A Direct Drive Permanent Magnet Generator Design for a Tidal

advertisement

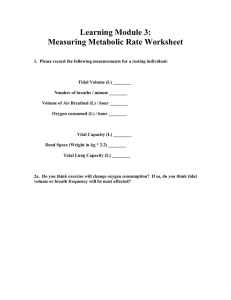

A Direct Drive Permanent Magnet Generator Design for a Tidal Current Turbine(SeaGen) Ozan Keysan∗ , Alasdair S. McDonald† , Markus Mueller† ∗† School of Engineering, Institute for Energy Systems University of Edinburgh, King’s Buildings, Edinburgh EH9 3JL United Kingdom ∗ Email: o.keysan@ed.ac.uk Abstract—In this study, the feasibility of a direct-drive permanent magnet generator for a tidal turbine power take-off system, namely MCT’s SeaGen –the world’s first full scale commercial tidal turbine– has been investigated. The investigated PM generator topology is called C-GEN which is an air-cored axial-flux generator developed in the University of Edinburgh. The C-GEN is prior to conventional PM generators by absence of magnetic attraction forces between rotor and stator, absence of cogging torque, ease of manufacturing, modularity and high fault-toleration [1]. Firstly, the integrated analytical design tool that couples electromagnetic, structural and thermal aspects of the generator has been introduced. Then, an optimization tool based on genetic algorithm has been used to maximize the annual electricity generation and to minimize the initial cost of the generator. The optimized generator is validated using FEA tools and the specifications of the generator has been presented. I. I NTRODUCTION The contribution of marine renewables to the world’s electricity generation is expected to increase in the next decades [2]. In the last years, UK government has introduced subsidies to wave and tidal energy companies to increase the marine renewable energy production. UK has abundant wave and tidal energy resources, especially, off the west coast of Scotland it has been estimated that 10 percent of the UK’s electricity may be provided by tidal energy [2]. The tidal currents are caused by the relative motion of the sun and the moon. The tides are predictable but tide velocity is varying through day and month [3]. There are roughly four current velocity peaks daily and one spring and neap periods monthly as given in Fig. 1. The tidal stream energy is the kinetic energy contained in the mass of moving water. The tidal power can be similarly expressed to wind energy as [4]; 1 3 Cp ρAVtide (1) 2 where Cp is the conversion ratio which is expected to be 0.3–0.4 for tidal turbines. The density of water is much higher than the density of air, so the same power can be extracted from a much smaller sweep area compared to wind turbines. As it can be observed from (1), the power of the tidal currents is proportional to velocity cubed. Thus, it is very important to find locations with the highest possible flow velocities if energy is to be extracted as cost-effectively as possible [5]. Compared to wind turbines, suitable locations for tidal turbines are more limited. An economically feasible P = location should have peak tidal current velocities higher than 2–2.5 m/sec which can only be found at pinch points, such as straits between islands and the mainland and shallows around headlands [6]. The advantages of tidal current energy have been listed in [5] as follows; • • • • The tidal currents can be predicted precisely, which allows contractable energy. Compared to wave energy converters, reduced extreme conditions make it easier to manufacture economically feasible devices. Environmental impact (i.e. threat of impact on marine wild-life, conflicts with other users of sea, pollution) is expected to be low. Energy Return on Energy Invested for a tidal turbine is predicted to be higher than for most marine renewable technologies. At present, there are at least three different tidal energy converter technology solutions: horizontal axis turbine, vertical axis rotating device and an oscillating hydroplane device [7]. Tidal energy device developers currently focus on the design of the prime mover, but they usually prefer to use off the shelf components for power take-off system which usually features an induction generator coupled with a gearbox or a hydraulic pump. These intermediate stages decrease the efficiency and more importantly decrease the reliability of the overall system, which is by far the most important issue for marine renewable devices. A few developers have built direct-drive tidal turbines such as: Open Hydro, Ireland [8], Clean Current, Canada [9]. Also, Swan Turbines [10] has proposed a commercial machine rated at 1 MW of unknown diameter [11] which will be the