

0.13506

0.18855

0.09871

0.09216

Ref. [51]

Ref. [52]

Ref. [20]

5.1. Potential format and fitting

For the binary Cu–Ta system, the mixed pair potential UCuTa ðrÞ

was represented by a Lenard–Jones potential with additional polynomial terms:

" (

)

#

11 & 'i

&a '12 &a '6

&r % r '

X

ai

12

6

c

%

þ

þ a0 w

;

r

r

r

h

i¼1; i–6

UCuTa ðrÞ ¼ E0

ð10Þ

where wðxÞ is the cutoff function defined by Eq. (6). The fitting

parameters of UCuTa ðrÞ are r c , h and the ai ’s. The mixed quadrupole

interaction function wCuTa ðrÞ was postulated in the form

&r % r '

c

wCuTa ðrÞ ¼ w

ðq1 e%q2 r þ q3 Þ;

h

ð11Þ

where q1 ; q2 and q3 are three additional fitting parameters. The cutoff parameters r c and h remain the same as in Eq. (10). Several alternate functional forms of UCuTa ðrÞ and wCuTa ðrÞ were also tested, but it

was found that Eqs. (10) and (11) offered the best accuracy of the

fitting.

Since the pure Cu potential [22] is in the EAM format, the

respective dipole and quadrupole interactions were set to zero.

During the fitting of the mixed interactions, all potential functions

were subject to invariant transformations [34,50,47] that did not

affect properties of pure Cu and Ta but provided additional degrees

of freedom for the optimization of mixed interactions. Such transformations involved three coefficients sTa ; g Cu and g Ta , which were

used as additional fitting parameters.

The potential functions (10) and (11) were fitted to firstprinciples formation energies of several imaginary Cu–Ta compounds with cubic structures (Table 3). Although none of these

compounds exists on the Cu–Ta phase diagram, their role is to represent various structural and chemical environments that may

occur during applications of the potential. As in the case of pure

Ta, the fitting parameters were optimized by a combination of a

genetic algorithm and simulated annealing. The optimized

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

(a)

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

E (eV/atom)

(b)

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

ADP energy (eV/atom)

0.1

Cu

−0.1

−0.2

CuTa

−0.3

Ta

E (eV/atom)

Energy (eV)

0.0

−0.4

(a)

−0.5

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

Distance (Å)

2

Energy (eV/Å )

0.35

0.30

0.25

0.20

0.15

Ta

0.10

0.05

CuTa

0.00

(b)

−0.05

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5

Distance (Å)

Fig. 12. Plots of: (a) mixed pair interaction function and (b) mixed quadrupole

interaction function for the binary Cu–Ta system in comparison with elemental

interaction functions for Ta and Cu.

mixed-interaction functions UCuTa ðrÞ and wCuTa ðrÞ are shown in

Fig. 12 together with the respective elemental functions. It should

be emphasized that, due to the invariant transformations mentioned above, the Cu and Ta pair potentials look in this plot different from their original forms. In particular, the pair interaction

UTaTa ðrÞ looks different from the curve plotted in Fig. 1. Nevertheless, when the binary potential developed here is applied to pure

Cu or pure Ta, all properties of these metals are exactly the same

as when using the original elemental potentials.

5.2. Properties of the Cu–Ta system

The imaginary compounds included in the potential fit had the

relatively simple crystalline structures such as B1, B2, B3, L10, L11,

L12 and D03. In addition, layered structures CuCuCuTaTaTa, CuCuTa

and CuTaTa (see [20] for details) were also included. This set of

compounds samples very diverse structures and different stoichiometries across the entire composition range between Cu and

Ta.

Three sources of first-principles data for the structural energies

were available for this work: the first-principles calculations by

Hashibon et al. [20] and the quantum–mechanical databases developed by the groups of Curtarolo (AFLOW) [51] and Wolverton

(OQMD: Open Quantum Materials Database) [52]. Certain discrepancies were found between the formation energies reported by the

three sources, apparently arising from different choices of calculation parameters. To give an idea about the scatter of the data, we

plot the predictions of Refs. [51,52] against each other for a set of

simple structures selected for this work (Fig. 13(a)). The rootmean-square deviation between these datasets is 0.072 eV and

Pearson’s correlation factor is 0.997. In view of these discrepancies,

the first-principles energies used as input for fitting and testing of

the potential were obtained by averaging the numbers coming

from all sources available for any particular compound.

