• Cognizant 20-20 Insights

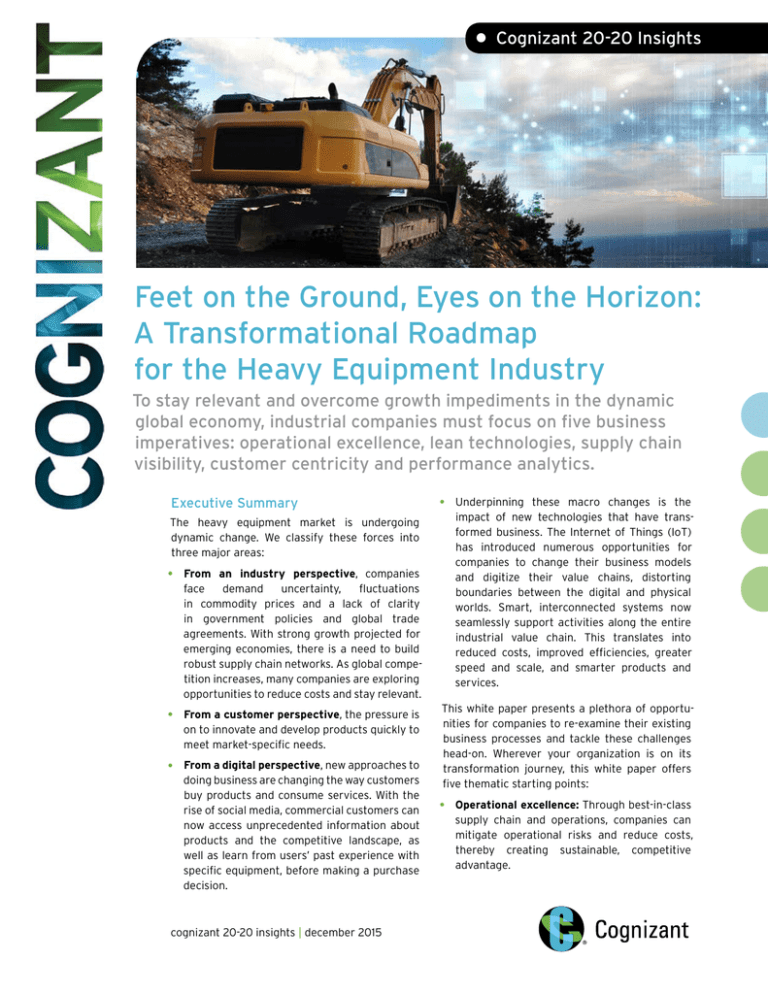

Feet on the Ground, Eyes on the Horizon:

A Transformational Roadmap

for the Heavy Equipment Industry

To stay relevant and overcome growth impediments in the dynamic

global economy, industrial companies must focus on five business

imperatives: operational excellence, lean technologies, supply chain

visibility, customer centricity and performance analytics.

Executive Summary

•

The heavy equipment market is undergoing

dynamic change. We classify these forces into

three major areas:

•

From an industry perspective, companies

face

demand

uncertainty,

fluctuations

in commodity prices and a lack of clarity

in government policies and global trade

agreements. With strong growth projected for

emerging economies, there is a need to build

robust supply chain networks. As global competition increases, many companies are exploring

opportunities to reduce costs and stay relevant.

•

From a customer perspective, the pressure is

on to innovate and develop products quickly to

meet market-specific needs.

•

From a digital perspective, new approaches to

doing business are changing the way customers

buy products and consume services. With the

rise of social media, commercial customers can

now access unprecedented information about

products and the competitive landscape, as

well as learn from users’ past experience with

specific equipment, before making a purchase

decision.

cognizant 20-20 insights | december 2015

Underpinning these macro changes is the

impact of new technologies that have transformed business. The Internet of Things (IoT)

has introduced numerous opportunities for

companies to change their business models

and digitize their value chains, distorting

boundaries between the digital and physical

worlds. Smart, interconnected systems now

seamlessly support activities along the entire

industrial value chain. This translates into

reduced costs, improved efficiencies, greater

speed and scale, and smarter products and

services.

