ICS Series 5-15 Ton Indoor Ducted Air

advertisement

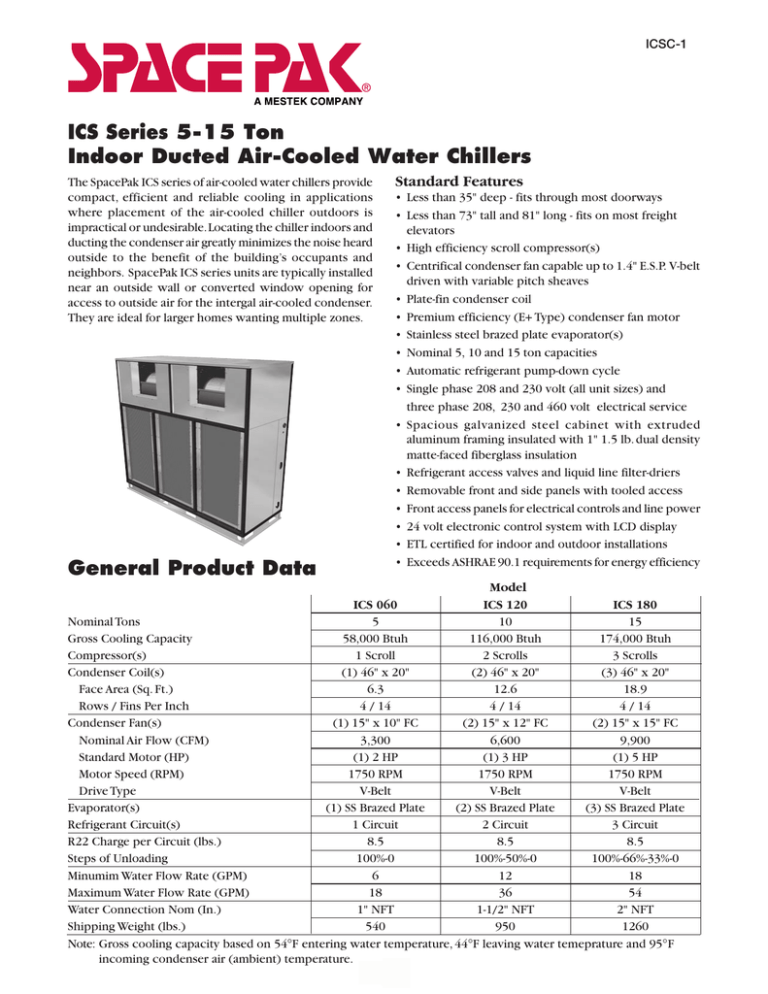

ICSC-1 ICS Series 5-15 Ton Indoor Ducted Air-Cooled Water Chillers The SpacePak ICS series of air-cooled water chillers provide compact, efficient and reliable cooling in applications where placement of the air-cooled chiller outdoors is impractical or undesirable. Locating the chiller indoors and ducting the condenser air greatly minimizes the noise heard outside to the benefit of the building’s occupants and neighbors. SpacePak ICS series units are typically installed near an outside wall or converted window opening for access to outside air for the intergal air-cooled condenser. They are ideal for larger homes wanting multiple zones. General Product Data Standard Features • Less than 35" deep - fits through most doorways • Less than 73" tall and 81" long - fits on most freight elevators • High efficiency scroll compressor(s) • Centrifical condenser fan capable up to 1.4" E.S.P. V-belt driven with variable pitch sheaves • Plate-fin condenser coil • Premium efficiency (E+ Type) condenser fan motor • Stainless steel brazed plate evaporator(s) • Nominal 5, 10 and 15 ton capacities • Automatic refrigerant pump-down cycle • Single phase 208 and 230 volt (all unit sizes) and three phase 208, 230 and 460 volt electrical service • Spacious galvanized steel cabinet with extruded aluminum framing insulated with 1" 1.5 lb. dual density matte-faced fiberglass insulation • Refrigerant access valves and liquid line filter-driers • Removable front and side panels with tooled access • Front access panels for electrical controls and line power • 24 volt electronic control system with LCD display • ETL certified for indoor and outdoor installations • Exceeds ASHRAE 90.1 requirements for energy efficiency Model ICS 060 ICS 120 ICS 180 Nominal Tons 5 10 15 Gross Cooling Capacity 58,000 Btuh 116,000 Btuh 174,000 Btuh Compressor(s) 1 Scroll 2 Scrolls 3 Scrolls Condenser Coil(s) (1) 46" x 20" (2) 46" x 20" (3) 46" x 20" Face Area (Sq. Ft.) 6.3 12.6 18.9 Rows / Fins Per Inch 4 / 14 4 / 14 4 / 14 Condenser Fan(s) (1) 15" x 10" FC (2) 15" x 12" FC (2) 15" x 15" FC Nominal Air Flow (CFM) 3,300 6,600 9,900 Standard Motor (HP) (1) 2 HP (1) 3 HP (1) 5 HP Motor Speed (RPM) 1750 RPM 1750 RPM 1750 RPM Drive Type V-Belt V-Belt V-Belt Evaporator(s) (1) SS Brazed Plate (2) SS Brazed Plate (3) SS Brazed Plate Refrigerant Circuit(s) 1 Circuit 2 Circuit 3 Circuit R22 Charge per Circuit (lbs.) 8.5 8.5 8.5 Steps of Unloading 100%-0 100%-50%-0 100%-66%-33%-0 Minumim Water Flow Rate (GPM) 6 12 18 Maximum Water Flow Rate (GPM) 18 36 54 Water Connection Nom (In.) 1" NFT 1-1/2" NFT 2" NFT Shipping Weight (lbs.) 540 950 1260 Note: Gross cooling capacity based on 54°F entering water temperature, 44°F leaving water temeprature and 95°F incoming condenser air (ambient) temperature. 