Backflow Prevention Reference

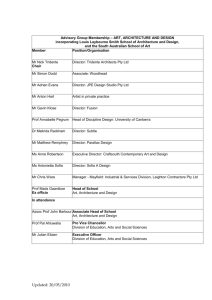

advertisement