This white paper presents a plethora of opportunities for companies to re-examine their existing

business processes and tackle these challenges

head-on. Wherever your organization is on its

transformation journey, this white paper offers

five thematic starting points:

•

Operational excellence: Through best-in-class

supply chain and operations, companies can

mitigate operational risks and reduce costs,

thereby creating sustainable, competitive

advantage.

•

Lean technology landscape: Having a lean

technology landscape from an IT perspective

can increase employee productivity, improve

business processes and reduce costs.

•

Global supply chain visibility: With better

visibility, companies can track sales, products

and components up to the final destination

through availability of real-time data.

•

Customer-centric innovation: This will be

driven through implementation of systems

that enrich the customer experience through

customer process-driven innovation.

•

Performance and analytics: A strong analytics

backbone can help companies identify opportunities to not only strengthen their decisionmaking capabilities but also improve partner

and supplier performance effectiveness.

ties for equipment sales.10 New technologies are

driving demand for equipment replacement, as

the enhanced efficiency often increases the economic feasibility of more frequent replacement of

equipment.11 We believe the following imperatives are needed

for heavy equipment companies to successfully

respond to these market forces.

•

Focus on growth through emerging markets:

With countries such as China and India

exhibiting steady economic growth, industrial

equipment makers need to provide customized

solutions to smaller farmers and provide them

with attractive finance schemes to increase

equipment affordability.

•

Build a world-class distribution network:

To enter emerging markets, it is essential

for companies to understand their supply

chains and build a strong distribution network,

customized to specific regions. Measures must

also be in place to mitigate risk and ensure

order fulfillment capabilities across locations.

The Heavy Equipment Marketplace

The heavy equipment market comprises three

industries: agricultural machinery (sized at about

$126 billion in 20131), construction equipment

(valued at $138.5 billion in 20122) and mining

equipment (valued at $71 billion in 20123).

Global demand for agricultural equipment is

forecast to expand 6.9% annually through 2018,

to $208 billion.4 The Asia/Pacific region, which

accounted for almost half (46%) of agricultural

equipment demand worldwide in 2013,5 according to the latest figures available, represents the

largest and fastest growing regional market.6 In

more developed markets, such as the U.S. and

Western Europe, growth in agricultural equipment

demand will be driven by efforts to reduce inputs

and maximize production capabilities through the

use of increasingly advanced high-value precision

farming technologies, such as global positioning

systems and yield monitors.7

• Sell smart products and services: Customers

want to optimize their resources and maximize

their returns. Therefore, companies need

to offer solutions that remotely monitor

equipment performance and usage patterns,

as well as generate reports that will provide

customers with real-time visibility into their

daily activities and assist them in running their

business more efficiently.

•

Forces Impacting the Industry

Industry advances are being propelled by the

growth of developing economies, government

support, access to capital and increasing mechanization of farming operations in developing

countries, with particularly sizable gains anticipated in China, India and Brazil.8

Ongoing economic expansion, population growth

and rising per capita calorie intake in these and

other developing nations is boosting demand

for food.9 This will not only place greater pressure on agricultural sectors to boost efficiency

and productivity, but it will also increase farm

incomes, thus creating additional opportuni-

cognizant 20-20 insights

Develop a 360-degree customer perspective: Companies must understand customers

holistically by gathering local data, ensuring

and sustaining customer engagement through

quality content and addressing their issues

immediately by putting early-warning systems

in place. This will boost customer confidence

and the company’s reputation.

Competitive View

The global market is dominated by large multinational players, such as Caterpillar, CNH, Deere &

Co., Komatsu, AGCO, Kubota, etc. These players

have large, diversified business portfolios, selling products and services in construction and

agriculture. Business diversification helps these

companies mitigate market risk and ensure

they are not overly dependent on one specific

industry. All these companies have a global focus,

and some sell their equipment under different

brand names and with a specific regional and

product focus.