1 ICS Series Configuration 2 ICS Series Typical Condenser Air Ductwork Arrangement Typical Water Piping Arrangement Short Water Piping Loop Considerations In systems with relatively short water piping loops, the volume of the water in the system can be insufficient causing swings in water temperature and short cycling. In these cases a chilled water storage tank should be installed in the return water piping before the chiller. This will increase the volume of the water in the system thereby reducing the fluctuations in return water temperature and reduce compressor cycling. The use of three way valves at the evaporator coil (in lieu of 2-way valves) and hot gas bypass is also recommended. Typically allow a minimum of 5 GPM per ton of chilled water storage. 3 ICS Series Performance Cooling Performance Data Model ICS 060 ICS 120 ICS 180 Leaving Water Temp. °F 40 45 50 40 45 50 40 45 50 85°F Ambient Air Temperature Mbh KW EER 56.5 5.5 10.3 61.3 5.6 11.0 66.3 5.7 11.6 112.9 10.9 10.3 122.6 11.2 11.0 132.6 11.5 11.6 169.4 16.4 10.2 183.9 16.8 11.1 198.9 17.2 11.7 Note: • Cooling capacities based on 10°F water temperature drop operating at sea level. • Refer to performance adjustment factors to reflect operation with ethylene glycol solution and altitudes above sea level. 95°F Ambient Air Temperature Mbh KW EER 53.8 6.0 9.0 58.6 6.1 9.6 63.5 6.2 10.2 107.7 12.0 9.0 117.2 12.2 9.5 127.0 12.5 10.2 161.5 18.0 9.1 175.8 18.3 9.6 190.4 18.7 10.1 105°F Ambient Air Temperature Mbh KW EER 50.9 6.6 7.7 55.5 6.7 8.3 60.2 6.9 8.8 101.8 13.2 7.7 111.0 13.4 8.2 120.4 13.7 8.7 152.7 19.7 7.7 166.5 20.2 8.3 180.7 20.6 8.8 • KW and EER ratings are for entire unit. • Minimum incoming condenser air (ambient) temperature for proper operation is 55°F. For ambient temperatures below 55°F, use the low ambient head pressure control accessory. 115°F Ambient Air Temperature Mbh KW EER 48.2 7.2 6.6 52.7 7.4 7.1 57.3 7.5 7.6 96.4 14.5 6.6 105.4 14.8 7.1 114.6 15.1 7.6 144.6 21.7 6.7 158.0 22.2 7.0 171.9 22.6 7.5 • Minimum water temperature drop is 8°F, maximum water temperature drop is 12°F. • Water f low (GPM) is cooling capacity (Btuh) divided by 500 times the water temperature drop (°F). Condenser Fan Data E.S.P. In. W.G. 0.20" 0.25" 0.30" 0.40" 0.60" 0.80" 1.00" 1.20" 1.40" ICS 120 6600 CFM ICS 060 3300 CFM RPM 762 776 789 815 866 915 963 1008 1052 BHP 1.24 1.27 1.31 1.38 1.54 1.70 1.87 2.04 2.21 RPM 784 797 809 835 881 943 976 1035 1068 ICS 180 9900 CFM BHP 2.51 2.59 2.66 2.81 3.30 3.40 3.50 3.65 3.80 RPM 800 813 827 853 903 952 999 1044 1089 BHP 4.47 4.58 4.69 4.90 5.33 5.77 6.22 6.80 7.16 Evaporator Data ICS 060 Water Flow Water Pressure (GPM) Drop (Ft.) 3 0.4 5 1.2 10 4.7 12 6.7 15 10.1 20 17.4 ICS 120 Water Flow Water Pressure (GPM) Drop (Ft.) 6 0.4 10 1.2 20 4.8 25 7.4 30 10.4 40 17.8 4 ICS 180 Water Flow Water Pressure (GPM) Drop (Ft.) 20 2.3 25 3.5 30 4.9 36 6.9 40 8.4 50 14.7 ICS Series Performance Fouling Factor and Elevation Performance Adjustment Factors Fouling Factor Cooling Capacity (Btuh) PAF .0005 .0010 .0020 0.98 0.96 0.90 Compressor Input (KW) PAF Elevation (Ft.) Above Sea Level Cooling Capacity (Btuh) PAF Compressor Input (KW) PAF 