first MW scale direct-drive tidal turbine. A novel air-cored permanent magnet generator topology has been developed in the University of Edinburgh [1]. The principal benefits of this technology in direct-drive systems are; absence of cogging torque, reduced structural mass, ease of manufacturing and fault tolerance owing to its stacked configuration. A 20 kW prototype test rig and a 15 kW machine for a wind turbine has been manufactured and tested previously. In addition to wind turbine, C-GEN technology can also be applied to direct-drive marine energy converters. In this study, the results of a direct-drive C-GEN permanent magnet generator power take-off system that is designed for SeaGen will be presented. 00:00 06:00 12:00 Time of Day 18:00 00:00 Coal 14% Fig. 2. The power output during a spring and neap tide. % max output Fig. 4. The installed plant mix for the Irish system in 2008. 1.00 0.66 0.33 0 5 10 15 Days Fig. 3. The power output from a tidal device over a 15 day period. Fig. 1. The power output from a tidal device over a 15 day period [3] addition, as shown in Fig. 3, the maximum tidal output varies throughout the month with the spring neap cycle. A. Marine Current Turbines-SeaGen Energy extraction from tidal currents in UK is being led by 3. CaseCurrent study Turbines (MCT). By the end of 1990’s, the Marine company gained the support of European Commission for the In order to quantify the costs and benefits of tidal generation a ‘Seaflow Project‘, to develop the world’s first full-scale (300 real electricity system was taken as a case study. Ireland is the kW) offshore tidalforturbine whichsince wasit successfully installed case study chosen this analysis is an island electricity and has exceeded the expected power under favourable flow system with a potentially rich tidal energy resource. In addition, Ireland has conditions [6].very limited interconnection to other systems allowing for a controlled of tidal generation. However, After Seaflow, MCT study initiated a £10 million projecttheto issues that are raised here are not unique to the case system and manufacture and install a twin rotor system rated at 1.2 MW, are likely to be relevant in other systems considering tidal called SeaGen and it was installed in Strangford Narrows, generation. NorthTheIreland 2008 historically [11]. The device is mounted to seabed Irish in system consisted of two separately operated but interconnected systems, the Republic of with a monopole structure. There areone twoin counter rotating Ireland one inasNorthern However, in 2004 blades in and the device shown inIreland. Fig. 2(a). Each rotor is 16anm the electricity regulators in the inagreement diameter was and reached drives abetween 600 kW power-train. The operation Republic and in the North to establish a single ‘all-island’ market range of SeaGen is shown in Fig. 2(b). The figure also shows for electricity. This new ‘all-island’ Single Electricity Market (SEM) the expected operation range of first-generation tidalSEM turbines was launched in November 2007 (SEMO, 2007). The is a with varyinggross rotorpool diameter mandatory market[2]. with centralised commitment of units. The marginalof generator sets the of system marginal price for The power-train MCT consists a multi-stage gearbox all generators in the gross pool market. In addition, to the gross and a induction generator designed as a sub-sea motor for the pool market there is a separate capacity payment mechanism. oilThus andgenerators’ gas industry [5]. The power-train is submersible, with bids should consist of their marginal and start a costs pair of planetary gearboxes are designed by Orbital2 only. This paper examineswhich this ‘all-island’ electricity system, and manufactured by ofWikov theNorthern Czech Ireland Republic [5]. The covering the Republic Irelandinand (referred to jointly in this is paper ‘Ireland’). gearbox ratio 70:1asand the rated speed of the generator is currently approximately of installed capacity. 