2

To understand how the market performed, we

analyzed the key efficiency ratios for the past

10 years of multinational players such as John

Deere, Komatsu, CNH, AGCO and Caterpillar. Our

observation is that the industry growth has tilted

to the negative side of the ledger;12 in fact growth

has been significantly lower for companies with

mining exposure such as CAT.13 Competition has

also impacted profit margins, while revenues

remained flat for 2013-2014.14 From our below

analysis, we have observed trends in certain

areas, indicating opportunities for improved operations and efficiencies.

•

Cash conversion cycle: This has exponentially increased for multiple companies over

the years, indicating that cash is tied up in

the business, impacting the bottom line. For

example, Deere’s cash conversion ratio has

risen about 2,000% since 2005.15

•

Days in inventory: An increase in days in

inventory indicates a company is taking more

time to convert its finished goods into sales.

For example, Komatsu’s days in inventory has

risen by almost 60% since 2004.16

• Asset

turnover ratio: All companies studied

have generated less revenue per dollar of

asset, with the ratio deteriorating between

2011 and 2014. This signifies excess production

and poor inventory management. Stagnating

sales growth over the past few years has also

negatively impacted these ratios. For example,

CAT has seen a 20% reduction in asset turnover

since 2005.17

These trends could be primarily attributed to

deceleration in the U.S. and EU markets, and a

slow shift of focus from mature markets to emerging markets. They also highlight the need for

effective distribution networks that can aggressively enter new markets, increase customer

focus and provide customized solutions that add

value to client relationships. Inventory levels

have also built up over the years, indicating the

potential to improve supply chain management.

Measuring Digital Footprints

The rise of technology platforms has put manufacturers in the driver’s seat. Companies are

improving their ability to develop their own technology platforms that offer real-time information

Correlating Business Mandates with Needs

IMPERATIVES

CAPABILITIES

Industry view

• Focus on cost reduction and maintaining competitiveness.

• Accelerated emphasis on global growth through

emerging markets.

• Focus on exceptional quality and innovative

products to capture market share.

• Utilize innovative ways of working to gain better

business and customer insights.

Digital technology view

• Digitization of value chain through IoT, thereby

transforming operations processes.

• Smarter connected products — telematics and

remote diagnostics.

• Rise of technology platforms, mobile devices and

social media offering real-time information to

customers.

Customer view

• Shift in customer need from products and services

to outcomes.

• Need for customized online content to manage

sentiment and enrich user experience.

• Need for intelligent products that reduce TCO and

provide quick ROI.

Figure 1

cognizant 20-20 insights

3

Operational excellence

Achieve operational excellence

through best-in-class supply

chain and operations.

Lean technology landscape

Make the existing technology

landscape lean and mean.

Global supply chain visibility

Build global visibility capabilities to stay on top of operations.

Customer-centric innovation

Use innovation to improve

customer touchpoints.

Performance and analytics

Build a strong analytics

backbone designed for the

future.

2

#

about farms, machines, equipment health monitoring, fleet management and area harvested.

Platforms such as MyJohnDeere18 provide the

blueprint for how companies will forge new value

chains on the fly to build, connect and deliver

applications specific to industry problems.

With Internet access exploding exponentially, particularly across undeveloped markets, and with

the rise of mobile devices, businesses are now

shifting their focus to creating online marketing

content. Relative to cloud-based transformation,

companies are either creating their own ecosystem (e.g., AGCO’s Open Approach, which is built

on the company’s Fuse™ technology platform19)

or partnering with companies on public platforms

(e.g., CNH as an active member of Open Ag Data

Alliance20) to share cross-industry information

and improve business processes.

With increased use of social media, industrial equipment companies need to find the right

balance of managing reach and content; online

reputation is key, as sentiments in different

channels play an important top-line role. On the

mobile front, only a few customers use mobile

apps for agriculture management. This indicates that companies lack a modern strategy for

understanding customers and their product preferences and need to encourage more use of the

mobile platform.