We were unable to achieve a perfect fit to all compounds chosen as targets. It was especially difficult to reproduce the formation

Ab initio energy (eV/atom)

0.40

385

Fig. 13. Formation energies (relative to equilibrium FCC Cu and BCC Ta) of selected

Cu–Ta compounds listed in Table 2. (a) First-principles data from AFLOW [51]

(abscissa) and OQMD [52] (ordinate). (b) Predictions of the ADP potential versus

average first-principles data. The bisecting dashed line is the line of perfect

correlation.

energies of the layered structures without significant sacrifices in

accuracy with respect to the simpler structures. We therefore

chose the strategy of putting less weight on the layered structures

and spreading the fitting errors more or less uniformly over the

remaining compounds. Table 3 summarizes the results of fitting

and testing. While for some compounds the agreement with

first-principles data is good, for others the discrepancies can reach

up to , 0:1 eV. Nevertheless, Fig. 13(b) demonstrates that the

entire set of the ADP formation energies exhibits a significant correlation with first-principles data. The root-mean-square deviation

between the ADP and first-principles energies is 0.089 eV and Pearson’s correlation factor is 0.978.

The zero-temperature energy of dilute solutions predicted by

the ADP potential is 0.6771 eV for Cu in BCC Ta and 1.66471 eV

for Ta in FCC Cu. Both energies are large enough to ensure that

the mutual solid-state solubility between Cu and Ta be very small

in agreement with the experimental phase diagram [12]. Calculation of the Cu–Ta phase diagram predicted by this potential is

beyond the scope of this work. It is interesting to note, however,

that the liquid Cu–Ta alloys exhibit a highly non-uniform structure

consisting of nanometer-scale Ta clusters embedded in the Cu

matrix. Similar thermodynamically stable nano-colloidal structures were found with the previous ADP potential [20] and were

explained by a strong stabilizing effect of the Cu/Ta interface curvature [53]. The reproducibility of this unusual structure with

two different potentials suggests that it is likely to be real and

not an artifact of an interatomic potential.

6. Structural stability of Cu–Ta alloys

6.1. Methodology of simulations

A 3D polycrystalline Cu sample was constructed by the Voronoi

tessellation method. Initially, 32 grain centers were selected as

386

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

points of a regular FCC lattice but were subsequently randomized

by adding random displacements. This ensured random sizes of

the grains in the polycrystal. The Voronoi tessellation was performed using the free open-source program voro++ [54,55]. After

the tessellation, the system was uniformly scaled in all three directions to the dimensions of 40 & 40 & 40 nm with periodic boundary conditions in all three directions. Next, the polyhedra were

filled with FCC Cu with crystallographic axes randomly orientated

in space. Some overlap was initially allowed between the lattices of

neighboring grains. Subsequently, the GB structures were optimized by identifying pairs of atoms separated by less than 0.6 of

the equilibrium first-neighbor distance in FCC Cu and replacing

them by a single atom. Further technical details of this procedure

can be found in [56,57]. To further relax the GBs, the polycrystal

was heated to the temperature of 300 K in 0.4 ns and annealed

for another 0.4 ns by NPT MD simulations. These steps resulted

in a 32-grain periodic polycrystalline sample containing about

5.4 million Cu atoms.

The initial grain size was estimated by d0 ¼ ðV=N g Þ1=3 - 12:5 nm,

where N g ¼ 32 is the number of grains and V is the system volume.

During the subsequent grain growth simulations, the grain size d

was defined by d ¼ d0 X 0 =X, where X is the number of GB atoms

and X 0 is the value of X in the initial state. To determine X for a given

MD snapshot, the latter was quenched by static energy minimization and analyzed for bond angle distortions using the OVITO visualization tool [58]. The bond angle analysis identifies atoms with

FCC and HCP environments, which correspond to the perfect FCC

lattice and intrinsic stacking faults, respectively. The remaining

atoms were attributed to GBs and their number was X. The implicit

assumption of this calculation of d is that the GB width remains constant, which may be a source of some error as the GB width may vary

during the simulations.

