Feature

Story

Unexpected Savings:

Variable-speed chillers cut energy

use in multiple applications

Roy S. Hubbard, Senior Marketing Manager, Johnson Controls Inc.

S

ome chiller plant owners and

designers believe there are certain

applications in which variablespeed drive (VSD) chillers do not save

energy. One such application is a multichiller plant, where the chillers have

traditionally operated at high average

loads. It is assumed that a multichiller

plant cannot benefit from VSDs, which

are thought to improve efficiency only

at lower chiller loads. Another application is a plant located where the design

outdoor temperatures are high. Because

VSD chillers are known to save energy

at lower outdoor temperatures, it is

assumed that they are not suitable for

higher-temperature applications.

Contrary to these assumptions, VSD

chillers are capable of saving energy in

both multichiller plants and high-ambient

locations. The key to understanding how

VSDs save energy in both cases is to

examine the impact of chiller load versus

lift (aka “head”) on chiller efficiency, the

impact of the sequencing logic used and

whether or not optimization algorithms

are employed. This article explains how

lift affects VSD chillers, how VSD chillers

should be sequenced differently from

constant-speed drive (CSD) chillers and

why that means VSD technology can offer

substantial energy savings in a wider

range of chiller plants than expected.

Understanding Chiller Load

and Lift

The assumption that VSD technology cannot save energy in multichiller

plants or in high-ambient applications

is usually based on a misunderstanding

of how load and lift affect VSD chiller

efficiency.

