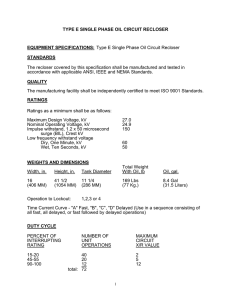

Automatic Circuit Recloser 15kV, 16kA, 630A 27kV, 12.5kA

advertisement

OSM Automatic Circuit Recloser 15kV, 16kA, 630A 27kV, 12.5kA, 630A Tavrida Electric is a specialist in the development and manufacturing of medium voltage switchgear products for indoor and outdoor applications. 20 years ago Tavrida Electric was the first company to introduce a vacuum circuit breaker with magnetic actuators. Through fundamental research into magnetic actuators, vacuum interrupters and insulator design, Tavrida Electric has created the most compact, light weight and reliable circuit breaker device in the market. More than 250,000 vacuum circuit breakers and over 13,000 reclosers installed worldwide make Tavrida Electric a leading manufacturer for medium voltage vacuum switchgear. All of our products have been extensively tested internally and by reputable independent laboratories such as KEMA, CESI, SABS and many more. We maintain a quality system in full compliance with ISO9001-2008 that is externally audited and certified by KEMA. Regional offices in more than 22 countries provide our customers with integrated solutions based on our innovative products combined with unrivalled service. Introduction Tavrida Electric’s autoreclosers are designed for use on overhead distribution lines as well as in distribution substation applications for voltages up to 27kV. Outdoor Circuit Breaker (OSM) The air insulated OSM incorporates Tavrida Electric's vacuum circuit breaker with single coil magnetic actuator in a tank made of corrosion resistant aluminium alloy. The six main circuit bushings are made from UV stable polymer and are completely covered by silicone rubber bushing boots. Each bushing has built-in current and voltage sensors. Recloser Control (RC) The RC is a microprocessor based controller that provides all protection, metering, data logging and communications functions. TELARM TELARM software allows easy communication between a PC and the recloser control. In addition TELARM allows the calculation and testing of best possible protection settings based on real network data taking into consideration upstream and downstream devices. Outdoor Circuit Breaker (OSM) Tavrida Electric’s outdoor circuit breakers provide the following advantages: Environmental Friendly The OSM/TEL 15.5-16/630-204 and the OSM/TEL 27-12.5/630-205 are air insulated outdoor circuit breaker. The patented combined insulation makes them an environmental friendly option. Built for the worst conditions, the OSM has been tested at the KIPTS harsh environment test labs in South Africa, achieving the highest rating for both pollution and weather resistance. Worldwide installations have shown the OSM performing at the most extreme temperatures, from -50��� °C� in Russia to +55����������������������� °C��������������������� in the Middle East. Lowest Weight Tavrida Electric’s light weight vacuum circuit breaker and the robust aluminium tank contribute to the total weight of the OSM of not more than 72kg making this the most light weight outdoor circuit breaker in the market. Consequently shipment, handling and installation are simplified to the greatest extent. Highest Availability 30,000 C-O operations with rated current and 200 operations with full short circuit breaking current without any maintenance makes them the most reliable product in the market. Optimized Measurement All OSMs are equipped with voltage sensors in all six bushings to measure each 3-phase voltages on both recloser sides. Non-saturable Rogowski coils in all 6 bushings guarantee high accuracy over a wide measurement range. They measure 3-phase currents and residual currents simultaneously. 1 2 3 1. Terminal 4 2. Six HV bushings 5 3. Current transformers built into the bushings 6 4. Vacuum circuit breaker 5. Protective tank 7 8 6. Mechanical position indicator 7. Manual trip operation mechanism 8. Protective lid with Harting connector 9 The OSM is provided with six main circuit bushings manufactured from UV stable polymer. They are covered by light grey silicone rubber bushing boots which provide a creepage distance of 500mm for the 15.5kV and 860mm for the 27kV version. Each OSM is equipped with a vacuum circuit breaker. Tavrida Electric has simplified the mechanical structure of the vacuum circuit breaker to the greatest possible degree. It uses three single coil magnetic actuators, one per