1000Ireland rpm when thehas blade is rotating9 GW at 14.3 rpm. The total The generation plant mix was traditionally based on large coal and mass of the drive-train is 27 tonnes [12]. The blades have full-span pitch control with carbon/glass fibre composite rotor blades [5]. The pitch control system can also be used to prevent power spikes to limit the power output and to ensure optimum performance during both the ebb and flood tides [11]. The blades and power take-off system can be raised above the sea surface for maintenance as shown in Fig. 2(c). II. I NTEGRATED D ESIGN OF C-GEN In the design of conventional electrical machines, firstly electromagnetic aspects of the generator are designed and optimized. Then, the structural parts are added to the generator design. On the other side, for large diameter direct-drive machines, the structural mass is dominant and structural issues should be carefully addressed. Better machines can be obtained with a coupled structural and electromagnetic design tool. Another issue is the thermal design of the generator for tidal turbines. A well-designed generator can benefit from improved oil fired generation plant with a small number of peat plants and old thermal gas generators. Since 1990 however, the share of high carbon content fuels such as coal has fallen in Ireland due to a large increase in the use of natural gas combined cycle plants (CCGTs). Gas fired generation now accounts for over 50% of the generation in Ireland (Deloitte, 2005). Ireland has one pumped storage station and a small number of hydropower plants. In addition, Ireland has one 500 MW interconnector to Scotland. The installed plant mix for the Irish electricity system as of March 2008 is illustrated in Fig. 4. Bryans et al. (2005b) determined the resource for tidal energy around Ireland using a 2 dimensional tidal model to simulate the tidal flows for the waters surrounding the entire island with a (a) 405 m by 405 m grid. They found that the resource currently accessible to the MCT tidal device (as shown in Fig. 1) is 374 MW around Ireland. However, it is predicted that into the future, TED development will lead to larger turbines which will be financially viable at greater depths and lower spring current velocities. Based on the predictions by Bryans et al. (2004), a tidal resource of up to 560 MW is investigated here, representing 6% of installed generation capacity. 4. Methodology During the design process of the Single Electricity Market in Ireland software from Energy Exemplar, known as PLEXOS for Power Systems, was used by the market design team to model the likely operation and prices in the new market (PLEXOS, 2006). The purpose of this modelling work was to assist industry participants in developing a greater understanding of the new (b) electricity market arrangements and to provide quantitative support in assessing the potential impacts of the arrangements on both the industry and the final customer (AIP, 2008). The PLEXOS tool is a sophisticated modelling technique which uses mixed integer optimisation to determine the unit commitment decisions and accounts for generator constraints such as minimum and maximum operation, ramp rates, start times and costs, maintenance schedules and transmission constraints. The optimisation also co-optimises for reserve provision and includes energy limited cascade constraints for the operation of hydrostations and genuine optimisation of the pumped hydro stations (PLEXOS, 2006). (c) Fig. 2. a) SeaGen operational mode (Courtesy of MCT), b) Extractable power from marine currents of a given velocity at average 30% efficiency and operation range of SeaGen [2], c) SeaGen maintenance mode and drivetrain(Photo:ISA [13]). heat transfer conditions while operating under water. To benefit from this advantage in SeaGen design, a coupled thermal model has been included in the analytical model. The multiphysics optimization design tool used in this study, ensures that the most appropriate generator design is produced taking into account the operating conditions of SeaGen. The design tool comprises of the following parts; electromagnetic design, structural design and thermal design. A. Electromagnetic Design The C-GEN machine takes its name from the C-shaped magnetic core structure. The permanent magnets are placed on each limb of the core as shown in Fig. 3. The armature composed of air-cored concentrated coils, reinforced with epoxy filling. One limitation of the air-cored windings is the decreased magnetic performance due to higher reluctance. On the other side, using air-cored windings magnetic attraction forces between rotor and stator are completely eliminated which reduces the mechanical load on structure. NI NI SPM Sag SPM Ssp Sl A NI Sl Ssp SPM Sag NI SPM A Ssp Sl NI Sl SspNI SPM Sag SPM (a) φPM A (a) Leakage Flux NI SPM Sag PM PM φst Linking Flux B Sst d A PM NI φPM SPM A d PM hm (b) Fig. 3. a) Reluctance network for three C-core modules seen end on, b) Intra-module reluctance network seen side on, common point labelled A The electromagnetic circuit of