TCS1 Control Block Diagram

advertisement

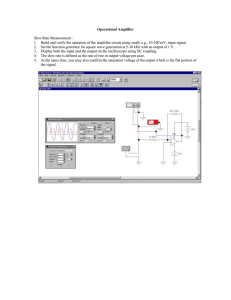

2 1 3 4 5 6 REVISION BLOCK DESCRIPTION REV DATE INCORP. BY OVERVIEW A The goal of this document is to present the TCS1 control system in a clear and understandable way and to derive the transfer functions to be used in SIMULINK. This document format combines notes, graphs, plots, graphics, etc. all on one page. It is not a traditional report style format. A The method used to present this material was to: 1) Present a hybrid block diagram of the entire system on one page. The block is not 100% mathematically or functionally correct. It is meant to present the system in an understandable way. 2) Explore each block or group of blocks, understand the function, and derive the transfer function for use in SIMULINK. NOTE: Because of the way the blocks are implemented physically (e.g. inverting summer amplifier) the negative signs on some transfer functions may not show up in the SIMULINK model. For example, an inverting summing amplifier followed by an inverting amplifier with a gain of -1 can be simply shown as a simple summer. SO, keep in mind that if a negative sign is dropped, either the input has already been inverted into the block or its output will be inverted in the next block. B C D TABLE OF CONTENTS PAGE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 BLOCK 1&2 3 4 5 6 6 7 8 9 10 11 12 12 13 13 - B DESCRIPTION TITLE PAGE (THIS PAGE) OVERALL BLOCK DIAGRAM COMMAND RECTIFIERS, PRE-LOADS, HIGH FREQUENCY TACHOMETER COMPENSATION TACHOMETER & TACHOMETER INPUT BUFFERS TACHOMETER SUMMER CIRCUIT ACCELERATION LIMITER MOTORS & BULL GEARS MOTOR DATASHEET COMMAND MAGNITUDE LIMITER (SLEW or OFFSET) POWER AMPLIFIER MOTOR DRIVER MAIN SUMMING BLOCK (PROPORTIONAL GAIN, INTEGRATOR, SLEW FEED FORWARD) INCREMENTAL ENCODER & FRICTION GEAR PROPORTIONAL GAIN INTEGRATOR WITH SHORTING AND OFFSET FEED FWD PULSES OFFSET FEED FWD PULSE EXPLANATION DIGITAL TO ANALOG CONVERTER COMPUTER/DIGITALLY GENERATED CONTROL SIGNALS (SLEW, OFFSET, POSITION ERROR) UNIT CONVERSIONS (SUMMER VOLTS to RAD/S & RAD/S to ARCSEC/S) APPENDIX: ABSOLUTE POSITION ENCODERS APPENDIX: TCS1 BLOCK DIAGRAM CIRCA 1980 APPENDIX: IRTF 123 - TELESCOPE SERVO CONTROL HA COMPUTER CMD & MAGNITUDE DETECT APPENDIX: IRTF 125 - TELESCOPE SERVO CONTROL HA SEQUENCE CONTROL BOARD APPENDIX: IRTF 127 & 128 - TELESCOPE SERVO CONTROL D/A, JOYSTICK, & INTEGRATOR APPENDIX: IRTF 130 - TELESCOPE SERVO CONTROL TACH SUMMER & TORQUE CMD APPENDIX: IRTF 131 - TELESCOPE SERVO CONTROL DEC TACH SUMMER & TORQUE CMD C University of Hawaii DWG # REV TITLE TCS1-CBD ENGINEER Eric Warmbier - Institute for Astronomy TCS1 Control Block Diagram LAST EDIT 12/12/2007 5:57:32 PM SIZE B FILE: Z:\public_html\Presentation\TCS1 Control Block Diagram_12_12_07.vsd 1 2 3 4 5 6 SHEET 1 of 25 D 1 2 Adj 0 to 8V Adj 0 to 0.5V BUF EAST SLEW DISABLE BUF EAST MOTION DISABLE A 13 14 bit PEC B0:B12,B25 -10 Digital position error CMD. 10 SWITCH 6 7 G=5 A Compensator .839 (1.0) Low Pass 0 -0.35 V (on output) Adj. pre-load 1 12 Ki= SWITCH RESET Ki ∫ v (t ) dt 2 0 1 SWITCH + 12 12 0 0.02 1 12 Ki= SWITCH 9 + + + + + 9 9 338 Hz + + + + + .839 (.513) Low Pass RESET Ki ∫ v (t ) dt 9 11 -11 Mag Limit POSITIVE LIMIT 7 ADJ 468 Hz 7 12 -8V 0V FD FWD WEST 0 1 SWITCH 5 + ADJ Mag Limit - 5 5 1000 1000 -11 Low Pass 5 5 11 Mag Limit Low Pass 4.5 -4.5 Mag Limit 12 680k 4 Ki ∫ v (t ) dt 330k Integrator + -1.2 - SWITCH + 8 AMP 0 Low Pass Half Wave Rectifier- + 1 + + 5 1 12 Ki= + 1 G=-2 0.35 V (on output) Adj. pre-load 0 0.02 + Mag Limit 1 1 240 Hz 1 12 10 G=-2 Half Wave Rectifier+ + 1 5 0 WEST 2 2 4 Ki= RESET NEGATIVE LIMIT Integrator B 2 2 240 Hz Integrator +8V 0V FD FWD EAST 8 12 .002 12 (active low) 7 338 Hz Low Pass 12 5 9 1.96 (1.33) DAC 7 (active low) 0V 4 SWITCH 11 1.59 kHz 11 3 7 (active low) 5.36 SWITCH 2 8.6Hz RESET Ki ∫ v (t ) dt 5.36 2 1 8.6Hz 