provincial electricity authority

r------------------------------------------------------------------------------------------~

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specification No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: 1

I

Form No. 01-1

I

Page I of7

,

.

Invitation to Bid No. :

C

Cl la

Material, equipment, and specifications for INSULATORS

General material and packing instructions

Additional to the general instructions, the following shall be observed :

Scope

These specifications cover insulators for overhead HV (up to 115 kV) and LV lines. lb Standard

The insulators shall be manufactured and tested m accordance with the latest edition of the following standards:

Thai Industrial Standards (TIS)

TIS 227

TIS 279

Spool-type porcelain insulators

Pin-type porcelain insulators

TIS 280

TIS 354

Strain-type porcelain insulators

Suspension-type porcelain insulators

TIS 563

TIS 1077

Suspension-type toughened glass insulators

Line-post type porcelain insulators

TIS 1251 Pin-post type porcelain insulators

American National Standards Institute (ANSI)

ANSI C29.1 Test methods for electrical power insulators

ANSI C29.2 Wet-process porcelain and toughened glass insulators- suspension type

ANSI C29.9 Wet-process porcelain insulators- apparatus, post- type

International Electrotechnical Commission (IEC)

IEC 60383-1 Insulators for overhead lines with a nominal voltage above 1 000 V - Part I:

Ceramic or glass insulator units for a.c. systems - Definitions, test methods and acceptance criteria

And all other relevant standards, unless otherwise specified in these specifications.

PEA will accept the design test reports carried out according to previous standard/edition, if there is no significant change in any item or no additional test item compared with the last standard/edition.

On the other hand, if there are significant(s) and/or additional test item(s), PEA will remain to accept the design test reports carried out according to previous standard/edition for three (3) years.

After three (3) years, the design testing shall be done to complete design test reports for the changed and/or additional test item(s) including relat~d item(s) (if any).

TT

....

\._...·

.

.

PROVINCIAL ELECTRICITY AUTHORITY

Specification No.: RINS-002/2553

POWER SYSTEM STANDARD DIVISION

INSULATORS

Approved date: 02/02/2553 Rev. No.: 1 FormNo. 01-l Page 2 of 7 lc

·tc.l lc.2

Principal requirement

General

The porcelain insulators shall be brown glazed.

The pin hole threads of the pin type insulators shall be zinc thimble according to TIS .

The insulator shells of suspension insulator of porcelain type shall be made of highest grade, dense, homogeneous, wet-process, high strength alumina porcelain.

The surface shells of suspension insulator of porcelain type exposed after the assembly shall be relatively smooth and free of imperfections.

The porcelain head of the suspension insulator shall be cylindrical headed with sand surfaces; the

"dove tail" shaped head shall not be accepted .

For the line-post insulator and pin-post insulator, the porcelain part shall be factory-fixed with stud, washer, nut, and lock nut.

Marking

Each insulator shall be marked legibly and durably, as follows:

(1) Manufacturer's name and/or Trade-mark.

(2) Year of manufacture.

(3) Only for suspension insulators :

- Tension-proof test load in kN, identified by the word "TEST".

- Combined mechanical and electrical strength in kN, identified by the symbol "M&E, except that of class 52-1.

(4) Only for line-post insulator and pin-post insulator: Magnitude of the power arc current in kA and duration in second, identified by the word "POW ARC".

(5) PEA's trademark, as the figure shown.

II lc.3

(6) Others according to manufacturer's design.

Sample

Samples shall be supplied on request. In case the samples are requested by PEA, The bidders have to supply samples of each item of the insulators within fifteen (15) calendar days. The bidders who cannot supply the requested samples shall be rejected.

PEA reserves the right to test the samples according to PEA's testing procedure. In case of the failing test results, the bidders shall be rejected.

The samples shall not be returned.

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specification No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: 1

I

Form No. 01-1

J

Page 3 of7

. lc.4 Tests and test reports

HV insulators and LV insulators shall be passed all items of design tests, quality conformance tests and routine tests in accordance with the latest relevant ANSI C29 or TIS.

The design tests for suspension insulator. line-post insulator and pin-post insulator shall conform to as follows:

(1) The proposed HV insulators shall have successfully passed the design tests in accordance with the latest relevant standard.

For suspension insulator, thermal-mechanical load cycle test in accordance with the latest

ANSI C29.2, or thermal-mechanical performance test in accordance with the latest IEC "

60383-1, shall be included.

(2) The additional acceptance criteria for determining conformance with PEA's requirements for thermal-mechanical load cycle test (or thermal-mechanical performance test) and combined mechanical and electrical strength tests (or electromechanical and mechanical failing load tests) shall be as follows :

Where:

R- R

8

= s

Q

8

~ 3

Criteria of judgement for acceptance

Os

R

=

=

Rs

s

=

=

Average value obtained from the test

Rated Mechanical and Electrical strength value of the insulator

Standard deviation from the test

Each value measured shall not be lower than the rated Mechanical and Electrical strength; electrical puncture shall not occur before reaching ultimate failure.

Sample size shall be often (10) units.

The insulators shall be passed the special tests as follows :

For line-post insulator and pin-post insulator: power arc test (see Appendix 1).

For suspension insulator: steep wave front impulse test and power arc test (see Appendix 2).

If Portland cement is used in the assembly of the insulators, it shall have an autoclave expansion limit of less than 0.12 percent when tested in accordance with ASTM C 151-84, Test method for autoclave expansion of portland cement.

All items of the design tests and the special tests shall be conducted by the acknowledged independent testing laboratories.

TT

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specification No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: I

I

Form No. 01-1 \ Page 4 of7

The following independent testing laboratories are accepted by PEA:

- KEMA

- V'Fall

- CRIEPI

- EdF

KEMA Laboratories (HOLLAND)

Staten Vattenfallsverk, The Swedish State Power Board (SWEDEN)

Central Research Institute of Electric Power Industry (JAPAN)

- CESI

- PLI

-TCA

Electricite de France (FRANCE)

Centro Elettrotecnico Sperimentale Italiano (ITALY)

Powertech High Power Laboratory (CANADA)

Testing and Certification (AUSTRALIA)

- OHT

-EGAT

Ontario Hydro Technologies (CANADA)

The Electricity Generating Authority of Thailand (THAILAND)

Testing Laboratory, Electrical Engineering Department, Faculty of

Engineering, Chulalongkom University (THAILAND)

- SATS

- ASTA

- IPH

-FGH

Scandinavian Association for Testing Electric Power Equipment (NORWAY)

AST A Certification Services (UK)

Institut "Pruffeld fur elektrische Hochleistungstechnik" GmbH (GERMANY)

FGH Engineering & Test GmbH (GERMANY)

The bidder are at liberty to quote the insulators which are tested by the other independent testing laboratories not mentioned above, but have to be subjected to approval of PEA before the tests are proceeded.

Retesting of insulators until they pass the test whether they are produced in the same batch or not, without substantial change in the design and construction, shall be considered that they fail the test and the proposed insulators shall be rejected.

The design test reports and the special test reports shall be submitted with the bid or within fifteen ·

(15) calendar days after the bid closing date. The Item offered without submitting the design test reports and the special test reports shall be rejected.

The insulators shall be passed additional routine tests as follows :

For suspension insulator: all units of porcelain suspension insulator shall be passed hydraulic inner pressure test and high- frequency test followed by low·- frequency test (see Appendix 3).

The cost of all tests and reports, including the tests and reports for acceptance inspection, shall be borne by the Contractor.

TT

""

.

--

'

'

.

~t.~~

-·f~ l1l'J"~"'..f

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specification No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: 1

I

Form No. 01-1

I

Page 5 of7

.

.

ld Packing

Each item shall be packed in export packages in sets or pieces. The packages shall be right-square or right-rectangular forms.

The packages of same item shall be assembled into a bundle and fastened with steel bands over a pallet to make it movable by a forklift truck. The pallet shall be designed in such a manner that the truck's forks can be inserted at any side of the pallet. The steel strapped bundle shall be strong enough to withstand rough handling during transit and inland transportation and of 400 - 900 kg .

If the package is made of rubber wood (Yang-para or Hevea brasiliensis) the wooden parts shall be • treated with wood preservative.