the generator is modelled using the lumped parameter method. The details of the calculations can be found in [14]. The magneto-motive force of the permanent magnets can be expressed as N I, which is the equivalent number of turns and current flow required to achieve the same magneto-motive force, as given in (2) and (3). Lm , hm , wm represents the length, the height and the width of the magnet. Br is the remanence flux density, µr is the relative permeability of the permanent magnet. N I = Φ.R hm Br hm N I = Br Lm wm = Lm wm µ0 µr µ0 µr (b) Fig. 4. a) Reluctance network for three C-Core modules seen end on, b) Intra-module reluctance network seen side on, common point labelled A magnetic potential difference is constant (2N I), but the length of the leakage path is varying. The leakage flux on part B can be approximated as in (6). The equivalent leakage reluctance can be defined as the magnetic potential difference between two magnets divided by the total leakage flux as given in (7). R= L µ.A (4) (2) R Zout Zhm (3) In the magnetic circuit, Sag is the airgap reluctance, SP M is the permanent magnet reluctance, Ssp is the spacer reluctance, Sweb is the web reluctance and Sl is the leakage path reluctance. The reluctance calculations for each element is straightforward and can be defined by using the well-known formula given in (4). On the other side, to increase the accuracy of the analytical model the leakage flux reluctance (Sl ) should be carefully estimated. Leakage flux travels between neighbouring magnets without crossing the airgap as seen on Fig. 4(b). The amount of leakage flux increases as the distance between magnets decreases. Assume the angle between magnets is θ in radians as given in Fig. 4(a) and the magnets lay between Rin and Rout . The height of the magnet is hm and the vertical gap between opposing pole magnets is 2d. The leakage flux can be divided into two parts; part A is the flux travelling between side walls of the magnets, part B is the flux travelling from top surfaces of the magnets. Then, ΦA can be calculated taking the double integral over magnet height and magnet length as in (5). The flux density is higher at upper levels of side wall due to increased magnetic potential difference. For ΦB , the ΦA = Rin 0 2N I.x hm = N Iµ0 hm (ln(Rout ) − ln(Rin )) θr µ0 .dx.dr (5) R ZoutZd 2N I ΦB = Rin 0 2( π 2x µ0 .dx.dr Sl = )+( 2N I ΦA + ΦB θr ) µ0 .dx.dr (6) (7) One important advantage of the C-GEN design is the paralleled design option, i.e. several machines can be stacked in the axial direction to reduce the overall active material mass. More over, these stacks can be independently controlled to increase fault-toleration of the generator. In Fig. 5(a) the magnetic flux direction in a single C-core for eight stacked machines is shown. The magnetic flux travels axially to the end of machine then to the neighbouring magnets as can be seen in Fig. 5(b). In order to verify the analytical model, simulations are performed using the Opera 3D FEA software. The maximum flux density in the airgap obtained from the qM axwell = (a) 2 B̂ag 2µ0 N/m2 (8) Another important issue is the deflection and torsion of the rotor torque-arm structure. The rotor structure is modelled using a six-arm hollow rectangle structure [17]. The rotor structure should cope with short-circuit torques (which may be up-to six times of the rated torque) and any axial loads than can arise during maintenance or transportation. During fast tidal currents, the tidal turbine structure has to cope with very large axial thrust forces. But, these thrust forces should be isolated from the generator using the main turbine bearing. C. Thermal Design (b) Fig. 5. a) Reluctance network for three C-Core modules seen end on, b) Intra-module reluctance network seen side on, common point labelled A analytical method is compared with the result obtained from the FEA software. For SeaGen case, the analytical model estimated the maximum airgap flux density as 0.61 T where FEA simulation result is 0.62 T. The analytical model are also compared with varying dimensions of, all of which are consistent with the FEA results and the error is less than 5% for all cases which is acceptable. B. Structural Design In a conventional permanent magnet machine, the main structural load is the magnetic attraction force between rotor and stator. Thus, the rotor structure should be stiff enough to keep the airgap clearance with certain tolerance. Owing to its air-cored armature structure, there is no attraction force between