Key Takeaways

Given the industry’s historical performance, there

are many lessons to learn from companies in

other industries.

•

Deeper

contextual

understanding

of

customers helps capture greater revenue and

improves operational effectiveness. Managing

big data will help businesses gain insights.

• Seamless

integration of digital and physical

supply chains can deliver comprehensive

solutions for customers.

•

Cross-industry collaboration and integrated

partners in the supply chain will help advance

business process improvement and decisionmaking.

• Smart products and the IoT can be leveraged

for performance monitoring across the value

chain to improve customer relationships and

conduct remote diagnostics or aftermarket

services.

Capabilities Surfaced by an Effective

Transformation Roadmap

Based on the aforementioned trends, it is clear

that the industry needs to increase its focus on

growth and efficiency imperatives. Figure 1 (previous page) highlights five capabilities that are

essential to streamlining operations, reducing

costs, understanding customer needs, driving

sales growth and sustaining leadership.

Capability #1: Operational Excellence

This is a key capability that industrial equipment

players must adopt to execute their business

strategy with consistency and reliability. Through

best-in-class supply chain and operational strategies, companies can mitigate risk and reduce

costs, thereby creating a sustainable competitive

advantage. Figure 2 reveals how organizations

can achieve operational excellence.

Attaining Operational Excellence (continued on next page)

Transformation Approach

Procurement risk management

How It Works

Helps standardize supplier

risk assessments and contract

management processes; enables

creation of a single online

repository for vendor and supplier

due diligence and contracts.

Figure 2

cognizant 20-20 insights

4

Example

In March 2015, AGCO was

awarded for actualizating

innovation in e-procurement

by rolling out a global

procurement transformation

effort in its materials and

supplier management function.

The company enabled global

commodity managers and buyers

to pool their experiences and

activities to make decisions

based on greater visibility into

supplier performance, as well as

identify and assess economic,

geopolitical and other risks.21

Attaining Operational Excellence (continued)

Transformation Approach

Dealer sales incentive

management

How It Works

Example

Provides a one-stop solution for

all sales incentive management

tracking by enabling incentive

planning, execution (e.g., marketing

campaigns,

promotions)

and

collaboration.

Caterpillar wants its dealers

to move more customers into

equipment management solutions.

By installing cameras, sensors and

satellite-based positioning control

and guidance systems on its

machines, Caterpillar believes its

dealers can use this information

to increase parts and service sales,

and help customers manage their

fleets more efficiently.22

Accurately estimates order

fulfillment across locations and

enables companies to ”make

anywhere” and “sell anywhere.”

Example: Texas-based

Commercial Metals Company

(CMC) implemented GATP

in its U.S. and international

operations, eliminating duplicate

work in its fabrication shops

when it comes to logistics and

inventory management. GATP

allowed the company to allocate

inventory among different

customers, protect inventory for

priority customers and react to

unforeseen changes in demand.23

Global availability to promise

(GATP)

Figure 2

Capability #2: Lean Technology Landscape

Having a lean technology landscape from an IT perspective can increase employee productivity, improve

business processes and reduce costs. Figure 3 offers ideas on how to implement lean.

Implementing Lean

Transformation Approach

How It Works

Provides an app store-based

approach to delivering employee

services; on-demand data

provisioning can be made easily

available at the click of a button.

We have implemented an

enterprise-wide app store

(One Cognizant) approach that

allows employees to access

multiple apps and other related

content from one location to

perform their jobs better; the

store’s social design encourages

collaboration and sharing with

others performing the same task.

Digitizes back-office processes

(finance, HR, admin) through

electronic workflow management

and approvals, digital signatures

and on-demand reports, reducing

use of paper and boosting efficiency

and productivity.