240Hz 1 10 8 AMP 0 B Mag Limit EAST 240Hz Integrator Bandpass HA CLEAR INTEGRATOR +8V 0V SLEW EAST/ 9 (active low) 9 9 SLEW WEST/ Low Pass 9 (active low) C Compensator 4 4 3.77 Hz Low Pass 9 0.488 Low Pass 338 Hz + 4 Low Pass 3 + 723 Hz 4.7 (4.7) 0V 3 723 Hz 338 Hz 6.26 (12.1) (active low) Compensator 9 9 SWITCH Joystick Circuit 1 6.26 (12.1) SWITCH -8V 0V Bandpass 2 338 Hz SWITCH Low Pass 9 9 Adj 0 to -8V Adj 0 to -0.5V BUF WEST SLEW DISABLE BUF WEST MOTION DISABLE 7 (active low) OPPOSING MOTORS APPLY TORQUE IN ONE DIRECTION ONLY 7 (active low) SWITCH C Low Pass 0V 7 ~180:1 friction gear ratio (encoder to bull gear) G=5 SWITCH 10 Incremental Encoder MOTOR 144:1 ratio (motor to bull gear) 3 SLEW E WEST Tach D MECHANICAL - PEC B0:B12,B25 Active low SLEW signals present when SLEW commanded in a direction. When SLEW is nearly complete and deceleration is required, the SLEW signals are removed (high) and the control goes back to standard control. This is based on DIP switch settings representing when to begin deceleration in number of counts from the end of the SLEW. Integrator is also shorted during this event. Desired Position EAST Tach 1 2 Counter + 3 6 Bull gear MOTOR 5 3 8 9 .2105 3 14 D .2105 Telescope Mount HA CLEAR INTEGRATOR 3 6 SLEW WEST/ SLEW WEST/ HA CLEAR INTEGRATOR BUF EAST SLEW DISABLE BUF WEST SLEW DISABLE If an offset is commanded, variable amounts of pulses are added to the integrator of opposite polarity to remove charge from the integrator and reduce overshoot. E FD FWD EAST FD FWD WEST F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - D SHEET 2 of 25 2 1 3 BLOCK GROUP #1 & #2 4 Inverting Amp with low pass. Gain =-300k/100k =-3 f(-3dB) =1/(2πRC) =1/(2π*300k*2200pF) =240 Hz B HOWEVER, the compensation up front will cause lower gain overall and will cause additional lower gain at lower frequencies. Also, filter is not a “brick wall” filter. Pass band will have lower gain than calculated as the simulation illustrates.. 6 Half Wave Rectifier Output EAST=negative output (positive for WEST) Gain adjust A Inverting Amp with band pass. Gain =-300k/56k =-5.357 in pass band f(low) =1/(2πRC) =1/(2π*300k*2200pF) =240 Hz ~f(high) =1/(2πRC) =1/(2π*56k*0.33uF) =~8.58 Hz 5 Inverting Amp (Gain = -2) Positive Values Only (EAST) Negative Values Only (WEST) A INVERTING SUMMING Adds a preload to the output and will be adjusted to add to the DAC output about: +0.35V (East) or -0.35 (West). Low pass filter f(-3dB) =1/(2πRC) =1/(2π*100*0.1uF) Sets maximum output clamp, =16 kHz which must be less than the series Zeners, or ~10.7V. This is really high compared to 240 Hz upstream filter. This is for high frequency electronic noise induced or picked up. B ACTUAL GAIN (input signal is 1V) TRANSFER FUNCTION(S) FOR SIMULINK C 12 - G=-2 0 - C 10 + Mag Limit + Pass band, shorted C8,R33 0 Mag Limit WEST -0.35 Compensated Input Plot from Mathcad Actual circuit 0 - - -12 0 G=-2 Mag Limit + + D -10 Mag Limit D EAST 0.35 DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 3 of 25 2 1 BLOCK GROUP #3 3 4 5 Identical amplifier input stage for EAST & WEST. TCS Tachometer Voltage vs. Speed Gain= Rf/Rs 10k/47k 2.000 0.213 f(-3dB) =1/(2πRC) 1.800 =1/(2π*10k*0.022uF) =723 Hz 1.600 A 6 y = 0.008845x + 0.005803 R2 = 0.999922 1.400 (Intercept set to Zero) Clamp Voltage (V) 1.200 y = 0.008764x R2 = 0.999979 A y = 0.008654x - 0.001271 R2 = 0.999997 East West 1.000 Average Linear (West) 0.800 Linear (East) 0.600 DIFFERENTIAL AMP w/ filtering Linear (Average) 0.400 0.200 B 0 100 150 200 250 Speed (as/s) V arc sec/ s ⋅ arc sec/ s rad / s 0.008764V 206264.81arc sec/ s Tach = ⋅ arc sec/ s rad / s 1807.704V Tach = rad / s Tach = C 50 -0.200 For the tachometer rad/s to volt conversion: TRANSFER FUNCTION(S) FOR SIMULINK B 0.000 Very high frequency passive filtering f(-3dB) =1/(2πRC) Where R is the line + source impedance which is low. NOTE: This conversion is from TELESCOPE axis rotational velocity to volts. The mechanical model in SIMULINK provides axis velocity in rad/s at each motor geared output (after the 1:144 ratio). C Tachometer Velocity (rad) D D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 4 of 25 2 1 3 BLOCK GROUP #4 VEL CMD 4 + Gain= -Rf/Rs 33.2k/68.1k -0.4875 f(-3dB) =1/(2πRC) =1/(2π*33.2k*(1uF+0.27uF) =3.77 Hz -1.2 - A 4 West Tach IN 4 3.77 Hz 0.488 Low Pass 6 West Tach IN 4 4 5 + + A 4 East Tach IN INVERTING SUMMING w/ filtering Velocity CMD B B INVERTING SUMMING Gain = -120/100 Gain = -1.2 East Tach IN By adding together ~½ of two individual signals, the output is approximately the average. TRANSFER FUNCTION(S) FOR SIMULINK C C NOTE: Be careful with the polarity signs here. The equation will be worked through to demonstrate the polarities. VEL CMD + - Vout = 1.2 ⋅ (−VCMD − Vsum _ amp ) Vout = 1.2 ⋅ (−VCMD − (−0.4875 ⋅ ( Etach + Wtach ))) Vout = 1.2 ⋅ (−VCMD + 0.4875( Etach + Wtach )) Vout = −1.2(VCMD − 0.4875( Etach + Wtach )) -1.2 West Tach IN + + D D East Tach IN DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 5 of 25 2 1 3 4 BLOCK GROUP #5 A 5 + - 5 1000 5 Op-amp supplies limit output to about +/- 12V. 5 11 -11 Mag Limit 5 1000 INTEGRATOR Since the input to the integrator will always be either +/-4.5V due to the total gain of 1 million and the clamping diodes, the current going into the integrator will always be +/- a constant value (4.5V/ resistor) and the result is a signal with a +/- constant slope. This slope is change in velocity, which is acceleration. The integrator uses a capacitor. Where the capacitor voltage change over time: i=Cdv/dt i/C=dv/dt 5 4.5 Ki= RESET -4.5 Mag Limit 680k Ki ∫ v (t ) dt 330k Integrator 5 0 1 HA CLEAR INTEGRATOR SWITCH 5 Notice the feedback and high gain of a million. This can be represented as a slew limited amplifier with a gain of +1. This circuit functions as an acceleration limiter. B INVERTING AMP Gain = -1000 INVERTING AMP Gain = -1000 1n5240 are 10V Zener Diodes, so output is limited to about: 10+0.7=10.7V. Roundoff to ~11V Output is clamped to about: 3.1+0.7+0.7 = ~4.5V 6 Therefore: 330kΩ case: i=4.5V/330kΩ i=13.64μA dv/dt=13.64μA/1μF dv/dt=13.64V/s C B 1010kΩ case: i=4.5V/1010kΩ i=4.46μA dv/dt=4.46μA/1μF dv/dt=4.46V/s NOTE: In this simulation the first stage was unclamped (it just saturated) and a 3.3V (1n746A) Zener was used. The result will be nearly identical with the exception that the slope will be a slightly larger value. 330kΩ used for integrator in simulation. TRANSFER FUNCTION(S) FOR SIMULINK A C +/- 13.64V/s Results, Rate Limit 12 0 +/- 4.46V/s 1 330kΩ simulation: dv/dt=-1V/83.5ms dv/dt=~12V/s -12 SWITCH Mag Limit Rate Limit D D HA CLEAR INTEGRATOR DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 6 of 25 2 1 BLOCK GROUP #6 Telescope Mount 6 MOTOR B The motors are driven by a current amplifier. The output of the motor has a 144:1 gear ratio to the HA Axis. Since the motor is driven by a current drive amplifier, the equations for the torque involve the torque constant of the motor, current, and gear ratio. The back EMF produced by the motor is used as feedback for the amplifier in the amplifier model. The back EMF reduces the maximum current output of the amplifier. See the amplifier section for more details. See next page for motor datasheet and parameter values. Imai measured 1Ω and 1.3Ω across the motors at the junction box with the amplifiers off but still connected on 11/2/07. This suggests “A” version of motor. 