rotor and stator in the C-GEN generator, which simplifies the rotor structure, especially for large diameters. But, the attraction force between C-core limbs that try to close the airgap still exists. The Maxwell stress in the C-core can be calculated using (8). For the SeaGen design, the maximum airgap flux density magnitude is 0.61 T which gives a Maxwell stress of 148 kN/m2 . The Maxwell stress is used as an input to the beam structure model which is presented in detail in [15]. In an axial flux machine, the magnets can be trapezoidal shaped. In this case, the deflection can be modelled with a trapezoidal force applied on a beam with one side is fixed as shown in [16]. The conventional generators used in tidal turbines do not benefit from the improved heat transfer paths by water unless they are specially designed for submerged operation. A better design with either higher efficiency or smaller mass can be achieved by utilizing the thermal advantage of submerged operation and by considering thermal aspects of the generator during design process [18]. In order to compare different options, thermal simulations are performed using the conventional, submerged (but airgap is not filled water), flooded (submerged and airgap is filled with water) generator types. Using the same dimensions and a current density of 6.8 A/mm2 , the maximum temperatures on the armature coil has been compared. The conventional air-cooled generator has a working temperature of 116 ◦ C, where for submerged machine it is 88 ◦ C, and for flooded generator it is 58 ◦ C. It is clear that, the flooded generator has the best thermal performance, but flooding the generator introduces many other challenges. Some of the most critical ones can be listed as: corrosion protection of the NdFeB permanent magnets, increased fluid drag losses due to water-filled airgap, electrical insulation problems, necessity to modify the bearing design. Due to these difficulties a flooded generator is not preferred, instead a submerged generator configuration has been used for SeaGen. In the submerged generator, heat conduction from armature coils in radial direction (from outer surface to tidal currents) can be increased using thermally conductive structural parts. For the optimization process, a lumped parameter thermal model is used to estimate the temperature of the armature windings and permanent magnets. The heat input to thermal model is the total copper loss and eddy current loss. The thermal model requires an iterative process since the coil resistance increases with temperature which means an increase in copper losses for the same amount of current (I 2 R). Once the thermal model converges, the output can be used to calculate the efficiency of the generator for that operation point. Dynamic analysis is not required, since the tidal currents do not vary as quickly as wind and highly predictable. The output of the thermal model is also used to define the power output limit and to identify any de-magnetization risk for permanent magnets. III. O PTIMIZATION FOR S EAG EN C ASE In order to get the most suitable solution for the SeaGen, electromagnetic, structural and thermal models should be coupled with each other. The coupled model creates a multivariable model with discontinuities. The inputs of the model are mainly the dimensions of the C-GEN and the material properties e.g. the remanence flux density of the PM. The optimized generator should match the torque characteristic of the turbine for each operating speed. There are several optimization methods. In this study, the genetic algorithm (GA) was chosen since it does not require any derivative information and has a minimum chance of trapping in a local minima. A. Objective Function For variable speed generators as in tidal turbines, the optimization process should not only be performed at the rated speed but for the whole operating range. The objective function of the optimization process should be thoroughly defined. Objective functions that consists of only material cost or efficiency may not result in the most optimum solution. For example, in [19] a very detailed description of the optimization of an axial flux generator has been given, but the machine has been optimized for minimum PM material cost, and then for maximum efficiency. The objective function should include the electricity generation income. In [20], Jung et al. coupled GA optimization with FEA software to get the best designs for annual energy production, but they neglected the initial cost