Volvo in the Netherlands

has implemented e-invoicing

solutions to digitize workflows,

improve financial reporting and

increase the speed of reporting,

thereby supporting faster

decision-making.24

App store

Paperless back office

Example

Figure 3

cognizant 20-20 insights

5

Figure 4

Capability #3: Global Supply Chain Visibility

As supply-demand networks become increasingly

complex and data is available in real time, global

supply chain visibility will allow companies to

more effectively track sales, products and com-

ponents through the final destination. Figure 4

details ways for industrial equipment companies

to move quickly and mitigate risk, thereby allowing them to stay on top of operations.

Enabling Supply Chain Visibility

Transformation Approach

How It Works

Provides last-mile retail point-ofsale visibility for original equipment

and parts.

Craftworks has implemented

software that allows managers

and staff to easily navigate POS

data and inventory at-a-glance.

The company is now able to

gather business intelligence on

new and existing locations and

compare theoretical vs. actual

costs and their impact on the

bottom line.25

Provides a “control tower,” or a

central hub within the supply chain,

that collects real-time data and

provides visibility into supply chain

activities to improve organizational

decision-making. This functionality

can provide near-real-time global

visibility of dealer orders and

supply chain inventory, as well

as predictive alerts that identify

supply and demand bottlenecks

based on available-to-promise (ATP)

capabilities.

CNH has implemented

transportation management

software that has enhanced

the efficiency of inbound

and outbound transportation,

optimized processes and enabled

complete visibility into the

supply chain through analytics

that help the company monitor

and track supply chain metrics

and identify issues.26

Provides global visibility of

inventory stock across the network,

as well as suggestions on order

fulfillment for pending customer

orders.

John Deere’s consumer and

construction equipment division

has successfully implemented

inventory management software

to improve distribution network

responsiveness, reduce order

lead times and increase network

efficiency through warehouse

consolidation, inventory

reduction and cost reduction.27

Retail POS visibility

Global order and inventory

visibility

Example

Dealer inventory visibility

Figure 4

cognizant 20-20 insights

6

Capability #4: Customer-Centric Innovation

To add value to customer relationships, it is essential to understand customer needs and implement

systems that support customer-centric innovation. Figure 5 suggests key transformational

ideas in this space.

Focusing on the Customer

Transformation Approach

How It Works

Enriches customer experience

through digital storefronts and

virtual showrooms. Moreover,

interactive services can enrich

product content on the Web.

AGCO and Mutual Mobile have

formed a strategic relationship

to improve the user experience28

and help consumers find the

right product through mobile

devices and Web interfaces.29

Collects vast amounts of employee

and customer interaction data

(consumption habits, preferences,

etc.) and provides targeted solutions

based on big data analytics.

John Deere collects and

processes massive amounts

of farm data and leverages

this data into the FarmSightTM

platform to remotely monitor

machines and ensure preventive

maintenance, optimize fuel

consumption and output

performance, and deliver

agronomic information to

farmers for better decisionmaking.30

Analyzes customer sentiment to

understand attitudes, opinions

and trends, and identifies primary

influencers within specific social

networks to manage online

reputation.

Among the key initiatives

of Caterpillar’s social media

strategy is a social listening

platform (managed by its

information analytics group)

that provides the business with

insights into customer sentiment

about industry trends, the

company and its competitors.

This data is also used to

develop a 360-degree view of

customers.31

Enables remote monitoring

of equipment usage patterns,

conditions and breakdowns through

a centralized dashboard.

John Deere and AGCO are

beginning to connect not

only farm equipment but also

irrigation systems and soil

and nutrient sources with

information on weather, crop

prices and commodity futures

to optimize overall farm

performance.32

Digital channel management

Big data service personalization

Social media analytics

Example

Connected products

Figure 5

Capability #5: Performance and Analytics

By developing a strong analytics backbone,

industrial equipment companies can identify

opportunities to not only improve their decision-

Figure 6

cognizant 20-20 insights

making but also increase partner and supplier

performance effectiveness. See Figure 6 (next

page) for ideas on how to develop this capability.