The number of sets or pieces per package and the number of packages per pallet for each item of insulators shall be as follows :

Type

Line- post type, class 57-2

Line- post type, class 57-4

Pin- post type, class 56/57-2

Pin- post type, class 56/57-4

Station post type TR No. 208

Station post type TRNo. 210

Station post type TR No. 202

Station post type TR No. 286

Suspension type (porcelain or toughened glass), class 52-1

Suspension type (porcelain or toughened glass), class 52-4

Suspension type (porcelain or toughened glass), class 52-3

Suspension type (porcelain or toughened glass), class 52-8

Pin type, class 56-2

Pin type, class 56-3

Pin, fog type

Spool type, class 53-2

Strain type, class 54-1

Strain type, class 54-4

PEA Material Number of sets or

No.

Number of pieces per package packages per pallet

1030010002 2 36

1030010004

1030010101

1030010102

30

25

1030010201

1030010202

1030010200

1030010203

1030020000

3

1

2

2

I

2

1

6

30

30

30

30

6

36

0

1030020002

1030020001

1030020003

1030000001

1030000002

1030000003

1030030000

1030030100

1030030103

6

6

6

4

4

2

100

100

25

20

20

16

20

20

20

12

12

12

TT

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specificat.ion No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: I

I

Form No. 01-1

I

Page 6 of7

I

------

..._.-

C2

2a

Material and packing data to be given by bidder

For each item offered, the following details shall be submitted :

Catalogue number.

Only for HV insulators, the test certificates of design tests and of the latest quality conformance tests with inspector's signature.

)Ezcifications of materials used for the component parts.

\2:)

Pin type

0

Suspension type

0

0

Strain type

@

Line/pin-post type

Spool type c~G0G0Q

ANSI Class or TIS Type or ........................ .

Dimensions

Leakage distance

Protected leakage distance

Dry-arcing distance

Minimum pin height mm

-

mm mm mm

-

-

-

-

-

-

mm

-

-

-

mm mm mm

-

Mechanical values

Cantilever strength

Combined mechanical and electrical strength

Electromechanical failing load

Mechanical failing load

Mechanical impact strength

Tension proof

Time load

Transverse strength

Tensile strength

Electrical values

Low-frequency dry flashover

Low-frequency wet flashover

Critical-impulse flashover, positive

Critical-impulse flashover, negative

Low-frequency puncture

Radio-influence-voltage data

Low-frequency test voltage, r.m.s. to ground

Maximum riv at 1,000 kHz

Weight of one insulator

Colour kN

-

-

kV kV kV kV kV

-

-

-

-

-

kV kV kV kV kV

-

kN kN kN cm-N kN kN

-

kV kV

J.lV kg

J.lV kg

........... ........... kV kV

-

-

-

-

-

-

-

-

-

-

kN

-

-

-

kg

··········· kV kV

-

-

-

-

-

-

-

-

-

-

kN

-

-

-

-

-

kN

-

-

-

. kV kV kV kV

-

-

-

kV

]JV kg kg

........... . ..........

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Specification No.: RINS-002/2553

INSULATORS

I

Approved date: 02/02/2553

I

Rev. No.: 1

I

Form No. 01-1

I

Page 7 of7

2b

2c

For each item offered, detail drawing(s) with dimensions and tolerances in mm, showing glazed and unglazed surface and the symbol identifying the manufacturer shall be submitted.

Packing details

Packing method (shown by drawing(s), describe packing materials, details of wood treatment for rubber wood package) .

Number of sets or pieces in each package.

Dimensions (length x width x height) of each package in em .

Volume of each package in m

3

•

Gross weight of each package in kg .

Net weight of each package in kg .

Number of packages.

If several packages are assembled into a bundle, further details are required

Number of packages in each bundle.

Dimensions (length x width x height) of each bundle in em .

Volume of each bundle in m

3

•

Gross weight of each bundle in kg .

Net weight of each bundle in kg .

Number of bundles.

Note: Conditions for documentation and consideration

1. The Bidders have to submit the sufficient references describing the previous experience of the • manufacturer (e.g. list of supply of equipment and/or materials having the same or similar design as proposed, field experience, the registration of TISI, the copies of license, and/or the inspection to supplier's factory by PEA's inspectors, etc.) to the satisfaction of PEA.

2. The Contractor has to supply report of design tests, special tests, quality conformance tests and routine tests of the insulators in English and/or Thai, before shipment/delivery, to the following address:

Power System Standard Division

Provincial Electricity Authority

200 Ngam Wong Wan Road, Chatuchak

Bangkok 10900

Thailand

II

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Appendix I

Power arc tests for line post/pin post type insulator

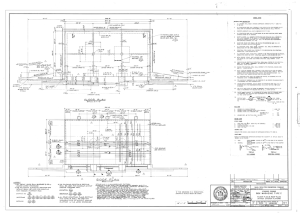

1. Test arrangement

The test arrangement shall be as shown in Drawing No. SA2-0 15/35042.

The power arc test shall be carried out in three-phase with three specimens simultaneously.

2. Power supply

The power supply shall be adequate to maintain the specified arc current for the specified duration. The arc current shall be practically sinusoidal and constant, and shall not deviate from the specified value by • more than 1

For long arc durations (greater than 20 cycles), the variation of the arc current may be greater than I 0%, in this case, the arc current may be evaluated by its average peak value during the test duration.

The supply frequency shall be the rated frequency of 50 Hz or 60 Hz.

3. Arc initiation

The arc shall be initiated by means of a fuse wire of suitable diameter attached to the insulator as shown in detail "A" in Drawing No. SA2-015/35042.

4. Characteristics of the power arcs

The number, current, and duration of the power arcs to be applied to each set shall be as shown in the table below:

57-2 and

56/57-2

57-4 and

56/57-4

Type oflnsulator

Number

Minimum test current, rms.

Minimum duration kA sec

10

0.40

3

0.65

10 3

0.40 0.79

5. Evaluation of the results

The insulators shall be considered to have passed the tests if there is no partial shed breakage on any insulators as the result of the power arc test.

I

.......

.. r . - X - · ---Y--~ ---z--~ i:

1'5'• ~ l

J n'l'i\J'ismruuai\

ASSEWBLY NO.

T

\000

MIN. i i

\000

M IN.

1

57-2 ond

57-4 ond

56/57-2 56/57-4

X MIN. 600 MIN. 750 y

MIN. 800 MIN. 900

:z

MIN. 750 MIN. 650 mm

:

~~"----'----'

"---@

I

:

:_,'7\

,_v

PLACED TO THE

GENERATOR SIDE

FUSE WIRE ATTACHt.AENl

EARTHING DIAGRAM DETAIL "A ..

NOTES

,J_)

CONCRETE CROSSARM, THE CROSSARM CAN. BE REPLACED BY A STEEL CHANNEL.

~i)

INSULATOR.

·)

STEEL WIRE, SOLID, DIAMETER OF 4 mm, IF ANY.

FUSE. WIRE. PLACED TO THE GENERATOR SIDE.

COVERED CONDUCTOR'.

STEEL STRANDED WlRE. DIAMETER OF 6.3 mm (BURIED IN CONCRETE POLE}, IF ANY.

(j)

SHORT -CIRCUIT GENERATOR.

@

CONCRETE POLE. THE POLE CAN BE REPLACED BY A STEEL POLE, IF ANY.

: nu~1~1n'l'lll1-tt,t'lu.~•IA~il·m~

· li'UU\J'U ............... ..

Wl1J1A'1n'i"i11 l..~~t~au:u:.~.~.~ ~

...

~

~~'l'l'l".....

. . . . . . . . . . . . . .

~"l"lf\'l'l: ..................... ' .................... ' ........ .

~QilUll~tJU

........... .

..

~.:;t-~~~·~· ----------------------------------~

:

1~1n'l

"'

~

. .,

~'l'II'IJ'1\UI.'1Jn

/

-.~.

:. . . -

Wt'nU'1Un'l'ini)~

.......... .

:.

'

: . u'lUn'1'iJoi'11J. ......... .

·~'Vl~M~~'i

POWER ARC TEST ARRANGMENT

FOR INSULATORS, FOR OVERHEAD LINES

.

