Metal-Semiconductor Contacts for Schottky Diode Fabrication

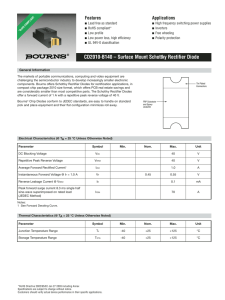

advertisement