Two types of Cu–Ta alloys were prepared. First, to model the

non-equilibrium solid solution created by mechanical alloying, a

set percentage of Ta atoms was introduced by random substitution

of Cu atoms using a random numbers generator. As a result, the Ta

atoms were randomly scattered over the system with the same

density regardless of the GBs or grain interiors. Second, more equilibrium states of the alloy were prepared by semi-grand canonical

Monte Carlo simulations [59] at zero pressure. In such simulations,

the temperature T and chemical potential difference Dl between

Ta and Cu are fixed while the distribution of Ta atoms over the system can vary to reach local thermodynamic equilibrium. The trial

moves include displacements of randomly selected atoms by a random amount in a random direction with simultaneous random reassignment of the chemical species of the chosen atom to either Ta

or Cu. Simultaneously, the dimensions of the simulation block in all

three directions are changed independently by random amounts

with corresponding re-scaling of atomic coordinates. The trial

move is accepted or rejected by a Metropolis algorithm. Further

technical details of this method can be found in [60–62]. The simulation temperature was chosen to be 800 K at which no significant

grain growth occurred during the Monte Carlo process, yet equilibrium could be reached by an affordable number of Monte Carlo

steps. The chemical potential difference Dl was adjusted to create

several alloys with chemical compositions up to a few at.%Ta. It

should be noted that these compositions are significantly higher

than the Ta solid solubility limit in Cu. Thus, the alloys created

by the Monte Carlo process are metastable and are intended to

model the experimental alloys after a thermal treatment.

6.2. Simulation results

To model grain growth in pure Cu, the initial sample was heated

to the temperature of 1200 K in 1.2 ns and annealed at this temper-

Fig. 14. Nanocrystalline Cu (a) before and (b) after a 10 ns long isothermal MD

simulation at 1200 K. The GBs are revealed by bond angle analysis using OVITO [58].

Dark blue atoms represent perfect FCC structure.

ature for at least 10 ns in the NPT MD ensemble. Typical snapshots

before and after the annealing are shown in Fig. 14. The GBs are

revealed by the bond angle analysis using OVITO [58]. The images

clearly demonstrate that significant grain growth has occurred

during the anneal (see online supplementary material [63] for animations of the grain growth). The dynamics of grain growth are

quantified in Fig. 15 by plotting the average grain size d as a function of time. The points represent individual MD snapshots. The

scatter of the points tends to increase with the grain size, especially when the sample is left with only 3–4 grains. The plot shows

that the grain size approximately doubles during the first 10 ns.

We now discuss the results for the Cu–Ta alloys. During the

Monte Carlo simulations, the Ta atoms introduced into Cu tended

to form nanometer-size clusters. Some of them appeared inside

the grains and were coherent with the FCC lattice. However, the

overwhelming majority of the clusters formed at GBs and triple

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

Grain size [nm]

30

Cu

0.1 at.% Ta

0.3 at.% Ta

0.5 at.% Ta

1.0 at.% Ta

2.0 at.% Ta

4.0 at.% Ta

25

20

15

10

(a)

0

Grain size [nm]

2

4

6

8

10

8

10

Time [ns]

30

Cu

0.1 at.% Ta

0.5 at.% Ta

1.0 at.% Ta

2.0 at.% Ta

25

20

15

10

(b)

387

0

2

4

6

Time [ns]

Fig. 15. Average grain size versus time for several compositions of Ta in Cu–Ta

alloys during isothermal anneals at 1200 K by NPT MD simulations. (a) Clustered Ta.

(b) Randomly dispersed Ta.

junctions as illustrated in Fig. 16(a). This microstructure is well

consistent with experimental TEM observation that also show

the preference of Ta clusters in nano-grained Cu samples [8].