pole. All switching elements are assembled along a single axis. All mechanical movements are therefore direct and linear. The three actuators are mounted in a steel frame and mechanically linked by a synchronizing shaft. The result is 30,000 C-O cycles at rated current or 200 operations at full short-circuit breaking current without the need to replace or adjust any parts of the vacuum circuit breaker. Tavrida Electric’s vacuum circuit breakers are entirely maintenance free over a total life expectancy of at least 25 years. The position indicator is located under a protective cover at the bottom of the tank and is clearly visible from the ground. The indicator colour is red when the OSM is closed and green when it is open. The OSM can be mechanically tripped using the mechanical hook stick operated lever in the base of the tank. When pulled down the OSM is mechanically locked in the OPEN position and electrically interlocked against closing. Until the hook stick lever is pushed back in the closed position the OSM remains locked and cannot be electrically operated. 9. Support rail Recloser Control (RC) The RC is a microprocessor based controller that provides directional overcurrent, earth fault and sensitive earth fault protection, auto reclosing, instantaneous metering, event log, demand logger and RTU for remote control in a single enclosure. The protection functions support applications such as radial line or ring line reclosers. Communication is supported by DNP3 and Modbus protocols. The operator panel is provided with a 6-line backlit LCD, a USB port and a keypad to provide local control functions. RC-05 The power supply module provides the auxiliary power supply, radio power supply and battery charging function. The power supply module accepts a range of 85 - 265 V AC and DC. Temperature compensated float charging is provided to the sealed lead acid batteries located in the RC control cubicle. Space is provided inside the RC control cubicle to install any communications equipment to be connected to the in-built RTU or I/O module. The cubicle is constructed out of powder coated aluminium for a long, maintenance free lifetime. The roof features a ceramic based insulating coating that provides a 16C reduction in internal temperature when the cubicle is exposed to 1.1kW of solar radiation. Protection The RC allows protection against the following types of faults: • Short circuit fault • Bolted fault (the bolted fault element works independently from the short-circuit protection elements and thus provides more settings flexibility) • Single-phase and double-phase earth-faults • High-resistive earth fault and leakage current • Upstream and downstream broken wire • Undervoltage Overvoltage • Underfrequency • The RC also provides hot line tag and advanced algorithm for zone sequence coordination. Loss of supply protection and automatic backfeed restoration allows for a smart power backup with automatic isolation of the faulty section whereby two feeders are tied by a ‘normally open’ recloser. Measurement Voltage and current is measured on all six bushings of the OSM: Value Range Accuracy the greater of ± 1% or ± 2A the greater of ± 5% or ± 5A Phase currents 0…7,000A Residual current 0…7,000A Positive sequence current 0…7,000A Negative sequence current 0…7,000A Positive sequence voltage 0…18kV Negative sequence voltage 0…18kV the greater of ± 1% or ± 0.1kV the greater of ± 1% or ± 0.1kV Frequency 40…65Hz ± 0.025Hz Single phase power factor 0….0.01 ± 0.02 Three phase power factor 0…0.01 ± 0.02 Phase-to-earth voltages 0…18kV Phase-to-phase voltages 0…30kV the greater of ± 1% or ± 0.1kV the greater of ± 1% or ± 0.1kV Positive sequence active power 0…65,535kW ± 2% Single-phase active power 0…65,535kW ± 2% Three-phase active power 0…65,535kW ± 2% Single-phase reactive power 0…65,535kVAr ± 2% Three-phase reactive power 0…65,535kVAr ± 2% Single-phase active energy 0…9,999,999kWh ± 2% Three-phase active energy 0…9,999,999kWh ± 2% Single-phase reactive energy 0…9,999,999kVArh ± 2% Three-phase reactive energy 0…9,999,999kVArh ± 2% the greater of ± 1% or ± 2A the greater of ± 1% or ± 2A Logs The RC provides an event log, time and date stamped with a resolution of 0.001 sec. The log is viewable from the LCD display and provides critical operations data for the linesman such as close/trip operations, fault types, phase and peak level of fault current and autoreclosing. The