VACUUM GRIPPERS VGS™5010

advertisement

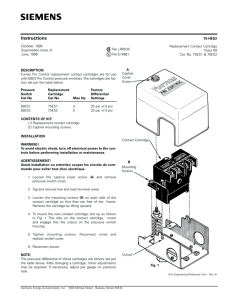

VACUUM GRIPPERS VGS™5010 VGS™5010 BF110P X Patented COAX® technology. X The suction cups are specially designed for X X X X handling larger parts, such as car body sheets. The soft, flexible lip makes the cup suitable for curved or uneven surfaces and the dual hardness version, PU30/60, is also recommended for rough or rugged surfaces to prevent microleakage, which can occur on plastic or composite work pieces. Available with a two or three-stage COAX® cartridge MIDI. Choose an Si cartridge for extra vacuum flow, a Pi cartridge for high performance at low feed pressure or an Xi cartridge when high flow and deep vacuum is needed. The three-stage cartridge will give extra high initial vacuum flow, suitable in high speed applications. Easy installation and flexible positioning with several mounting options. TECHNICAL DATA Description Feed pressure, max. Noise level Temperature range Weight Material Unit MPa dBA °C g Value 0.7 73–83 10–50 373–548 Al, SS, NBR, PA, PP, PU VACUUM FLOW COAX® Cartridge Feed Air Vacuum flow (Nl/s) at pressure consumption MPa Nl/s 0 10 20 30 40 Pi48-2 0.30 2.0 5.6 2.5 1.8 1.1 0.65 Pi48-3 0.30 2.0 5.6 2.5 1.8 1.1 0.65 Si32-2 0.60 1.75 3.3 3.0 2.6 1.7 0.90 Si32-3 0.60 1.75 6.0 3.5 2.6 1.7 0.90 Xi40-2 0.45 1.83 2.8 2.3 1.6 1.0 0.73 Xi40-3 0.45 1.83 5.9 3.0 2.0 1.3 0.73 For vacuum flows at other feed pressures, see COAX® Cartridge data sheets. different vacuum levels (-kPa) 50 0.50 0.50 0.60 0.60 0.58 0.58 60 0.35 0.35 0.50 0.50 0.43 0.43 70 0.25 0.25 0.35 0.35 0.32 0.32 80 0.10 0.10 — — 0.18 0.18 90 — — — — 0.03 0.03 Max vacuum -kPa 90 90 75 75 95 95 EVACUATION TIME COAX® Cartridge Feed Air Evacuation time (s/l) to reach pressure consumption MPa Nl/s 10 20 30 40 Pi48-2 0.30 2.0 0.030 0.070 0.13 0.26 Pi48-3 0.30 2.0 0.020 0.060 0.12 0.25 Si32-2 0.60 1.75 0.030 0.070 0.10 0.18 Si32-3 0.60 1.75 0.020 0.050 0.10 0.18 Xi40-2 0.45 1.83 0.04 0.09 0.17 0.28 Xi40-3 0.45 1.83 0.022 0.062 0.12 0.22 For evacuation times at other feed pressures, see COAX® Cartridge data sheets. 1 different vacuum levels (-kPa) 50 0.46 0.45 0.33 0.33 0.44 0.37 60 0.70 0.70 0.53 0.53 0.63 0.57 70 1.0 1.0 0.80 0.80 0.90 0.84 80 1.6 1.6 — — 1.3 1.2 90 4.0 4.0 — — 2.3 2.2 Max vacuum -kPa 90 90 75 75 95 95 Specifications subject to change without notice. VACUUM GRIPPERS VGS™5010 LIFTING FORCES & TECHNICAL DATA BF110P Material PU30°/60° PU60° Lifting force vertical to the surface, N, at vacuum level 20 -kPa 128 161 60 -kPa 229 334 90 -kPa 225 293 Lifting force parallel to the surface, N, at vacuum level 20 -kPa 106 123 60 -kPa 210 231 90 -kPa 246 305 Volume cm3 110 110 Min. curve radius mm 55 70 Max. vertical movement mm 24 24 Weight rubber part g 110 110 a b c d a b c d a b c d 1. COAX® cartridge No COAX® cartridge (slave unit) COAX® cartridge MIDI Pi48-2 COAX® cartridge MIDI Pi48-3 COAX® cartridge MIDI Pi48-2, non-return valve COAX® cartridge MIDI Pi48-3, non-return valve COAX® cartridge MIDI Si32-2 COAX® cartridge MIDI Si32-3 COAX® cartridge MIDI Si32-2, non-return valve COAX® cartridge MIDI Si32-3, non-return valve COAX® cartridge MIDI Xi40-2 COAX® cartridge MIDI Xi40-3 COAX® cartridge MIDI Xi40-2, non-return valve COAX® cartridge MIDI Xi40-3, non-return valve VGS code AA AB AC AD AE AF AG AH AI AJ AK AL AM i j k i j k 2. Mounting/orientation 4x M6 top, flush mount 4x M6 top, angle bracket M12 20 mm top M12 20 mm right M12 20 mm left M12 20 mm top, angle bracket M12 20 mm right, angle bracket M12 20 mm left, angle bracket VGS code 00 01 02 03 04 05 06 07 3. Suction cup with fitting No suction cup BF110P 30°/60° Shore A BF110P 60° Shore A Example VGS™5010 BF110P – Pi48-2, M12 20 mm top, BF110P 30/60° Shore A Specifications subject to change without notice. Vacuum grippers VGS™5010 ORDERING INFORMATION VGS code BA CO CP Ordering number VGS5010 AB 02 CO 2 VACUUM GRIPPERS VGS™5010 3 Specifications subject to change without notice.