MESSKO® MPreC® PrESSurE rEliEf DEviCE SAfETy GuArANTEED.

advertisement

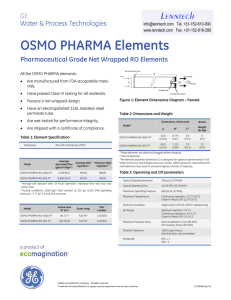

MESSKO® MPreC® PrESSurE rEliEf DEviCE SAfETy GuArANTEED. M ES SKO iN S Tr u M E NTS MESSKO ® MPreC ® MESSKO® MPreC® – SOMETHiNG yOu CAN rEly ON. MESSKO® MPreC® are pressure relief devices for transformers and tap changers – in Messko’s reputable high quality. Our objective has to improve and expand existing functions. Demands on transformer equipment are rising steadily. As operating times increase, reliable monitoring equipment becomes essential. For your safety „The increasing number of spurious release cases and leakage in pressure relief devices results in a great deal of expenses for us, through the resulting on-site service.” We have been listening to such comments during more and more visits to customers in recent years. That is reason enough for us to provide relief. Quality you can feel your fingers can tell you what differentiates Messko pressure relief devices from the rest. No perceptible sharp edges; perfect fits; high-quality materials. Selected material MESSKO® MPreC® Pressure Relief Device Each and every part is tested for months and optimised in our Messko and Mr testing laboratories. Perfectly adjusted springs, optimised seals, tested components and functional design demonstrate our know-how. For more precision if you want to protect your transformers and tap changers, you can not settle for less than the highest quality. We exclusively use high-quality materials – such as saltwaterproof, cast aluminium and anodised aluminium. We make our KTl-coated springs according to EN 10270-1-SH. We purposely avoid the use of galvanised, lacquered or plastic components. KTL–coated springs Functionality you can count on. If the maximum permissible opening pressure in the tap changer or transformer pressure relief device is exceeded, the cover lifts and the device opens – within milliseconds. When the pressure falls back below the opening pressure, the device closes once again. Subsequently, the self-engaging signal pin just has to be pressed back into its normal position. The optional signalling contacts are also reset. With self protection Our pressure relief device protects itself with a saltwaterproof cap. This cap shields all functional components from external influences. This means that neither damage nor impurities can influence its release performance. With optimal characteristics The internal signalling contacts and the valve disk are protected from direct environmental influences through its standard integrated cover. The outlet openings provide for immediate, downward oil drainage. The indicator pin is made of weather-resistant anodised aluminium. It possesses two notches that prevent the pin from falling back if it has not completely sprung up, e.g. in the case of weak oil currents. This ensures its clear release and engagement. Signal pin, switching contact During normal operation, a pressure relief device should have a tight seal. However, in cases of malfunction, it must release promptly and transmit the corresponding signal. This prevents the transformer and/or tap changer from suffering more serious damage. With MESSKO® MPreC®, we have succeeded in optimising this core function. For more safety The switching contacts are situated inside the device; this ensures absolute stability. In addition, they are also protected from UV exposure, hail or hot gushes of oil. The internal seals are slanted toward the valve disk. This enables them to seal better and prevent spurious releases. Up to two further contacts can be installed in the device or even retrofitted without complication. With a reaction time of less than 2 ms – which corresponds to a defined pressure relief valve lift of approx. 4 mm – the optional switching contacts are forced to react. With directed oil flow The pressure relief device can be optional equipped with a special cover to direct the hot oil to a containment device in case of fault condition. The piping can be easy fitted to the cover via the flanges (welding neck flange and flange with an internal thread). The „oil directed” version of the MESSKO® MPreC® helps to ensure employee safety, addresses environmental concerns and avoid time and cost intensive cleaning. MESSKO® MPreC® „Oil directed” PrODuCTiON WiTH AN EyE fOr DETAil. A product is only as good as its components. That’s why we pay especial attention to detail in the production of individual parts: We exclusively use high-quality materials and exceptional production processes for the better protection of your transformer or tap changer – and thus yourself. It pays to be precise Stringent quality testing is an integral part of the assembly process with regard to the protection area of