7

Enabling Analytics

Transformation Approach

How It Works

Example

Helps collect sourcing and

procurement data from multiple

systems and apply sourcing, spend,

supplier performance and indirect

spend analytics.

AGCO successfully implemented

a solution to connect and

transact business more

efficiently and effectively with its

customers. AGCO has achieved

greater visibility into and control

over its spend, which has fueled

more favorable contracts and

pricing terms.33

How It Works

Example

Provides real-time visibility into

critical business processes through

push-based dashboards and

alerts powered by an event-driven

architecture.

Mercedes-AMG piloted a

real-time quality assurance

platform that harnesses

predictive analytics to optimize

engine-testing processes when

manufacturing its vehicles.34

The ability to correlate historical

test data with sensor data in

real time enables engineers to

identify problems more quickly.35

Performs activities such as

surveying fields, capturing images,

identifying and classifying infected

regions, estimating pesticide

quantity and optimizing pesticide

usage. One such autonomous robot

is eAGROBOT.

To address the aging and

declining population of Japan,

Komatsu wants to revamp the

industry segments it serves

with a robotics revolution. It

aims to automate tractors and

other equipment by 2020 and

to implement over 20 robotic

processes in multiple industries,

including food processing.36

Spend analytics

Transformation Approach

Business activity monitoring

Robotics

Figure 6

The Way Forward

Heavy equipment suppliers have many opportunities to transform their business, especially in

the areas of inventory management, asset management and customer insights. By adopting new

capabilities in operational excellence, lean technology and global supply chain visibility, these

companies can boost process efficiency, improve

product delivery, reduce costs and mitigate risk.

Establishing new approaches to customer centricity, meanwhile, will enable these companies to

gain insight into customer buying behavior, atti-

tudes and trends, and help them develop holistic

view of customers, thereby speeding innovation.

Analytics capabilities will further improve organizational effectiveness and support faster

decision-making. And finally, all these areas of the

business can learn from one another by examining best practices in the industry.

Studying the five key capabilities outlined in this

paper will enable industrial equipment companies

to support global expansion, create a customercentric focus and prepare for unfavorable and

uncertain market situations, thereby ensuring

business relevance and continued viability.

Footnotes

1

Global Agricultural Machinery Industry, http://en.wikipedia.org/wiki/Agricultural_machinery_industry.

2

“Construction Equipment Market Analysis by Product And Segment Forecasts to 2020,” Grand View

Research,

September

2015,

http://www.grandviewresearch.com/industry-analysis/constructionequipment-market-analysis.

3

“Mining Equipment Market Will Reach USD 117.0 Billion by 2018: Transparency Market Research,” PR

Newswire, Oct. 22, 2014, http://www.prnewswire.com/news-releases/mining-equipment-market-willreach-usd-1170-billion-by-2018-transparency-market-research-280051182.html.

cognizant 20-20 insights

8

4

“Global Demand for Agricultural Equipment to Reach $208 Billion,” Farm Equipment, Aug. 5, 2014, http://

www.farm-equipment.com/articles/10687-global-demand-for-agricultural-equipment-to-reach-208-billion.

5

“World Agricultural Equipment Market,” PR Newsire, Nov. 26, 2014, http://www.prnewswire.com/newsreleases/world-agricultural-equipment-market-300001970.html.

6

Ibid.

7

Ibid.

8

“Global Demand for Agricultural Equipment to Reach $208 Billion,” Farm Equipment, Aug. 5, 2014,

http://www.farm-equipment.com/articles/10687-global-demand-for-agricultural-equipment-toreach-208-billion.

9

Ibid.

10

Ibid.

11

“World Agricultural Equipment Market,” PR Newswire, Nov. 26, 2014, http://www.prnewswire.com/newsreleases/world-agricultural-equipment-market-300001970.html.

12

Cognizant analysis of key financial ratios based on data from “Morningstar” for companies such as Deere,

CNH, CAT, Komatsu, AGCO.

13

Ibid.

14

Ibid.

