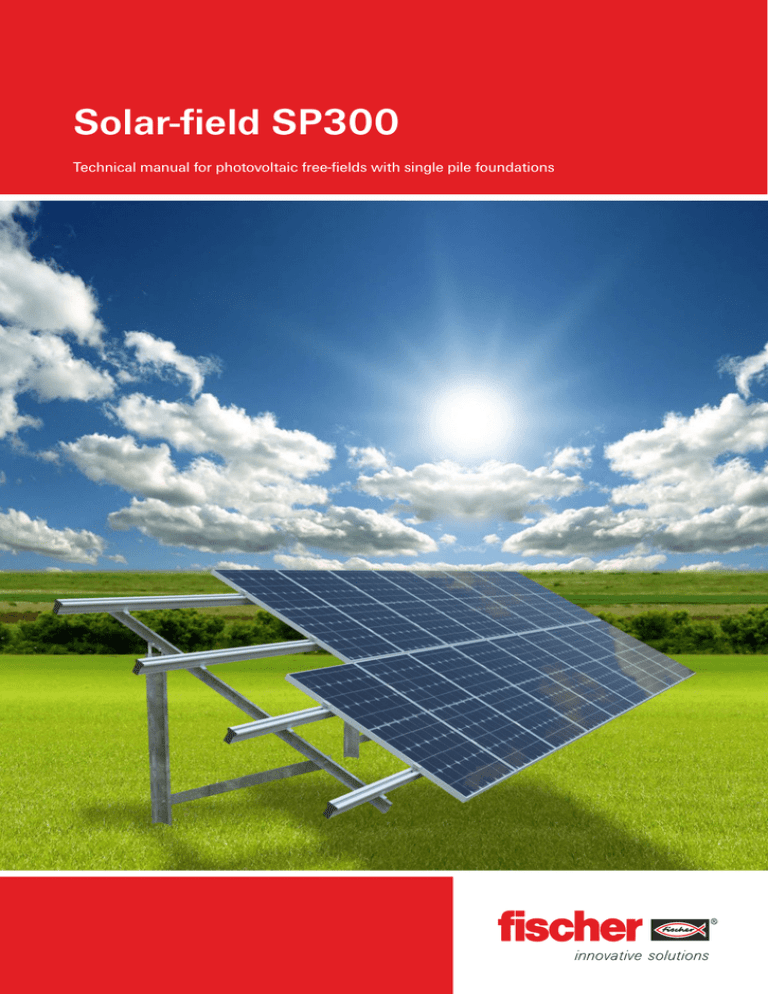

Solar-field SP300

advertisement

Solar-field SP300 Technical manual for photovoltaic free-fields with single pile foundations 1 1. Single pile support systems for free-fields 1.1 The single pile support system for free-fields is made from galvanized steel. The quality of the steel finish has a minimum coating of hot dip galvanization 45 microns. The purlins can be either from aluminium or galvanized steel. All of the steel accessories (bolts, nuts, etc...) are made from stainless steel A2. The system is available in 2 versions, 2 portrait & 3 landscape with angles of 25°,30°,35°. The foundation of the system can be made with steel driven piles or with concrete piles. Typology Double Pile 25° Double Pile 30° Double Pile 35° Purlin PV panel layout Code Aluminium Portrait SAP-25 Aluminium Landscape SAL-25 Galv. Steel Portrait SGP-25 Galv. Steel Landscape SGL-25 Aluminium Portrait SAP-30 Aluminium Landscape SAL-30 Galv. Steel Portrait SGP-30 Galv. Steel Landscape SGL-30 Aluminium Portrait SAP-35 Aluminium Landscape SAL-35 Galv. Steel Portrait SGP-35 Galv. Steel Landscape SGL-35 2 2. Assembly of support system The individual parts for assembling the support system are provided with the necessary machining for easier and faster installation. 2.1 PILE FOUNDATION Pile driving should be performed by specialist, and should be according to the installation specifications and drawings. The piles should be placed with the large surface area parallel to the North-South axis. S Pile Foundation Concrete Foundation The depth of the foundation is determined by the soil conditions and may vary for reinforced concrete. Depth of foundation Depth of foundation 3 2.2 INSTALLING THE GIRDER CONNECTOR The girder connector is fastened inside the web of the pile with stainless steel fasteners M10x25 on each side and safety nuts M10. Girder Connector Safety nut M10 Pile Fastener Μ 10x25 2.3 INSTALLING THE GIRDER The girder beam is fastened over the top of the girder connector with two fasteners M10x25 and safety nuts M10. Girder Beam Girder Connector Safety nuts M10 Pile Fastener Μ 10x25 4 2.4 INSTALLING DIAGONAL BRACING The diagonal bracing is used to connect the pile to the girder beam. It is fastened with M12x30 bolts and M12 safety nuts. Bolt Μ 12x30 Bolt Μ 12x30 Diagonal bracing Safety nut Μ 12 Girder beam Diagonal bracing Pile Safety nut Μ 12 5 3. Installing and aligning the support structure The piles are placed in rows and are spaced at a maximum distance of 3,00 meters. 3, 0m 3, 0m 3, 0m If needed the girders can be adjusted in order to insure the correct alignment. 