EPA Performance Requirements for Laboratory Fume

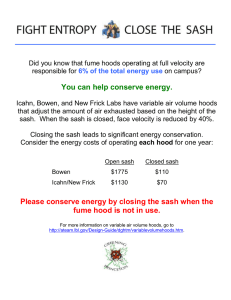

advertisement