J .. :

~.~

... .

~~~-:-:C?.'.~/~2

. ~~-~-~).~Yiv i •

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Appendix 2

Special tests for suspension insulators

(class 52-1, 52-4, 52-3 and 52-8)

The special tests are as follows :

1. Steep wave front impulse test

The test shall be performed on ten (1 0) units of insulator selected at random.

The insulator shall be subject to ten (10) successive positive and negative impulse flashovers with a wave having an effective rate of rise of2,500 kV/J.ts. The insulators shall be tested singly.

Each unit shall then be verified to be electrically intact by applying low-frequency voltage, dry or wet.

In case of wet test, the rated wet low-frequency withstand voltage shall be applied to each unit and no electrical puncture shall occur.

In case of dry test, the five (5) flashovers of the low-frequency dry flashover test in accordance with the latest ANSI C29.1 shall be applied and shall have a flashover value of not less than 95% of the rated value.

Failure of any one (I) unit either in the front-of-wave test or subsequent low frequency withstand voltage test shall cause for testing another twenty (20) units.

Failure of more than one (1) unit from total so tested shall constitute failure of this insulator design and will not meet requirements of these specifications.

2. Power arc test

Nine (9) insulator units of each type, in 3-unit strings, mounted vertically without arcmg horns or conductors, shall be subject to power arcs of 12 kA r.m.s., symmetrical for 0.1 seconds of of 6 kA r.m.s., symmetrical for 0.2 seconds.

The insulator string shall withstand the power arc without shell breakage. Failure of nay one (1) string in the test shall be caused for testing another three (3) strings of the same type.

Failure of more than one (1) string from the total so tested shall constitute failure of this insulator design and will not meet requirements of these specifications.

II

AnnrnvPrl tl!ltP• 07./07./1.'\'\~

I

PROVINCIAL ELECTRICITY AUTHORITY

POWER SYSTEM STANDARD DIVISION

Appendix 3

Additional routine tests for porcelain suspension insulators

(class 52-1, 52-4, 52-3 and 52-8)

The additional routine tests are as follows :

1. Hydraulic inner pressure test

The test shall be performed by injecting water into porcelain head portion for at least 2.5 second. The water pressure shall be as follows :

Suspension insulator

Class

52-1

52-4

52-3

52-8

Minimum water pressure

Kg/em

80

140

140

180

W at.er pressure

2

Hydraulic inner pressure test

2. High- frequency test follow by low- frequency test

Not withstanding those specified in ANSI C29.2, routine flashover test of suspension insulator shall be performed by applied high-frequency test 100- 500kHz for at least 3 seconds follow by low- frequency test for at least 3 minutes.

II

Approved date: 02/0212553 Page 1 of 1

B

,/

I

I

I

,,.-\ J

....

-.... ,-

....

\

\

I

\

,

I

I

I

\

\

\,

I

I

I 1

,-

........

_,, I

\,

I

, j

\

,_,

I

~------------------------A------------------------~

TIS 354 SUSPENSION-TYPE PORCELAIN INSULATOR

A, maximum mm

DIMENSIONS

B mm

MINIMUM

DIMENSIONS

Leakage distance mm

MECHANICAL

VALUES

Combined mechanical and electrical strength kN

Mechanical impact strength cm-N

Tension proof

Time load kN kN

Low-frequency dry flashover

Low-frequency wet flashover kV kV kV

ELECTRICAL

VALUES

Critica1-impluse flashover, positive

Critical-impluse flashover, negative kV

Low-frequency puncture kV

Low-frequency test voltage, rms to ground kV

RADIO-INFLUENCE

VOLTAGE DATA

Maximum RIV at 1 ,000 kHz llV

COLOUR OF INSULATOR

TypeC

Class 52-3

273

1462:3

292

66.72

621.34

33.36

44.48

80

50

125

130

110

10

50

TypeE

Class 52-8

298

146±3

BROWN

279.5

130

110

10

50

160.13

1,016.73

80.06

106.75

80

50

125

.

.

Page 3 of 4

1~~=---+--------------------~

~----------------------A----------------------~

B

TIS 563 SUSPENSION-TYPE TOUGHENED GLASS INSULATOR

DIMENSIONS

A, maximum

B mm mm

MINIMUM

DIMENSIONS

Leakage distance mm

MECHANICAL

VALUES

Combined mechanical and electrical strength kN

Mechanical impact strength

Tension proof cm-N kN

Time load

Low-frequency dry flashover

Low-frequency wet flashover kN kV kV

ELECTRICAL

VALUES

Critical-impluse flashover, positive

Critical-impluse flashover, negative kV kV

Low-frequency puncture kV

Low-frequency test voltage, rms to ground kV

RADIO-INFLUENCE

VOLTAGE DATA

Maximum RIV at I ,000 kHz IN

Class 52-3

273

146±.3

292

67

6.0

33.5

44

80

50

125

130

II 0

10

50

Class 52-8

298

146±.3

279

160

10

80

107

80

50

125

130

110

10

50

.

,__ ______ 9r--------'

------- =UNGLAZED

CATALOGUE NO. HRAA-025571C

Catalogue No.

Leakage Distance

Dry Arcing Distance

Cantiliver strength

Minimum Flashover

Volage

Low Frequency

Dry

Wet

Positive

Critical Impluse

Low Frequency

Negative

Dry

Wet Withstand Voltage

Critical Impluse

Low Frequency Puncture Voltage

Test Voltage to Ground

Radio Influence

Voltage Data

Maximum RIV at 1 ,000 kHz

COLOUR OF INSULATOR kV kV kV

~-tV lb kV kV kV inch

HRAA-025571C

36 3/4 inch 14 114

3,000

140

115 kV kV kV

210

245

120

90

190

210

30

200

BROWN

- l . hivitilt.icin to ·md .No. :

SpecinJatlon

\, '

No. :

RHDW~oi3/2s53·

C

1\iatcrlal;ce'quipmc·nt,

i'fn~ SR~~~jj~ations

Tor OVERIIEAD LINE

HAR])\VARE:

Cl

Ge11eraf inaterla! UJ.ld packing instructions

A~lditio.nal to the gcf1cral instf'uctions, the following shall be observed:

'ia S4,':opc-

-Thcsc spec ilicatlonnovcr line hardware for overhead lii1e construction. l b Standard.

The-overhead line hardware sl1ap be ir1 ·accordance with .the latest TIS, VDE Regulations,

DIN, and 1>EA Drawings attached to these specifications, or equivalent. lc Principal re(JUiremcnt

The u'ic'rh·ead line :bardwitre shall be. marked with manufacturer's name or tr:~dc-mnrk, except full thread double am1ing bolts, full thread stubbing bolts, and washers.

Ali ferrous ma!crials s,hal}bc gaivanizcdafier manufacturing. Method of galvanizing and thi<::kncss o{ coating shalr be· according to the attached Table "THICKNESS OF ZINC

CCiA:TlNG" .. Free samples shall be supplied on request. The samples will not be returned, ld Packing

Each !tern

~hquld

IJe 'packed in suitable packages ir1 sets ol· pieces of 10\50, I 00, or .that specified in Table ''PackiligDctails for Ov.crl1cnd Line Hardware" ·(sec page 3 of 3).

The woss weight Of each package should nor cx<::ced

4p

kg .

If ihcn;: Qrc Sc;lycra'f p_a,ckages, the number ofpackage shall be stamped on' each paLbgc or cad; tag, as fci lli:r\vs :

· package number i total purJ:1lJcrof p<lckage;s.

:Fo11n No. 93··2/1 0.10

II

- 2 -

Ci :Material imd packii1g 'data to be given by bidder

.2a For cac)1 item ot~'ered, the following de.tails sh('lll be _su\;lmitted with the bid,:

'Ci1 taJogue: l)UQ!b<;t :. l c • "

Description of mat~rials usc(ftor the colnponent parts.

Suri':icc finishing

ofthe

componenlparts.

Zinc coating in g/m

2 or pm (I flTI1 =

0~001 l'ilm)

Mihiinum breaking strength in kgf.

Weight in kg/set~ or piece.

""

2b For each item offered, a detalidnnvjng with dimensions in nun shall be submittcq with a the bid.

2c Packing dct11ils

Packing, method.

Number of sets or pieces in each package .

.Dimensions of each package in c:ni .

Gross '\v9ight ofcach package in kg (should. not cxcccdAU.kg) .

Net w~:.~ight of each package.ii(kg

Number of' packages ..

If several ,p;lckages a,re contained in one big cnsc, further details nrc required :

Nurribcr of packages in. each· case:

Dimensions of each chse in em .

Gross weight of each casc·in kg

Numb~r of cases.

Fon'i1 No. 9.3·2/IO.'IO

Pngc 2 of3

II ~

. 3 -

Table l)acking Details for Overhead line Hardware

I'EA Material No.

1000120004, 1010000103

1010200001, 1010200002

1010010100. 1010200004.

1010200005, 1010200009

1010200007

10l0110200. 1010110201'

I 010140000, 1010170001,

1010180001

1010110202,1010110203

1010110204, 1010110205,

101014UOOI, 1010140002

IOIOl 10206, 1010110207,

1010110208, 1010110401, l0l0120000, 1010120001,

1010120002. 1010130000,

1010130001, 1010130002,

I 0 I 0 I ,10003

1010180100. 1010180201

1010180301

I 020·+40 I 02

1020440103

18

20

50

Quantity

Per Package

150 ( 15

150

100

75

50

500

5,000

30

60 per layer)

Packing Method

Bundle

Bundle

Bundle

Bundle

Sack

Sack

Sack

Sack

Sack

Sack

Snck

Sack

Form No. 93-2/10.10

Page 3 of3

II

-4-

Invitation to Bid No. :

Specification No. : RUDW-013/2553

C3 SchedJll~"J.IJ.llet~.qyirement

PEA

Item Material Quantity

No.

1 01000103

(1010000103)

Description

Channel steel crossarm, according to Table 4 of TIS 122 7, with :