To quantify the cluster size, the size distribution histograms

were computed. To this end, all Cu atoms were removed from

the relaxed MD snapshot and the remaining Ta atoms were processed by the cluster analysis algorithm implemented in the OVITO

tool [58]. This analysis enabled us to construct the distribution

function of the number of atoms in the clusters. This function is

re-plotted in Fig. 17 as the normalized probability versus the cluster size dc . The latter was defined by dc ¼ ðN c V=NÞ1=3 , where N c is

the number of Ta atoms in the cluster and N is the total number of

atoms in the system. The plots are somewhat noisy because the

statistics were obtained from only one snapshot (corresponding

to the given simulation time) and the number of Ta atoms is relatively small due to the low Ta concentration. The first peak at

dc < 0:5 nm is caused by single Ta atoms and their small groups

of 2–3 atoms. The second peak is caused by the nano-clusters,

which have a typical size of about 0.7 nm. Note that the number

of clusters (the peak hight) tends to increase with the alloy concentration with only a small effect on the cluster size. This trend, and

in fact the very existence of the peak, suggest that the clusters constitute a well-defined and well-reproducible structural feature of

the alloy and are not caused by mere statistical fluctuations in

the Ta distribution.

As demonstrated in Fig. 15(a), the addition of Ta in the form of

clusters can drastically reduce the grain growth. While the addition of 0.1 at.%Ta has little effect, in the alloy with 0.3 at.%Ta the

grain size increases only slightly and soon reaches a stagnation

[63]. The alloys with P 1 at.%Ta exhibit no grain growth within

the uncertainty of the calculations. The final structure of the

0.3 at.%Ta alloy after a 10 ns anneal is illustrated in Fig. 16(b). Most

of the clusters remain at GBs, suggesting strong pinning. It is interesting to note, however, that a number of clusters can now be

Fig. 16. Nanocrystalline Cu-0.3at.%Ta alloys (a) before and (b) after a 10 ns

isothermal MD simulation at 1200 K. The GBs are revealed by bond angle analysis

using OVITO [58]. The Ta atoms are shown in green and are larger than Cu atoms.

found inside larger grains that underwent some growth. Animations of the grain growth [63] confirm that such cluster initially

formed at GBs, which were then able to break away from the clusters and leave them behind inside the grains. The strong pinning of

GBs by Ta clusters is consistent with experimental studies of

microstructure and thermal stability of nano-crystalline Cu–Ta

alloys [8,9,7]. Such studies indicate that the precipitation of Ta

clusters and larger particles at GBs drastically reduces the grain

growth by the Zener pinning mechanism. The slight increase in

the cluster size in the 4 at.%Ta alloy suggested by Fig. 17(b) can

be explained by some coarsening due to Ta ‘‘short-circuit” diffusion

along GBs. While the time scale limitation of MD prevents us from

observing further growth of these cluster, their trend for coarsening is in agreement with the experimental observation of a large

spectrum of cluster sizes, from a nano-meter size to a few tens of

nanometers, with larger clusters located at GBs [8].

388

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

0.60

0.50

0.40

0.30

0.20

(a)

0.5

0.6

0.7

0.8

0.9

0.60

1.1

1.2

0.10

0.40

0.30

0.20

0.6

0.8

1.0

1.2

0.00

0.3

0.4

0.5

0.6

0.7

0.8

Fig. 19. Ta cluster size distribution in Cu-1at.%Ta alloy before and after a 10.8 ns

anneal at 1200 K. The initial state was created by purely random dispersion of Ta

atoms.

0.10

(b)

0.15

Cluster size [nm]

0 ns

10 ns

0.50

Probability

1.0

Cluster size [nm]

0.00

0.4

0.20

0.05

0.10

0.00

0.4

0 ns

10.8 ns

0.25

Probability

Probability

0.30

0 ns

10 ns

1.4

1.6

Cluster size [nm]

Fig. 17. Ta cluster size distribution in Cu–Ta alloys before and after a 10 ns anneal

at 1200 K. (a) Cu-0.1at.%Ta alloy. (b) Cu-4at.%Ta alloy. The initial clusters were

created by a semi-grand canonical Monte Carlo simulation at 800 K.

grain growth for the first 5 ns. In fact, a slight grain growth is even

seen in the random 2 at.%Ta alloy [63].