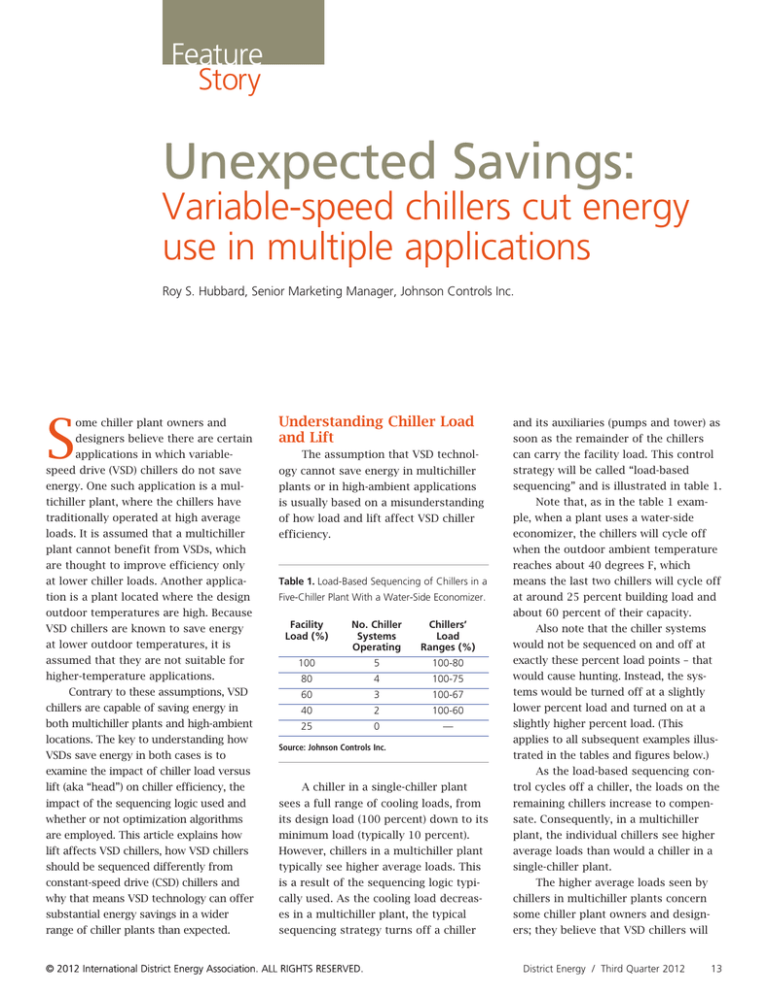

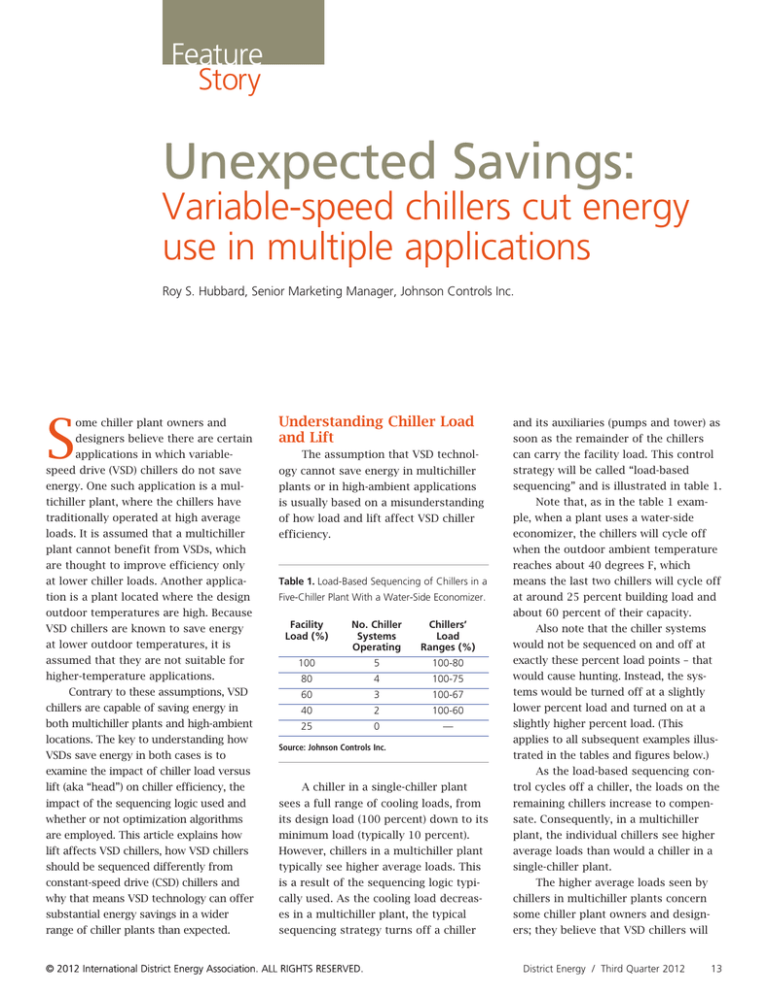

Table 1. Load-Based Sequencing of Chillers in a

Five-Chiller Plant With a Water-Side Economizer.

Facility Load (%) No. Chiller

Systems Operating

Chillers’

Load

Ranges (%)

100

5

100-80

80

4

100-75

60

3

100-67

40

2

100-60

25

0

—

Source: Johnson Controls Inc.

A chiller in a single-chiller plant

sees a full range of cooling loads, from

its design load (100 percent) down to its

minimum load (typically 10 percent).

However, chillers in a multichiller plant

typically see higher average loads. This

is a result of the sequencing logic typically used. As the cooling load decreases in a multichiller plant, the typical

sequencing strategy turns off a chiller

© 2012 International District Energy Association. ALL RIGHTS RESERVED.

and its auxiliaries (pumps and tower) as

soon as the remainder of the chillers

can carry the facility load. This control

strategy will be called “load-based

sequencing” and is illustrated in table 1.

Note that, as in the table 1 example, when a plant uses a water-side

economizer, the chillers will cycle off

when the outdoor ambient temperature

reaches about 40 degrees F, which

means the last two chillers will cycle off

at around 25 percent building load and

about 60 percent of their capacity.

Also note that the chiller systems

would not be sequenced on and off at

exactly these percent load points – that

would cause hunting. Instead, the systems would be turned off at a slightly

lower percent load and turned on at a

slightly higher percent load. (This

applies to all subsequent examples illustrated in the tables and figures below.)

As the load-based sequencing control cycles off a chiller, the loads on the

remaining chillers increase to compensate. Consequently, in a multichiller

plant, the individual chillers see higher

average loads than would a chiller in a

single-chiller plant.

The higher average loads seen by

chillers in multichiller plants concern

some chiller plant owners and designers; they believe that VSD chillers will

District Energy / Third Quarter 2012

13

not save energy in this application.

However, they are neglecting to account

for changes in lift.

“Lift” is defined as the pressure differential against which the compressor

operates. In a water chiller, the lower

pressure is driven by the refrigerant

evaporating temperature, which is determined primarily by the leaving chilledwater temperature. The higher pressure

is determined by the refrigerant condensing temperature, which is primarily

a function of the weather conditions.