full log with all operational history including setting change, operational and fault history logs is viewable on PC with TELARM. Load profile is logged with a user configured integration period of 5, 10, 15, 30 or 60 minutes. The following parameters are logged separately for both positive and negative power flow: • 3 phase kW, kVA and kVAr • 1 phase kW, kVA and kVAr for each Up to 3840 events can be stored in the memory which corresponds to 160 days with a 60 minute integration period. TELARM software can be used to upload and plot the data. An outstanding feature of the RC log is its ability to provide a fault profile. Each time the controller detects a fault in the line, it is recorded and can be downloaded and viewed on a P.C at a later stage. The fault profile consists of measured and calculated fault parameters and recloser protection elements statuses. Starting from the fault appearance the RC records fault parameters like phase currents, zero sequence current and positive/negative sequence voltages every cycle until the recloser trips. This allows to analyze evolving faults. Up to 10,000 records can be stored in the RC. The fault profile supplies the engineer with all the data required for an in-depth analysis of each fault. TELARM A significant issue for any recloser commissioning is to be certain that the settings will properly protect the grid. The existing method of developing protection settings is highly complex. A protection and control design is based on a single-line diagram, indicating the bus arrangement and components such as reclosers, generators, power transformers, fuses, and capacitors. Third-party software tools are widely used for the calculation. These tools are often not compatible and demand manual transfer of results into the recloser controls. Once the protection settings have been developed the design then has to be tested with different fault scenarios in order to ensure that the grid is adequately protected. The RC-05 is designed to work with Tavrida’s TELARM recloser software. TELARM has been designed to eliminate the extraordinary complexity of calculating and testing of optimal recloser settings. Tavrida Electric offers a complete hardware and software solution that allows the engineer to: Conveniently and accurately model the distribution grid with intuitive single line diagrams • Configure all recloser settings • Automatically calculate optimum recloser settings based on real network data • Simulate and test the recloser settings even under the most complex fault scenarios in the realistic modelled real network environment • Upload the tested settings directly to the recloser control • Download settings and log data from the recloser control • Generate graphs of fault and load profile data • With an increasingly complex grid, TELARM represents a true SmartGrid solution. With recloser controls offering an almost exponential number of possible settings, TELARM solves the problem of determining the optimal settings and thereby utilizing the full advantages of a recloser network. Recloser Settings Calculation - the TELARM Way step 1: Using easy graphic editor to model your grid with all the protection devices installed. step 2: Automatically calculate protection settings of the installed reclosers. Settings will be automatically coordinated with existing protection devices like fuses. step 3: Simulate and verify the grid behaviour under normal and fault operating conditions. step 4: Download settings to devices installed in real feeder. TELARM Dispatcher Interface The TELARM Dispatcher Interface allows remote communication with the OSM reclosers via Internet. SSL technology is used to secure communications with the reclosers. TELARM can be connected to all reclosers simultaneously. Selectable indication signals can be displayed in the network diagram near the corresponding recloser. User-Defined Data Generator (UDDG) The RC supports the generation of user-defined signals. For this purpose TELARM provides graphical editor with easy and intuitive interface for the schematic drawing of a special signal. Any indication signal can be processed using the set of operators (logical OR, AND, XOR as well as relay and trigger). A sample circuit is shown which generates an alarm signal when the current in either of 3 phases exceeds the level of 50A. User defined signals are available through any communication interfaces supported in