15

Key ratio analysis for Deere & Co., Morningstar, http://financials.morningstar.com/ratios/r.html?t=DE.

16

Key ratio analysis for Komatsu Ltd., Morningstar, http://financials.morningstar.com/ratios/r.html?t=KMTUY.

17

Key ratio analysis for Caterpillar, Inc., Morningstar, http://financials.morningstar.com/ratios/r.html?t=CAT.

18

“John Deere Opens the MyJohnDeere Platform to Collaborating Software Developers and Companies,”

John Deere, Nov. 14, 2013, https://www.deere.com/en_US/corporate/our_company/news_and_media/

press_releases/2013/corporate/2013nov14_corporaterelease.page.

19

“Taking an Open Approach Leads to New Partnerships,” AGCO, April 10, 2014, http://www.agcotechnologies.com/news/article/taking-an-open-approach-leads-to-new-partnerships/.

20

Open Ag Data Alliance website, http://openag.io/about-us/.

21

“AGCO and riskmethods Win BME Award for Electronic Procurement,” Spend Matters, March 30, 2015,

https://spendmatters.com/2015/03/30/agco-and-riskmethods-wins-bme-award-for-electronic-procurement/.

22

James B. Kelleher, “Caterpillar: Our Dealers Are Missing Up To $18 Billion In Easy Sales,” Business Insider,

March 20, 2014, http://www.businessinsider.com/r-insight-from-dumb-iron-to-big-data-caterpillars-dealer-sales-push-2014-20?IR=T.

23

Todd Morrison, “Manufacturer Consolidates Supply Chain Silos with SAP GATP,” TechTarget, Aug. 26,

2011, http://searchsap.techtarget.com/news/2240069639/Manufacturer-consolidates-supply-chain-siloswith-SAP-GATP.

24

“Volvo Cars Netherlands Uses Anachron Corporate E-Invoicing Platform to Digitize Workflows and

Improve Financial Reporting,” Anachron, Dec. 18, 2014, http://www.anachron.com/volvo-cars-netherlandsuses-anachron-corporate-e-invoicing-platform-digitize-workflows-improve-financial-reporting-2/.

25

“Craftworks Restaurants: Success Story,” Ctuit, Sept. 4, 2012, http://www.ctuit.com/2012/09/04/

success-story-craftworks-restaurants/.

26

Ethan Burton, “CNH Cuts Transportation & Logistics Overhead,” Oracle Supply Chain Management blog,

March 4, 2015, https://blogs.oracle.com/scm/entry/vce_cnh_cuts_transportation_logistics.

27

“A Supply Chain Overhaul That Delivers It All to Deere & Co.,” Supply Chain Brain, http://www.

supplychainbrain.com/content/research-analysis/supply-chain-innovation-awards/single-article-page/

article/a-supply-chain-overhaul-that-delivers-it-all-to-deere-co-1/.

cognizant 20-20 insights

9

28

“AGCO and Mutual Mobile Lead Next Generation of Connected Agriculture,” Mutual Mobile, Dec. 9, 2014,

http://www.mutualmobile.com/press-releases/agco-mutual-mobile-lead-next-generation-connectedagriculture.

29

“Online Car Shopping Takes a New Turn,” AutoTrader, http://www.mutualmobile.com/work/autotrader.

30

“John Deere Is Revolutionizing Farming With Big Data,” Datafloq, https://datafloq.com/read/

john-deere-revolutionizing-farming-big-data/511.

31

Paul Dunay, “What Does Social Shake-up Mean to Caterpillar?” Social Media Today, June 4, 2013, http://

www.socialmediatoday.com/content/what-does-social-shake-mean-caterpillar.

32

Michael E. Porter and James E. Heppelmann: “How Smart, Connected Products Are

Transforming Competition,” Harvard Business Review, November 2014, https://hbr.org/2014/11/

how-smart-connected-products-are-transforming-competition.

33

“SHI and AGCO Collaborate to Win,” Business Wire, April 2, 2013, http://www.businesswire.com/news/

home/20130402005288/en/SHI-AGCO-Collaborate-Win#.VSueZdzoRZ5.