2000 4000 6000 0.98 0.94 0.89 1.01 1.02 1.04 0.99 0.98 0.94 Ethylene Glycol Performance Adjustment Factors % Glycol by Weight Freezing Temperature (°F) Water Flow (GPM) PAF Cooling Capacity (Btuh) PAF Compressor Input (KW) PAF 10% 20% 30% 40% 50% 25°F 17°F 5°F -12°F -32°F 1.02 1.04 1.07 1.10 1.14 1.00 0.98 0.97 0.95 0.94 1.00 0.99 0.98 0.98 0.97 Electrical Data Model ICS 060 ICS 120 ICS 180 Electrical Line Power 208-230/60/3 460/60/3 208-230/60/1 208-230/60/3 460/60/3 208-230/60/1 208-230/60/3 460/60/3 208-230/60/1 208-230/60/3 460/60/3 208-230/60/1 208-230/60/3 460/60/3 208-230/60/1 Circuit 1 Circuit 2 208-230/60/3 460/60/3 Condenser Fan Motor FLA HP 5.9/5.4 2.0 2.7 2.0 19.4/17.6 2.0 9.1/8.2 3.0 4.1 3.0 13.0/11.8 3.0 9.1/8.2 3.0 4.1 3.0 13.0/11.8 3.0 14.1/12.8 5.0 6.4 5.0 21.1/19.1 5.0 14.1/12.8 5.0 6.4 5.0 21.1/19.1 5.0 Compressor (each) RLA 20.7 10.0 32.1 20.7 10.0 32.1 20.7 10.0 32.1 20.7 10.0 32.1 20.7 10.0 32.1 20.7 10.0 LRA 156.0 75.0 176.0 156.0 75.0 176.0 156.0 75.0 176.0 156.0 75.0 176.0 156.0 75.0 176.0 156.0 75.0 7.5 7.5 22.1/20.0 10.0 MCA 31.3 15.2 57.7 34.1 16.6 51.9 54.8 26.6 84.0 59.4 28.9 91.3 80.1 38.9 Max. Fuse 52.0 25.2 89.8 54.8 26.6 84.0 75.5 36.6 116.1 80.1 38.9 123.4 100.8 48.9 Rec. Fuse 45 20 75 45 20 75 60 30 100 70 35 110 90 45 59.2 72.2 87.3 42.5 91.3 104.3 108.0 52.5 75 90 100 45 Note: • All 5 and 10 ton 1-phase and 3-phase units and 15 ton 3-phase units have single point line power connection. Single phase 15 ton units have dual point line power connections. • Minimum circuit ampacity calculated per UL formula: MCA = (1.25 x largest load) + the sum of other loads. • Maximum fuse size is calculated per UL formula: Max. Fuse = (2.25 x largest load) + the sum of all other loads. • Time delay fuses and circuit breakers are recommended. 5 ICS Series Dimensions SpacePak ICS WATER CHILLER - PHYSICAL DIMENSIONS (INCHES) MODEL OVERALL DIM’S A B C DUCT DIM’S D E F G WATER CONN. H J K L ELEC. CONN. M N P ICS060 72.06 34.00 27.74 4.00 20.47 48.00 25.09 1.19 4.50 4.39 23.20 43.75 46.75 3.72 ICS120 72.06 34.00 54.10 4.00 20.47 48.00 51.34 1.19 4.28 4.39 23.20 43.75 46.75 3.72 ICS180 72.06 34.00 80.22 4.00 20.47 48.00 77.60 1.19 3.94 4.39 23.20 43.75 46.75 3.72 SPACEPAK RESERVES THE RIGHT TO MAKE CHANGES AND IMPROVEMENTS WITHOUT NOTICE. CONTACT FACTORY AT TIME OF ORDER FOR CERTIFIED DRAWINGS. 6 Sterling AquaKing™ Chiller Model Number Description 1 2 3 UT 4 5 CP 6 7 CA 8 9 10 11 12 13 14+ PL CC RT SV CB CM OP (Internal use Only) All Field Installed Accessories are to be ordered as a separate line items. 1, 2, 3 - Unit Type [UT] ICS - Indoor Ducted Water Chiller FIELD INSTALLED ACCESSORIES AC-A1 - Water Flow Switch AC-A2 - 1" Fine Mesh Fluid Strainer AC-A3 - 11/2" Fine Mesh Fluid Strainer AC-A4 - 2" Fine Mesh Fluid Strainer AC-B1 - 30 Amp Non-Fused Disconnect AC-B2 - 60 Amp Non-Fused Disconnect AC-B3 - 100 Amp Non-Fused Disconnect AC-B4 - 30 Amp Fused Disconnect AC-B5 - 60 Amp Fused Disconnect AC-B6 - 100 Amp Fused Disconnect AC-C1 - Rubber-in-shear Vibration Isolation