5 6 SPARE, Model 12016A MOTOR TORQUE Torque = IKT ⋅ Gear _ Ratio Torque = IKT ⋅ Gear _ Ratio lb ⋅ ft ⎤ ⎡ Torque = I ⎢12.8 ⋅ (144) A ⎥⎦ ⎣ lb ⋅ ft ⎤ ⎡ Torque = I ⎢1843.2 A ⎥⎦ ⎣ lb ⋅ ft ⎤ ⎡ Torque = I ⎢3.90 ⋅ (144) A ⎥⎦ ⎣ lb ⋅ ft ⎤ ⎡ Torque = I ⎢561.6 A ⎥⎦ ⎣ MOTOR 144:1 ratio (motor to bull gear) Bull gear 4 ORIGINAL, Model 12016A 6 A 3 A lb ⋅ ft ⎤ ⎡1.355 817 952 N ⋅ m ⎤ ⎡ Torque = I ⎢1843.2 ⋅ ⎥ A ⎥⎦ ⎢⎣ lb ⋅ ft ⎣ ⎦ 2499.04 N ⋅ m Torque = I ⋅ A lb ⋅ ft ⎤ ⎡1.355 817 952 N ⋅ m ⎤ ⎡ Torque = I ⎢561.6 ⋅ ⎥ A ⎥⎦ ⎢⎣ lb ⋅ ft ⎣ ⎦ 761.427 N ⋅ m Torque = I ⋅ A MOTOR IMPEDANCE (@25C) MOTOR IMPEDANCE (@25C) Z motor = Z L _ winding + Rwinding B Z motor = Z L _ winding + Rwinding Z motor = s (0.008)Ω + 0.97Ω Z motor = s (0.017)Ω + 0.4.50Ω BACK EMF (used in amplifier section) BACK EMF (used in amplifier section) Back _ EMF = θ M ⋅ K b Back _ EMF = θ M ⋅ K b V Back _ EMF = θ M ⋅ 5.30 rad / s Back _ EMF = θ M ⋅ 17.4 V rad / s C C TRANSFER FUNCTION(S) FOR SIMULINK Current (A) Torque (N•m/A) 761.427 D D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 7 of 25 2 1 3 4 5 6 BLOCK GROUP #6 CONTINUED 6 Telescope A Mount A MOTOR 144:1 ratio (motor to bull gear) 6 Bull gear MOTOR B B C C Imai measured 1Ω and 1.3Ω across the motors at the junction box with the amplifiers off but still connected on 11/2/07. This implies model “A”. D D SPARE MOTOR CURRENT MOTOR IN USE DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 8 of 25 2 1 3 4 BLOCK GROUP #7 Adj 0 to 8V Adj 0 to 0.5V A 7 (active low) BUF EAST SLEW DISABLE BUF EAST MOTION DISABLE SWITCH 7 (active low) 0V INVERTING Summing AMP with half wave rectifier. Only positive outputs allowed. 7 Op-amp equation when Vcmd is ≤ -5*Vrefp: Vout=-Vrefp-0.2*Vcmd G=5 SWITCH 7 POSITIVE LIMIT 7 ADJ 468 Hz Else, Vout=0. Mag Limit Adj 0 to -8V Adj 0 to -0.5V (active low) BUF WEST SLEW DISABLE BUF WEST MOTION DISABLE B SWITCH 0V INVERTING summing amp. This stage subtracts the exact amount from the command that is required to clip it and keep it within 5*ref voltage . The final result is the inverted value. A (-5*VREFP is the actual negative output voltage limit of Z9) Low Pass NEGATIVE LIMIT 7 6 It also provides a filter. ADJ 7 (active low) 5 7 G=5 SWITCH B This is just a selectable magnitude limiter with a filter. The “BUF MOTION DISABLE” can be ignored since it is a personnel safety feature, which isn’t part of the servo analysis. Also, it can be assumed that EAST and WEST slewing will have equal magnitude limiting. (-5*VREFN is the actual positive output voltage limit of Z9) C INVERTING Summing AMP with half wave rectifier. Only negative outputs allowed. TRANSFER FUNCTION(S) FOR SIMULINK 0.720 0.160 BUF EAST SLEW DISABLE 1 SWITCH Z8A-9= 160 mV Z8A-5= 717 mV Z7A-5= -720 mV Z7A-9= -150 mV (EAST track) (EAST slew) (WEST track) (WEST slew) Else Vout=0. (Velocity CMD input only, excludes limit refs) For model, use +/- 160 mV for tracking/offset +/- 720 mV for SLEW ADJ Mag Limit NEGATIVE LIMIT D Op-amp equation when Vcmd is ≥ -5Vrefn: Vout=-Vrefn-0.2*Vcmd Testing 11/7/07 G=5 POSITIVE LIMIT ADJ -0.720 -0.160 BUF WEST SLEW DISABLE C 0 D 0 1 G=5 SWITCH DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 9 of 25 2 1 3 BLOCK GROUP #8 Absolute value of power supply. +90V (supply voltage) Functionally, the amplifier becomes a transconductance amplifier - with a transfer function of 10.5 amps of equivalent output current per volt of input command voltage. This is the nominal specified value. See test results below. However, the amplifier output current is limited by the impedance it is driving and its +90V supply used in the TCS. The motor impedance will change with frequency due to the inductance and the motor will also create a back EMF, which further reduces the available voltage to drive the motor. The CSR amp uses an H-Bridge driver. This means that it only uses a +90V supply but it can reverse the polarity on the motor, resulting in current flowing the opposite direction. In regards to modeling, it would appear as if the amplifier could supply +/- 90V to the motor. - C BACK EMF (see motor modeling) 1 0 - D SWITCH Motor Drive Current (A) + |ABS| 1/(Motor Inductance) (see motor) |Maximum current| that the amplifier can provide to the motor due to