Another interesting feature of Fig. 15(b) is that, for all compositions larger than 0.1 at.%Ta, the grain growth stops after about 5 ns,

as it typically does also in the alloys with clusters. A plausible

explanation of this effect is the formation of Ta clusters at the moving and stationary GBs during the anneal of random alloys. This is

consistent with the images and animations [63] of the alloy structure. As an example, Fig. 18 shows a typical snapshot revealing initial stages of cluster formation in the random Cu-1at.%Ta alloy. The

cluster formation is further confirmed by the cluster size distribution plotted in Fig. 19. As before, the sharp peak at small cluster

sizes (< 0:3 nm) represents individual Ta atoms and their 2–3

atom clusters created by pure chance during the sample preparation. After the 10.8 ns anneal, a new peak begins to form reflecting

the formation of larger clusters with the size of about 0.45 nm. If

longer anneals could be afforded by our computation resources,

we expect that the peak would grow in height and shift towards

larger cluster sizes of about 0.8 nm. But already the observation

of the early stages of peak formation combined with MD snapshots

provide evidence for the clustering of the initially dispersed Ta

atoms. These newly formed clusters eventually pin the GBs and

stop the grain growth. This observation is consistent with experiments [8] and a possible mechanism for the formation of Ta clusters in GB locations during the heat treatment of mechanically

alloyed Cu–Ta alloys [8].

7. Discussion and conclusions

Fig. 18. Snapshot of the Cu-2at.%Ta alloy after a 10.8 ns isothermal MD simulation

at 1200 K. The initial state was created by purely random dispersion of Ta atoms.

The GBs are revealed by bond angle analysis using OVITO [58]. The Ta atoms are

shown in green and are larger than Cu atoms.

We now turn to alloys with randomly dispersed Ta atoms. In

this case, the addition of Ta also reduces the grain growth

(Fig. 15(b)), but the effect is not as strong as in the previous case.

For example, while the addition of 1 at.%Ta in the form of clusters

practically stops the grain growth (cf. Fig. 15(a)), the alloy with a

random distribution of the same amount of Ta still shows some

We have developed an ADP potential for the Cu–Ta system by

fitting to a large database of first-principles and experimental data

and employing a combination of a genetic algorithm and simulated

annealing for parameter optimization. We utilize an available EAM

Cu potential [22] but construct a new ADP potential for Ta. We

chose the ADP potential format [30,23,20,31,32] over the regular

central force EAM for two reasons. First, the ADP format offers

additional adjustable parameters that can be utilized for more

accurate fitting to target properties. Second, and perhaps more

important, the ADP format captures the directional component of

chemical bonding and is more appropriate for BCC transition metals. For this reason, even if the accuracy of fitting to target properties is the same, an ADP potential can be expected to be more

transferable to a wider set of properties of Ta and Ta alloys in comparison with regular EAM. Extensive tests show that the new

potential accurately reproduces many properties of Ta and is transferable to severely deformed states and diverse atomic environments different from the equilibrium BCC lattice. The potential

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

should be widely applicable to simulations of thermal and

mechanical properties of Ta in the future. It is more accurate than

most of the previously proposed Ta potentials and is comparable in

accuracy with the recently developed EAM potential by Ravelo and

co-workers [29]. In fact, the ADP potential shows some improvements over [29] with respect to surface energies, interstitial formation energies and the melting point. For example, the melting

temperature predicted by the ADP potential is within a few degrees

from the experimental value. Given that the ADP format is physically more appropriate for Ta, we believe that in the long run,

the proposed potential will demonstrate a better reliability in a

wide range of applications than could not be achieved within the

standard EAM framework [21].

To obtain the binary Cu–Ta potential, the elemental Cu and Ta

potentials have been crossed by fitting the mixed-interaction functions to first-principles energies for a set of imaginary intermetallic

compounds that do not exist on the phase diagram but sample various atomic environments and chemical compositions.

The main application of the proposed Cu–Ta potential that

motivated the present work is the problem of structural stability

and strength of nano-crystalline Cu–Ta alloys. Detailed atomistic

simulations of these properties are the subject on ongoing work

that will be reported elsewhere. In the present paper, we confine

ourselves to some preliminary tests intended to demonstrate some

of the capabilities of the potential. We focused on the grain growth

retardation effect caused by Ta alloying. It was found that Ta precipitates in the form of atomic-scale clusters preferentially located

at GBs and triple junctions, forming a microstructure observed in

recent experiments [8] by transmission electron microscopy.