the transformer and tap changers: Each device is checked for leaks using helium. in addition, the „sealing” and „release” functions are inspected on Messko‘s fully automated test bench. At the site of the final inspection, multiple activation testing is performed. The response characte-ristic curve – at the time of delivery and according to the values specified by the customer – is recorded. These data are accessible for each device sold even after a period of years. Computer-controlled pressure test Each device that leaves our production line has its own „history”. At the start of each and every assembly procedure, it is subjected to a helium leakage test. A tradition of successful applications The MESSKO® MPreC® pressure relief devices are primarily used for tap changers or transformers. The MESSKO® MPreC® was developed over months of dialogue with international OEMs and end-user. As a result, we have achieved functional improvements in comparison to conventional systems. Whether a large distribution transformer or a power transformer – the MESSKO® MPreC® will reliably protect your equipment from extended downtime. A separate report is written for each individual test. This is a safety guarantee for our customers that our employees confirm by signature. Even more safety with the mobile MESSKO® MPreC® test bench MESSKO® MPreC® – mounted on an on-load tap-changer Messko GmbH developed the mobile MESSKO® MPreC® test bench as an additional safety package during the commissioning, inspection and maintenance of pressure relief valves. Weighing approx. 50 kg [110 lb], it is portable and can be used in the laboratory, in the test bay and also during commissioning and maintenance procedures. The test bench tests and logs the accuracy and functional safety of pressure relief devices on oil-filled transformers in the disassembled state. MESSKO® MPreC® test bench with pressure relief valve installed MESSKO® MPreC® – Pressure Relief Device. Technical Data: MESSKO® MPreC® Materials Flange Seawater resistant cast aluminum Standard cover Aluminium, with powder coating in RAL 7033 or RAL 7038 Oil directed cover Seawater resistant cast aluminum, with powder coating in RAL 7033 or RAL 7038, cover and flange sealings Nitrile (NBR), internal sealing Fluorocarbon rubber FKM (Viton®) Valve head Stainless steel (1.4301) Sealing Nitrile (NBR); Fluorocarbon rubber FKM (Viton®) (optional) Springs Spring steel acc. EN 10270-1-SH, synthetic coated (cathodic corrosion protection) Indicator pin Seawater resistant aluminum, red or blue anodized Semaphore Stainless steel with acrylic coating in RAL 1026, Lime-yellow Bleed screw Stainless steel for oil bleeding, optional without bleed screw Dimensions Mounting Ø 235 mm (Ø 9.25”) hole circle with 6 fixing holes Ø 15.5 mm (Ø 0.61”) Cover Ø 291 mm (Ø 11.46”) Height Position “OPERATION”: 184.5 mm (7.26”); position “ALARM”: 234.5 mm (9.23”) With semaphore: Position “OPERATION”: 230 mm (9.06”); position “ALARM”: 340 mm (13.39”) With oil-directed cover: Position “OPERATION”: 196.5 mm (7.74”); position “ALARM”: 246.5 mm (9.71”) Weight With standard cover: approx. 6 kg (13 lb) With oil-directed cover: approx.13 kg (29 lb) Mounting gasket Ø 200 x Ø 178.5 x 4.25 (Ø 7.87” x Ø 7.03” x 0.17”), nitrile (optional available) Operating temperatures Ambient –50 °C to +80 °C / -58 °F to +176 °F (mechanical); –40 °C to +80 °C / -40 °F to +176 °F (micro-switches) Oil -30 °C to +120 °C / -22 °F to +248 °F Micro-switches Housing material Seawater resistant cast aluminum Contacts Per micro-swith 1 x NO, 1 x NC; galvanically isolated Connection types Cable gland connection with 1 x or 2 x M 20 x 1.5 cable gland Terminal Box with 1 x or 2 x M 25 x 1.5 cable gland ANSI connector with 16 AWG, SOOW cable, available in different lengths Utilization category IEC 60947-5-1: AC-15/DC-13 Contact load As per IEC 60947-5-1: AC: 240 V/3 A; 120 V/6 A DC: 250 V/1.1 A; 125 V/2.2 A Max. continious current 10 A Rated insualtion voltage AC: 2,5 kV/1 min. Pressure ranges: Type PSI Bar kPa LMPRD 04 4 PSI ± 1 0.28 bar 28 kPa LMPRD 06 6 PSI ± 1 0.41 bar 41 kPa LMPRD 08 8 PSI ± 1 0.55 bar 55 kPa LMPRD 10 10 PSI ± 1 0.69 bar 69 kPa LMPRD 12 12 PSI ± 1 0.83 bar 83 kPa LMPRD 15 15 PSI ± 2 1.03 bar 103 kPa LMPRD 20 20 PSI ± 2 1.38 bar 138 kPa LMPRD 25 25 PSI ± 2 1.72 bar 172 kPa LMPRD 30 30 PSI ± 2 2.07 bar 207 kPa Messko GmbH Gewerbegebiet An den Drei Hasen Messko-Platz 1 61440 Oberursel, Germany Phone: +49 6171 6398 0 fax: +49 6171 6398 98 E-mail: info@messko.com www.messko.com Please note: The information contained in all of our publications may differ in detail from the actual equipment delivered. We reserve the right to make changes without notice. iN2065/06/01 EN – MESSKO® MPreC® – MS99093105 – 03/15 – ©Messko GmbH 2015