the back EMF and motor impedance. B The voltage could be positive or negative for the back EMF. These blocks are used as a comparison to see if the current magnitude requested can be supplied. Rotational Speed (rad/s) 5.30 CMD (A/V) -6.202532 -6.162791 -6.097561 -6.116071 -6 -6.541667 -6.18677 Monitor (A/V) 11.66667 11.77778 11.90476 17.125 16.66667 18.47059 14.60191 WEST 17.42075 NORTH D DWG # REV TCS1-CBD 1 C DESCRIPTION Measurments taken at NC307 amplifiers to compare the volts to amps command conversion and the amps to volts current monitor. FLUKE DVM put in series with actual armature wire originating at the NC307. "+" of multimeter was hooke up to "+" armature, so current flow is measured coming out of the amplifier. MOTOR & FLUKE Term 6 Term 8 Axis Tracking AXIS Current (A) CMD (V) Monitor (V) Speed (as/s) WEST 4.9 -0.79 0.42 10 WEST 5.3 -0.86 0.45 6 WEST 5 -0.82 0.42 30 NORTH 2.74 -0.448 0.16 15 NORTH 2.7 -0.45 0.162 30 NORTH 3.14 -0.48 0.17 50 average average 1 0.008s + 0.970 - Select the lower value between desired and available: IF desired < available, control value is positive “1”, use desired value IF desired > available, control value is negative “0”, use max value Date Created: 11/28/07 Author: E. Warmbier |ABS| + - Ideal amplifier model: This model is a very simplified model of a transconductance amplifier. It does not take into account any frequency response of any kind. However, for the purposes of the TCS model, it should be sufficient. The switching frequency of the amplifier is 20 kHz. The response of the amplifier is DC to 1000 Hz at rated current. The TCS control system is limited to the hundreds of hertz. -6.2 +90V A SWITCH |ABS| TRANSFER FUNCTION(S) FOR SIMULINK Current CMD (in volts) Motor Drive Current (A) 0 + + B 1 |ABS| Each of the two motors is operated by a dedicated power amplifier (CSR Contraves, NC307). These amplifiers are classic switching amplifiers, in that they utilize an alternating polarity square wave with an adjustable duty cycle, to control the equivalent DC current. Their switching frequency is 20 kHz. 6 10.5 A/V AMP A 5 Desired command current Current CMD (in volts) 8 4 2 3 4 5 - 6 SHEET 10 of 25 2 1 3 4 5 6 BLOCK GROUP #9 (proportional output ->) A A INVERTING Summing Amp with filtering and output magnitude limiting to about +/- 10.7V or ~11V. B B (integrator output ->) INVERTING Summing Amp with filtering and output magnitude limiting to about +/10.7V or roundoff to ~+/-11V. However, the +/- 11V clamp may be ignored for the purposes of this model. There is another limiter of lower magnitude that follows this stage. See block #7. w/ amp above SLEW EAST/ TRANSFER FUNCTION(S) FOR SIMULINK C C w/ amp above (proportional output ->) SLEW WEST/ (integrator output ->) D +8V 0V SLEW EAST/ (active low) JOYSTICK (ignore) D SWITCH -8V 0V SLEW WEST/ + + + + + (active low) Not using during servo modeling – ignore. SWITCH DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 11 of 25 2 1 3 4 5 6 BLOCK GROUP #10 A ~180:1 friction gear ratio (encoder to bull gear) Telescope A Mount 10 Incremental Encoder B Bull gear The encoder input is in terms of rotation position (radians) and output is in volts ultimately at the digital to analog converter. 1 encoder pulse Friction A/D increments Gear Scaling Encoder position Ratio (see block #12) counter by 1 B Teledyne Gurley Incrementel encoders, model 8626. Both of the current incremental encoders have a 3600 line count and associated electronics capable of 40x interpolation for a total of 144 000 pulses/ revolution. ⎛ 3600⋅ 40 pulses revolution 180turns 20V bit ⎞ ⎟⎟ ⋅ Radians Output _ Voltage = ⎜⎜ ⋅ ⋅ ⋅ 14 ⋅ ⎝ revolution (2π )radians 1turns 2 bits pulse ⎠ Output _ Voltage ⎛ 3600⋅ 40 pulses revolution 180turns 20V bit ⎞ ⎟⎟ = ⎜⎜ ⋅ ⋅ ⋅ 14 ⋅ ( 2 ) 1 2 π Radians revolution radians turns bits pulse ⎝ ⎠ From BEI’s website gloassary: http://www.motion-control-info.com/encoder_glossary.html Output _ Voltage V = 5035.762 Radians radians C C There is quantization of position due to the encoder. The encoder provides pulses, not a continuous output. The quantization is the number of radians that must be traveled before the next pulse. This is calculated as follows: revolution (2π )radians 1 radians ⋅ ⋅ = 242 .41 ⋅ 10 − 9 3600 ⋅ 40 pulses revolution 180 pulse radians 242 .41 ⋅ 10 − 9 ⋅ 1 pulse = 242 .41 ⋅ 10 − 9 radians pulse TRANSFER FUNCTION(S) FOR SIMULINK D D 5035.762 Encoder 242.41E-9 quantization interval DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 12 of 25 2 1 3 4 5 6 BLOCK GROUP #11 11 1.59 kHz 11 1.96 (1.33) Low Pass A A This is proportional gain of the PID with a low pass filter. Inverting amplifier with filtering: Gain= Rf/Rs 10k/5.11k 1.96 f(-3dB) =1/(2πRC) =1/(2π*10k*0.01uF) =1.59 kHz B DEC AXIS: HA AXIS B C C HA TRANSFER FUNCTION(S) FOR SIMULINK DEC TRANSFER FUNCTION(S) FOR SIMULINK D D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 13 of 25 2 1 3 4 5 6 300Ω “Short” BLOCK GROUP #12 300Ω “Short” Normal Normal A B A B TRANSFER FUNCTION(S) FOR SIMULINK INVERTING Summing Integrator under normal operation. Position Error Signal (from DAC) Very low gain inverting summer with filter when R17 via switch is active (SLEW mode). Essentially the integrator is shorted out since 300Ω is a low value and therefore the gains become very small. 0 1 SWITCH C +8V 0V FD FWD EAST C (active low) 0 1 0 1 SWITCH SWITCH -8V 0V FD FWD WEST Bottom line: “I” term for the PID controller is either active or it is shorted. + + + + + 0 0 1 1 SWITCH SWITCH D D HA CLEAR INTEGRATOR DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 14 of 25 1 2 3 BLOCK GROUP #12 Continued 4 5 6 MANUAL (finger pushing button), REPETITIVE +/- 60 ARCSEC OFFSETS, 11/7/07 A A CH1: “VOUT” TP CH2: Integrator Output TP2 CH3: FD FWD East B B Below is a portion of the Ev Irwin memo about the offset operation and how the FD FWD is used. From Ev Irwin Memo: C “In addition to using the PEC D/A signal as an input, during offset or beam switching operations, the Integrator receives pulses of fixed amplitude but varying numbers. These pulses inject charge into the integrator of opposite polarity as is the direction of desired position change. The purpose of these pulses is to reduce overshoot and improve settling time. The number of pulses – and therefore total injected charge is one-for-one equal to the commanded number of steps required for relative position change. In other words, when the telescope is commanded to step 400 steps to the east, there is a delay while the telescope moves to the east. During that time, the integrator integrates the error so that when the telescope finally reaches the desired new position, there is excess charge in the integrator. To remove this charge, there would have to be an overshoot with a negative error. The feed-forwarding pulses inject negative charge into the integrator thereby shortening or eliminating the need for overshoot. NOTE – At first, one might wonder why not simply short out the integrator, as is done during slew operations? Unfortunately, during tracking, the integrator contains the amount of charge necessary to produce an output voltage equal to the value required to track the telescope. To short the integrator, would remove that charge, forcing the telescope to briefly stop and thereby worsening the settling time – not improving it.” C FD FWD pulse initially causes large jump in opposite polarity of error signal. The scope plot seems to confirm the above statement. When the error reaches zero (CH1) the integrator output (CH2) is approximately the same as the value when the offset started. This is due to the charge injected by the FD FWD pulse (CH3). If this pulse did not exist, the integrator would have a positive value on its output due to integrating the error signal when the error reaches zero. D Error signal is then integrated which brings output back close to initial value. (Keep in mind that the op-amp is inverting.) DWG # Remember: inverting amplifier configuration. 