3.1 ADJUSTMENTS The following adjustments can be made: Girder beam The girder connector can be adjusted in the vertical direction +/- 2cm The girder beam can be adjusted in the horizontal direction +/- 2cm Steel fastener for girder beam Girder connector Before making adjustments the bolts must be loosened. Steel fastener for girder connector 3.3 TABLE FOR FASTENER TORQUE Drawing Description Torque Fastener Μ 10x25 56 Nm Fastener Μ 12x30 56 Nm 6 4. Installing purlins Two types of purlins are available: Ÿ Aluminium purlin ( SolarPrime) Ÿ Steel purlin ( FUS62 ) 4.1 ALUMINIUM PURLIN ( SolarPrime ) The aluminium purlin (Solar Prime) is fastened to the steel girder beam with the corner clamp connector that is inserted into the channel on the side of the purlin and then it is fastened with an allen screw and a safety nut M8 to the girder beam. Aluminium purlin Allen screw M8x30 Safety nut M8 Corner clamp connector Girder beam 4.1.1 PURLIN CONNECTOR When the purlin is used continuously to span over several girders, then a special purlin connector is used to fasten the two purlins together. The purlin connector is inserted into the chamber of the purlin and fastened with self-tapping stainless steel screws. Screw St4,2x13 Purlin Aluminium purlin connector 7 4.2 STEEL PURLIN ( FUS62 ) For connecting the steel purlin (FUS62) to the girder beam, use an allen screw M12x30 and M12 washer with safety nut M12. Allen screw M12x30 Washer M12 Steel purlin Safety nut M12 Girder beam 4.2.1 PURLIN CONNECTOR When the purlin is used continuously to span over several girders, then a special purlin connector is used to fasten the two purlins together. The purlin connector is fastened to the under side of the purlin with four allen screws M12x30 and washers M12. Safety nuts are not required as the connector has been threaded to directly receive the M12 bolts. Allen screw M12x30 Washer M12 Steel purlin Steel purlin connector 8 5. Installing the panels The panels are fixed to the purlins with special clamps. There are end clamps that are used to fix the panels at the beginning and the end of a series, and there are middle clamps that are used between two panels. The clamps are available preassembled (with allen screw, spring, plastic grip, hammer-head nut) and are availble for every panel thickness. The hammer head nut is inserted into the channel of the purlin and turned to lock into the desired position. Then the clamp is fastened into place with the allen screw. Allen screw Clamp Hammer head nut 9 6. Technical data sheets 1- point load F SolarFine 150 L/2 Height 150 mm Width 41 mm Perimeter 522,34 mm Ix 229,10 cm4 L 2- point load F L/3 25,71 Iy cm4 Wx 29,68 cm3 Wy cm3 12,54 F L/3 L 2 supports - Uniformly load q Radii(x) 5,06 cm Radii(y) 1,70 cm L Area 894,02 mm2 3 supports - Uniformly load Weight 2413,85 gr/m F (N) 20000 qL qL L L SolarFine 150 19000 18000 17000 16000 15000 14000 13000 12000 3-supports 11000 2-supports 10000 1 point load 9000 8000 2 point load 7000 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 10 1- point load F SolarFine 100 L/2 Height 100 mm Width 41 mm Perimeter 422,34 mm L 2- point load F F cm4 Ix 78,53 Iy 18,79 cm4 L/3 L/3 L Wx 14,87 cm3 Wy 9,17 cm3 Radii(x) 3,32 