Nominal size IOOx SOx 5 mm

Length 4,200 mm

Thickness of

zinc

coating,

minimum

average : 85 Jlffi

Punched holes, and fabricated as shown m Drawing

No. SA2·0 1 5/39009.

2 01000202

(l0J()(X)()202)

Channel steel crossarm, according to Table 4 ofTlS 1227, with:

Nominal size 125

x

65

x

6 mm

Lengtlt 2,500

mm

Thickness of zinc coating,

minimum

average 85 f.lm

Punched holes, and fabricated as shown in Drawing

No. SA2·015/40005.

3 01000301

(I 01 0000301)

Channel steel crossarm, according to Table 4 of TIS 1227, with:

Nominal size

Length

150

x

75

x

6.5

mm

4.000

mm

Thickness of zinc coating,

minimum

average 100 ~un

Punched holes, and fabricated as shown in Drawing

No. SA2·015/40009.

II

- 5-

Invitation to Bid No.:

Specification No.: IUIDW-013/2553

C3

S~.Ul\'

J!t de.lld!c!L.r.c.auin\~DJ

Hem

4

PEA

Material

No.

01000302

(I 0 HXXXl302)

Quantity

Description

Channel steel beam, according to

Table

4 of TIS 1227, with:

Nominal

size

Length

150 x 75 x 6.5 mm

4,500mm

Thick"lless of zinc coating,

minimum

average

: 100

,u.m

Punched boles/slots, and fabricated as shown in Drawing No.

SA2-015/22001.

5 01000303

(l 0 HXXXl303)

Ditto as Item 4, but

Length 6,000 mm

6 01010100

(!OIOOL0100)

7 01010101

(1010010101)

Angle steel beam, according to

Table

2 of TIS 1227, with:

Nominal size

Length

75 x 75 x 6 mm

3,500 mm

Thickness of

zinc

coating, minimum average : 85 J!m

Punched boles/slots, and

fabricated)

as shown in Drawing No.

SA2-0 15/22002.

Ditto as Item 6, but

Len1:,Tth 4,100 mm

I1

- 6.

Invitation to Bid No.:

Specification No.: RHDW-013/2553

C3 S.~duj_r. _nf._jlmlJ.~.!Lr~qulrcmeru:

PEA

Item Material Quantity

No.

8 00120002

( HXXl 12@2)

Description

Angle steel crossamt, according to Table 3 of TIS 1227, with:

Nomjnal size 150 x .100 x 12 nun

Length 4,500mm

Thickness of

zinc

coating, minimum average : 100 J..llll

Punched holes/slots, and fabricated as shown in Drawing No.

SA2-015/26014.

Altematiy!;t

Ditto as Item 8, but according to Table 2 of TIS 1227, with :

Nominal size : 150 x 150 x 12

mm

9 00120003

(l (XX) 1200'13)

Angle steel crossarm, according to Table 3 of TIS 1227, with:

Nominal size 150

x

100

x

12 mm

Length 5,000

mm

Thickness of zinc coating,

minimum

average : 100 J..llll

Punched holes/slots, and fabricated as shown in Drawing No.

SA2-0 15/26014.

Al.lernative

Ditto as Item 9. but according to Table 2 of TIS 1227, with:

Nominal size : 150x l50x l2rnm

10 OJ 150050

(1010150050)

Bolt, double arming, oval eye, forged steel, M 16, 250 mm long, full thread; complete \Vith three (3) square nuts, minimum breaking strength not less than 6,500 kgf, see Drawing No. SA2··

015/40010.

- 7-

Invitation to Bid No.:

Spedfieatlon No.: RHDW-013/2553

C3 S.rotdJLl!utt.dmUtd...r~rrnJJm.t

PEA

Item Material

No. ll

Oll50051

(l01015005l)

Quantity Description

Ditto

as

Item 10, but M 16, 300 mm long.

12 01150052

(1010150052)

\...._.;•

13 02440105

(1 021}140 1 05)

Ditto as Item

10,

but

M 16, 350

mm long.

Bracket, of channel steel, 75 X 40 X 5 mm, for aerial cable tangent support, see Drawing No. SA2-015/40018.

14

05100003

(1050100003)

15

1010200009

Bracket, steel, for transformer secondary

lead.

Complete with one

(1)

machine

bolt Ml6x130

mm, one

(1)

nut, and one

(1)

lock"Washer, see Drawing No. SBl-015/22011.

Brace, alley arm, of angle steel, 50x50x6 mm, 1 ,000 mm long. see Drawing No. SA3 -0 15/5 3004 .

~:

1. Pitches of steel bolts

and

nuts shall be according to the attached

2.

"Nominal Threa.d Diameters and .Pitches of Steel bolts and

Nuts".

Dimensions and tolerances of

M 16

machine

bolts shall be as

specified

in the attached

"Dimensions and

Tolerances of M 16

Machine

Bolts".

3. ONLY threads of steel bolt and nut

shall

meet

acceptance

tests specified

in the attached "Acceptance Tests for Threads of Steel

Bolts, Anchor Rod, and Nut".

II

------------------------------------------·-------------

[PRELIMINARYj

0

.

'

I

0 lf)

"

0

-l-

en )

0 lf'l

0 l lfj

0 lf)

~

0

T

If)

"1

0

If) t

0

!{) f

0

-t

0

If)

If)

0

0 t~

J_

0

If)

+

;z

.

E

E liQIE.S

1. ALL DIMENSIONS ARE IN mm .

2. CHANNEL STEEL ACCORDING TO TIS 1227

TABLE 4 .

3. TO BE HOT-DIP GALVANIZED ACCORDING

TO PEA STANDARD . n

...

.

El\ll

~lm~":-iL 'i'~VJlU.E'I::~~~ iJ\l1l

~

CHANNEL STEEL, 150 x 75 x 6.5 mm,

\l.\JUL<HJ~ SA2-ol~l/4oooa

4.0 m LONG

rmtl1:n~~~

( jOlOOOC!>03) f.J,AI NO. 01000303

0

0

0

·I·

1~

·I·

7~o----+-7~-·-+-t

_,o---+-•><>---11-oo

6,000

~

-

~··

1,200--·-+-j-ooo_, too

J

_['

10

I

iL "" •

.

18

~

MAT. NO. NJMeER ry: HOLES

13 t' l8

(1010000j03) 01000303 t1C\OOOO!>O!l) 0()()()302 9

NOTE:

L ALL OIII(Jreii()N$

2. CHAHHE'L 5TE!L

OF ns 1227

Alfl. tc - .

~

}. HOT-GP G.AL\iiii.NIZE:O.

4

'

..

' . t , , . . . . . .

____

..

_

........ -·.

_ .... :

··--------

.. ·-·.

,.,~,,.,~J,

"nnfl r.x> X

-----

T~

'x

6.~ ~

; ' .......

L.~l{·-·····

· - - - - - - · · ---· t · · - - - - - - - - 6

1 ot·\Jilii~~~;:~,Uga-

OIANNEL STEEL 80•~

SlZE 1!10 X 7~ X 6 ~ mm

' l ,,.,,;;,

.L'f'llf'il,.,~<,.L_

r) .E~LIMINAiiY

~TE

I. ALL ~NSK>NS m m

2. ANGLE STEEL ACCORDING TO TAGLE

'3 HOT- DIP GALVAMZEO

?. OF' TIS l '227 n1•'"'n r;/<tt~·

'---------------------1

·. f~

.•

IRII<x~Jr

'

"'\+1t'l 7$ X 75X6 ww.

. .... ;,.; .. ~.?.L.~

..

...

UI'IIIIJV 1'-fi ... - •••••• ......

~~.~"-······---'!~---·-· w·1,.11~1

.......

.l~.:Q..---

-

-. .. -;;......:...;.

;J,' til4r

't.f,,lh•IIIJIJ ···--·· ___ .•.. ··-

~mmJI'\(JliiJ\l_

ANGLE STEEL OCAM

SIZE 75 X 75 X 6 mm

------I

r--··

"000--·--t-··- 900 ···-1

·t

c::__

_::+:-~],~;-'m~::-:+::c~-=-:__]

SCC OCTAl\. B ~ ~SLOl 22x68 _..- SE.F DE! AIL C

, { _ t:5i= r•. f-·· 750 -+---1,000--+- 500 -1-· 500 ·-t--1,000 ---1--750 - - l

-1250f-·--1,100-·-t1,800·-------t---1.100---12501

4,500 ---· - - - - - - · - - - - - - - - - - - - - l

L 150x100x12 mm or 150X"1ti0xl2 mm LONG

(10001'l00o'-)

MAT.N0.00120002 l

150

T

~~-SCE

1

0G~

I tl::-150 so-+.

:=or ''

100

::f>O

_,31'

150

,750----~

-12501--3,000

-12 50 1250 !-· 500

-+-·

500 -12501250 f-· 500 . ....;-500 -t500

-+-

500 --t-· 500 -12 5012 50 1--

! - - - - - - - - - -- - - - -

5.000

( 1 0001~ ooo;)

MAT.N0.00120003 L 150:.:100x12 mm or 150x150x12 rnm, 5,000 mm LONG

')'l!J~:Lfltl~

DETAIL

D

,ool[w

~'-------'--'LtJ:J

1-tJ.o~

'i'11J~:lt1r

101

DETAIL c co"' wunco T t:: r--CU1

rtc•"'

wrr.om

'-""~

C

-rr--}·1-

100

L

::.x!:r.:..

so

>---ISOJJ

1. ALL DIMENSIONS IN mm.

2. ANGLE STEEL ACCOrWING TO TAllL[ J OR TABLE 2 OF 115.1227.

3. HOT -DIP GALVANIZED. n<l41A1n'l'll~Y!.,i..,~:;;[;~n>~ lo/'11J1:.1"lll'i'ilJ

~l~!l'IJ

...

~i~n~~,;')E\.'l

..... rn~ 1 tJ '

'W~1~1tJ.n:}j.n'lv;)

'J

---------- ·---------------

eJmmvl..lrm m1 ........... .

-----~----··-~--····-·--·-·--·--·-·-·---l \ttJUL:i11"l1\J~.

14. jj,!J •. /Jl

"~"1'11"~-

.. .. . . .. . . . .. .. . .. tl'~

'lr:l"lf'l"i ..................... .

~ ~

111Yiti'1LlW'Ufl.

~

£....-..,<£~

WD'11.l1tlf'l'1'in

11~ ~: ~-

·.- .·;: • ••

~tl'1\J1!Jn'1'1~'1U

.......... .

_ _ , . -

"ir.J~~

1'1fl'1'iL Y1AUAU:i1

..

-

:tJin'1'i

~1'ln'l"-2

....................

STE[I.

:~~_ ·.:.:..:.:.:~~-~:_·~:

~~-·il~tl

1 50x 1 SOx 1 2 lJll.

~···

At:l\Jl

~~no1n l!iJ'Ir;l 150x 1 OOx 1 2 lJl.J.

__

--------·-------------------·

w!: •• ii J';...

.. ,J-

~~

-I.Jfi

,s

~A ~

~·"·~-~: ii::<-"'LlJI1'1 ll'1P.";'1~')1J. ~

.:

-~ 9.·.

.. : ....

1. :. (. ~?

3

..

------------·-·-···

CROSSARf.~

SIZE 150x100x12 mm

UlltJL~Il'r\.W:-.0.1.5./.~~!~

..

_______________________

__.~

___________

.

____ _

---,.----·---------------·---------

\PRELIMIN~

]

FORGED OVAL EYE

8

LL 'N

;!~ 'l.h t

Ei

0

nn.

..

~

U1\-4Wl

nn.fioo

iu

DIWENStONS IN mm BREAKING 'ftiGHT lrUTERlAL 1:

STRENGTH

WATERIAL NUWBER 0

1

A B C

SURfACE f1NISHTNC k& kg/100 Pes.

~10\6QOSO)

011!>0050 ).116 250 50 38

> 6,5oo

L'>'~nna;a•t~u t--;-:::-::-:--::--::-:---::--t--l--+--+-+--+----~----1 tl1Ud'\1nc~~~1J11111l1U

Ollll.

( 1010150051)

01150051 W:l6 300 50 38 14

>

6.000 WILD S'TEEL t--;-::::-:::-.-:::::::-:::-::.-t--1f--f--+---+--+----1-----l

H01'-D!P GA.LVANtZED

<

01150052 lU6 350 50 38 14

>

6,500 ACC. TO PEA STANDARD r------------~--~---+---+--1------r-------4--------l

~--------J---~--~--L---L--~-------~----~-----------~

-----·-··-··----------iP I n1".i1

"r'h~1 A1 UJJ 1'lll1 A

U.ti'ULutlft SAZ-015/40010

BOLT, DOUBLE AHMING, OVAL !WE, M 16

I

PRELIMINARY\

. .

~-·~-~-~· ~

. . . . . . . M

I

. . . . . . . . . . . . . . . . .

2 ()

1 5

"-----

50

1 0

50 . iaj'!La'tlfl c 1o2oAAotos)

• 02440105

MAT. NO.

'!ftlll•t6x30 'l.J'l.J.

-"'Surr

mm