1 2 3 4 5 REV TCS1-CBD - 6 SHEET 15 of 25 D 2 1 3 4 5 6 BLOCK GROUP #13 13 14 bit PEC B0:B12,B25 A Digital position error CMD. -10 10 DAC A Digital to analog converter. Voltage output. The digital to analog converter gain was lumped into the encoder block. See block #10. Note: no datasheet was located on the internet. (It’s an older obsolete DAC.) B B It is known from operation and the above schematic that the DAC uses +/- 15V supplies, outputs +/-10V, and is 14 bits. Given this information, the resolution can be calculated as: 10 − (−10)V = 1.22mV / bit 214 bits This value is used as the quantization interval for the quantization block in Simulink. C C In addition, the DAC can only output +/- 10V. A limiter can be placed on the output. DEC TRANSFER FUNCTION(S) FOR SIMULINK 1.22E-3 quantization interval 10 D PEC B0:B12,B25 Digital position error CMD. -10 DAC D Mag Limit DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 16 of 25 1 2 3 4 5 6 BLOCK GROUP #13 CONTINUED A B A B The SIMULINK modeling of this will be much simpler than the large amounts of digital circuitry that were required to create these signals. SEE BLOCK #12 for more information on the offset pulses. (“FD FWD EAST” and “FD FWD WEST”) More work needs to done here. As of 11/27/07 two things are unknown: 1) Position error magnitude at which a slew ends 2) Offset pulse characteristics C The model currently uses values that work well in the simulation. C D D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 17 of 25 2 1 3 4 5 6 CONVERSIONS CONVERSION FOR SIMULINK The tachometer summer circuit has a scaled, averaged, tachometer output in volts. In the SIMULINK simulation, it is convenient to display this in arcsec/sec. See conversion derivation for rad/s to arcsec/s used below. This is the feedback that the control system uses. A tach summer out (volts) 548.78 radian/sec A arc sec arc sec/ s _ conversion 1 1 1 1 = Output(V ) ⋅ ⋅ ⋅ ⋅ ⋅ Tach _ conv Diff _ Amp summer _ gain Num _ tach _ input rad / s sec radians 1 1 1 206264.81arcsec/s 1 = Output(V ) ⋅ ⋅ ⋅ ⋅ ⋅ 1808V 0.213 0.488 2 rad / s sec rad / s radians 548.78arc sec/ s = Output(V ) ⋅ sec V B B C C CONVERSION FOR SIMULINK D radians/sec 206264.81 In Simulink, some of the outputs will be displayed on a scope. Radians/second are used in the model for radial velocity, but arcsec/sec is what the telescope control displays and uses. Converting it makes it easier to understand and compare to actual telescope data. arcsec/sec radians radian 180 deg 60arc min 60arc sec = ⋅ ⋅ ⋅ sec sec π ⋅ radian deg arc min radians arc sec = 206264.81 sec sec D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 18 of 25 1 2 3 4 5 6 APPENDIX: ABSOLUTE POSITION ENCODERS The current RA absolute position encoder (APE) is located in the North Pier. It is an inductosyn encoder with one half mounted on the yoke, and the other half mounted to the pier. A A The DEC APE is located in the west arm of the yoke. It is also an induction type encoder (identical to the RA encoder) with one half mounted to the telescope central section, and the other half mounted on the yoke. Both of the current APEs have a resolution of 0.1 arcsec. B B C C D D DWG # REV TCS1-CBD 1 2 3 4 5 - 6 SHEET 19 of 25 5 MCC TRACK WEST PULSES COMPUTER SLEW EAST (SOUTH) COMMAND COMPUTER SLEW WEST (NORTH) COMMAND EXCESS POSITION ERROR A RAMPDOWN DISTANCE SWITCH MEMORY IRTF 123 HA IRTF 124 DEC Y X (MCB) EAST (SOUTH) TELESCOPE MOTION PULSES 19.9028 PULSES/ARC-SEC ≈ 0.05 ARC-SEC/PULSE 19.9472 PULSES/ARC-SEC ≈ 0.05 ARC-SEC/PULSE B INCREMENTAL ENCODER COUNT UP/DN CONTROL POSITION ERROR WINDOW LOGIC IRTF 125 HA IRTF 126 DEC BITS 