Package AC-C2 - 4" Caster Kit (4) - Requires Fork Lift compatible base AC-D1 - 30 Gallon Insulated Chilled Water Storage Tank AC-D2 - 60 Gallon Insulated Chilled Water Storage Tank AC-D3 - 90 Gallon Insulated Chilled Water Storage Tank AC-D4 - 30 psi Water Pressure Relief Valve AC-D5 - 100 psi Water Pressure Relief Valve OP-D5 - Low Ambient Head Pressure Control Kit AC-E5 - 5 Ton AC-E6 - 10 Ton AC-E7 - 15 Ton OP-E3 - Condenser Duct Connection Kit with Access Covers AC-H5 - 5 Ton AC-H6 - 10 Ton AC-H7 - 15 Ton OP-G3 - Wall Louver and Sleeve AC-J5 - 5 Ton AC-J6 - 10 Ton AC-J7 - 15 Ton OP-H1 - Condenser 2" Filter Rack AC-K9 - 5 Ton AC-K10 - 10 Ton AC-K11 - 15 Ton 2" Throw-away Filter Set for Condenser Filter Rack AC-K12 - 5 Ton AC-K13 - 10 Ton AC-K14- 15 Ton 4 - Number of Circuits/Compressors [CP] S - Single (5 Tons) D - Dual (10 Tons) T - Triple (15 Tons) 5, 6, 7 - Nominal Cooling Capacity [CA] 060 - 60,000 Btuh (5 Tons) 120 - 120,000 Btuh (10 Tons) 180 - 180,000 Btuh (15 Tons) 8 - Piping Location [PL] (Facing Front of Unit) A - Left Hand (Standard) B - Right Hand 9 - Cabinet Construction [CC] 1 - Galvanized Steel 2 - Painted Steel 3 - Stainless Steel 10 - Refrigerant Type [RT] A - R22 11 - Supply Voltage [SV] 2 3 4 5 6 - 208/1/60 - 230/1/60 - 208/3/60 - 230/3/60 - 460/3/60 12 - Condenser Blower Type [CB] B - Forward Curved Belt Drive 13 - Condenser Fan Motor Size and Type [CM] 1 - 2 HP Open Drip-proof 2 - 3 HP Open Drip-proof 3 - 5 HP Open Drip-proof 4 -7-1/2 HP Open Drip-proof 5 - 2 HP Totally Enclosed 6 - 3 HP Totally Enclosed 7 - 5 HP Totally Enclosed 8 - 7-1/2 HP Totally Enclosed 14 - Factory Installed Options [OP] - All Factory Installed Options are to be entered in the model number Digit #14+. R - Refrigerant Pressure Relief Valve(s) - Chicago Code H - Hot Gas Bypass (One Circuit Only) E - Epoxy Coated Condenser Coil(s) B - Fork Lift Compatible Base P - Freeze Protection (Heaters on Evaporator and Internal Water Piping) W - Water Flow Switch S - Fluid Strainer L - Low Ambient Head Pressure Control New York City MEA Listed Note: Specials in any digit in the model number are designated with a “Z”. 7 ICS Series Suggested Mounting Methods F L O OR MOUNT TYPICAL MOUNTING HARDWARE : (4) 3/4" FLOOR ANCHORS (4) 3/4" NUTS & LOCK WASHERS (4) VIBRATION ISOLATORS (10) LEVELING SHIMS NUT & LOCK WASHER VIBRATION ISOLATORS CONCRETE FLOOR FLOOR ANCHOR E L E VA T E D F L OO R MOUNT TYPICAL MOUNTING HARDWARE : (4) FLOOR ANCHORS (4) LEGS (6 TO 72") (4) VIBRATION ISOLATORS (10) LEVELING SHIMS (8) 3/4" NUTS (8) 3/4" LOCK WASHERS CROSS BRACING OVER 24" 3/4" NUT & LOCK WASHER CROSS BRACE OVER 24" IN HEIGHT 3/4" NUT VIBRATION ISOLATOR 3" DIA. LEG 3/4" LOCK WASHER FLOOR ANCHOR CONCRETE FLOOR 8 ICS Series Typical Wiring 9 ICS Series Specifications Cabinet Refrigerant Circuit(s) The cabinet is constructed from heavy gauge galvanized steel panels with extruded aluminum framing insulated with 1" 1.5 lb. dual density matte-faced fiberglass insulation. Easy service access is provided through panels