Although the mutual solid solubility of Cu and Ta is extremely

small, the high-energy cryogenic ball milling forced Ta atoms into

the Cu lattice forming a far-from equilibrium solution. Theoretically, the Ta and Cu atoms are expected to completely separate

during the subsequent annealing of the alloy. In reality, due to

the slow diffusion of Ta in the Cu lattice [7], the separation can only

occur to a limited degree. It is reasonable to assume that the process starts with a spinodal decomposition of the solution resulting

in the formation of a set of Ta clusters coherent with the Cu matrix.

In the perfect lattice, such clusters are unlikely to grow much further. However, in the presence of GBs, dislocations and other

defects providing high-diffusivity paths (‘‘short-circuit” diffusion),

the clusters may grow in size and eventually lose coherency with

the matrix. In the present simulations, this was confirmed by the

observation of coarsening of the clusters located at GBs, a process

which is similar to Ostwald ripening. The clusters never reached

the large sizes often observed in experiments due to the limited

time scale of MD simulations (tens of ns). A further confirmation

comes from the finding that, in alloys with a totally random distribution of Ta atoms (imitating the as-milled states of the material),

Ta clusters spontaneously begin to nucleate and grow at GBs by

diffusion-controlled redistribution of Ta atoms. Although this

agreement between the simulations and experiments is reassuring,

further work is needed for a quantitative comparison. This requires

calculations of Ta GB diffusivities and detailed investigations of the

cluster nucleation and growth kinetics depending on the alloy

composition, temperature and GB type.

Besides this kinetic factor, there must be a thermodynamic preference for the cluster nucleation at GBs (heterogeneous nucleation). Indeed, the preferential formation of clusters at GBs was

observed in semi-grand canonical Monte Carlo simulations, in

which the re-distribution of atoms is implemented by an artificial

switching process that does not involve diffusion. Validation of the

heterogeneous nucleation hypothesis requires a special study

involving calculations of the GB and interface free energies and

the elastic strain energies associated with the cluster formation.

389

The present simulations also reproduce the drastic retardation

effect of Ta on the grain growth kinetics known from experimental

studies [8] as well as previous simulations [7]. The fact that nearly

all Ta atoms located at GBs exist in the form of clusters is a strong

indication that the retardation effect is due to the Zener pinning

mechanism. It is most likely that in this class of alloys, other stabilization mechanisms, such as solute drag or reduction in the GB

free energy by segregation, are less important. The rare GBs that

were able to break away from the Ta clusters remained pure Cu

boundaries and only stopped when encountered other clusters.

Finally, previous simulations [7] have revealed a significant

increase in tensile strength caused by Ta alloying. While this conclusion is in agreement with experiment [8], the exact strengthening mechanism responsible for this effect remains elusive. As was

mentioned in Section 1, the preservation of the small grain size

alone cannot explain the strength in excess of the Hall–Petch relation [8]. Atomistic simulations of the deformation process may

provide insights into the effect of the GB clusters on deformation

mechanisms leading to the high strength of Cu–Ta alloys.

Acknowledgments

We are grateful to Dr. Ramon Ravelo for providing firstprinciples data for the gamma surfaces and tensile compression

stresses from Ref. [29] in numerical format, which enabled direct

comparison with the ADP predictions in Figs. 3 and 6. This work

was supported by the U.S. Army Research Office under a contract

number W911NF-15-1-0077.

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in

the online version, at http://dx.doi.org/10.1016/j.actamat.2015.08.

052. These data include animations of Figures 14, 16 and 18 of this

article.

References

[1] E. Ma, Alloys created between immiscible elements, Prog. Mater. Sci. 50 (2005)

413–509.

[2] C.C. Koch, R.O. Scattergood, K.A. Darling, J.E. Semones, Stabilization of

nanocrystalline grain sizes by solute additions, J. Mater. Sci. 43 (2008) 7264–

7272.

[3] N.Q. Vo, R.S. Averback, P.B.A. Caro, Yield strength in nanocrystalline Cu during

high strain rate deformation, Scr. Mater. 61 (2009) 76–79.