0 - 23 MANUAL SLEW CLEAR PEC LOADER IRTF 122 POSITION ERROR UP/DOWN COUNTER (PEC) (24 BITS) IRTF 125 HA IRTF 126 DEC EXCESS POSITION ERROR TELEDYNE GURLEY MODEL 8626 144,000 PULSES PER ENCODER REVOLUTION BIT 23 (MSB) DIGITAL TO ANALOG CONV. BITS 0 - 12 24 BIT PARALLEL COMMAND IRTF 122 8 A WEST (NORTH) TELESCOPE MOTION PULSES DIVIDE BY 2 LOGIC (BINARY SHIFT) IRTF 123 HA IRTF 124 DEC C COMPUTER INTERFACE X-Y DIGITAL SWITCH IRTF 123 HA IRTF 124 DEC HARDWARE CONTROLLED SLEW LOGIC MASTER CONTROL BUS ARITHMETIC SUBTRACTION LOGIC IRTF 123 HA IRTF 124 DEC 7 ANTICOINCIDENCE SCANNER IRTF 125 HA IRTF 126 DEC COUNTDOWN B COMPUTER COMMAND MAGNITUDE ANALYSIS LOGIC IRTF 123 HA IRTF 124 DES IRTF 123 HA IRTF 124 DEC *OR* COMMAND / 2 SLEW MODE MINIMUM COMMAND SWITCH MEMORY IRTF 123 HA IRTF 124 DEC LOAD AND COUNT COMMAND MINUS DECEL. DISTANCE COMMAND > MINIMUM COMMAND SETTING FOR SLEW DISTANCE BEFORE RAMPDOWN COUNTER BEGIN DECEL. SELECT COMMAND ≥ 2 TIMES DECELERATING DISTANCE COMPUTER COMMAND TIMING AND MODE SEQUENCE CONTROL IRTF 125 HA IRTF 126 DEC 6 (MANUAL MODE AND COMPUTER SLEWS ONLY) 4 MCC TRACK EAST PULSES 3 OPERATION COMPLETE 2 (MANUAL MODE AND COMPUTER SLEWS ONLY) 1 APPENDIX: TCS1 BLOCK DIAGRAM CIRCA 1980 C 0V = NULL BULL GEAR ERROR NULL =10000000000000 HARDWARE CONTROLLED SLEW LOGIC CONTROLS TELESCOPE DURING COMPUTER INITIATED SLEW OPERATIONS. IT INITIATES ACCELERATION, CALCULATES THE DECELERATION POINT, AND RETURNS THE SERVO TO LINEAR MODE. OPPOSING DRIVES EAST (SOUTH) DRIVE MOTOR WEST (NORTH) DRIVE MOTOR 0 TO ±10 VOLT ANALOG POSITION ERROR SIGNAL DC TACH DC TACH WEST DRIVE TACH SIGNAL (NORTH) EAST DRIVE TACH SIGNAL (SOUTH) INLAND D HIGH FREQ WEST DRIVE MOTOR TACH SIGNAL F MCC2 JOYSTICK SIGNAL MANUAL SLEW JOYSTICK BUFFER, DUAL SLOP GENERATOR COMPUTER SLEW EAST (SOUTH) COMMAND COMPUTER SLEW WEST (NORTH) COMMAND PRODUCES WEST (NORTH) TORQUE COMMAND ONLY + TELESCOPE EAST (SOUTH) SLEW LIMIT SWITCH -8V +8V TELESCOPE WEST (NORTH) STOP LIMIT SWITCH INTEGRATOR TORQUE SPLITTER COMPENSATION NETWORK LOW FREQUENCY TACH SUM E SUMMING AMP EAST (SOUTH) DRIVE TACH SIGNAl 3HZ HIGH FREQ FILTER LOW FREQ FILTER - SUMMING AMP & PREC RECTIFIER HIGH FREQ EAST DRIVE MOTOR TACH SIGNAL + WEST DRIVE TACH SIGNAL + EAST DRIVE TACH SIGNAL + + - SUMMING AMP & PREC RECTIFIER SWITCH - PRECISION RAMP AMPLIFIER PRECISION AMPLITUDE LIMITER SUMMING AMP SUMMING AMP & PREC RECTIFIER + SHORTED DURING SLEWS + + + + + CSR POWER AMP SUMMING AMP & PREC RECTIFIER + VELOCITY LIMITED CSR POWER AMP + ACCELERATION LIMITED LOW FREQ FILTER WEST (NORTH) DRIVE TORQUE CMD BUFFER AMP WEST (NORTH) DRIVE TACH SIGNAl + D E WEST (NORTH) PRE-LOAD EAST (SOUTH) PRE-LOAD EAST (SOUTH) DRIVE MOTOR TORQUE COMMAND PRODUCES EAST (SOUTH) TORQUE COMMAND ONLY SUMMING AMP F (TELESCOPE LIMIT SWITCH INITIATED) DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 20 of 25 1 2 3 4 5 6 7 8 APPENDIX: IRTF 123 - TELESCOPE SERVO CONTROL HA COMPUTER CMD & MAGNITUDE DETECT A A B B C C D D E E F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 21 of 25 1 2 3 4 5 6 7 8 APPENDIX: IRTF 125 - TELESCOPE SERVO CONTROL HA SEQUENCE CONTROL BOARD A A B B C C D D E E F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 22 of 25 1 2 3 4 5 6 7 8 APPENDIX: IRTF 127 & 128 TELESCOPE SERVO CONTROL D/A, JOYSTICK, & INTEGRATOR A A B B C C D D E E F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 23 of 25 1 2 3 4 5 6 7 8 APPENDIX: IRTF 130 - TELESCOPE SERVO CONTROL TACH SUMMER & TORQUE CMD A A B B C C D D E E F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 24 of 25 1 2 3 4 5 6 7 8 APPENDIX: IRTF 131 - TELESCOPE SERVO CONTROL DEC TACH SUMMER & TORQUE CMD A A B B C C D D E E F F DWG # REV SIZE TCS1-CBD 1 2 3 4 5 6 7 8 - SHEET D 25 of 25

![5: “OPERATIONAL AMPLIFIER IMPERFECTIONS AND APPLICATIONS” [1, pg. 23]](http://s2.studylib.net/store/data/014264266_1-2db71c70e14bfbbd5962c9add234b539-300x300.png)