Specifically, it is driven by the dry-bulb

temperature of the air entering an aircooled chiller or the wet-bulb temperature of the air entering the cooling

tower, which in turn determines the

entering condenser water temperature

(ECWT) for a water-cooled chiller.

Here is a key point: The cooling

towers all experience the same weather,

and therefore they supply water at the

same instantaneous ECWT to the chillers in the plant, regardless of the load.

To analyze the impact on energy

performance caused by changes in load

and lift, figure 1 will be used. It shows

energy performance curves that are

“industry average,” reflecting averages

of published curves for multiple brands

of water-cooled VSD centrifugal chillers.

How do load changes impact energy

consumption of a VSD chiller? In figure 2,

the lift is held constant at 85 F ECWT, and

the load is allowed to vary. The result is

that the kilowatts per ton of cooling vary

relatively little – only about 15 percent.

On the other hand, how do lift

changes impact energy consumption? In

figure 3, the load is held constant at

100 percent, and the lift is allowed to

vary. The variation in chiller efficiency

is around 45 percent. Compared to the

15 percent impact of variable load, that

is a 3-1 ratio! This demonstrates that

lift has a major impact on chiller efficiency, while load has a much lower

impact. Therefore, VSDs can save energy

in multichiller plants, even though the

average chiller loads are higher. One key

to saving energy with VSD chillers is the

lift variation.

One key to saving energy with

VSD chillers is the lift variation.

Performance in Multichiller

Plants

The influence of load and lift on

VSD and CSD chillers was examined by

this author in an analysis of a hypothetical large U.S. district cooling plant.

The plant was assumed to contain

five 2,250-ton (7.9 MW) water-cooled

centrifugal chillers, each with dedicated

auxiliaries: chilled-water pump, condenser water pump and cooling tower.

A typical load line was assumed, as was

24/7 operation. A water-side economizer was also assumed.

The choice of weather data used

in this analysis required a compromise.

Rather than drawing on data from any

one particular location, the concept

of “average U.S. weather data” was

employed to make the analysis as widely applicable as possible. This is the

same weather data used by the AirConditioning, Heating, and Refrigeration

Institute (AHRI) to calculate the IPLV/

NPLV (integrated part-load value/nonstandard part-load valve) ratings for

chillers in AHRI Standard 550/590-98.

The data was created by looking at

weather data in the 29 cities across the

United States that correlated with 80 percent of all the centrifugal chiller sales

over a 25-year period. The data for the

29 cities were then averaged. The concept of average U.S. weather data has

been approved by the major chiller

manufacturers as an acceptable compromise for use in analyzing chiller

energy consumption.

Only chiller energy consumption

was examined in the study as well as

for this article. Inclusion of the auxiliaries (cooling towers and pumps) would

have required a large number of variables, such as how they are driven (CSD

or VSD), the piping scheme (headered or

dedicated pumping, primary-secondary

or variable primary, etc.) and the operating method used (manual, automated or

Figure 1. Performance of an “Industry Average” Water-Cooled

Figure 2. Efficiency Changes With Variable Load on a VSD Centrifugal

VSD Centrifugal Chiller.

Chiller.

.80

Kilowatts per ton of cooling

.60

.50

.40

.30

n

n

n

n

.20

.10

85 F ECWT

75 F ECWT

65 F ECWT

55 F ECWT

| |||||| ||

.00 20% 30%40%50%60%70%80% 90%100%

Load

Source: Johnson Controls Inc.

District Energy / Third Quarter 2012

.70

.60

Kilowatts per ton of cooling

.70

14

.80

Design performance

100% Load

85 F ECWT

0.600kW/ton

15%

.50

.40

.30

.20

.10

n

n

n

n

85 F ECWT

75 F ECWT

65 F ECWT

55 F ECWT

| |||||| ||

.00 20% 30%40%50%60%70%80% 90%100%

Load

Source: Johnson Controls Inc.

© 2012 International District Energy Association. ALL RIGHTS RESERVED.

optimized). Since the intent of this article is to examine the impact of adding

VSDs to the chillers, the impact of the

auxiliaries has not been calculated.