of the generator. The objective function should include the electricity generation income as well as the manufacturing cost of the generator; any other manufacturing constraints (e.g. maximum diameter)should also be included. The objective function in this study has been defined in 10 discrete operating conditions as given in (9), where x is the input vector that defines generator’s dimensions [16]. Fcost (x) = + k.fmaterial (x) 10 X X (−pi fincome (x) + wi fpenalty (x))(9) i=1 fmaterial (x) represents the material and the manufacturing cost of the generator, details of which have been given in [16]. Firstly, the permanent magnet mass, copper mass, iron and structural steel mass are separately calculated and multiplied by material prices as follows; Pmagnet =£35/kg, Pcopper =£10/kg, Psteel =£3/kg. However, the material prices change continuously, this ratio gives a good approximation of the contribution of each material to total generator cost. Then, the total material cost is multiplied by a factor (k), which is assumed as 2.5, to estimate the manufacturing and assembly cost. fincome (x) is the electricity generation income over the generator’s lifetime. pi is the probability density of each operating point. The rated speed of the SeaGen is 14.3 rpm [12], but due to non-disclosure agreement the full operating Fig. 6. Optimization outputs with varying diameter for 600 kW SeaGen generator (a) (b) Fig. 7. a) Optimised 600 kW direct-drive axial-flux C-GEN machine. b)Cross-section view of the generator (8 parallel machines) characteristics of the generator cannot be published. The availability of the generator and the losses in power electronics and transformers should be also included. The kWh price of the electricity generated from renewable sources changes according to Renewables Obligation Certificate (ROC) [21]. For SeaGen, it is estimated as £14.4/W over ten years of period. fpenalty (x) is used to define the required constraints on the design such as; maximum phase voltage, maximum flux density in the core, temperature limits of the armature coils and magnets, structure deflection limits. Each constraint is multiplied by a weighting factor wi to adjust the priority of each constraint. B. Optimized Design An axial-flux C-GEN machine for SeaGen has been designed using the defined cost function and GA. Ambient temperature is assumed to be 10◦ C. Firstly, GA has been applied with different diameter limits. Fig. 6 shows the variation of efficiency, total mass, axial length and material cost with TABLE I S PECIFICATIONS OF THE OPTIMIZED GENERATOR FOR S EAG EN Rating Number of Stacks Peak Efficiency Average Efficiency Outer Diameter Axial Length Generator Weight Number of Poles Airgap Flux Density 600 kW 8 x 75 kW 94.1 % 88.8 % 3.2 m 0.75 m 17.5 t 120 0.61 T diameter. It can be observed that the maximum efficiency of the generator converges to 94% for diameters larger than 3 m. The generators with small diameter are heavy due to active material mass requirements (i.e. magnet mass) which can also be observed in the soared material cost. As the diameter is increased the mass reduces to a minimum value of 14 tonnes when the diameter is around 4 m. As the diameter is further increased, the mass of the generator starts to increase again. But this time, total mass is increased due to increase in structural materials which can be observed from the nearly constant material cost. Secondly, the optimization has been performed without any limits on the diameter. The GA has been initiated with a population of 1500, and then has been run for 60 generations with a population of 300. The output of the optimization is a generator with 3.2 m diameter. The generator consists of eight parallel generators stacked axially. In Fig. 7(a), the optimised generator is shown with a human figure for scaling. The cross-section view of the generator is given in Fig. 7(b). Full specifications of the generator are presented in Table I. IV. C ONCLUSION In this paper, an axial flux PM direct drive generator for MCT’s SeaGen tidal turbine has been designed. It is showed that the C-GEN topology is feasible for tidal turbine applications. It is easier to obtain the most suitable design over all operating conditions using the GA optimization with a coupled multi-physics analytical design tool. The most important issue in the electrical machine optimization is a realistic definition of the objective function. In this study, the electricity generation income as well as the material cost have been included in