[4] N.Q. Vo, S.W. Chee, D. Schwen, X.A. Zhang, P. Bellon, R.S. Averback,

Microstructural stability of nanostructured Cu alloys during hightemperature irradiation, Scr. Mater. 63 (2010) 929–932.

[5] N.Q. Vo, J. Schäfer, R.S. Averbach, K. Albe, Y. Ashkenazy, P. Bellon, Reaching

theoretical strengths in nanocrystalline Cu by grain boundary doping, Scr.

Mater. 65 (2011) 660–663.

[6] S. Ozerinc, K. Tai, N.Q. Vo, P. Bellon, R.S. Averback, W.P. King, Grain boundary

doping strengthens nano-crystalline copper alloys, Scr. Mater. 67 (2012) 720–

723.

[7] T. Frolov, K.A. Darling, L.J. Kecskes, Y. Mishin, Stabilization and strengthening of

nanocrystalline copper by alloying with tantalum, Acta Mater. 60 (2012)

2158–2168.

[8] K.A. Darling, A.J. Roberts, Y. Mishin, S.N. Mathaudhu, L.J. Kecskes, Grain size

stabilization of nanocrystalline copper at high temperatures by alloying with

tantalum, J. Alloys Compd. 573 (2013) 142–150.

[9] K. Darling, M. Tschopp, R. Guduru, W. Yin, Q. Wei, L. Kecskes, Microstructure

and mechanical properties of bulk nanostructured Cu–Ta alloys consolidated

by equal channel angular extrusion, Acta Mater. 76 (2014) 168–185.

[10] K.A. Darling, M.A. Tschopp, B.K. VanLeeuwen, M.A. Atwater, Z.K. Liu, Mitigating

grain growth in binary nanocrystalline alloys through solute selection based

on thermodynamic stability maps, Comput. Mater. Sci. 84 (2014) 255–266.

[11] R.A. Andrievski, Review of thermal stability of nanomaterials, J. Mater. Sci. 49

(2014) 1449–1460.

[12] T.B. Massalski (Ed.), Binary Alloy Phase Diagrams, ASM, Materials Park, OH,

1986.

[13] E. Nes, N. Ryum, O. Hunderi, On the Zener drag, Acta Metall. 33 (1985) 11–22.

[14] E.O. Hall, The deformation and ageing of mild steel. 3. Discussion of results,

Proc. Phys. Soc. London B 64 (1951) 747–753.

390

G.P. Purja Pun et al. / Acta Materialia 100 (2015) 377–391

[15] N.J. Petch, The cleavage strength of polycrystals, J. Iron Steel Inst. 174 (1953)

25–28.

[16] A. Guinier, Structure of age-hardened aluminum–copper alloys, Nature 142

(1938) 569.

[17] G.D. Preston, Structure of age-hardened aluminum–copper alloys, Proc. R. Soc.

London A 167 (1938) 526.

[18] S. Takeuchi, The mechanism of the inverse Hall–Petch relation of nanocrystals, Scr. Mater. 44 (2001) 1483–1487.

[19] S. Yip (Ed.), Handbook of Materials Modeling, Springer, Dordrecht, The

Netherlands, 2005.

[20] A. Hashibon, A.Y. Lozovoi, Y. Mishin, C. Elsässer, P. Gumbsch, Interatomic

potential for the Cu–Ta system and its application to surface wetting and

dewetting, Phys. Rev. B 77 (2008) 094131.

[21] M.S. Daw, M.I. Baskes, Embedded-atom method: derivation and application to

impurities, surfaces, and other defects in metals, Phys. Rev. B 29 (1984) 6443–

6453.

[22] Y. Mishin, M.J. Mehl, D.A. Papaconstantopoulos, A.F. Voter, J.D. Kress, Structural

stability and lattice defects in copper: ab initio, tight-binding and embeddedatom calculations, Phys. Rev. B 63 (2001) 224106.

[23] Y. Mishin, A.Y. Lozovoi, Angular-dependent interatomic potential for tantalum,

Acta Mater. 54 (2006) 5013–5026.

[24] G.J. Ackland, R. Thetford, An improved N-body semi-empirical model for bodycentred cubic transition metals, Philos. Mag. A 56 (1987) 15–30.