at each side and front with tooled access. A convenient control box access panel allows the unit to be operating while the controls are accessible. Each refrigerant circuit includes thermostatic expansion valve, refrigerant access valves, liquid line filter-dryer and shipped with an operating charge of R22. Automatic refrigerant pump-down cycle with solenoid valves on each circuit. Compressor(s) Individually circuited compressors are high efficiency hermetic scroll with internal thermal overload protection, internal suspension system, centrifugal oil pump and crankcase heater. Condenser Fan Motor Ball bearing open drip-proof premium efficiency (E+ Type) condenser fan motor with thermal overload protection. Condenser Fan(s) Fans are forward curve centrifugal fans.The fan wheels are statically and dynamically balanced. Dual condenser fans are driven by a common motor. Shaft bearings are permanently lubricated. V-belt drives include a blower pulley, adjustable pitch motor sheave and V-belt. Condenser Coil(s) Coils are constructed from 3/8" OD seamless, internally enhanced copper tube of not less than .012" wall thickness. Aluminum fins are of a die formed, enhanced louver design no less than .0045" thick. Tubes shall be mechanically expanded to assure a good mechanical bond between the tube and fin. Coil manifolds are Type “L” seamless copper tubing. Evaporator(s) Stainless steel brazed plate heat exchangers with working pressures to 450 psig. Evaporator and water lines insulated with closed-cell insulation. Drain plug provided for the water piping. Electrical ETL certified for indoor or outdoor use. Control system shall be 24-volt electronic temperature control with LCD display, compressor contactors, high/low pressure safety controls and line voltage-24 volt control transformer. Antirecycle function standard on all units and automatic compressor lead-lag function standard on all units (except on units with hot gas bypass option). Electronic control system consists of a fully configurable and programmable electronic microprocessor, adaptable to standard LON, N2Open, and BACnet MSTP Building Automation System protocols. Controller shall have capabilities to provide both local (unit mounted) and remotely mounted User Interface modules to distances up to 300 meters. User Interface module shall have a 4 x 20 backlit LCD, IP54 display with an extended operating range from -20°C to +50°C. All units exceed Ashrae 90.1 requirements for energy efficiency. FACTORY INSTALLED OPTIONS Painted Cabinet Same specifications as the standard cabinet, except the exterior of the cabinet is painted in gray color. Stainless Steel Cabinet Same specifications as the standard cabinet, except the exterior panels and bottom base pan are constructed of 430 alloy stainless steel for corrosion resistance with extruded aluminum framing. Fork Lift Compatible Base The units base has fork lift tine openings for handling from any side. Refrigerant Relief Valve(s) Relief valves for each refrigerant circuit installed