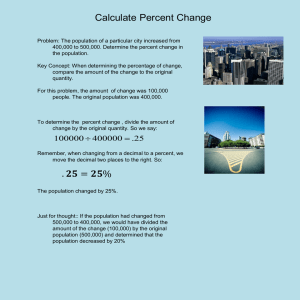

axial-flux wind turbine for rural alaska

advertisement