[25] M.I. Baskes, Modified embedded-atom potentials for cubic metals and

impurities, Phys. Rev. B 46 (1992) 2727–2742.

[26] P. Klaver, B. Thijsse, Thin Ta films: growth, stability, and diffusion studied by

molecular-dynamics simulations, Thin Solid Films 413 (2002) 110–120.

[27] Y. Li, D.J. Siegel, J.B. Adams, X.-Y. Liu, Embedded-atom-method tantalum

potential developed by the force-matching method, Phys. Rev. B 67 (2003)

125101.

[28] X.W. Zhou, R.A. Johnson, H.N.G. Wadley, Misfit-energy-increasing dislocations

in vapor-deposited CoFe/NiFe multilayers, Phys. Rev. B 69 (2004) 144113.

[29] R. Ravelo, T.C. Germann, O. Guerrero, Q. An, B.L. Holian, Shock-induced

plasticity in tantalum single crystals: interatomic potentials and large-scale

molecular-dynamics simulations, Phys. Rev. B 88 (2013) 134101.

[30] Y. Mishin, M.J. Mehl, D.A. Papaconstantopoulos, Phase stability in the Fe–Ni

system: investigation by first-principles calculations and atomistic

simulations, Acta Mater. 53 (2005) 4029–4041.

[31] F. Apostol, Y. Mishin, Angular-dependent interatomic potential for the

aluminum–hydrogen system, Phys. Rev. B 82 (2010) 144115.

[32] F. Apostol, Y. Mishin, Interatomic potential for the Al–Cu system, Phys. Rev. B

83 (2011) 054116.

[33] R.A. Johnson, Alloy models with the embedded-atom method, Phys. Rev. B 39

(1989) 12554.

[34] Y. Mishin, Interatomic potentials for metals, in: S. Yip (Ed.), Handbook of

Materials Modeling, Springer, Dordrecht, The Netherlands, 2005, pp. 459–478.

[35] Y. Mishin, M.R. Srensen, A.F. Voter, Calculation of point defect entropy in

metals, Philos. Mag. A 81 (2001) 2591–2612.

[36] H. Jónsson, G. Mills, K.W. Jacobsen, Nudged elastic band method for finding

minimum energy paths of transitions, in: B.J. Berne, G. Ciccotti, D.F. Coker

(Eds.), Classical and Quantum Dynamics in Condensed Phase Simulations,

World Scientific, Singapore, 1998. p. 1. P. 1.

[37] G. Henkelman, H. Jonsson, Improved tangent estimate in the nudged elastic

band method for finding minimum energy paths and saddle points, J. Chem.

Phys. 113 (2000) 9978–9985.

[38] V. Vitek, Theory of the core structures of dislocations in bcc metals, Crystal

Lattice Defects 5 (1974) 1.

[39] S. Plimpton, Fast parallel algorithms for short-range molecular-dynamics, J.

Comput. Phys. 117 (1995) 1–19.

[40] L.T. Kong, Phonon dispersion measured directly from molecular dynamics

simulations, Comput. Phys. Commun. 182 (2011) 2201–2207.

[41] A.D.B. Woods, Lattice dynamics of tantalum, Phys. Rev. 136 (1964) A781–

A783.

[42] S.L. Frederiksen, K.W. Jacobsen, Density functional theory studies of screw

dislocation core structures in bcc metals, Philos. Mag. 83 (2003) 365–375.

[43] I. Lazic, P. Klaver, B. Thijsse, Microstructure of a Cu film grown on bcc Ta (1 0 0)

by large-scale molecular-dynamics simulations, Phys. Rev. B 81 (2010)

045410.

[44] C.M. Müller, A.S. Sologubenko, S.S. Gerstlb, R. Spolenak, On spinodal

decomposition in Cu–34 at.%Ta thin films – an atom probe tomography and

transmission electron microscopy study, Acta Mater. 89 (2015) 181–192.

[45] Y.-S. Lin, M. Mrovec, V. Vitek, A new method for development of bond-order

potentials for transition bcc metals, Model. Simul. Mater. Sci. Eng. 22 (2014)