34

Stephanie Overby, “Mercedes-AMG: A Showcase for Real-Time Business Decisions,” Forbes Insights,

August 2014, http://www.sap.com/bin/sapcom/pt_pt/downloadasset.2014-10-oct-17-19.mercedes-amg-ashowcase-for-real-time-business-decisions-pdf.html.

35

36

Ibid.

Andrew Dewit, “Komatsu, Smart Construction, Creative Destruction, and Japan’s Robot Revolution,” The

Asia-Pacific Journal, Feb. 2, 2015, http://japanfocus.org/-Andrew-DeWit/4266.

cognizant 20-20 insights

10

About the Authors

Ganesh Iyer is a Senior Manager within Cognizant Business Consulting’s Manufacturing and Logistics

Consulting Practice. His primary areas of expertise include supply chain management and business process harmonization. He can be reached at Ganesh.Iyer@cognizant.com.

Arun Krishnan is a Director in Cognizant Business Consulting, where he leads the consulting practice for

discrete manufacturing industries. He has over 20 years of experience across industry and consulting.

He can be reached at Arun.Krishnan2@cognizant.com.

Suraj Subramoniam is a Senior Consultant within Cognizant Business Consulting’s Manufacturing and

Logistics Practice. His area of expertise is in operations and project management across the manufacturing space, spanning value chain optimization through strategy development. He can be reached at

Suraj.Subramoniam@cognizant.com.

About Cognizant’s Manufacturing and Logistics

Cognizant’s Manufacturing and Logistics business unit operates as a trusted partner to global manufacturing leaders, helping them accelerate business performance in the digital world. The unit is recognized for its forward-looking

approach by industry gurus, such as IDC MarketScape, which bestowed on it a “Leader” rating for service lifecycle

management. Our business consulting professionals ensure that manufacturing and logistics clients receive exceptional business results from their technology investments and sourcing programs. Our domain solutions leverage

digital technologies to build smart products, connect with digital consumers, provide real-time visibility into manufacturing operations, and automate knowledge work with cognitive computing. Learn more at www.cognizant.com/

manufacturing.

About Cognizant

Cognizant (NASDAQ: CTSH) is a leading provider of information technology, consulting, and business process outsourcing services, dedicated to helping the world’s leading companies build stronger businesses. Headquartered in

Teaneck, New Jersey (U.S.), Cognizant combines a passion for client satisfaction, technology innovation, deep industry

and business process expertise, and a global, collaborative workforce that embodies the future of work. With over

100 development and delivery centers worldwide and approximately 219,300 employees as of September 30, 2015,

Cognizant is a member of the NASDAQ-100, the S&P 500, the Forbes Global 2000, and the Fortune 500 and is ranked

among the top performing and fastest growing companies in the world. Visit us online at www.cognizant.com or follow

us on Twitter: Cognizant.

World Headquarters

European Headquarters

India Operations Headquarters

500 Frank W. Burr Blvd.

Teaneck, NJ 07666 USA

Phone: +1 201 801 0233

Fax: +1 201 801 0243

Toll Free: +1 888 937 3277

Email: inquiry@cognizant.com

1 Kingdom Street

Paddington Central

London W2 6BD

Phone: +44 (0) 20 7297 7600

Fax: +44 (0) 20 7121 0102

Email: infouk@cognizant.com

#5/535, Old Mahabalipuram Road

Okkiyam Pettai, Thoraipakkam

Chennai, 600 096 India

Phone: +91 (0) 44 4209 6000

Fax: +91 (0) 44 4209 6060

Email: inquiryindia@cognizant.com

­­© Copyright 2015, Cognizant. All rights reserved. No part of this document may be reproduced, stored in a retrieval system, transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the express written permission from Cognizant. The information contained herein is

subject to change without notice. All other trademarks mentioned herein are the property of their respective owners. TL Codex 1561