cm Radii(y) 1,62 cm Area 714,02 mm2 Weight 1927,85 gr/m 2 supports - Uniformly load q L 3 supports - Uniformly load qL qL L L SolarFine 100 F (N) 15000 14000 13000 12000 11000 10000 3-supports 9000 2-supports 8000 1 point load 7000 2 point load 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 11 SolarPrime 105 1- point load F 105 mm Width 77,8 mm Perimeter 490,32 mm Ix 107,81 cm4 Iy 39,11 cm4 Wx 18,24 cm3 Wy 10,05 cm3 Radii(x) 3,75 cm Radii(y) 2,26 cm Area 768,05 mm2 Weight 2073,72 gr/m 2 supports Uniformly load q 2- point load F Height F 3 supports Uniformly load qL qL L/3 L/3 L/2 L L L F (N) L SolarPrime 105 15000 14000 13000 12000 11000 10000 3-supports 9000 2-supports 8000 1 point load 7000 2 point load 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) L 12 SolarPrime 80 1- point load F L/3 L/2 F Width 77,8 mm Perimeter 440,32 mm Ix 53,90 cm4 Iy 34,43 cm4 Wx 12,00 cm3 Wy 8,85 cm3 Radii(x) 2,80 cm Radii(y) 2,24 cm Area 688,05 mm2 Weight 1857,72 gr/m 3 supports Uniformly load qL qL L/3 L L L 80 mm 2 supports Uniformly load q 2- point load F Height L SolarPrime 80 F (N) 15000 14000 13000 12000 11000 10000 2-supports 9000 3-supports 8000 1 point load 7000 2 point load 6000 5000 4000 3000 2000 1000 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) L 13 1- point load FUS 62 F Height 62 mm Width 41 mm Perimeter 365,19 mm Ix 17,70 cm4 Iy 12,90 cm4 Wx 5,62 cm3 Wy 6,29 cm3 Area 405 mm2 L/2 L 2- point load F L/3 F L/3 L 2 supports - Uniformly load q Weight 3270 gr/m L 3 supports - Uniformly load F (N) 10000 qL qL L L FUS 62 9500 9000 8500 8000 7500 7000 6500 6000 3-supports 5500 2-supports 5000 1 point load 4500 4000 2 point load 3500 3000 2500 2000 1500 1000 500 0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 L (m) 14 7. Structural design loads of brackets Load 1: Vertical compression (10kN) Load 2: Horizontal forces (10kN) Load 3: Vertical tensile forces (10kN) 10kN 10kN 10kN Founded in 1958, the fischer brand is synonymous for safe, innovative and sophisticated technical solutions which set new standards in fixing engineering. The products and applications are unique fixing systems that are invented and produced by fischer. That is the reason that there exist unlimited solutions and a large range of applications, and today is recognised as the leader in the market of fixing systems. Chemical Fixing Systems Metal Fixing Systems Nylon Fixing Systems Gypsum Board Fixing Systems Photovoltaic Fixing Systems Drill Bits & Accessories MEP Fixing Systems Fasteners Chemical Building products Exterior Insulation Fixing Systems fischer Hellas Emporiki EPE G. Papandreou 125, Metamorphosi 144 52, Athens Tel.: +30 210 28 38 167, Fax: +30 210 28 38 169 info@fischer.gr www.fischer.gr The contents of this manual are subject to change without prior notice. Fischer Hellas Emporiki EPE is not responsible for typographical errors. PLS012 05/2012 1958, the beginning. 2012, world-wide.