Drawing on data from the analysis,

the following scenarios demonstrate the

performance of CSD and VSD chillers

using different sequencing methods:

Scenario 1: CSD Chillers With

Traditional Load-Based Sequencing

In scenario 1, the chillers were all

CSD and used the performance curves

in figure 4, which are averages of published curves for multiple brands of

water-cooled CSD centrifugal chillers.

The load-based sequencing strategy was

also used.

The tool/method used to do the

energy analysis was the ASHRAE modified temperature bin method (Simplified

Energy Analysis Using the Modified Bin

Method, ASHRAE, David E. Knebel, principal investigator, 1983).

Table 2 shows how the five chillers

unload when controlled by the traditional

load-based sequencing control strategy,

heretofore considered the most efficient

method of sequencing a plant. The red

rectangles show the chillers cycling off,

while the green rectangles show the loads

on the remaining on-line chillers increasing to pick up the remaining building

load. The water-side economizer enabled

the chillers to be completely cycled off

when the outdoor air was below 40 F.

Table 3 shows how the efficiency

values from figure 4, the loads from

table 2 and the weather data were used

to calculate the annual energy consumption for CSD chiller No. 1. It is important

to note that the 95.0-99.0 F temperature

bin does not represent design conditions

only. It is an average of the few hours

spent at design conditions plus a number of hours spent at off-design conditions. That is why the load and efficiency

values are lower than at design.

The annual energy consumption for

CSD chiller No. 1 was 5,972,580 kWh.

The same calculation process was used

for CSD chillers Nos. 2-5 (not shown

because of limited space). The total

annual energy consumption for all five

chillers was 18.35 million kWh.

Scenario 2: VSD Chillers With

Traditional Load-Based Sequencing

In scenario 2, all the chillers were

equipped with VSDs, and the energy performance curves in figure 1 were used.

Built into figure 1 is a 3 percent loss for

the VSDs. The load-based sequencing

strategy was used again. The total annual

energy consumption for all five VSD

chillers was 15.4 million kWh, a savings

of 16 percent.

Scenario 3: VSD Chillers With EnergyBased Sequencing

In scenario 3, the chillers were

again equipped with VSDs, but the

Figure 3. Efficiency Changes With Variable Lift on a VSD Centrifugal Chiller.

sequencing strategy was modified.

Because VSDs offer the most energy

savings at lower loads and lower

ECWTs, it makes sense to keep them on

line for as long as possible while the

cooling load of the facility decreases.

Therefore, a chiller system was not

turned off until the energy consumption

of operating all the on-line chillers

exceeded the energy consumption of

operating all the on-line chillers minus

one. This control strategy – which is

really an optimization algorithm – will

be called “energy-based sequencing™.”

Table 4 shows how the five chillers

unload when optimized by the energybased sequencing strategy. Once again,

the red rectangles show the chillers

cycling off, while the green rectangles

show the loads on the remaining on-line

chillers increasing to pick up the remaining building load.

The sequencing points are significantly different from the points used

with the load-based sequencing strategy. For instance, the most cost-efficient

point at which the first chiller system

should be turned off was when the facility load had fallen to about 33 percent.

The sequencing points are not linear;

they are determined by the energy consumption and not just the load. Note

also that the chiller loads, indicated by

the green rectangles, are lower than

when load-based sequencing strategy is

used. Determining the sequencing

Figure 4. Performance of an “Industry Average” Water-Cooled CSD

Centrifugal Chiller.

.80

.80

.70

.70

.60

45%

.50

.40

.30

.20

.10

n

n

n

n

85 F ECWT

75 F ECWT

65 F ECWT

55 F ECWT

| |||||| ||

.00 20% 30%40%50%60%70%80% 90%100%

Load

Source: Johnson Controls Inc.

© 2012 International District Energy Association. ALL RIGHTS RESERVED.

Kilowatts per ton of cooling

Kilowatts per ton of cooling

.60

Design performance

100% Load

85 F ECWT

0.582 kW/ton

.50

.40

.30

.20

.10

n

n

n

n

85 F ECWT

75 F ECWT

65 F ECWT

55 F ECWT

| |||||| ||

.00 20% 30%40%50%60%70%80% 90%100%

Load

Source: Johnson Controls Inc.

District Energy / Third Quarter 2012

15

Table 2. Chiller Loading When Using Load-Based Sequencing.