on the discharge lines and terminated in a 1/2" male fitting for piping to outside of building. Hot Gas Bypass Hot gas bypass valve to modulate the cooling capacity below the minimum step of unloading on one circuit. Epoxy Coated Condenser Coil(s) Same specifications as the standard coils, except the coil is coated with an epoxy type electro-deposition coating highly resistant to corrosive environments. The thickness of the coating is computer controlled at 0.001" (+/0.0002").The coating has a thermal heat transfer reduction of less than 1%. Low Ambient Freeze Protection Thermostatically controlled electric heat tape for freeze protection of the evaporator and water piping. Totally Enclosed Condenser Fan Motor Ball bearing totally enclosed premium efficiency condenser fan motor with thermal overload protection. Fluid Strainer Fine mesh fluid strainer for the water piping. (Also available as a field installed accessory.) Water Flow Switch An interlocking flow switch in the evaporator water piping is required to prevent unit operation without water flow. (Also available as a field installed accessory.) 10 ICS Series Specifications FACTORY INSTALLED OPTIONS (CONTINUED) Low Ambient Head Pressure Control FIELD INSTALLED ACCESSORIES (SHIPPED SEPARATELY) Electrical Disconnect Switches A variable frequency drive on the condenser fan that regulates head pressure to allow operation at low outdoor ambient temperatures down to 0° F (recommended when ambient temperatures fall below 55° F). Includes antirecycle and bypass timers. (Also available as a field installed accessory kit.) Fused or non-fused electrical disconnect switches for the line power. Wall Louver and Sleeve Architectural galvaneal wall louver with screen for the condenser air opening in a wall suitable for painting. Condenser Duct Connection Kit with Access Covers A knocked-down ductwork kit with access covers and flex connectors to connect to the condenser air opening to the wall sleeve, while providing access for cleaning the condenser coil. Casters Heavy duty, large diameter, locking casters to provide portability and ease installations in tight retrofit applications (requires fork lift compatible base option). Vibration Isolation Package Rubber-in-shear isolation package. Chilled Water Storage Tanks Insulated 30, 60 or 90 gallon chilled water storage tank with suitable tappings to serve as a buffer with fluid tappings. Water Pressure Relief Valve 30 or 100 PSI water relief valve. Condenser Air 2" Filter Rack Condenser Air inlet filter rack. Condenser Air Filters 2" pleated throw-away filters for the condenser air filter rack. 11 260 NORTH ELM ST., WESTFIELD, MA 01085 TEL: (413) 564-9571 • FAX: (413) 568-2969 5211 CREEKBANK RD., MISSISSAUGA, ONT. L4W 1R3 CANADA TEL: (905) 325-2991 • FAX: (905) 625-6610 www.spacepak.com In the interest of product improvement, manufacturer reserves the right to make changes in specifications without notice and without incurring obligation to make those changes in previously supplied units.