the objective function to find the most cost-effective solution. The optimized 600 kW direct-drive generator for the SeaGen weights 17.5 tonnes, which is comparable with the actual power-train of the device. The efficiency of the generator can be increased by better utilization of tidal currents as a passive cooling medium. The removal of gearbox decreased the moving parts in the power take-off increasing the robustness of the system. Also paralleled structure of the C-GEN generator provides a fault-proof system. The generator is able to continue to operate at reduced rating even one of the stages had to be turned off due to a fault. All these features show that, the C-GEN direct-drive generator is a feasible option for tidal energy converters. ACKNOWLEDGMENT This research is funded by NPower Juice. The authors would like to thank Peter Fraenkel and Marine Current Turbines for their support and collaboration. R EFERENCES [1] M. Mueller and A. McDonald, “A lightweight low-speed permanent magnet electrical generator for direct-drive wind turbines,” Wind Energy, vol. 12, no. 8, pp. 768–780, 2009. [2] E. Commission, “The Exploitation of Tidal Marine Currents (Report: EUR 16683 EN),” IT Power Ltd, 1996. [3] E. Denny, “The economics of tidal energy,” Energy Policy, vol. 37, no. 5, pp. 1914–1924, May 2009. [4] S. Elghali, Ben Eddine, M. E. H. Benbouzid, T. Ahmed-Ali, and J. F. Charpentier, “High-Order Sliding Mode Control of a Marine Current Turbine Driven Doubly-Fed Induction Generator,” IEEE Journal of Oceanic Engineering, vol. 35, no. 2, pp. 402–411, Apr. 2010. [5] P. Fraenkel, “Marine current turbines: pioneering the development of marine kinetic energy converters,” Proc.of the Inst.of Mechanical Engineers, Part A: Journal of Power and Energy, vol. 221, no. 2, pp. 159–169, Jan. 2007. [6] P. Frankel, “Tidal Current Energy Technologies,” Ibis, vol. 148, pp. 145– 151, Mar. 2006. [7] M. Mueller and N. Baker, “Direct drive electrical power take-off for offshore marine energy converters,” Proc.of the Inst.of Mechanical Engineers, Part A: Journal of Power and Energy, vol. 219, no. 3, pp. 223–234, Jan. 2005. [8] “OpenHydro, UK.” [Online]. Available: http://www.openhydro.com/home.html [9] “Clean Current, Canada.” [Online]. Available: http://www.cleancurrent.com/index.htm [10] “Swanturbines, UK.” [Online]. Available: http://www.swanturbines.co.uk/ [11] J. King and T. Tryfonas, “Tidal stream power technology - state of the art,” Oceans 2009-Europe, no. 2, pp. 1–8, May 2009. [12] “Seagen Facts.” [Online]. Available: http://www.seageneration.co.uk/downloads/recent/General Documents/Seagen Facts EXTERNAL 2.pdf [13] “Island Environmental Accountancy.” [Online]. Available: http://ieaci.com/photos for web/Sea-Gen-2.jpg [14] A. McDonald, “Structural analysis of low speed, high torque electrical generators for direct drive renewable energy converters,” PhD Thesis, University of Edinburgh, UK, 2008. [15] A. McDonald, M. Mueller, R. Crozier, S. Caraher, and J. P. Chick, “Integrated design of direct-drive linear generators for wave energy converters,” 2009 International Conference on Sustainable Power Generation and Supply, pp. 1–7, 2009. [16] O. Keysan, A. McDonald, and M. Mueller, “Integrated Design and Optimization of a Direct Drive Axial Flux Permanent Magnet Generator for a Tidal Turbine,” in International Conference on Renewable Energies and Power Quality - ICREPQ’10, Granada, 2010. [17] O. Keysan, A. McDonald, M. Mueller, R. Doherty, and M. Hamilton, “CGEN, a lightweight direct drive generator for marine energy converters,” 5th IET International Conference on Power Electronics, Machines and Drives (PEMD 2010), pp. 1–6, 2010. [18] M. Mueller, N. Hodgins, W. Tease, and D. Staton, “Measurement and modelling of induction generator performance in an oscillating water column wave energy converter,” 4th IET International Conference on Power Electronics, Machines and Drives (PEMD 2008), no. 1, pp. 76– 80, 2008. [19] W. Rong-Jie, K. Van Der Westhuizen, M. Kamper, and J. F. Gieras, “Optimal design of a coreless stator axial flux permanent-magnet generator,” IEEE Transactions on Magnetics, vol. 41, no. 1, pp. 55–64, 2005. [20] S.-Y. Jung, H. Jung, S.-C. Hahn, H.-K. Jung, and C.-G. Lee, “Optimal Design of Direct-Driven PM Wind Generator for Maximum Annual Energy Production,” IEEE Trans. on Magnetics, vol. 44, no. 6, pp. 1062– 1065, Jun. 2008. [21] “The Office of Gas and Electricity Markets Renewables Obligation.” [Online]. Available: http://www.ofgem.gov.uk/sustainability/environment/renewablobl