Temperature Building

Bin (°F)

Load

(Tons)

Building

Load (%)

Chiller

Chiller Capacities (Tons)

Capacity

No. 1 No. 2 No. 3 No. 4 No. 5

(%)

95.0-99.9 10,810

96.1

96.1

2,1622,1622,1622,1622,162

90.0-94.9

9,935

88.3

88.3

1,9871,9871,9871,9871,987

85.0-89.9

9,060

80.5

80.5

1,8121,8121,8121,8121,812

80.0-84.9

8,180

72.7

90.9

2,0452,0452,0452,045

0

75.0-79.9

7,304

64.9

81.2

1,8261,8261,8261,826

0

70.0-74.9

6,426

57.1

95.2

2,1422,1422,142

00

65.0-69.9

5,550

49.3

82.2

1,8501,8501,850

0

0

60.0-64.9

4,674

41.5

69.2

1,5581,5581,558

0

0

55.0-59.9

3,800

33.7

84.4

1,9001,900

0 00

50.0-54.93,272 29.1 72.61,636

1,636 0 00

45.0-49.93,066 27.2 68.11,533

1,533 0 00

40.0-44.92,858 25.4 63.61,429

1,429 0 00

Table 3. Annual Energy Consumption for CSD Chiller No. 1 With Traditional Load-Based Sequencing.

Temp. Average

Tower

Entering

Load Efficiency Draw Hours Energy

Bin (°F) Wet-Bulb Approach Condenser (Tons) (kW/Ton) (kW) (kWh) Usage

Temp. (°F)

(ºF)

Water

Temp. (°F)

points when using energy-based

sequencing requires a central plant

optimization (CPO) system, which can

analyze the multitude of variables that

impact the decision beyond just load.

The total annual energy consumption for all five VSD chillers, controlled

by energy-based sequencing, was

12.87 million kWh. That is a savings

of 30 percent. By controlling the VSD

chillers with energy-based sequencing

using a CPO system, the savings was

increased an additional 14 percent.

This analysis shows that VSDs can

significantly reduce chiller energy consumption in multichiller plants. Even

if the average chiller load is high, as

when using the load-based sequencing,

the chiller lift decreases, and lift has a

bigger impact on chiller efficiency than

does load.

95.0-99.9 72.0

7.9

79.9

2,1620.5601,212 37 44,844

Energy-based sequencing is

90.0-94.9 71.0

7.6

78.6

1,9870.5441,081120129,671

85.0-89.9

7.4

76.4

1,812

another key to maximizing

80.0-84.9 68.0

8.4

76.4

2,0450.5331,089515561,075

75.0-79.9

8.0

74.0

1,826

70.0-74.9 63.0

9.8

72.8

2,1420.5141,101928

1,021,684

65.0-69.9

59.0

9.6

68.6

1,850

0.484

895

895

801,228

60.0-64.9

55.0

9.2

64.2

1,558

0.458

713

856

610,421

55.0-59.9

50.0

12.0

62.0

1,898

0.447

848

776

658,062

50.0-54.9

45.0

11.9

56.9

1,635

0.411

672

679

456,483

45.0-49.9

41.0

14.0

55.0

1,533

0.397

608

586

356,535

40.0-44.9

37.0

18.0

55.0

1,430

0.397

568

549

311,903

69.0

66.0

0.526

0.514

953

938

303

780

288,897

731,777

Subtotal

5,972,580

Table 4. Chiller Loading When Using Energy-Based Sequencing.

Temperature Building

Bin (°F)

Load

(Tons)

Building

Load (%)

Chiller

Chiller Capacities (Tons)

Capacity

No. 1 No. 2 No. 3 No. 4 No. 5

(%)

95.0-99.9

10,81096.196.1

2,162

2,162

2,162

2,162

2,162

90.0-94.9

9,93588.388.3

1,987

1,987

1,987

1,987

1,987

85.0-89.9

9,06080.580.5

1,812

1,812

1,812

1,812

1,812

80.0-84.9

8,18072.772.7

1,636

1,636

1,636

1,636

1,636

75.0-79.9

7,30564.964.9

1,461

1,461

1,461

1,461

1,461

70.0-74.9

6,42557.157.1

1,286

1,285

1,285

1,285

1,285

65.0-69.9

5,55049.349.3

1,110

1,110

1,110

1,110

1,110

60.0-64.9

4,67541.541.5 935

935

935

935

935

55.0-59.9

3,80033.833.8 760

760

760

760

760

50.0-54.9

3,272

29.1

36.4

45.0-49.9

3,066

27.3

45.4

818 818 818818 0

1,0221,022 1,022

00

40.0-44.9

2,85925.442.4 953

953

9530

0

Tables 2, 3 and 4 source: Johnson Controls Inc.