~~~nrmu~r~~uar.nmAY11~!;1~\l

AERlAL CABLE TANGENT SUPPORT BRACKET l1l£llirnfi \..i'a1ulflln:~P\1lJlJ1rl'i!J1U'tlttll n-M11.

-

L'>l!'in:\J•nllulltht"d\J.G~'ii!"l~ll\.L

>n'l.J 'l.JiJn. 1227 llJ2IE HOT-DtP GALVANIZED ACCORDING TO PEA STANDAHD

CHANNEL STEEL ACCORDING TO TIS 1227

BRACKET, FOR AERIAL CABLE

TANGENT SUPPORT

...

.

..

1-l\l\llCltJ~

SA2-0!5/40018

I.,

~,ij\J!I

\

~-·

--1•1-

8--~---li

....

'

MAT. NO.

"'

D£SCR~t

'

(i)

8:RAO<ET ,STEEL

G)

( 1 oso 10000:!>)

05100003 l<i~m~ I

I'M IG X 130 U:.:.

W 16 X 130

1ntt1.

®

®

~mti-R( ~~

16

\ll.ASI-ER ~

®

®

-r.. ~ i'' r'l11"r.tt

~

'

MAT'EJUL t<NO FIN~

1~M~m41

&11!fl 55

IJI{t t1~,1'rr~li

FlAT STEEL B.ARS

•.ace.

TO TlS.S-5

N.JJ ~

STA~ARQ

G.:-J..V. N:.C. TO

I4..D STU:L,

ICC. TQ

...

I-lOT C.P GIJ...V.

STAI'()AAD

~~

'

's~ STEEL,r+OT

~

DIP GJ.L.V.

ACC. TO ST~

* .....

'~h.· f---~~~~~-

06JOOOOS

10SO\bo&i3) .

L.

Ofw..r..:k"'<Jil\.'t;

~

.......

-

.......

-

....

~

"'\ 'II

.~ to.,...~~,.,.,,.

"'

n zt

.:'11'1~....2.1!.

. -

...