RC. Outdoor Circuit Breaker (OSM) Basic Operating Parameters OSM/TEL 15.5-16/630-204 OSM/TEL 27-12.5/630-205 Rated data Rated voltage (Ur) 15.5 kV 27 kV Rated power frequency withstand voltage (Ud), 1 min dry 50 kV 60 kV Rated power frequency withstand voltage, 10 s wet 45 kV 50 kV Rated lightning impulse withstand voltage (peak) (Up) 110 kV 125 kV 1) Rated current (Ir) 630 A Cable charging current 31.5 A Line charging current 10 A Rated short-circuit breaking current (Isc) 16 kA Rated peak withstand current (Ip) 40 kA 31.5kA Rated short-time withstand current (Ik) 16 kA 12.5 kA 4s 4s Rated duration of short ciruit (tk) 12.5kA Rated frequency (fr) 50/60 Hz Switching performance Mechanical life (CO-cycles) 30,000 Operating cycles, rated current (CO-cyles) 30,000 Operating cycles, rated-short circuit breaking current (O-operations) 200 Closing time, not more than 77 ms Opening time, not more than Rated operating sequence 32 ms O-0.1s-CO-1s-CO-1s-CO Standards IEC 62271-100 IEC 62271-200 IEC C37.60-2003 Standards Other data Resistance of main circuit Weight < 85 µOhm < 95 µOhm 65 kg 70 kg Altitude 3000 m (above 1000m derating according to ANSI C37.60) Humidity 100%, condensing 1.1 kW/m2 Solar radiation ≤ Temperature range -40�� °C...+55�� °C Type of driving mechanism Pollution level Monostable magnetic actuator very heavy (as defined in IEC 60815) Recloser Control (RC) Value Basic Operating Parameters RC/TEL-05E Rated frequency 50/60 Hz Rated cubicle (auxiliary) supply voltage 85...265 V AC/DC Rated operating sequence O-0.1s-CO-1s-CO-1s-CO-60s Degree of protection IP54 Temperature range -40�� °C...+55�� °C Maximum humidity 100 % Maximum altitude above sea level 2000 m Vibration endurance (Pole mounted) IEC 60255-21-1 Class 1, test acceleration 1.5g Vibration response (Pole mounted) IEC 60255-21-1 Class 2 Shock response (Pole mounted) IEC 60255-21-2 Class 1 Bump GOST 17516.1-90, class M7, GOST 16962.2-90 Seismic Operating time after loss of auxiliary supply - at +25�� °C - at -40�� °C - at +55�� °C IEC 60255-21-3 Class 1 2), hours,not less: 48 12 48 RTU power supply: - voltage range - max output power - max output power at 0.5 duty cycle (range 12-15 V) 5...15 V, step 0.5 V 15 W 30 W Maximum power consumption of RC from auxiliary supply 60 W Weight Dimensions Notes: 1) 150kV on request 2) Without providing power for RTU and USB, without IOM, CPM off 3) Battery, IOM and RTU are not included. 29 kg 3) 450x860x390 mm Australia China Tavrida Electric Australia Pty Ltd. 5/490 Frankston Dandenong Road Carrum Downs Victoria 3201 Australia Phone: +61 3 97867444 Fax: +61 3 90119681 E-Mail: info@tavrida.com.au Web: www.tavrida.com.au Tavrida Electric (Beijing) Co., Ltd. First Floor West, Building 11, No. 28 Yuhua Road, Area B, Beijing Airport Industrial Zone, 101300 Beijing, China Phone: +86 (10) 8049 2474/5474 Fax: +86 (10) 8049 7114 E-Mail: info@tavrida.cn Web: www.tavrida.cn Germany India Tavrida Electric GmbH Georgstr. 7, 88069 Tettnang Germany Phone: + 49 (0) 7542 9467851 Fax: + 49 (0) 7542 9467861 E-Mail: info@tavrida.de Web: www.tavrida.de Tavrida Electric India Private Limited 15 NC, Block-A, New Alipore Kolkata - 700 053, West Bengal, India Phone: +91 33 2488 1715/3260 8634 Fax: +91 33 2488 1766 E-Mail: info@tavrida.in Web: www.tavrida.in South Africa Switzerland Tavrida Electric Africa (Pty) Ltd. Cnr.Van Dyk and Commissioner Streets Boksburg East, Gauteng, Republic of South Africa Phone: + 27 11 9142199 Fax: + 27 11 9180584 E-Mail: info@tavrida.co.za Web: www.tavrida.co.za Tavrida Electric AG Rheinweg 4, 8200 Schaffhausen Switzerland Phone: + 41 (0) 52 630 26 00 Fax: + 41 (0) 52 630 26 09 E-Mail: info@tavrida.ch Web: www.tavrida.ch If your country is not listed above please consult www.tavrida.com to find your nearest Tavrida Electric partner. This document is copyright and is intended for users and distributors of Tavrida Electric product. It contains information that is the intellectual property of Tavrida Electric and the document, or any part thereof, should not be copied or reproduced in any form without written permission from Tavrida Electric. 1600-PG-001 Recloser PG EN 06/2010 Tavrida Electric applies a policy of ongoing development and reserves the right to change product without notice. Tavrida Electric does not accept any responsibility for loss or damage incurred as a result of acting or refraining from action based on information in this Product Guide.