16

District Energy / Third

FourthQuarter

Quarter2012

2011

savings in VSD chiller plants.

Resequencing VSD chillers based

on energy means they will run in their

sweet spot – or sweet span – as much

as possible, which often means lower

loads. Energy-based sequencing is

another key to maximizing savings in

VSD chiller plants. This strategy leverages the savings capabilities of VSDs

at lower loads and, most importantly,

lower ECWTs. The auxiliaries can marginally add to or subtract from these

savings, depending on the piping configuration and control.

Although this analysis was done

on a large chiller plant, the percentages of savings are scalable to any

size plant; and, because industry

average efficiency curves were used,

the analysis is valid for any brand of

VSD chiller.

The cost-effectiveness of adding

VSDs to the chillers will depend on a

number of factors, including the capital and installation costs of the VSDs,

local electricity cost and cooling load

profile. These factors are highly individual and outside the scope of this

article.

© 2012 International District Energy Association. ALL RIGHTS RESERVED.

Performance in HighAmbient Locations

Are VSD chillers a good investment

in locations that experience high outdoor temperatures, such as the Middle

East? The answer is, “Often.” Once

again, it depends on the weather. The

design dry-bulb and wet-bulb temperatures are not the critical factors. Most

important is whether there is a significant variation in the temperatures

throughout the cooling season.

Dhahran, Saudi Arabia, has design

temperatures of 110 F dry bulb and 86

F wet bulb, making it one of the warmest and most humid cities in the world.

However, the outdoor temperatures can

also fall to 35 F dry bulb and 32 F wet

bulb. This substantial change in outdoor

temperatures indicates VSDs are likely

to provide significant energy savings.

The same 11,250-ton (39.5 MW)

plant analyzed above was relocated to

Dhahran, with the efficiency of the chillers adjusted for the higher lift. The total

annual energy consumption for all five

CSD chillers, controlled with load-based

sequencing, was 32.08 million kWh.

When the chillers were equipped

with VSDs, and operated with CPOdriven energy-based sequencing, the

total annual energy consumption was

23.31 million kWh – an energy savings

of 27 percent.

So, even in high-ambient locations,

putting VSDs on the chillers and using

an energy-based sequencing strategy

reduced plant energy consumption significantly. The key is that the location has

temperatures that vary throughout the

day and the cooling season; the design

temperatures are rarely applicable.

Conclusion

Water-cooled VSD chillers are capable of saving energy in both multichiller

plants and high-ambient locations. If the

leaving chilled-water temperature and

condenser water flow are constant, the

key to their performance is the variation

in entering condenser water temperature,

which lowers the chiller lift. Additional

energy savings can be obtained by

sequencing the chillers according to an

energy-based sequencing strategy,

designed to get the maximum performance from the VSDs. Energy-based

sequencing requires a central plant optimization system, which can analyze the

multitude of variables that impact the

decision beyond just load. As a result,

chiller plant owners and designers will

find VSD chillers yield substantial energy

savings in a surprisingly wide range of

chiller plants.

Roy S. Hubbard is senior marketing

manager with Johnson Controls Inc.,

a global provider of HVAC

equipment, controls and service

solutions. He has more than 30 years

of experience in sales, marketing and

applications, with particular focus on

chilled-water systems. He is also the architect for

YORKcalc, Johnson Controls’ operating cost software

for chiller plants. Hubbard holds a bachelor’s degree in

engineering from the U.S. Military Academy at West

Point. He can be reached at roy.s.hubbard@jci.com.

The Water Treatment Choice of Over 100 Colleges & Universities

Chem-Aqua, Inc. • 1-800-527-9921 • www.chemaqua.com

Irving, TX • Monmouth, NJ • Jacksonville, FL • Indianapolis, IN • Macon, GA • Las Vegas, NV • Sunnyvale, CA • Brampton, ON

IDEA_DistrictEnergy_Q3_2012.indd

1

© 2012

International District Energy

Association. ALL RIGHTS RESERVED.

7/5/2012

10:42:06 AM

District Energy / Third Quarter

2012

17