11n"~ltl1

Uti. __ ·-- . • . • __ • ilii.tht.. . _II _II_·--·.-·--·

1.nn11~lu

. • . • • • . . • ___ •

1.000

35--j f-

18x30

MAT. NO. 1010200009 u

-·

WELDED

DETAIL A

018

16x30

Pf:TA!L B tiQ1:E

I. ,\NGLE STEEL 50 x 50 x 6 mm ACCORDING TO TIS 1227 TABLE 2. CLASS SMxxx

2. TO BE f!OT DIP GALVANIZED ACCORD!NG TO. REA STANDARD not. lo scnlc

~liYi'

1 t;l.A. 2553

BRACE, ALLEY ARM. 50x50x6 mm, 1,000' mm LONG

·-·,·--··----

(l

·(I

TABLE IHICKNESS OF ZJNciCOATING

STEEL CATEGORY/MATERIAL

STEEL nn~

(mn)

P..Li.STP.NERS:

• ~GLT, PIN. ~"UT, LOCK NUT;

-UP TOM 10

-OVER M 10

- WASHER, LOCKWASHER

-

-

-

< 4.76

4.76- 6.35

- 1\J'iCHOR ROD

.CASTIN.GS :

· SOCKET EYE, SOCKET CLEVIS, STRAIN CLAMP, etc.,

EORGEI2..AR.TI.CLES :

·BALL HOOK, Y CLEVIS BALL. BALL CLEVIS, BALL EYE,

CLEVIS EYB, ANCHOR SHACKLES, etc.,

S.TR U.CT_URA.L__SH.t\P.E :

- STf:i'.L CH.Al'<:-.'EL, STEEL ANGLE, CROSSARM STEEL,

BA Y0:-.1:T, GROUND ROD, etc.,

-

-

< 1.6

< 3.2

3.2 • 6.4

> 6.4

SJ.Rir :

- BR:\CT1. GUY THL\lliLE, GUY GUARD, RACK, CLEVIS,

STF::EL BRACKET, PLATE STEEL, SPACER PLA.Tf!, etc.,

< 1.6

< 3.2

< 4.8

4.8 - 6.4

>6.4

MINIMUM AVERAGE

COATING THICKNESS (J.Wl)

43

53

43

53

80

86

56

45

65

85

100

45

65

75

85

100

Plrr:

-

- - - - - -

NOTE : 'ilf()<J\.'ES§ -OF-CDAi1:NG'OFSPEOMENS Sl-WL BE MFASURED

~ 3.2

75

- - - - - - - - - - - - - - - wnH

AMAGNEflC

MFASUR!!'.'G INSTRUMENI

":-rllCROIEST "OR u

ELECTROMAGN"'EilC CDKI1NG 1HICK1\Tf.SS GAUGE " fum ?'\o. 9.3.()/2.%

F~~~ ! c/ 1

Dimensions and Tolerances of H 16 Machine Bolts

K 16 machine belts shall have dimensions and

~ole~ances as specified in the table below

PEA

Hat.No.

Machine

Bolt

Size ds 1

Dimensions in mm

(Tolerances in mm} b I< e m

Olll0200 H

10\0110200)

16xl30 c+

-

16

0.95) <+

0. 70

130 s·

- 0

>

(

35 10.5

+ 6) (+2

- 0

.o)

-0.9

26 or 24 13

( +

-

0

o.al

( + 0.9)

01110201 M

~010110201)

16 170 50 10.5 26 or 24 l3

16xl70 (+ 0.95) (+ 3

-

0.70 - 2

) (

+ 6) (+'2.0)

- 0 -0.9

o.s>

(

-

+ 0.9)

01110202 M

(1010110202)

16 200

so

10.5 26 or 24 13

16x200 (+ 0.95)

(+ 3 )

0. 70 - 2.3

(

+ 6) (+2.0) ( + 0

- 0 -0.9 o.s> { + 0.9)

01110203

H

( 1010110203)

16 250

16x250

(+ 0.95) ( + 5 )

(

+

-

0. 70 2.3

75 10.5 26 or .24 a,

(+2.0) ( + 0

o.a>

- 0 -0.9

0111020!· H

( 10t0110MA)

16 300 15 10.5

16x300 (+ 0.95) ( + 5 l

(

+ s) (+2.0)

0.70 - 2.6 - 0 -0.9

13

( + 0.9)

(

26 or 24 13

-

+ 0

0.8)

(

-

+ 0.9)

01110205 H t 10i01l020!>)

16

16x:350 (+ 0. 95 ) + 5

0. 70. .

350 75

+ el

(_ 2.B5) ( - 0

10

.s .·,·

(+2.0f

-0. ~~

(

26 or 24

-

+ 0

o.s>

(

13

+ 0.9)

01110206

H

( l01011020b)

16x400 (+ 0.95)

-

16

0. 70

+

<_

400 s

2.85}

(

100 10.5 26 or 24 13

+ 8) (+2.0). ( +

- 0 -0.9

-

0 o. a) ( + 0.9)

01110207 H

:c

1010\

\0~0'?)

16 450

16x450 (+ 0.95) + 7

-

0. 70

(_ 3.15)

(

100

+ 8)

- 0

10.5

( +2. 0)

-0.9

(

26 or 24 13

-

+ 0

0. 8)

(

Olli020E H

(1o1o11o2oa >

16 lExSOO ,+ 0. 9 5)

\

(+ -

0. 70

-

500

7

3. 15)

(

150 10.5

1-

8 ) (+2.0)

-

0 -0.9

{

26 or 24 13

+ 0 )

(

0.8

+

0 . 9 )

Note Thread length (b) is measured from the end of the bolt to the last thread of nut entering.

....

~,

~~'Nomin<11

Tfnoead Diameters ond E'itcl1cs of Steel Bolts and Nuts

Bolts and Nu~s shaLl have nominal thread diame~et~(d) and coarse pi tct1 (p l as specH i,ed in the tnble below :

,,

Nominal

Thread Di'ameter(dl in mm

6

.

•.

,

Coarse Pitch(~) in mm r

1.25 8

Hi

12

'

1.5

1.75

16

20

.2

2 .5.

2.4 3

r· .. , r-.~:

' • \. ;._ L

' "

~

' •, '

i I \i i • 1

1\

R'

- \ (

/

-----

750 l

"~~ u·nnh~

CHJJiNEL STEEL

:

HOLE

~18

I

400

_l

<4200

000

900

L · - - ·

-l

:.150 lilliE .

1. ALL D!VENSlONS ARE IN mm.

Z. snxL CHANJ'aL ACCORDING

TO TABU:

4

OF TIS.

3 HOT-DIP CALVANlZED

1227

---·--

t.IAT. NO. 0!000103

(1otooroJ03)

~

'i il\l C! 11 ni'i

CHANNEL STEEL c:IZE 100x50x5 mm 4 2 m LONG

I.:.'JUW!l~

SAZ-015/39009

\l.tl~)\

1

'!IB~lU)U l IWU

() (

)

00~ ON~-~-""~

--,-OH•-m , -

I i

.. J! L"'!

.:

"!"""'!"

~' 2J

,_, ~~

.::) z::

::;(

Z::•

~

::;_,. z::

.,,

:::J

~

~

:n

o.J

:::J

.J)

.J)

~

I iit r1 n

- i ~ ~Ul

';" p;;

J> rru~ ln t-el

~

M

~ t - i

X n

I

Z u-z

Ulf:1

~ j ) s=

:l)

"

::D·

.JILl

~~ c:;.!

:Jl

HOLE ¢10 rtM w ru

U1

!

I

~

1----i z

::>-

A)

X I

(;'(/)

-!

J f'1

J f'1

' I

2 i

I

!!. _I

~I

PIN HOLE

. . J l

~

ttJ22

MM

1 i-

~run g;7J oo

3 (/}

3 (/)

J> r7J o~ z~

Cl r.;.

~ c:

•. s;

::J

~g r.n

Go

.I.J~

-'

> t.:

I ~ ~ r_.-. i

., I i

:::JI

.J) ' ~

I

:::il

..JI

~~

:;I

~)

..J!

:U.! o.J !

BOLT HOLE

liQIES

I

~---500----~---

,___ _ _ _ _ _ _ _ _ _ _ _ 2,500

!

HOLE $18

MM

CHANNEL STEEL CROSSARM

I

125 X 65 X 6 r'lr'l

I

2,500

Mr'l

LONG

.s

!

~

~

..J

:'D

1. ALL DIMENSIONS ARE IN mm

2. CHANNEL STEEL ACCORDING TO TABLE 4 OF TIS 1227

LJ __ _

'

3. HOT-DIP GALVANIZED ACCORDING TO PEA STANDARD

-

[PRELIMINARY]

0

0

()\

T

0

--t-

0

0

(")

0

(")

..i.

/

j_

0 l(}

T

;:4!

. v ro

r

;;:)

;:4!

.

;:4! g

E

...r

1.0 rd

X tO cO

ID l'-

X

X tO l'-

6

0

ID s 0 tO

X fP

...:i tx:l

~r

0~ tx:l

Een

'?

r

1[0

-;;:> < lf"O" c nee:

.....:1 tx:l

z

::X:: u

E

E

1:'

1iQ.T.ES t. ALL DIMENSIONS ARE IN mm .

2. CHANNEL STEEL ACCORDING TO TIS 1227

TABLE 4 .

3. TO BE HOT-DIP GALVANIZED ACCORDING

TO PEA STANDARD .

... ' n u\l1~lm~~.iL v~.,·Jiu.s::.~P.~t'l\im~ m ·~'\. ~ ~l'Uil

!1 Ill R

~

C1

··! E x 75 x 6.5 mm,

4.0 m LONG

U.\JUllltJ~ SA2··0!~!/4000!l

rrmlttm)\Hfl'ffi

ASS€to.CBLY NO.

'T

'•

-.

..,

~

1]

'··

.,

-

.\

-

-----

'>'"' ~

','(' -

~

).

I

I

... t1 'MWW'8t.lfl

( joJ0000.!>0.3) /

:=) sh

DETAIL A

It a

~ o

0

$

l-f-"o

1-

"o

I ""' ·I· '"'

4·

750

-+-7~

6,000

_..,._!

_,o-l--•><>---11-

l

$ ...

1,200---+-l----i

,

f""

------------------ T r-~ ~I

~----1~~-----r·• ~~CH~L

,..,._~ ~-

C

T

A

NOTE:

I.

2.

ALL OltliDtSOHS ARE. I'C - . c::HAHNfl. ST!f:L ~ 4

Of TlS 12:7

3. HOT-CW G.AL""NIZEO.

~/w.f;._,r-'1-" l

'

, i11M~·

;1"{·)'

1

-.J . j

' . r:lJu.J:r--.:~.r

••

~·

11'H1W1 ntl t ~~

,,.>. ·;"1

-

..

·------

...... ·--· I

\ . . , ·, ·. :

~r.~

__ ttn.~tt

SIZE

OW4NEL STEEL 8£..A~

150 X 7~ X 6 ~ mm

'

. ' · 4.'1, ..

............ * . . . . . . ...

"\ i -'" ... ~IUttf

.. ""tt ., ... _ .... L.~----·-

---·- t · · - - - - - - - - - f

\

H•\11"11~~~l·•.,'•~• .. l.."'lrt'"w ..

L_M

rr·ntinnt'Jil~ft

ASSOBJ' NO

............._

....

--·------·-----

IOQi

~~~~-

....

~·•Jlnf'l

A --GG

S££ t£TAL _ _ _ ::::i{)

1.-

I,IISO·--=-:.===~j

·

I,MO-~-=-~=·-~ ~00

1-.--·-----------····-S,t<XI--------. _

• t"' · - - - - · -

·--4,100---··

I. AU. ONENSIONS IN m m

2. ANGLE STE:EL ACCORDING TO TMlLE. ]. OF TIS 1 '227

3 HOT- DIP GAl VAlUED

.4W, ,.-""

. . . -~I

I

'l.f\., ..

11\J\l ..... --·---. ----. · flnllf'l.:lf'liJHIJII ____ - - - · ·

'"'""'lf;"'

_....~; ·--·-:--------------------'---------------; t

,jf'l'-1

~"'.

~ ~.

?L!!!LJL

1

·.;__;_;,

- - - - - - - - - - - - - - - - - 1 f - - - : - - - - - - 1

IIU \1+1111flW,. t Mmt

•-..J,t·i"i~f"

ANGLE STEEL ££AM

SIZE 75 X 75 )( 6 "'"'

t--~900 ----t-~

,~

r:::-::_::--

I

.::_'_1">..;-"'f'$[~~-~~-=

/·--SLOl 22x6B _,....-SET DeTAIL C S[E DL!Ail.. 8 ---....._ t-- ... 750 --t----1,000 ----+-500-+- 500 ·-+--1 ,000

--i2~',ot--·· 1,100-

750 -----4

1,800 -------j------1,100----12501

4,500 ·---···------·-·····----!

L 150x100x12 mm or 150x150x12 rnm, 4,500 rnm LONG

( 1000 I 'LOCO~)

MAT .. N0 .. 00120002 l

150

T

L_i_

~SLo; ,,.; .-\ · :.,a . 1

• •

:::J

:rgo

C' ~,...

I _ I I I I I

"'

-··

~ -~---

SEE OETAJL D

I I I ..

I

1

~~0

.J ::=~9-1:1 :

1 3'(l too tho

1 --i2~>o 1 3,ooo ---.7so-------4

-; 25012501-- 500

-+--

500 -1250 12501-- 500 --+-500 -+500

-+-

500 _ _,__ 500-; 25012 50 1-·

1 - · - - - - - - - - - - - - - - 5,000 ~----------··-.. ·-------1

L 150x100x12 mm or 150x150x12 rnm, 5,000 mm LONG

( 1 ooon ooo;)

MAT NO.OO 120003

'11tl~=LfltJCi\

D

DETAIL

1. ALL DIMENSIONS IN mm.

2. 1\NGLE STEEL ACCORDING TO TAULE .1 OR TABLE 2 OF 11$.1227 ..

3. HOT-DIP GALVANIZED.

ldu.

m;u

UlJ ................. .

·...,-------· ----+-----------------··--·-·· -----------------

... :(l(J.Vfl. ..

""'""'""'

.. 1-o I } J"\ • •• ' • ' • • • • • • • • • • • ' '

" ·

VJ1'ln'l"L .................................................. .

~nLL T\tJ~!IU lltl ........... . ln!!1.Jtli;~·)u~.

H. iJ.!J,. 7.G

'lr11f1"l .................... .

~ ..

Wl'r11.J'ILlW'Uft

J. .... ,l./~

. f; .•.. :;..:.- .

~il"'''U1£Jfl"l'intl.t1.?'..

/:-: •..

~D'IU'l!lfl

1

"l~'IU

••.•...•.. f.lti'\JL.,~mnn

ZI'\Jiril 150x 1 ODx 12 lllJ. l1~tl

1 SOx 1 SOx 1 2 lJlJ. iiRt111J ....

-~~~~~-=

..... . f.-----·-···--·----·------------·-· ··--·-·------.--·-

"i0~~1'1fl'l'iLYIAtJAm~=t!'in1'i

ANGLE STEEL CROSSARf.-1 SIZE 150x100x12 mm

Ull\Jlllll~.W.:-P.1.!i/.~~!~

..

OR 150x150x12 mm UW'J~.J.1!t.N~1U11.J.

J.

UJ.iu

--------·------------------------------------·------·

\PRELIMINAR]

] f'ORCED OVAL EYE

8 i"i.l'll«ll~

WATERIAL NUWBER

( t010\500BO)

01150050

( 10\0;5005')

01150051

(10\0tSOoS~)

01l50052 o, o~ ~u'U llll.

DIWENSIOHS IN

"

B mm

c

D:z u.~\'1;\\l'\.l'hao

nn. nn.

..

'U1\4Wl

/100

il"'u

i

. lfl1''K11U lj1

WEICHT BRE:.A..KING

WATERIAL 6:

STRENC:Til

SURFACE t1N1SH1NC kg/100 Pc•. lq

Wt6 250 50 38

Wl6 300 50 38

H

14

) 6,500

) 6,500 '

L

'.4Anna1a•"!u il1\Jd't~n&QsmJll111n,!1'U mill.

WILD STEEL

HOT-DIP GALVANIZED

ACC. iO PF..A STANDARD

W16 350 50 38 14

>

6,500 t•

--

L - .

"' '

\.1.\J\JLI:ltl" SAZ-015/40010 iu"

21 lJt1~1"~

2541

BOLT, DOUBLE AHMING, OVAL EYE. M 16

L .• _____ ,. - - - - - - - - · - - - ' - - - - - - - - - · u.Uu~

1 llilll~lU1U

1

WU

------·-------··---·__l.------------

\._,

I

PRELIMINARY\

250>--------'ilf-------2511

• H H - _ -

2 0 lfltuJR1U\livi'1

ELECTRIC lrEI..DEO

5

· · - - -

·-

50

- - -

.

-

-

1 0

- - -

- sp __

iail~atJfl

• c 1o2oHotosJ

02440105

WAT. NO.

1 •t6lJlJ.

HOLE mm

'!lull

~

SLOT

*18x30 lJlJ. mm

~VI~ mu.1 u~r~

L a tl1 m ~h11\i

&1,\l

AERlAL CABLE TANGENT SUPPORT BRACKET l!lJ1tl\¥f! -

'tia,ulflln:aPJ1lJ'W1r~'l~flUtlull nwn.

~~an1tl'l11lui

\\Ju't'l-:l.li'l'r;l;au

~1lJ ll<Jn. 1221

}l_QIE HOT-DIP GALVANiZED ACCORDING TO PEA STANDARD

CHANNEL STEEL ACCORDING TO TIS 1227 n tN-,

"

. u\lna

BRACKET' FOR AERIAL CABLE

L4\M£1tJ~ SA2-DI5/~0018

TANGENT SUPPORT

f-

~-i

-Wr----------00

E~

" /r.-

;J

~y~

.

I

"'

W.Ai. NO.

( 1 050 10000.!>)

05100003

...

.,.._.t4~1HI

OCSCR lPTl::f'•

-

\

WfU flif"r.tJ

~l

~AL AND FIN!SalG mttm\J

G)

9RAO<ET ,STEEL

CD

1 m41

~

55

IJftt t'i~IC'tr~U

AKJ K::TT D*=' GALIJ.

STAI'4)ARtl

.tee. TO TIS. 55

ICC. T 0 l(fiM{.'-rl l

""

IG XOO ~ro.J, JUQfM W ~X 130 rnm.

@

. '

..

® baLD STEEL, HOT IJP GJoLV.

/ICC. TQ ST»>:>AAD omt~.q. tit

16

WJS£R ~J..OC:( , I.e IG

(i)

(~

'l;S~ STEEL,rKJT D

ACC. TO

GJt.L.

ST~

V.

... J fij "'~ ~t 1 J\t

..

;yrr:1-cu

...

-8 ... u~ .61..

'..-:.~

~r.;f...~~~::t..

........... .

t:J.,.,,~;,;~ n l!.:'11'i ... .z:!. i)fi,fl4 ••.• _11_1<.; _____ ----

IJ)I111il« . . . . • • . . • - - - ·

I ,000

·------'-''"'-----

·35-1

I-:

\Bx30

MAT. NO. 1010200009

12ETAIL A

016

DETAIL B l:tCtrE

L ANGLE STEEL 50 x

2. i'O

50 x 6 rl'ui1 ACCOHDING TO TIS 1227 TABLE 2. CLASS SMxxx

DE

HOT' DIP. (;ALYANIZED .ACCOHDING TO PEA STANDARD t8x36

BRACE, AtLEY ARM, 50x50K6 rnm, \,000 rom LONG

(·

(

TABLE THICKNESS OF

ZINCjCOATING

STEEL CATEGORY/MATERIAL

SIEEL TinCKNF$ RANGE

(um)

P.ASTP..'3ERS :

- !<OLT, ?IN. NUT, LOCK NUT:

·UP TOM 10

·OVER M 10

-\\'ASHER, LOCKWASHER

<4.76

4.76-6.35

- AJ'!CHOR ROD

.CASTIN.GS :

· :-:OCKET EYE, SOCKET CLEVIS, STRAIN CLAMP, etc.,

E.ORG.ED...ARll.CLES :

• RALL HOOK, Y CLEVIS BALL, BALL CLEVIS, BALL BYE,

Ci.f:VIS EYE. ,\."l'CHOR SHACKLES, etc.,

S:TR U.c:T.UR.AL_SH..~_E :

· .STf"::i'.L CH.A.l'."?'·H!L, STEEL ANGLE, CROSSARM STEEL,

BA Ymm.T, GROUl'iD ROD, etc.,

< 1.6

< 3.2

3.2 • 6.4

> 6.4

.SI.Rir :

-BRACE, GUY THIMBLE, GUY GUARD, RACK, CLEVIS,

ST::~L BRt\CKET, PLATE STEEL, SPACER PLATE, etc.,

< 1.6

< 3.2

< 4.8

4.8 . 6.4

>6.4

MINIMUM AVERAGE

COATING THICKNESS (J.Wt)

43

53

43

53

80

86

56

45

65

85

100

45

65

75

85

100 p;nr• l. ..

).13.2 75

NOTE · 'iHC!(}.t.S$-OF-d5.-\"ft:N3 6FSPEOM8'1S SI-IAUJ BE MFASURED

'~ H U

WiiH A

:".JiCROIFST OR F.LECTROMAGNEI1C CDA'Tt:NG 1Hia<NESS GAUGE

MAGNEI1C

U

MEASUR£t·K1 INSTRU\1ENT fmn )'.;,") 9.?-0!2.%

.fu:':~ 1 c/!

Dimensions and Tolerances of M 16 Machine Bolts

K 16 machine belts shall have dimensions and

:tole~ances as specified in the table below

PEA

Mat.No.

Olll0200 H

\0\0l102Cl0)

Machine

Bolt

Size

-as

1

Dimensions in

(Tolerances in mm mm} b k e m

16 130

16xl30 (+ 0.95) (+ 5

) ( -

0. 70 - 0

35 10.5

+ 6) (+2.0)

- 0 -0.9

26 or 24 13 o.e) ( + 0.9)

01110201 H

\010110201) l6x170

16 170 so 10.5 26 or 24 13

(+

-

0.95) c+ 3

0. 70 - 2

) (

+ 6) (+'2.0)

- 0 -0.9

o.a>

( + 0.9)

16 200 so

10.5 26 or 24 13

01110202 M l6x200 (+ 0.95)

(+ 3 ) t 10\0110202) ~

(

+ 6} (+2.0)

(

+ 0 )

( -

0.10 - 2.3 0 -0.9 - 0.8

-

+ 0.9)

01110203 H l6x250

(1010110~)

(+

16 2.50 75 10.5 26

0.95)

0. 70

( + 5

2.3

)

(

+ a, {+2.0)

- 0 -0.9

( + or .24 13

0

0.8)

( + 0.9)

0111020·~

'10101 1o~o .. n

H l5x300

16 300 15 10.5 26

(+ 0.95) ( + 5 l

(

+ 9) (+2.0)

( -

0. 70 - 2.6 - 0 -0.9

-

+ or 24 13

0 o.s> ( + 0.9)

01110205 M l10\Cll 1020!'>) l6x350 (+

16

0.95) + 5

0. 70. .

35 0 75

+ el

(_ 2.85) ( - 0

10

.s ' 26 or 24 13 c+z.of

-0.

~·

( -

+ 0

0.8)

( + 0.9)

01110206 H 16x400

( 101011020£.)

16 4 00

(+

-

0.95} + 5

0. 70

<_

2.85)

(

100 10.5 26 or 24 13

+ 8) (+2.0).

- 0 -0.9

( -

+ 0

o.e>

( + 0.9)

01110207

H

(1010\\020'?)

16x4 50

(+

16 450

0.95) + 7

0. 70

(_ 3.15)

(

100 10.5

+ 8) ( +2. 0)

- 0 -0.9

01110208 K

(10i01i020i)

16x500

16 500

(+

-

0.95)

(+

7

0.70

-

3 .15)

(

15 0 10.5

I· 8) ( +2. 0)

0 -0.9

(

26

-

+ or 24 13

0

0. 8)

( + 0.9l

(

26 or 24 13

+ 0 )

(

0.8

+

0. 9)

Note Thread length (b) is measured from the end of the bolt to the last thread of nut entering.

<

'

'

'

No.minal 'I~hr.'ead Diameters and P:l:,tc.:.~es .of Steel Bolts and Nuts

Bolts ~nd Nuts shall have hominal thread diameters(4) and coarse pitch (p) as, :Specified in the table· below :

..

Nominal

1'h read Dl·amet·er (d l

.. ... in fum

:6

,8

·Coarse Pitch(t:J in mn\

1

.

~-.

1.25

.

10.

12

16

20

24

.. ...

.

1.5 l. 75

2

2.5

3